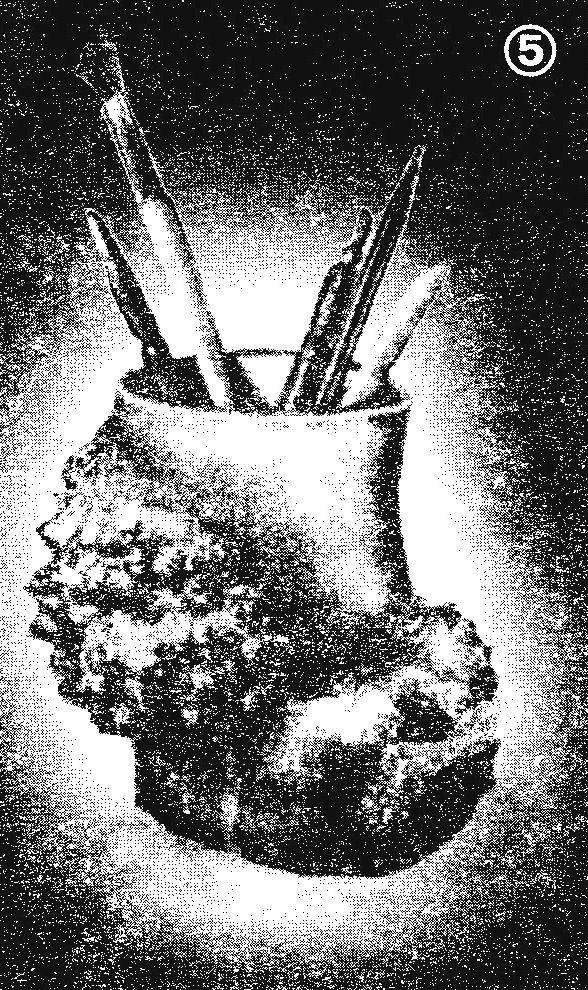

Exhibitions amazingly beautiful decorative pieces of KAPA compete even with the amber jewelry—seafood and resinous prehistoric forests. Cap (in other words—influx) is a growth on the trunks of trees that represent an anomalous development of the wood. Once in the hands of a master, he is transformed into a work of art decorative art: original planters and flower vases, unusual dishes and bowls, pencil holders, ashtrays. All of these items look as if created by nature itself, and people only found these treasures in the woods, spying them in intricate swellings on the trunks (by the way, is detrimental to the tree).

Exhibitions amazingly beautiful decorative pieces of KAPA compete even with the amber jewelry—seafood and resinous prehistoric forests. Cap (in other words—influx) is a growth on the trunks of trees that represent an anomalous development of the wood. Once in the hands of a master, he is transformed into a work of art decorative art: original planters and flower vases, unusual dishes and bowls, pencil holders, ashtrays. All of these items look as if created by nature itself, and people only found these treasures in the woods, spying them in intricate swellings on the trunks (by the way, is detrimental to the tree).

Types of growths

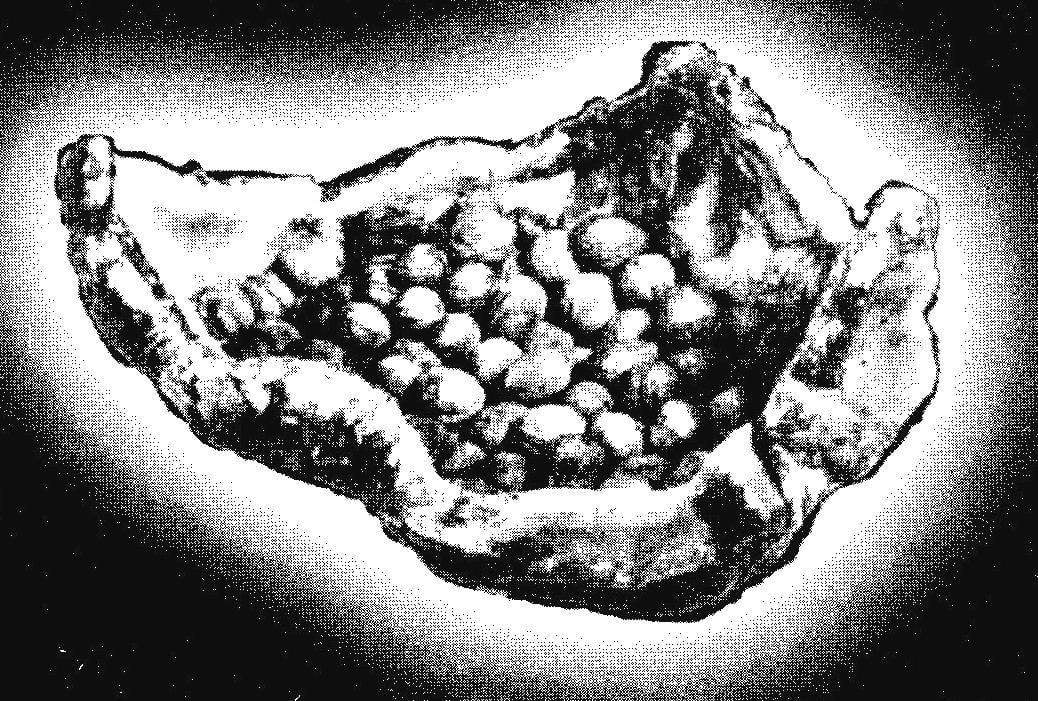

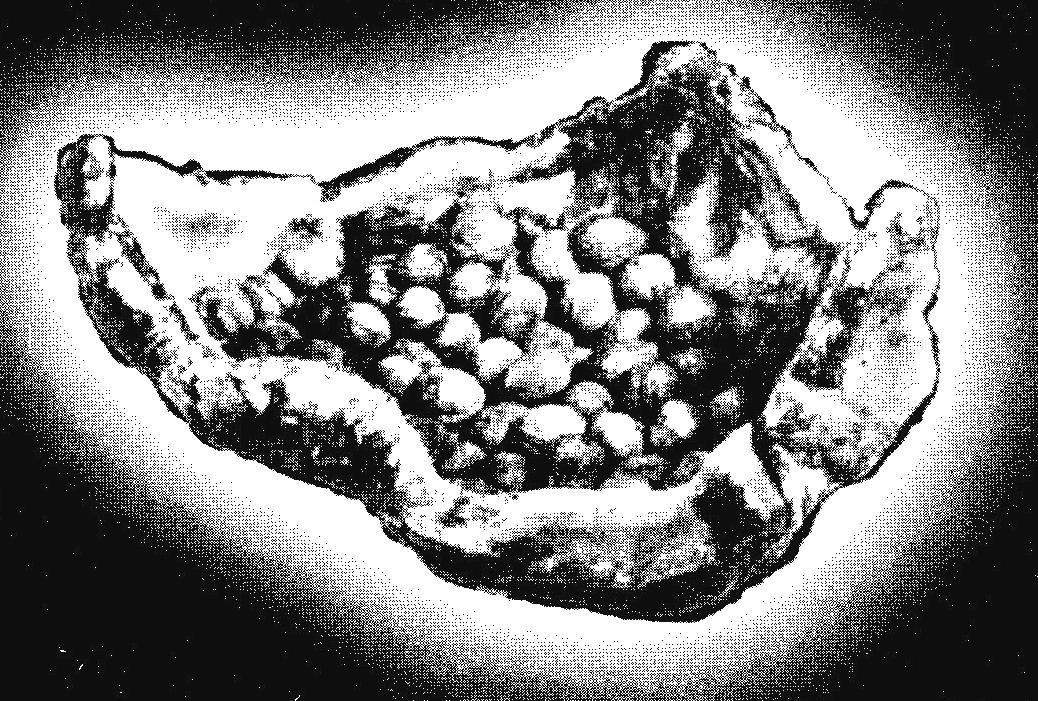

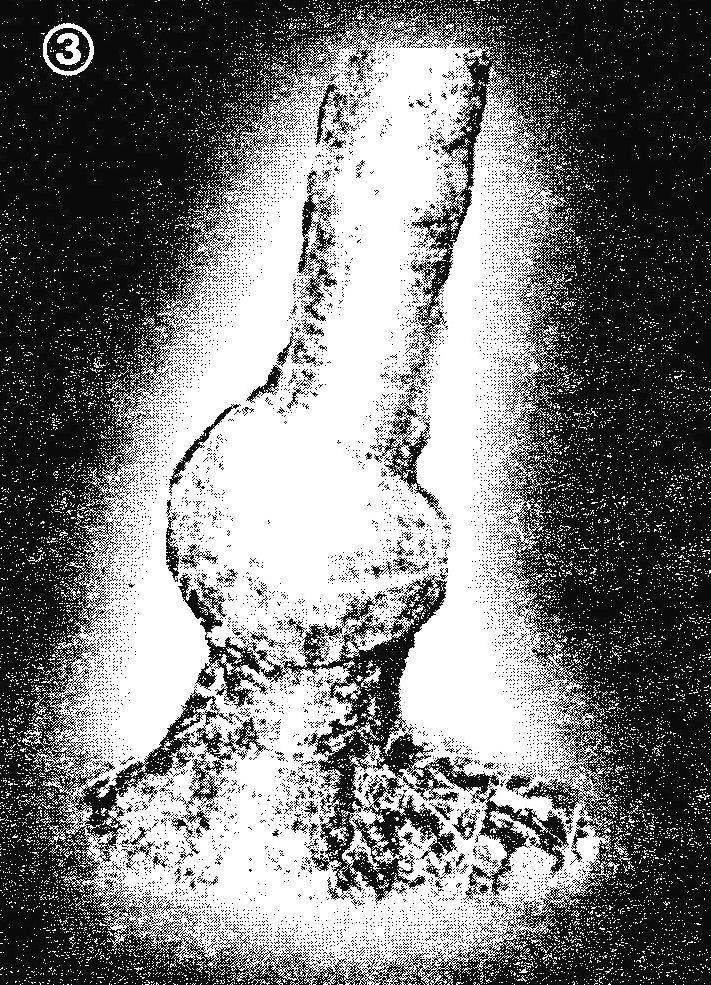

All the buildup with a large variety of forms according to their origin are divided into two types. The first is the outgrowth of dormant buds that permeate the wood; the second, from the abnormal wood. The main symptom of the growth of the first type — the presence under the bark of many tubercles, which are sometimes awakened as the kidneys and give coppice shoots. These bumps and then create beautiful external form product. But the inner surface of products due to these same undeveloped kidney has an extraordinary appeal. Obviously, such a texture is formed from gnarled wood, permeated the nascent buds. The inner surface of the polished slice is so unusual that it can be compared only with the texture of this rare and valuable wood Karelian birch.

The second type of growth more numerous in form, and therefore, it is possible to produce a wide variety of products. Often it consists of one continuous hill svilevatoj wood or a few medium bumps that constitute one common.

This type of growth texture richer than that of simple wood, but much easier than the burls from dormant buds, and that’s why beauty products—mostly at the expense of external forms.

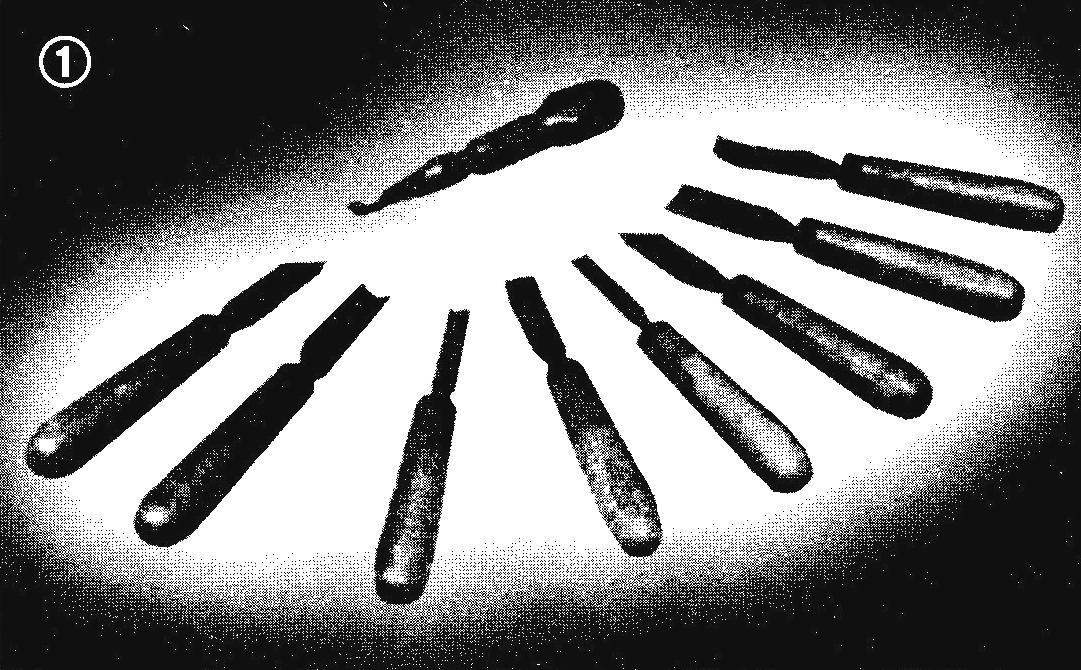

1. A set of chisels for hand sampling

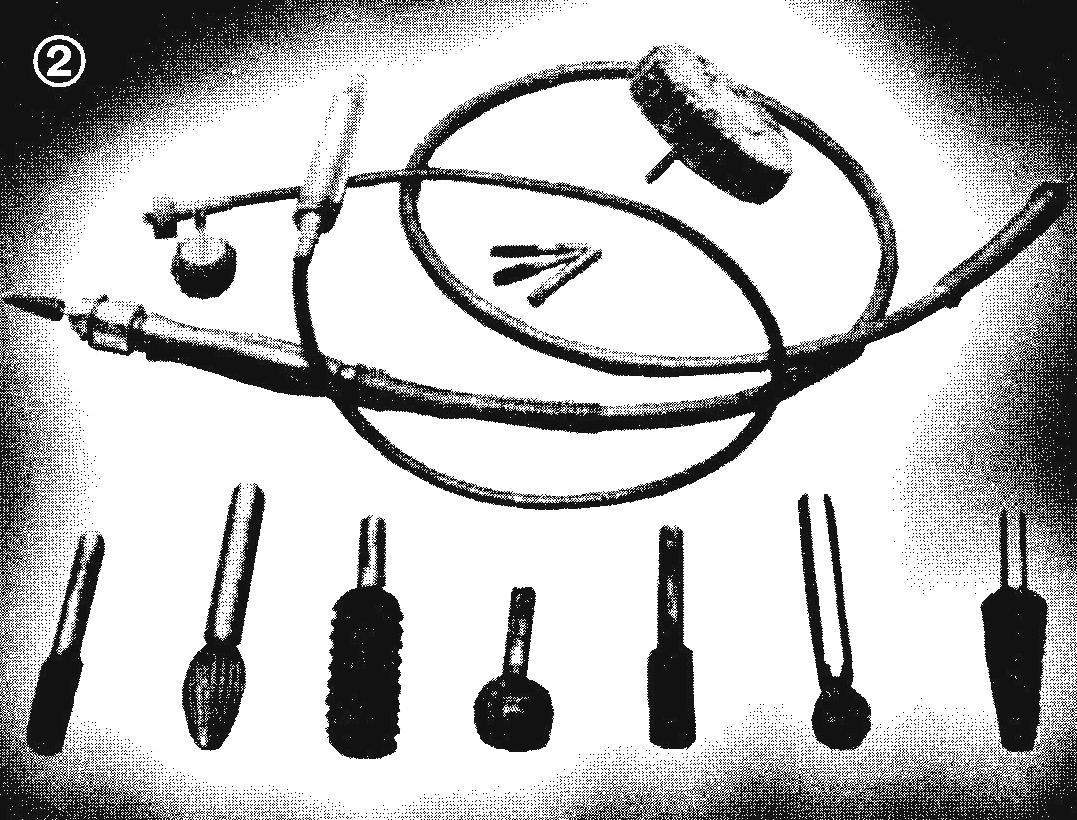

2. Flexible shafts to the drill with a set of cutters and grinding attachments for processing of Capa

3. Double spruce growth — material for vases

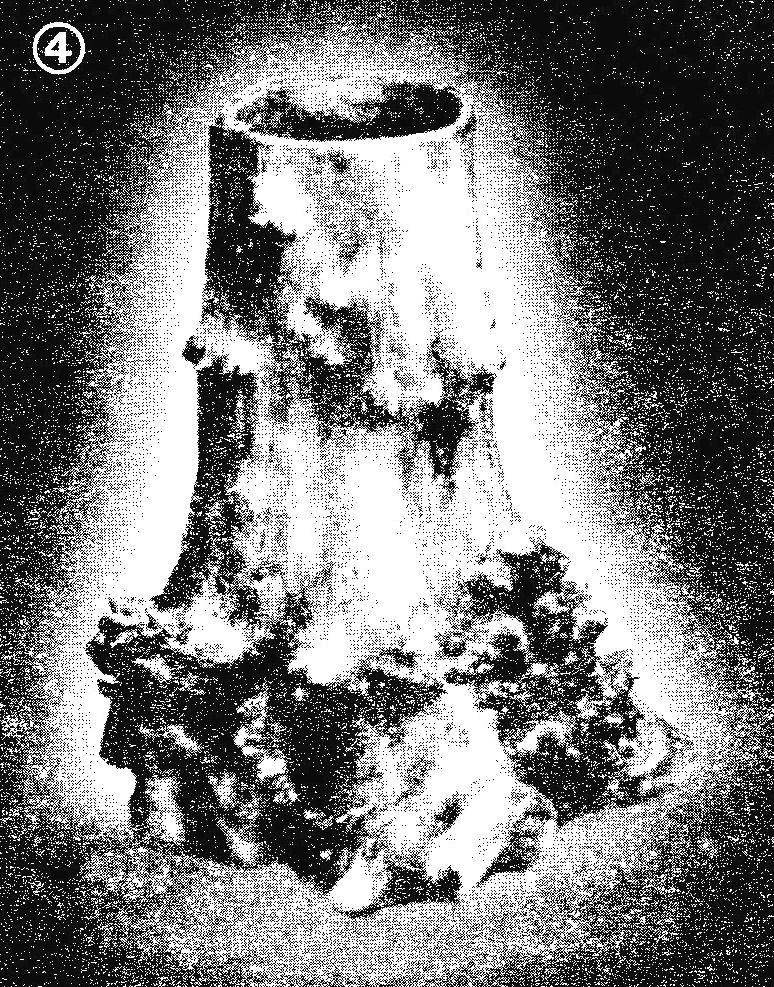

4. The principle perform such vases are not complicated

Material for pots, vases, a variety of bowls made from a large build-up with a strong bend around the barrel, — all this requires sawing off a whole part of the trunk along with a influx.

To take the excess part of the stem is necessary in order to prevent the formation of cracks in manufactured vases and pots. In addition, the workpieces it is advisable to drill a few holes in the brain stem at the site of the future container. This will provide additional insurance against cracking as the evaporation of moisture from the workpiece will go harder inside through the holes, pulling the moisture from the outer parts of the workpiece. Thus the deformation from the shrinkage (compression) of the workpiece will go inward (not outward, with the inevitable cracking).

Cap can be harvested throughout the year, but better to do it in the spring, when the intensity is formed of the growth layer of the tree — the cambium. It was during this period the bark is easily separated. At another time of the growth layer of the tree is compacted, increasing the relation of bark with the wood, so much so that separation becomes more difficult.

With regard to the growth of dormant buds, it is better to harvest exclusively in the period of intensive growth of the tree, at other times the cap separated from the barrel becomes impossible.

Search Capa

The growths can be in any of the trees in odnorodnyh and mixed forests. It is noticed that the birch they are detected more often than in other breeds.

Nodules from dormant buds occur almost exclusively in the trees are able to coppice resume—mainly birch, maple. They sometimes occur at the same time dozens of growths of different sizes — from small to medium.

Trees, with the ability only to seed reproduction (pine, spruce), influx from dormant buds do not form, but only from the abnormal wood. Only rarely you can find one more growths on the trunk.

Cap can appear at any height of the trunk and on roots and even on the branches of a tree of any age. Most of the growth in middle-aged stands.

In weakened stands (for example, due to periodic long-term flooding), the author observed the formation of a significant amount of growth from dormant buds on the birch, mainly in the basal part of the trunk.

The appearance of the growths in forests is directly related to the development in it of undergrowth: the denser the vegetation, the smaller the probability of finding the cap and Vice versa.

Remember that you can’t take the build-up from oak — this is a rare, dollarstoday and very valuable breed, besides the wood of this tree because of the large hardness is very difficult for harvesting and processing it into the product.

How to extract growth?

Tool hunter of growth needs to be easy to use, light, efficient and durable.

A concrete example of it can serve as an improvised bow saw, made by the author from aluminium. It is suitable for treatment of the trunk as in the procurement of material, and while working with the product.

In marching a saw consists of several collapsible elements of the back, two side handles (with tension screw in one of them) and the saw blade.

This tool, losing the weight of the wooden attic shaped bow-shaped saws, has a number of advantages, covering this lack, the most important being the strength and rigidity of the mounting elements, to achieve a strong tension of the saw blade. This makes the process of sawing, as one of the most time-consuming stages of the work, much easier. This is especially important when sawing trees of considerable thickness and of hardwood.

Disassembling (or assembling) this saw does not exceed three minutes. Wrapped in a bag, it fits easily in a backpack.

Hand tool

To create a blank product, you should produce two kinds of works—removal of excess material and subsequent grinding of the surfaces.

During manual execution of these works the right set of chisels and grinding material with different grain size. Chisels differ from one another in the profile and width of the leaf; they may be straight or semicircular. Sharpen them at an angle of 18-20° to work so it will be easier than chisels with a steeper sharpening.

Semicircular chisels are different degree of curvature—from almost flat to the blade with a significant radius of curvature (gentle, medium and steep). Sharpen them both outside and inside, depending on the nature of the work.

A narrow chisel can be made of files, stachiw last accordingly a sanding disc. With the exception of the cutting end of the metal should “let go” by heating on low flame until yellow. If this is not done, the chisel will turn out brittle as a metal nail file is hardened throughout its length.

Well-trained and properly mounted tool enables the cutting of wood with less effort, quickly and with high quality. Same dull and badly adjusted tool will block, as they say, not just hands, but desire. Only by working a sharp and handy tool, the wizard does not get tired and get satisfaction. Some of the products, even if not very large, it can be done in less than a week.

Possible mechanization

The most universal tool that allows to mechanize the sample material and the grinding of the product of Capa, is a drill with a flexible shaft and driven by a motor, with a set of cutters and grinding attachments.

The specifics of the processed material, abundance of large number of irregularities, requires a tool of small size, capable of producing sample and grinding between these irregularities, as if imitating them.

Very well proved during the execution of these works ball mill. It has versatility, allowing you to fetch in logging everywhere. Edging products are slouchy enough of conical or cylindrical cutters. Nozzles for grinding convenient to work on the workpieces up to a width of 2 cm and a diameter of 5 cm.

Use the drill motor with lots of rpm, which gives a multiple increase productivity, is the best option of the mechanized processing of the product. But even the use of this tool may not completely eliminate manual labor. The drill in combination with the cutters due to the low number of revolutions the sample does not accelerate, but in combination with nozzles performance increases.

For starters, the entire surface of the build-up drilled to the maximum number of holes, then selected manually by knocking out the whole pieces with semicircular chisels and chisels.

It should be wary of drilling through the workpiece. The final phases of sample material and grinding needs to be done manually.

Processing of the product

When performing the polishing product must always be remembered that this is one of responsible stages of processing, when the detected texture—something for which, in fact, valued ornamental creation.

Very often when processing material is found natural through-holes or there are the inevitable small cracks when drying blanks — all this reduces the quality of the product. In such cases, the defects are smeared with a glutinous mass, which is preparing the master from sawdust and dust generated when grinding (it color should approach this product), and colorless glue. Then smeared and dried defective areas should be sanded.

5. Pencil

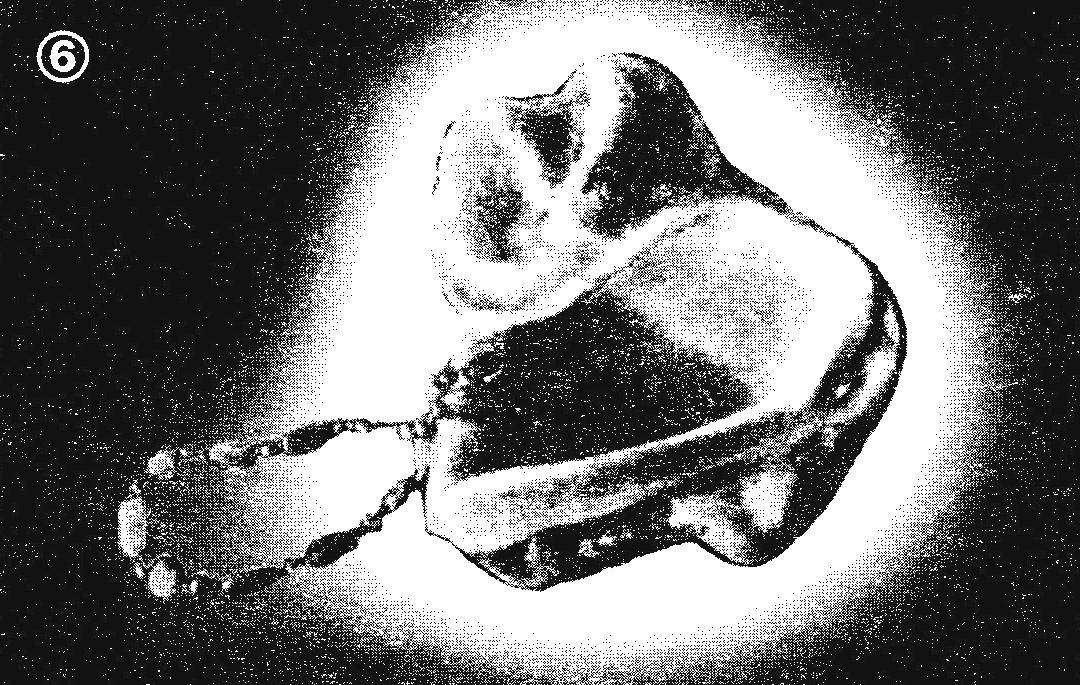

6. Bowl “Frog” out of the growth of birch

7. In this type of products, the value of the capacitor determines the growth

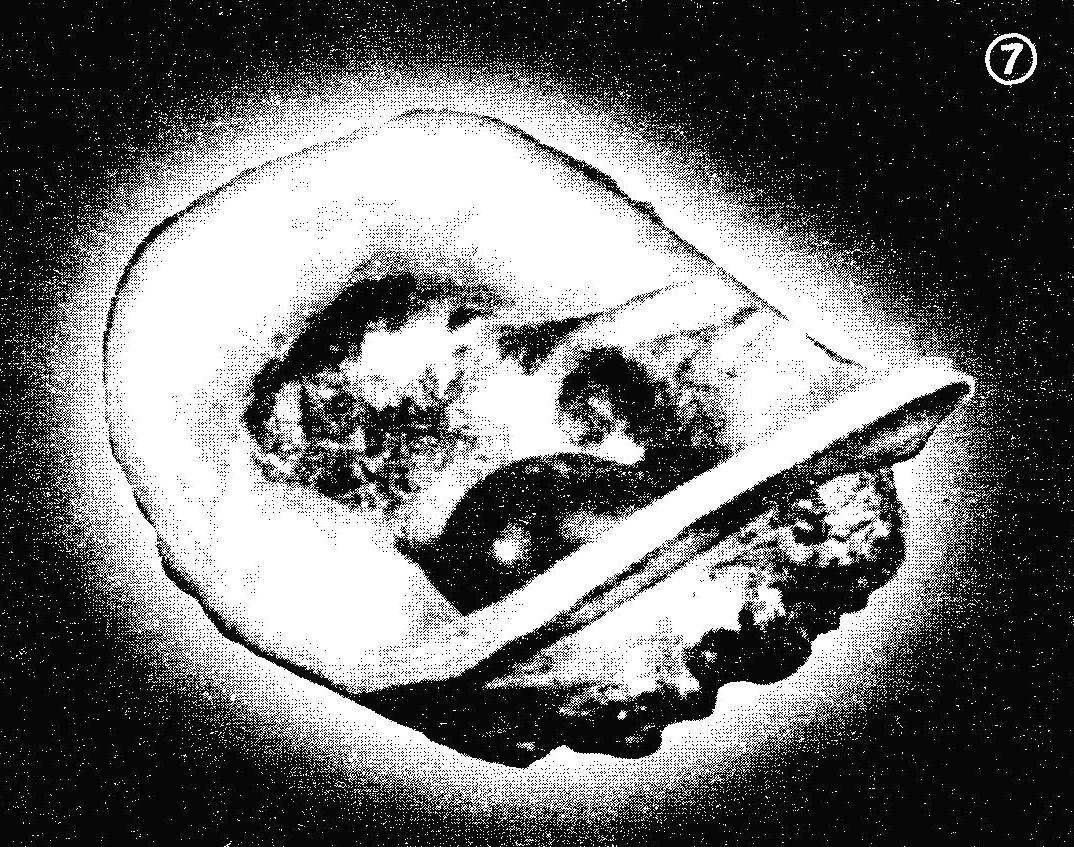

8. This cap is an excellent material for products with a slouchy fit, but harvesting it can be taken only with the part of the trunk

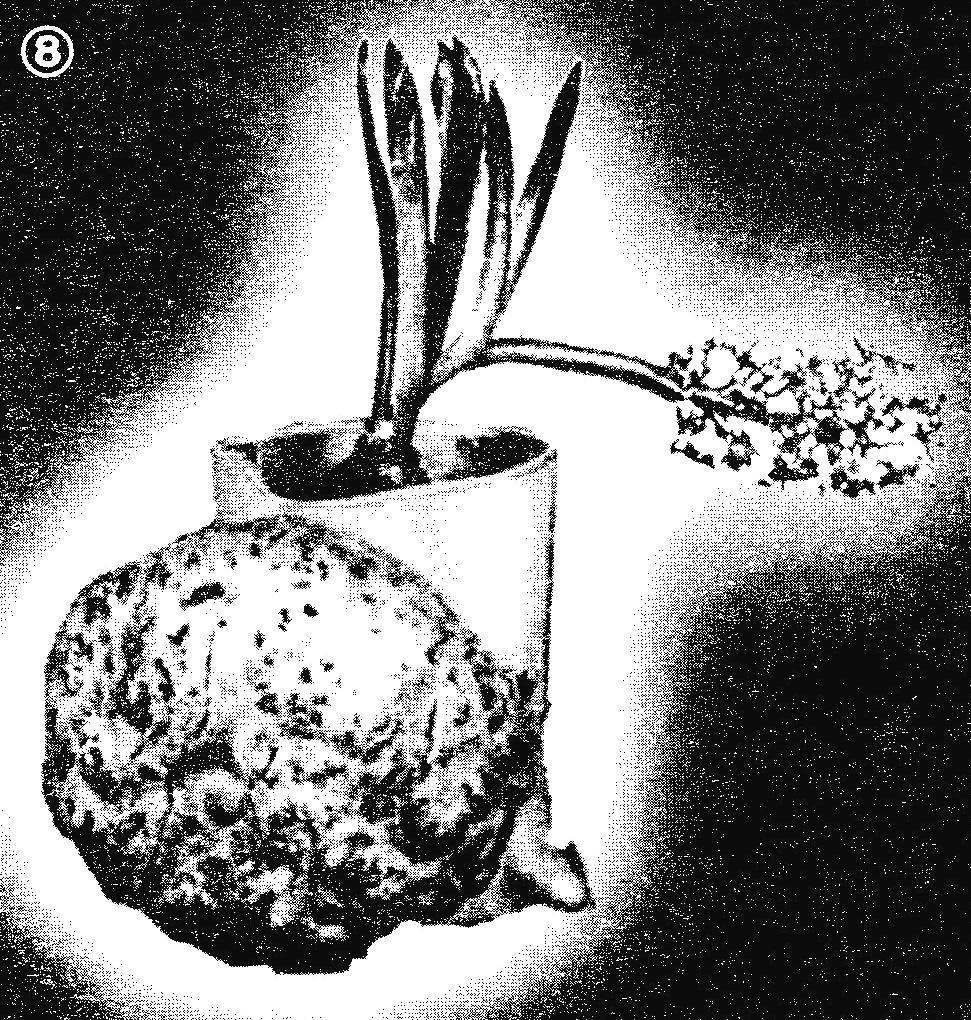

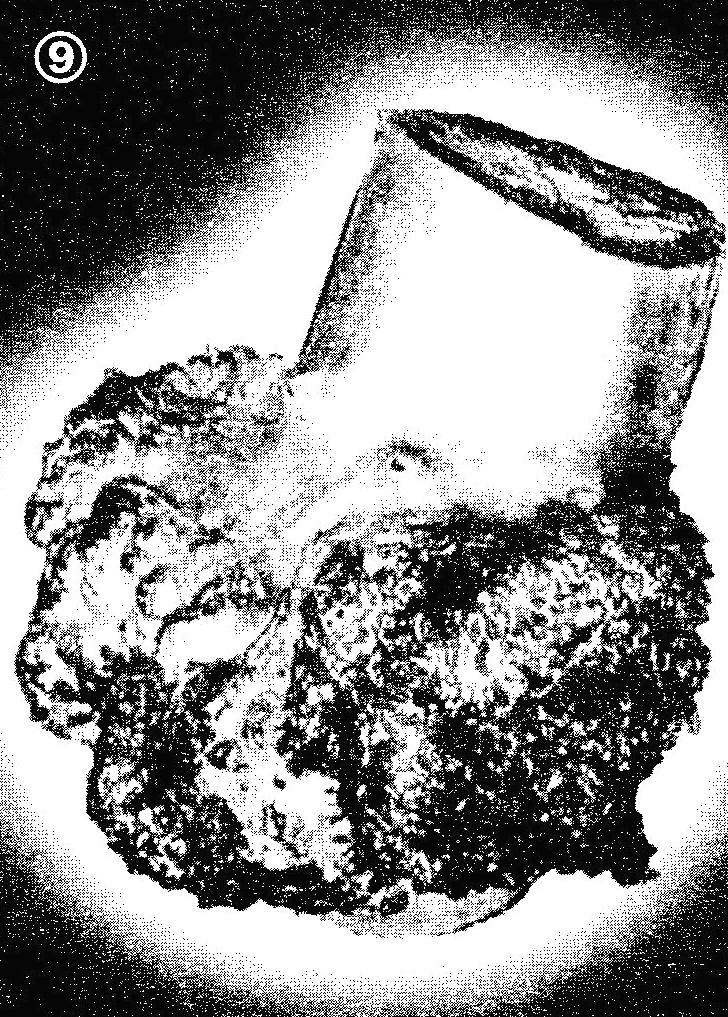

9. The product will be free of defects, since its stem is in the form of the workpiece was much longer

Some minor natural holes are closed up by pasting them in segments of knots, which hole first, reams. In subsequent tipped material cut zashlifovyvayutsya to the surface of the product. This creates the impression that the knots were originally present in the material and therefore, even decorates the product.

Large openings are not sealed at all: the impression of their naturalness, they often do precious creation even more original.

I must say that in all elements of the finished product is necessary to avoid sharp corners and sharp edges—they should be smooth and rounded.

Mechanization of work allows you to considerably speed up and facilitate labour-intensive processes such as selection and grinding. But there is this method and negative—emerging strong dust. Therefore, perform sampling and grinding needs in a sufficiently dense gauze bandage, and eyes while protecting protective goggles. The ideal equipment of the workplace is the active exhaust ventilation.

The surface finish of the finished product

The final phase of work is technically the easiest and least time consuming. However, largely depends on the end result: either success, or… failure.

The fairs demonstrated products, the bulk of which is covered with a natural wax varnish, and only a small party — artificial vitreous. Products with natural grass are usually in great demand.

Varnishing products wax

The Polish on the product is carried out in several layers on the inner surface and one on the outer.

The technique of multiple coatings of wax varnish required wiping with a cloth of one of the intermediate layers (usually the third and definitely the last) until they are dry immediately after application.

This is due to the fact that the type of lacquer consists of two components — natural solvent and wax. The solvent is absorbed more intensely than wax, and usually after the second layer, when it dries on the surface of the product remains whitish layer of dry wax (it and rubbed very noticeable). To remove it fails when applied to the third layer, when navetny and dried previous layers of wax is softened in the solvent of the third layer when rubbing it with a cloth can be removed. The operation is followed by the rubbing of the surface after it dries. Gives good results using a Terry cloth.

The outer surface can be covered with only one layer, as accumulated with a large number of layers of wax due to the irregularity cannot be removed and therefore, it becomes very noticeable. Rubbing the dried layer is made in combination: equal parts of surface — Terry cloth bumps is carefully wiped off with a thick hair brush.

Rubbing coating outer and inner surfaces is the last and important stage of the work: it is then possible to best identify the texture, to give the product a soft satin sheen, and then it becomes a subject of applied art.

The sequence of mechanized and manual handling of the product is as follows:

1 — mechanized sample; 2 — manual Daliborka to the required residual thickness; 3 — primary mechanized grinding coarse sandpaper; 4 — smoothing hand-sanding it; 5 —mechanized grinding of medium-grain sandpaper; 6 — hand-grinding it; 7 — mechanical polishing fine sandpaper; 8 — with her help — manual needs to be polished products

E. MARKOV