It would seem that this device has already acquired a classical form; in any case, each representation there is a tool with movable and stationary jaws, and a screw feed. However, innovators are creating new kinds: specific and universal. That’s the job of the innovator K. Malkova (Leningrad plant conveying systems named after S. M. Kirov). His grip is possible, first, to simultaneously process multiple parts. Secondly, they are easy to attach versatile-modular fixtures. Finally, the vise can be used for installation on the drilling machine to facilitate the clamping of large parts.

It would seem that this device has already acquired a classical form; in any case, each representation there is a tool with movable and stationary jaws, and a screw feed. However, innovators are creating new kinds: specific and universal. That’s the job of the innovator K. Malkova (Leningrad plant conveying systems named after S. M. Kirov). His grip is possible, first, to simultaneously process multiple parts. Secondly, they are easy to attach versatile-modular fixtures. Finally, the vise can be used for installation on the drilling machine to facilitate the clamping of large parts.

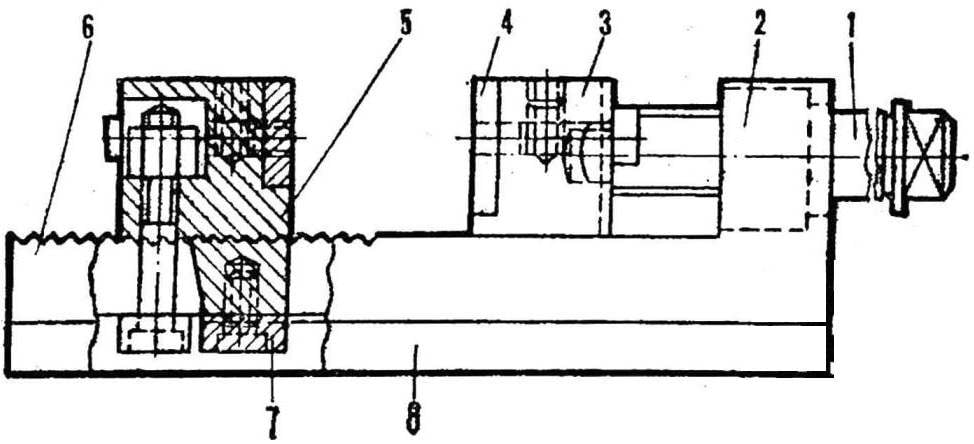

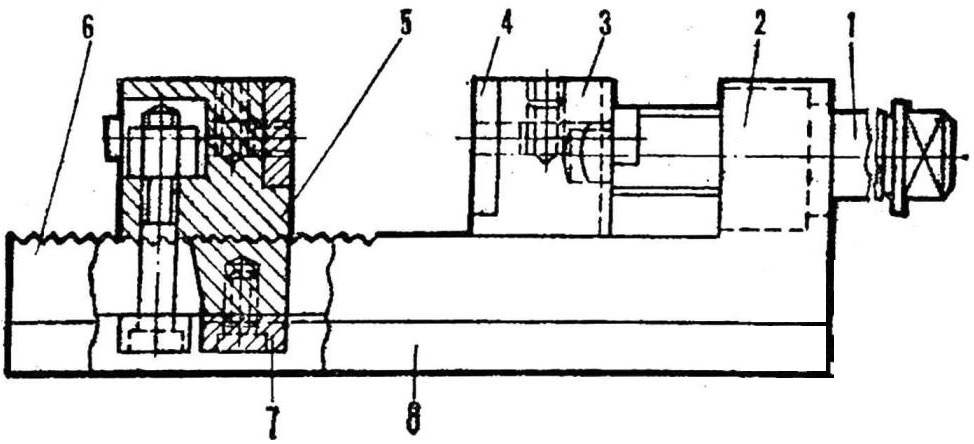

Vise:

1 — feeding screw, 2 — sleeve, 3 — movable jaw, 4 — removable cheek, 5 — Adjuster sponge, 6 — notch 7 — clamping strip 8 base.

While most of the clutches of one of the jaws is necessarily immobile, these both apart. The lower part of one of them, the adjustment of the sponge, and under it the surface of the base have a major notch, providing the necessary fixation of the sponge. Improved and a second clamping part; her cheek interchangeable: not only flat, but also curly. This facilitates the clamping of workpieces of complex shape.