ROLLING MILL IN THE ROOM?! Is it possible? We are accustomed to the fact that the machine with such name in size comparable to the multi-storey house. And then the baby, a free fit on the table. And still the mill! Or drawing machine or a press… Yes, does it matter which category of Metalworking machinery will be recognized as the product of young designers. Here is the most important the other machine performs the same operations as he churns out the angles, and channels, lugs (stretches to a smaller diameter) wire, the strip grips the tube, and the wire unrolls into a flat plate or even the “AmiNET” in the bar. Using such devices to perform many other works, if you add some accessories.

ROLLING MILL IN THE ROOM?! Is it possible? We are accustomed to the fact that the machine with such name in size comparable to the multi-storey house. And then the baby, a free fit on the table. And still the mill! Or drawing machine or a press… Yes, does it matter which category of Metalworking machinery will be recognized as the product of young designers. Here is the most important the other machine performs the same operations as he churns out the angles, and channels, lugs (stretches to a smaller diameter) wire, the strip grips the tube, and the wire unrolls into a flat plate or even the “AmiNET” in the bar. Using such devices to perform many other works, if you add some accessories.

Design workshop in the school, any such device is extremely interesting and very useful. You will have to master the essential techniques of Metalworking: CNC turning and machining, milling and drilling, grinding and the like. In addition, you have to become a draftsmen-designers, fitters, mechanics. In the circle doing this, usually the same guys. So, when you create a machine, device, devices, which then should facilitate your labor, you will certainly visit to designers, and Metalworkers, workers-assemblers, and then the test.

This is the first advantage of such work. The second is that by using a homemade stanochki and accessories you can provide a circle of material of almost any profiles that are made from a soft sheet, expanded metal or wire.

Apply to business skilled hands, perseverance, be the terpene eat and your circle will be small shop, which will provide you with invaluable assistance. It will be useful, of course, and the lessons of labor in school workshop.

In the future articles Kochergin and A. A. Efimova, you will learn about some other improvised devices and tools for metal, plastics, wood, and interesting and important properties and characteristics of structural materials.

FIXTURES FOR THE MANUFACTURE OF PROFILES MADE OF THIN SHEET METAL.

Angles and channels made of sheet metal, cut into strips whose width is equal to the sum of the sizes of the bands plus an allowance for cutting and Stripping edges.

At small length and small number of them doing so. Mark on the strip of the desired size of the shelf and cut the bending place along about half the thickness of the sheet, bend the shelf parts in a vise, and channels — on the steel plate with a width size of the inner channel.

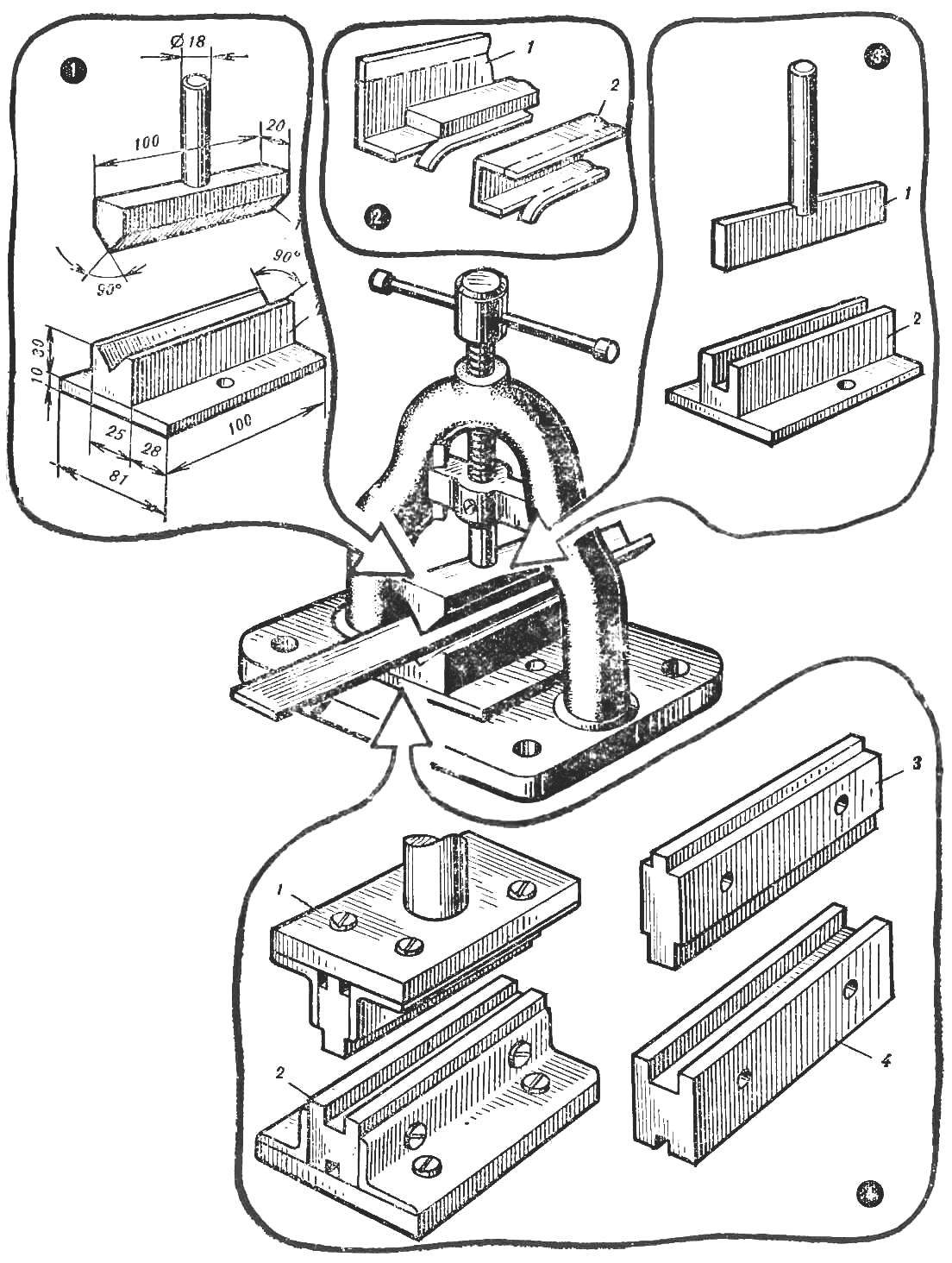

Fig. 1. The stamp for the manufacture of parts:

1 — punch, 2 — matrix.

Fig. 2. Trim the seam allowance:

1 — pattern, 2 — on the markup.

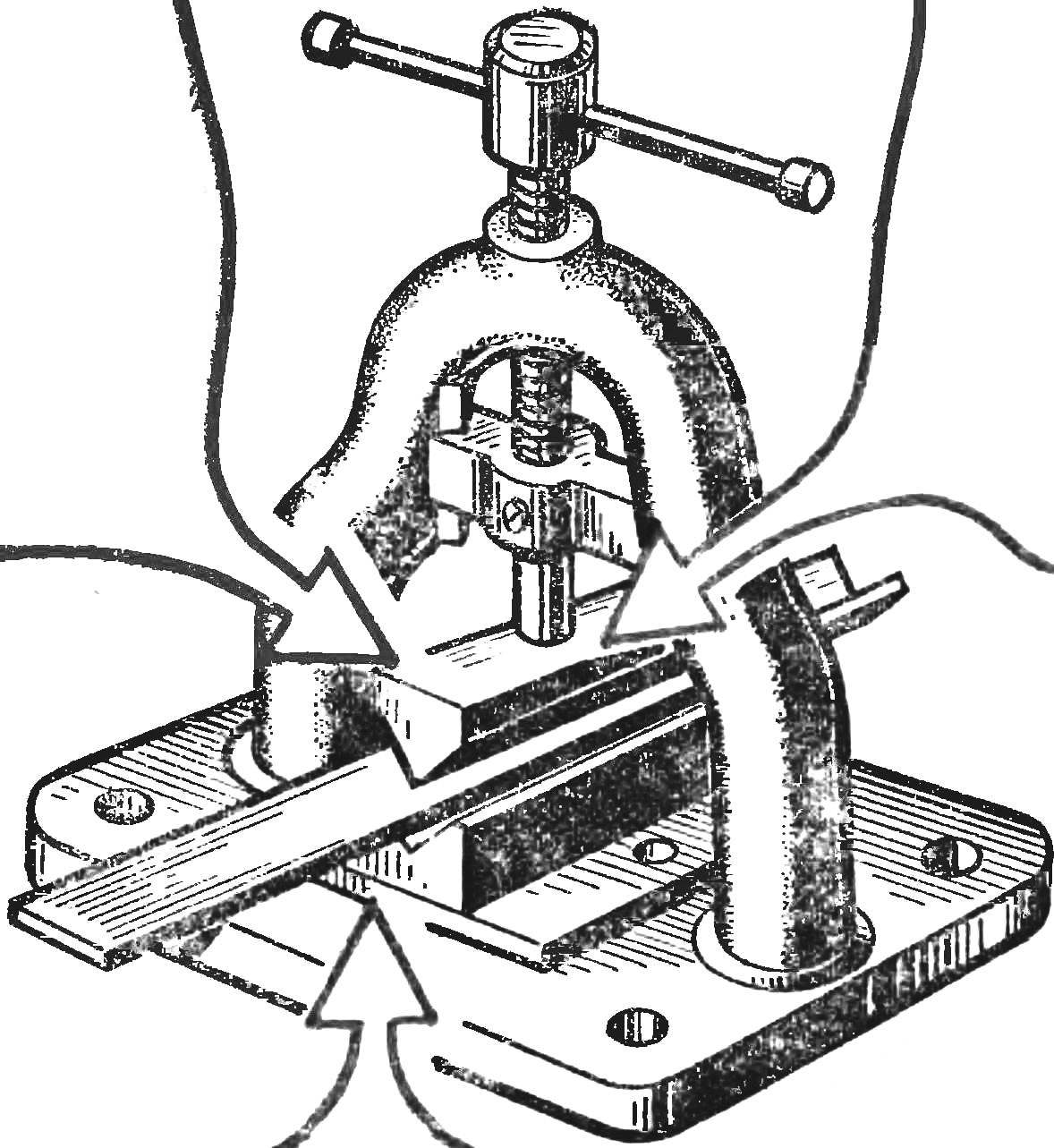

Fig. 3. The stamp for the manufacture of channels:

1 — punch, 2 — matrix.

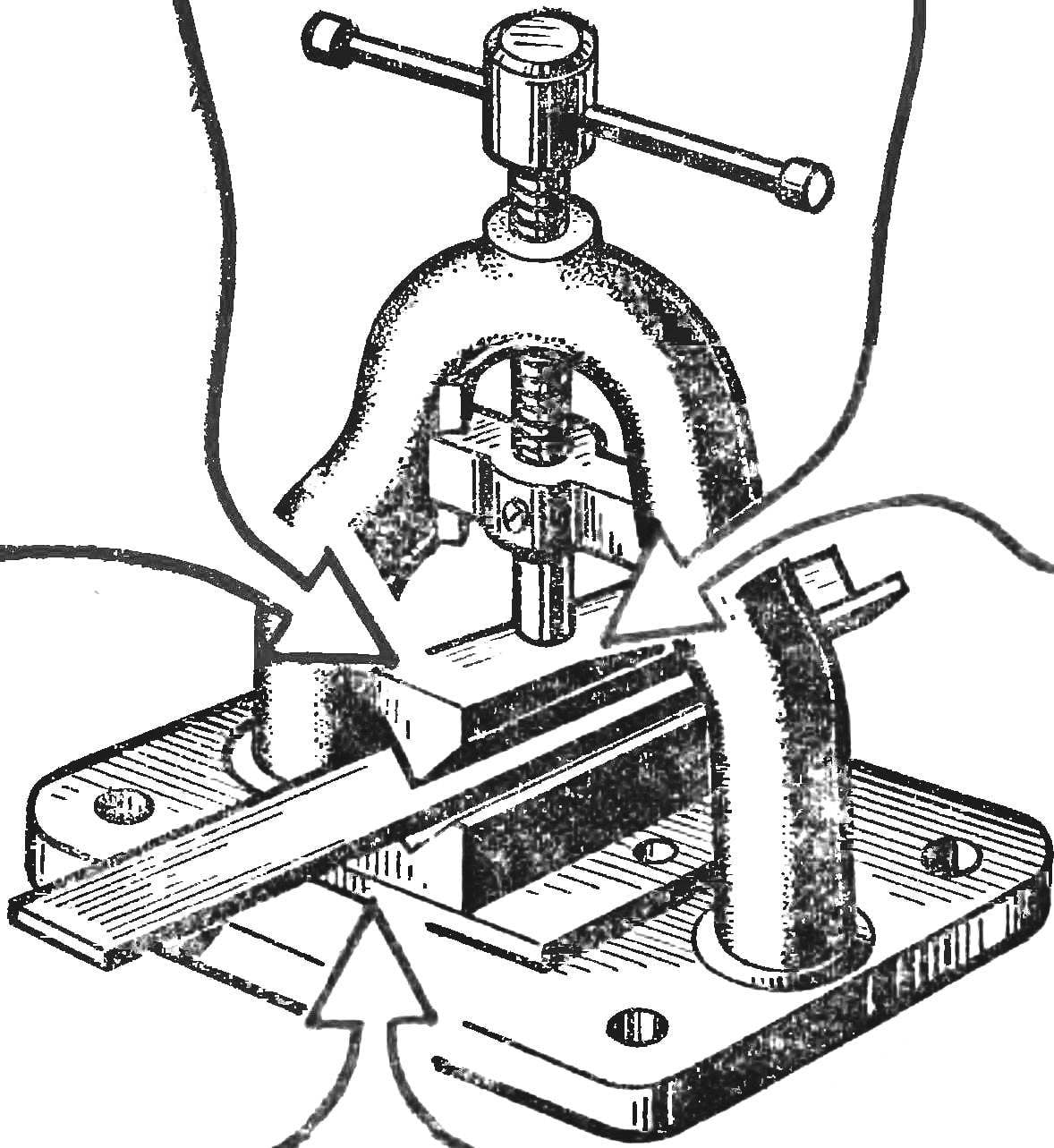

Fig. 4. Stamp with replaceable working bodies:

1 — mount punch 2 — fastening of a matrix 3 — replacement punch, 4 — replaceable matrix.

If corners and channels need a lot, they are easier and faster to do the stamping on the device, consisting of a steel matrix and of the punch (Fig. 1). Before treatment, the steel is annealed: heated to a cherry-red heat (760-800° C) and allowed to slowly cool down. Working plane of the dies must be cleaned on a planer or sawdust strictly under the ruler and set square.

For forming of channels between the matrix and the punch should provide gaps corresponding to the thickness of stamping material (Fig. 3). More efficient for forming of channels of different sizes to make removable punches and moving of the matrix (Fig. 4).

Stamping profiles from soft sheet metal thickness up to 0.8 mm can be produced on the unhardened die. So it does not rust, paint it with oil paint and working surfaces are clean of machine oil, grease or technical vaseline.

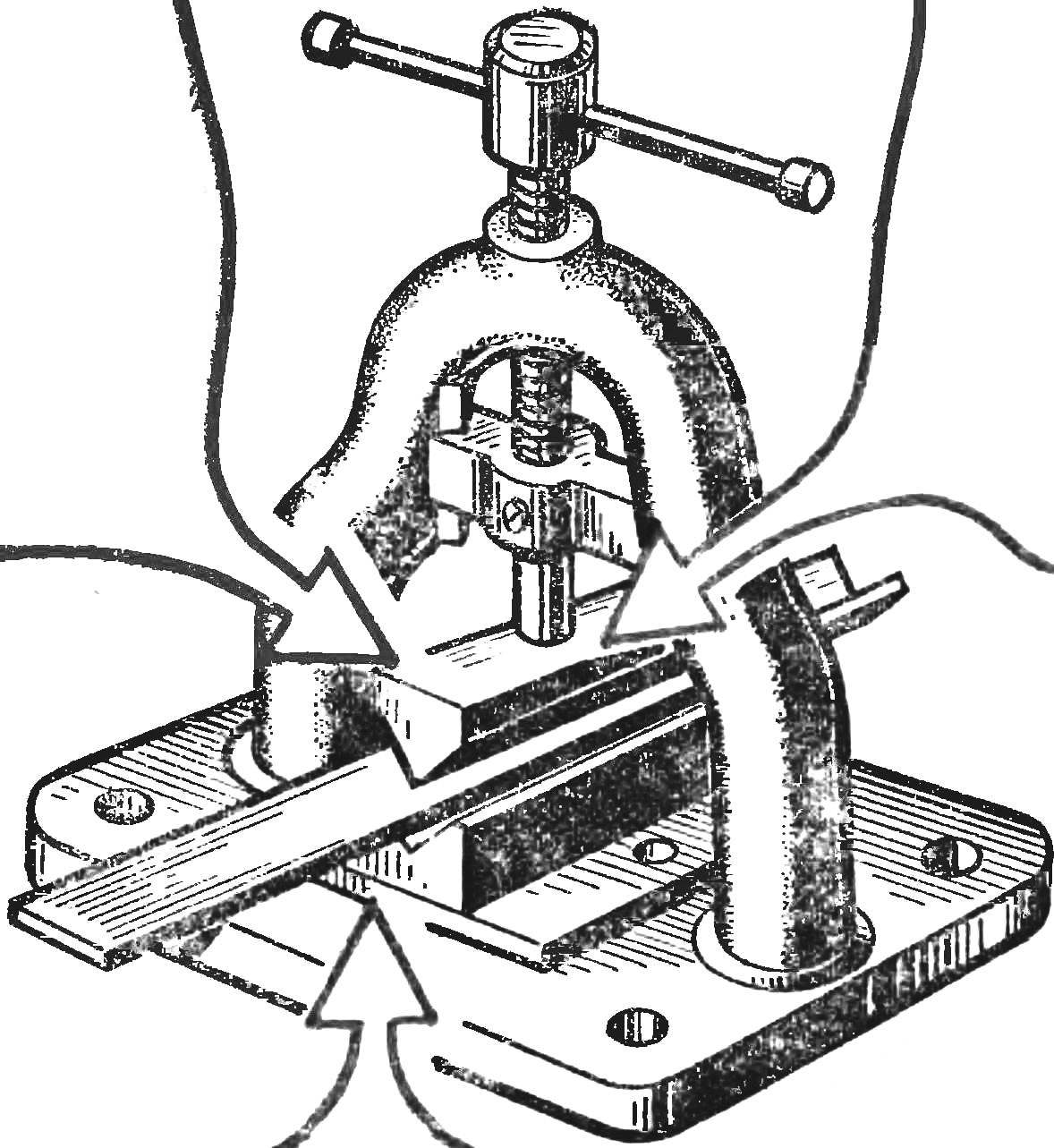

Stamping parts and channels are made on a screw or adapted for this Bindery press, on a movable frame which is attached to the matrix, and the movable part is set to the punch.

For material thickness up to 0.5 mm can accommodate large metal Clamp, making her attachment TO install the matrix and punch. In this case, the frame clamp can be clamped in table vise.

The corners of the flange width from 1.5 mm to 20 mm are punched on the device in the following sequence: cut to size a strip of material placed on a die and a punch of the punch bends the workpiece to the desired shape. It is necessary to make sure that her shelves were the same. Then, gradually pushing the band forward about half the length of the punch and hitting it periodically, give the strip the desired profile. Stamped with an allowance of shelves cut the pattern with scissors to predetermined sizes, as shown in figure 2.

If after cutting the profile and grimaced, then straightening it again a little stamp — leveling on the device.

Likewise, performed stamping of channels.

The device can be die-cut angles, and channels longer than 1 m.

Recommend to read

AND FOR THE JOINER AND CARPENTER

AND FOR THE JOINER AND CARPENTER

Please tell about your Hobbies. Like to create: to create with their hands the things that enhance the comfort and beauty home. I especially like working with wood — carpentry,... AND THEN CAME JACK…

AND THEN CAME JACK…

In the last issue we talked about last representatives of cruisers with over 20 years of ex-one of the most important and revered ships in the fleets of all the major Maritime powers....

ROLLING MILL IN THE ROOM?! Is it possible? We are accustomed to the fact that the machine with such name in size comparable to the multi-storey house. And then the baby, a free fit on the table. And still the mill! Or drawing machine or a press… Yes, does it matter which category of Metalworking machinery will be recognized as the product of young designers. Here is the most important the other machine performs the same operations as he churns out the angles, and channels, lugs (stretches to a smaller diameter) wire, the strip grips the tube, and the wire unrolls into a flat plate or even the “AmiNET” in the bar. Using such devices to perform many other works, if you add some accessories.

ROLLING MILL IN THE ROOM?! Is it possible? We are accustomed to the fact that the machine with such name in size comparable to the multi-storey house. And then the baby, a free fit on the table. And still the mill! Or drawing machine or a press… Yes, does it matter which category of Metalworking machinery will be recognized as the product of young designers. Here is the most important the other machine performs the same operations as he churns out the angles, and channels, lugs (stretches to a smaller diameter) wire, the strip grips the tube, and the wire unrolls into a flat plate or even the “AmiNET” in the bar. Using such devices to perform many other works, if you add some accessories.