The widespread use of electric guitar inherited a system from its predecessor — the six-string Spanish guitar. In this case the highest note that you can use on the tool — usually “e” in the 3rd octave (for comparison: the violin this note — “mi” 4th octave, while the piano — 5th-octave). Most electric guitars such high notes can be achieved only through the console of the frequency doublers, which are not widely received. You can also increase the number of frets on the fretboard. Some professional guitarist in a TV interview said that he had ordered the master guitar with 38 frets, but this is the exception rather than the rule. Industrial electric are issued usually for not more than 24 (usually 22) scales, and their sound range is about 4 octaves.

The widespread use of electric guitar inherited a system from its predecessor — the six-string Spanish guitar. In this case the highest note that you can use on the tool — usually “e” in the 3rd octave (for comparison: the violin this note — “mi” 4th octave, while the piano — 5th-octave). Most electric guitars such high notes can be achieved only through the console of the frequency doublers, which are not widely received. You can also increase the number of frets on the fretboard. Some professional guitarist in a TV interview said that he had ordered the master guitar with 38 frets, but this is the exception rather than the rule. Industrial electric are issued usually for not more than 24 (usually 22) scales, and their sound range is about 4 octaves.

Introduce readers to the design 5-string electric guitar-“Piccolo” (Italian — “reduced”), mainly dedicated to the performance of the solo parties. Her range is 4 octaves, from the note “salt” great octave to the note “Sol” of the 3rd octave. From standard electric guitars it also has a shorter scale (the working length of the strings) — 546 mm instead of 650 mm and setup: between the 1st and 2nd, 2nd and 3rd strings a Quint interval (setting at the 7th fret), and between 3rd and 4th, 4th and 5th a quart (set up at the 5th fret). This allows, in my opinion, when playing solo, especially on the first three strings, to more evenly distribute the load on the 4 fingers. The standard electric guitars Stroy kvantovo-fifths.

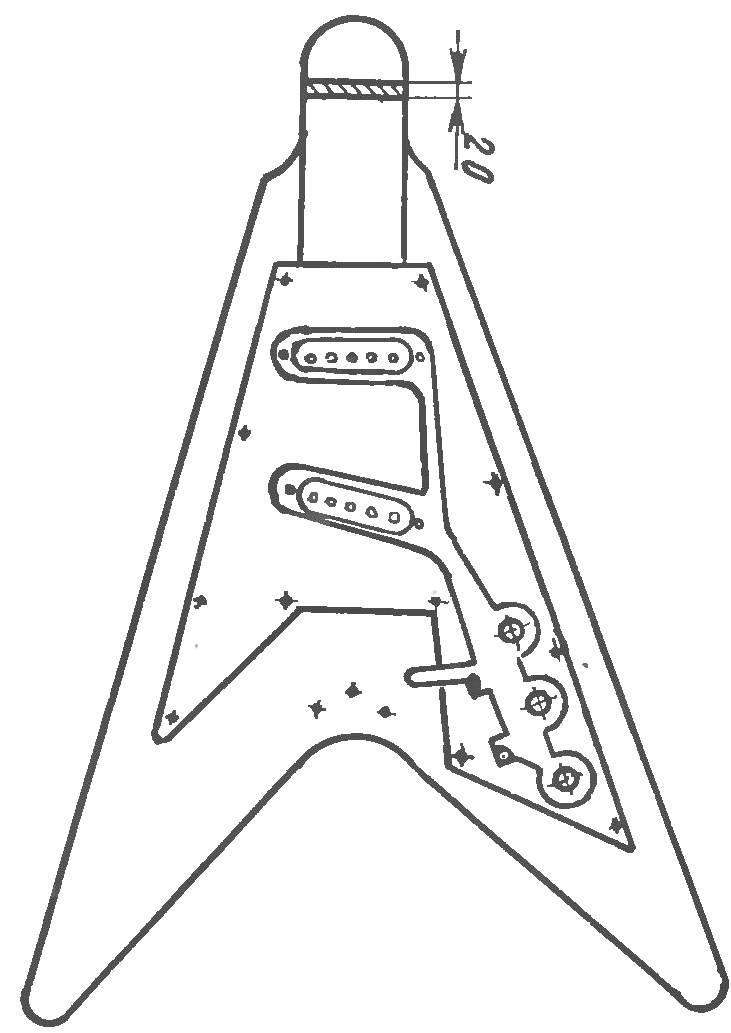

Body electric guitar made from wood of medium hardness. The best material is maple, but you can also use spruce, birch, pine, alder, Linden, ash or other well dried quality Board. It is permissible to glue the body of several more narrow closely fitting bars. Thickness of about 40 mm (but can be from 35 mm to 42 mm), while at the point of attachment of the neck thickness should be 20 mm. If the shell is of a thickness less than 40 mm, it is necessary to reduce the depth of the grooves in the body under the pickups and increase the height of the stand for the strings.

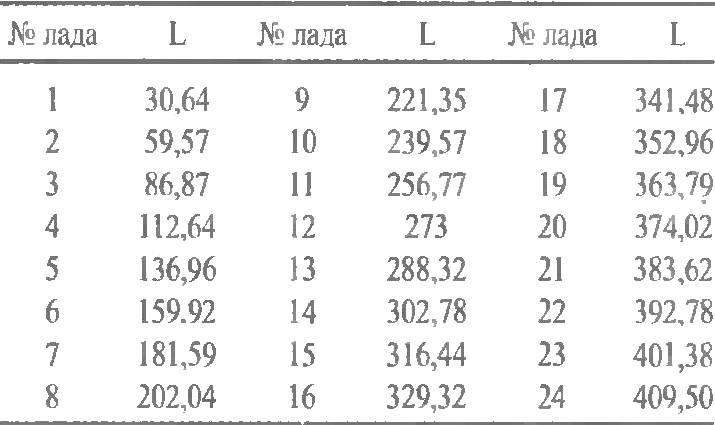

Table 1. The distance from the left edge of the fretboard to fret (L, mm)

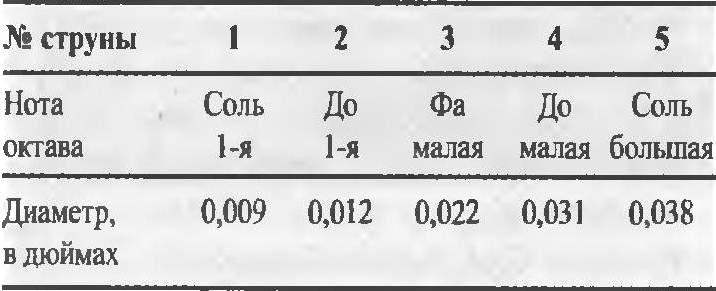

Table 2

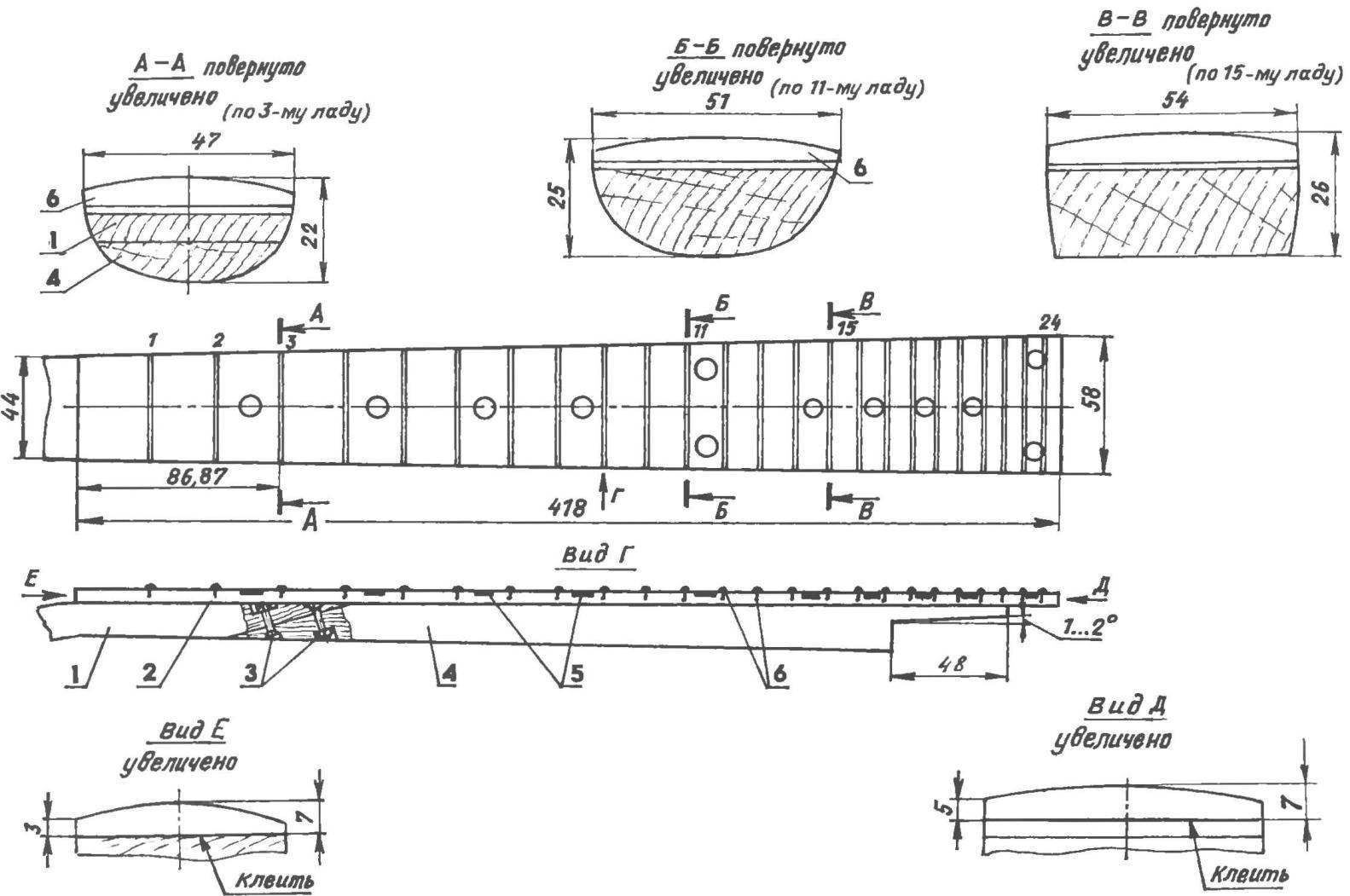

In the case hollow out with a chisel the grooves for the cartridges to (LC), wire and other electrical components as well as a groove for installation of the neck (under the existing hollows out a vulture); drill an inclined hole with a diameter of 4 mm for the wires connecting the tailpiece with the common wire circuit. I used the neck from an old children’s guitar. Staff head sawed off on the “seam”, and in its place installed a homemade birch. Fingerboard can be made independently from wood of high hardness (ash, oak, maple). To do this, given his drawing. Head attached to the neck with epoxy glue and two screws M5 flat head, with nuts and washers.

The pad is also made from solid wood with a thickness of 7 mm and glued to the assembled fingerboard. Then attach convex in cross-section form at the top of the nut, the curvature maximum, and the 24th fret it gradually decreases.

Next is the layout of the fretboard. While taking into account the fact that the frequencies of the two neighboring semitones, for example, “before” and “C sharp” evenly tempered tones are like 1/2=12 and, accordingly, the working length of the same string when taking notes in a way the above is shortened about 1.04427 times. For example, if the length of the open (neprijatelj) strings 546 mm, the working length of the strings on the 1st fret will be approximately 515,35 mm. Distance from the left edge of the fretboard to each of the frets are summarized in the table.

On the fingerboard of the neck sharpened pencil spend a centerline of symmetry. Then from the edge of the lining where it should be installed the nut, say using a metal ruler (you can use a tape measure, but not on the zero mark) and a sharp awl the distance to the next fret (on the table). Next, using a square and sharp pencil or an awl mark transverse lines to install frets.

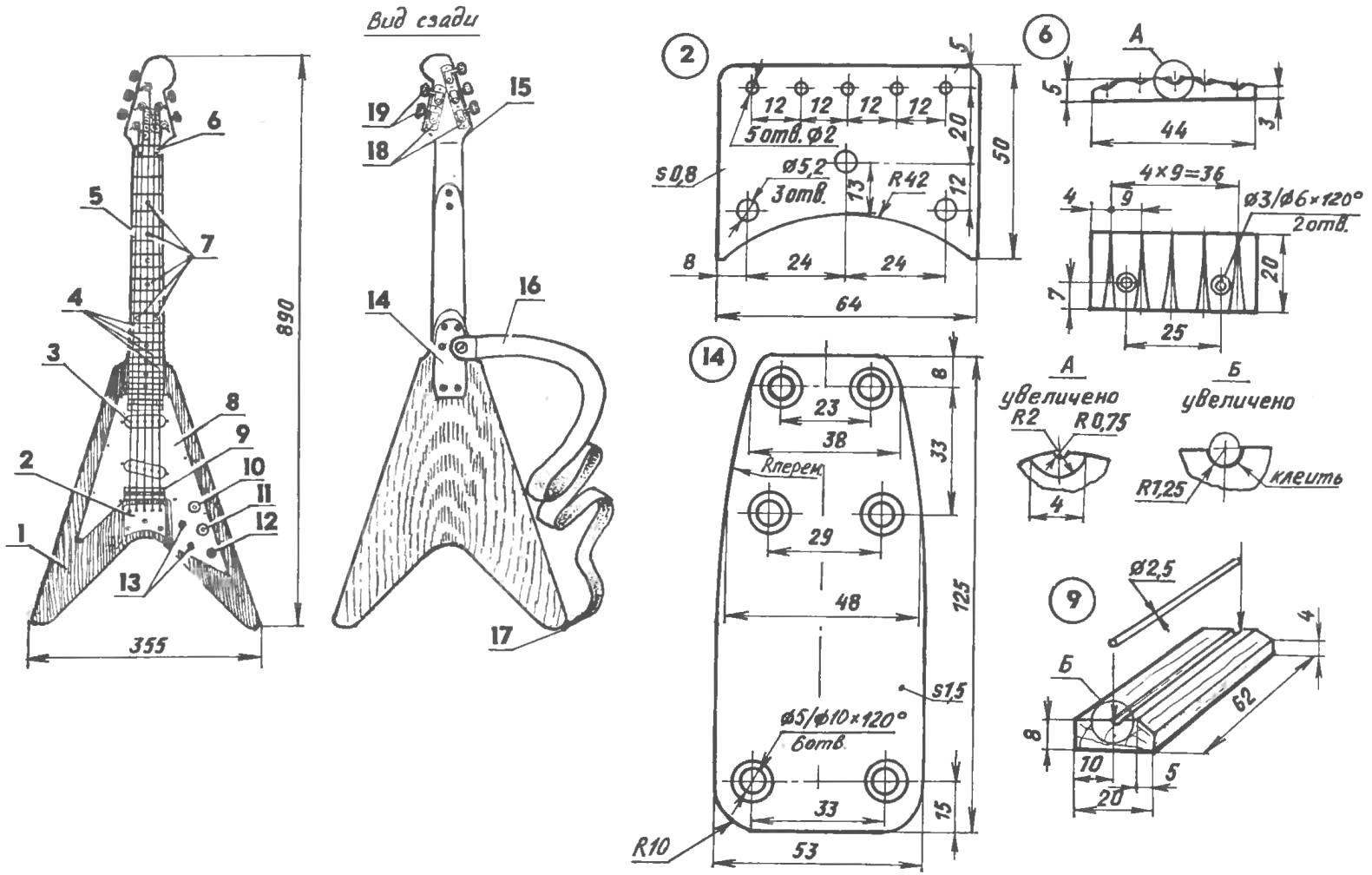

The guitar-Piccolo:

1 — case (hardwood s42); 2 — tailpiece (brass, s0,8); 3 — pickups; 4 — strings; 5 — neck; 6 — upper nut; 7 — “point” (12 PCs); 8 — decorative armour (plexiglass s2,5); 9 — stand for strings; 10 — level control (R1); 11 — tone control (R2); 12 — output Jack; 13 — switch; 14 — cover plate (metal plate); 15 head and neck; 16 — belt (in the front view is not shown); 17 — screw for attaching the strap; 18 — base pins; 19 — the peg line mechanism (children’s guitars)

Grif:

1 — head (tree of firm breeds); 2 — pad (hardwood); 3 – mounting bolts M5 countersunk head with nuts and washers (2 PCs); 4 — vulture (hardwood); 5 (white nitroenamel); 6 — okay (purchased)

The configuration of the slots in the housing for mounting devices and circuits

In my instrument the frets are applied with a thickness of 2.6 mm (acceptable to use and with a thickness of 2.5 — 2.8 mm, sold in a music store). Cuts at the frets can be done with a hacksaw with a slightly divorced teeth (better to use a hacksaw or “Litovko”). The frets gently hammer a hammer, rasp, and then removed, to avoid sharp edges, the ends treated with a needle file. Then put one “point” before 3, 5, 7, 9, 15, 17, 19-m and 21st frets, and prior 12-m and 24-m — 2 “points”, which helps the guitar player to “focus” on the fretboard while playing. Using a 5-mm drill to make the hole to a depth of 0.3 mm and is filled with white enamel (nitro – or type PF-115). After this the frets are mounted on adhesive (“Point-1”) finally. If the footing supports more than is necessary, it is trimmed with a hammer or a file from the final refinement.

The instrument scale is chosen equal to 546 mm, which is about three fret shorter than a standard guitar (650 mm). As the neck without the anchor rod, it is recommended to use strings from the standard kit medium, or weak stretches (sets in which the thinnest string has a diameter of 0.009 and 0.008 inches even with the same tension). Table 2 summarizes the notes, which are configured on the open strings of an electric guitar. Here is specified the corresponding approximate diameter of the strings.

Peg line mechanism used is also from a children’s guitar. In the headstock drilled the holes for the bushings for the tuning pegs turned on a lathe from brass. This is done so that the wood head of the neck is not as exposed to abrasion due to friction of parts peg line mechanism. Possibly the use of other pegs designed for metal strings, but then you have to decrease the distance between them. For this metal plate, which serves as a base, cut between adjacent pegs, and parts of sets overlap. The transverse holes for the strings in the axes of the pins should be drilled new, but the same diameter. Sleeve is smeared with glue and hammered with a hammer. Peg line mechanism is fixed with screws 2×7 or 2×10 mm. the nut is made from steel or aluminum and secured with two screws 2,3×13 mm wooden lining.

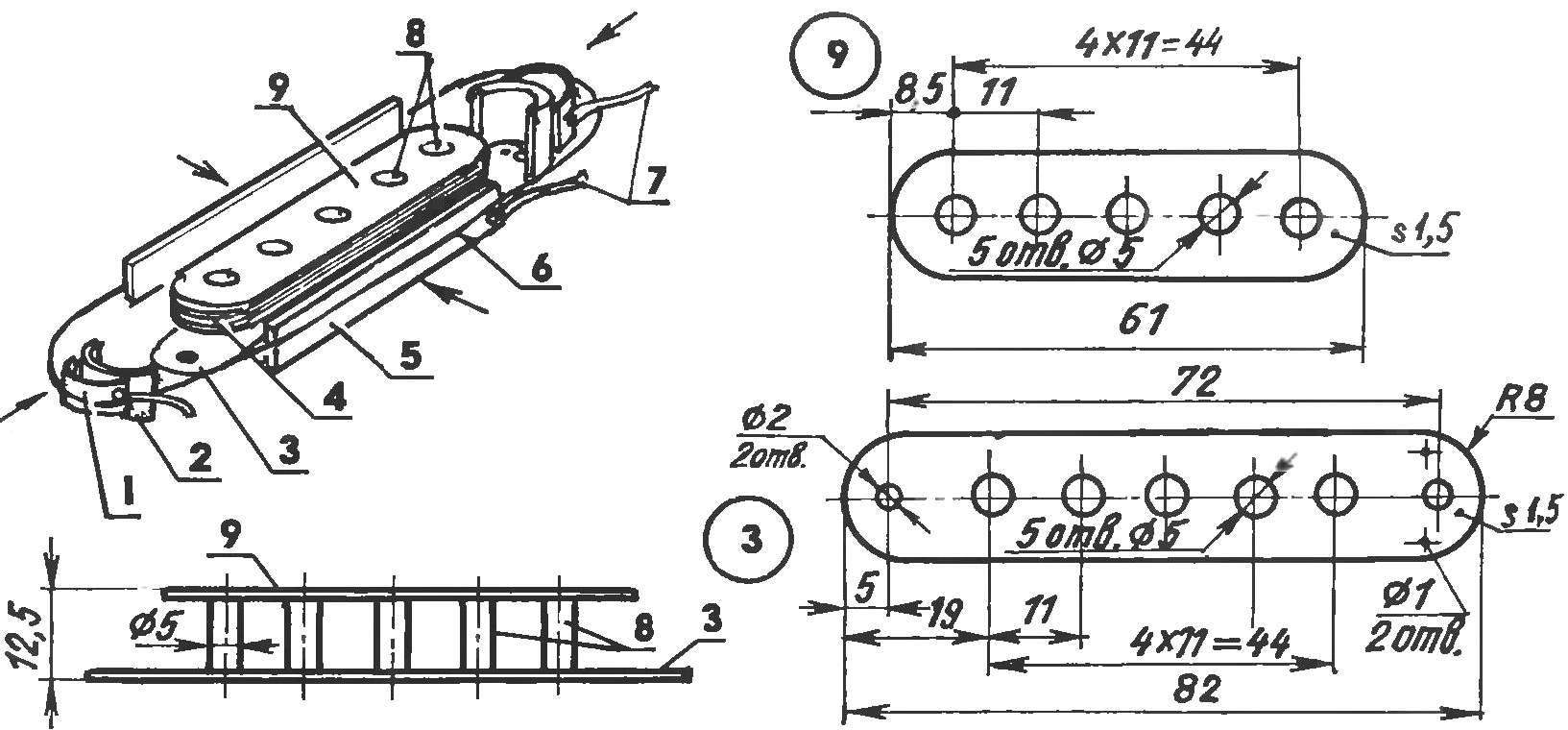

Upper cheeks pickups from furniture white plastic base — from Micarta. The core of each of the pickups has 5 (number of strings) of 12.5-mm segments of the rod of 5 mm diameter made of magnetic steel. For their manufacturing it is possible to use reinforcing wire. To give the “magnitomyagkikh” blank “let go” — heat on a gas burner and allowed to cool in air to room temperature. The ends of the cores are put on glue to the base of the cartridge (ZS) and the upper cheek, then the cores are overlaid with a layer of transformer paper (tracing paper or varnished cloth overlap) and produce a wound. Each pickup will fit on 1200 turns of wire PEV-1 0,1. If you take a wire diameter of 0.06 mm, the number of turns can be increased to 2000 — 2500 and even more, which will increase the EMF signal. The terminals of winding is fixed to the contact pins tin-plated 1-mm wire — insert them into the holes with a diameter of 1 mm at the base and is bent into a ring. Then made the screens ZS sensors. The side walls of screens made from-sided glass epoxy (Micarta) and glued to the pickup foil to the outside. Dimensions of workpieces: for the first pickup — 45×12 mm, for the second — 48×12 mm (2 pieces). Before installation of the workpiece should be about-tin plating in those places where it is supposed to solder the ground wire. If there is no foil material, these parts can be made of a non-foiled, and the copper foil to be glued later. The end part of the screens are made of 1-mm Plexiglas, sizes 28×11 mm (4 PCs.). Rounded shape blanks, holding them over the flame of a gas burner or hot plate. Then blanks are glued to the semi-circular ends of the grounds, and it’s on top of copper foil, which is pre-soldered wire. Four foil plates are brazed to each other so as to form an open spiral. The resulting screen attract to the pickup thread and connected to one of the terminals.

Pickup:

1 — pad (copper foil, 2); 2 —end of the screen (plexiglass, s1, 2); 3 — base (Micarta, s1,5); 4 — winding (copper wire PEV-1, Ø 0,1); 5 — side part of the screen (one-sided foil Micarta, s1, 2); 6 — binding (thread); 7 — findings (copper wire, Ø 0,5); 8 — cores (armature wire Ø 5, 5 PCs.); 9 — the upper cheek (white plastic, s1,5)

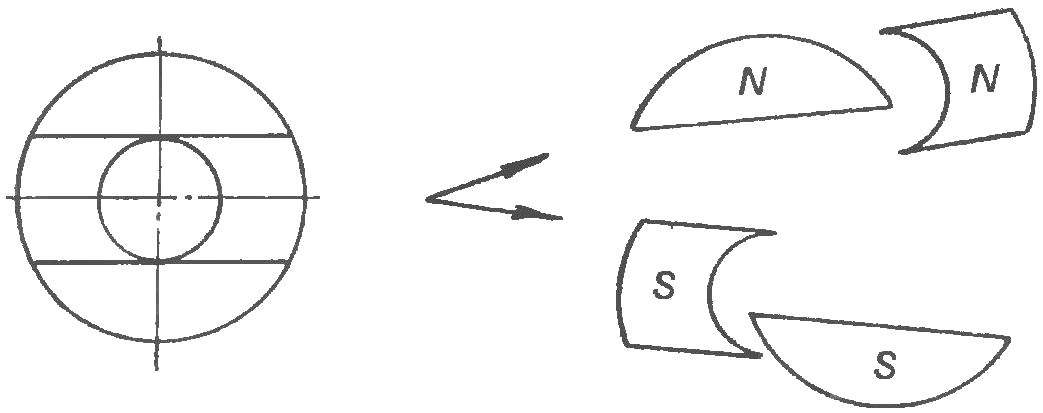

The separation of the magnet into pieces

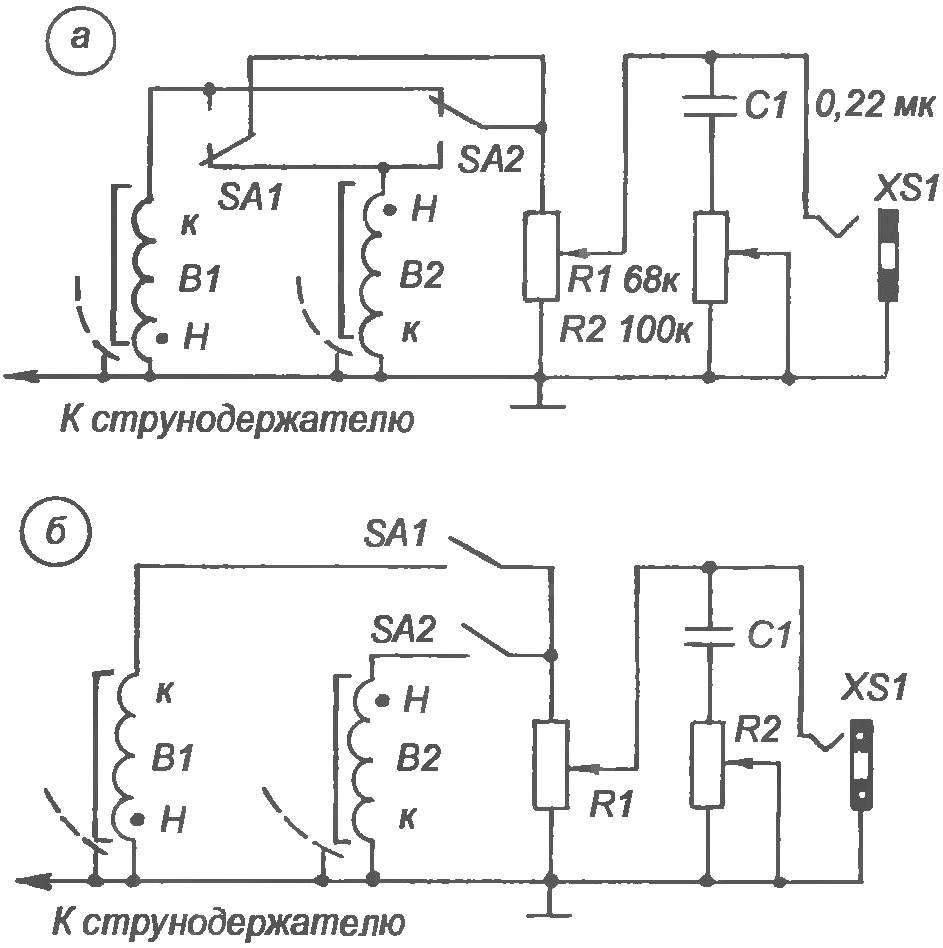

Electric circuit electric guitar:

a) — included pickups (at least one); b) — included no pickups

Used magnets from old speakers. Each is marked with a pencil, dividing it into 4 parts, clamped in a vise at the pencil lines and part beat off with a hammer. Then, Paramonova, the parts glued to the bottom of the pickup glue “Moment-1” so that they touch the core and each other, and wrapped around the perimeter with adhesive tape for reliability. At the same pole of the magnets of one of the pickups needs to be directed in one direction and another in opposite. This is done so that when the two pickups were provided with noise mode. In the applied guitar pickups design “single”, providing, in comparison with the same double omegaseamaster devices design “hambacher”, best quality (transparent) audio (though with a smaller EMF) when playing solo. This is especially apparent when you use homemade pickups. Network interference is markedly reduced due to the shielding, and the inclusion in the circuit of tone control makes the background in the speaker completely invisible.

The pickups are connected inside the guitar with the rest of the circuit elements shielded wire, the winding of which is grounded. The tailpiece from the back side also fluster wire that is grounded — it threaded through a special hole in the housing.

Decorative shell made of 2.5 mm plexiglass. Holes of complex shape under pickups can virest with a screwdriver heated on the fire, or with the help of Thermaltake. After drilling the holes, the shell is covered with the inner side of the enamel (nitro – or PF-115). If the plexiglass has minor scratches — no problem. Even a plexiglass covered with paint from the back side, looks much better covered from the outside.

The body, the head and the back of the guitar neck tinted stain and coated with 3-4 coats of nitro lacquer (for example, SC-243). The inscription on the stamp is made with the cautery. After varnishing the fretboard lettering is filled with white enamel. At varnishing lateral parts of neck and body the first 15 — 20 minutes they should be kept horizontally until the varnish sets.

The Assembly scheme can be produced in two ways. In the first case (scheme a) always included at least one AP, but such a scheme requires more wires and less reliable. The second scheme (b) more reliable, so the beginner is better to choose it, but it is the position of the switches when not working, no CS. As SA1, SA2 applied microtubles; resistors CP3-30A it is advisable to choose from the groups In (R1) and (R2); socket ХЅ1 under finger plug diameter: 6.3 mm Capacitor C1 is ceramic, group Н90. Details of the scheme and connect the shielded wire, the braid of which is grounded.

Stand for the strings of the guitar applied simplest. Wooden part tinted stained and varnished, and the metal is made from a nail with a diameter of 2.5 mm, with the bitten off head and honed with a file. With the help of the stand put the correct bore — to harmonics at the 12th and 24th frets are exactly matched the notes on those frets. If you wish you can make more complex and better stand for the strings, which is governed by the scale of each string separately.

The neck is attached to the case by six screws 5×40 mm, passed through the slip metal plate; it is rejected from the body forward by 1 — 2°.

The base of the pickups screw to the shell by screws M3, which in a subsequent adjustment exhibit optimal distance between the AP and strings. The shell is attached to the housing 11 by screws 2×7 mm.

The tailpiece is attached to the housing with three screws 4,5×25 mm. Podpilivaya the back part of the stand for the strings or placing it under the strips of veneer, set the height of the strings over the 24th fret of 2.5 — 3.5 mm, while the upper sill above the 1st fret of about 0.6 mm.

Strap length 115 — 120 cm bolted to the guitar with screws 5×40 mm; holes are on the strap finished with leather lining.

Peg line mechanism in place of gear-worm gear suggest periodically lubricated with engine oil. It will significantly increase its service life and will facilitate the stretch of the strings.

A. BRANITSKY, Minsk, Belarus

LITERATURE

1. Electric guitar. The Magazine “Radio”, 1969, No. 12.

2. Guziewicz O. N., Medvedovski.With. Electric guitar. P., “Energy” 1970.

3. Kukushkin V. Electric Guitar. Modelist-Konstruktor, 1971, No. 10.

4. Sergovskyi V. Guitar with melodic electronic channel. Radio, 1972, No. 1, pp. 45 — 48.

5. Guziewicz O. N., Medvedovsky D. With An Electric Guitar. In using the ham radio. Radio, No. 42, pp. 55 — 66.

6. Ketner V. the Guitar — organ. Radio, 1976, no. 1, pp. 45 — 48.

7. Guziewicz O. N., D. S. Medvedovsky Musical stringed instruments.— I, “Energy”, 1979.

8. Turchin A. Electric Guitar. Junior technician, 1988, № 2, 3, pp. 65 — 69.

9. Savinov N. Noise-free pickups for electric guitar. Radio, 1977, vol. 10, pp. 57, 58.