The oldest crafts – weaving – has always been honored in Russia. And was put on the importance often above all else. Even mentioned: “It pletenica about the gold pure.”

The oldest crafts – weaving – has always been honored in Russia. And was put on the importance often above all else. Even mentioned: “It pletenica about the gold pure.”

And why not just cut a master so ancient rakomelo! Of bird cherry bar, for example, wove away the sled, light carriage, suitcases and travel bags. From the osier – baskets, all sorts of things for the dining table. And sometimes the table itself: lace, durable, and surprisingly lightweight. Even toys wove, – there are all sorts of baskets, boxes, trinkets (rattles), etc.

Who knit for themselves, and who for sale. Especially famous for the products of skilled craftsmen from the region, artisans of Kineshma, of craftsmen from Kostroma, Ivanovo provinces. It and is clear: land fertility was not different. Plots of the peasants were miserable. That had to get out, to do in the offseason so profitable a trade like weaving. The good – the source material never had.

The secrets undeservedly half-forgotten craftsmanship – skillful weaving -is told in the following article.

The secrets undeservedly half-forgotten craftsmanship – skillful weaving -is told in the following article.

According to scientists, the netting mankind has learned much earlier than pottery. Not surprising. The technology here is quite simple, the equipment and instruments is almost “zero”. And the material, that is, inspired by nature itself. It is always at hand.

As in ancient times, for weaving is used most often shoots different willows growing along the banks of rivers, ponds and lakes, in ravines and other low places. Preference usually give the so-called willow and basket willow. They were almost equivalent belocal. Gives it a clean and fairly long rod.

Thin and good material can be bredina (goat willow). The more that it is widely distributed, grows in moist woods. Good for weaving and ultrasonic.

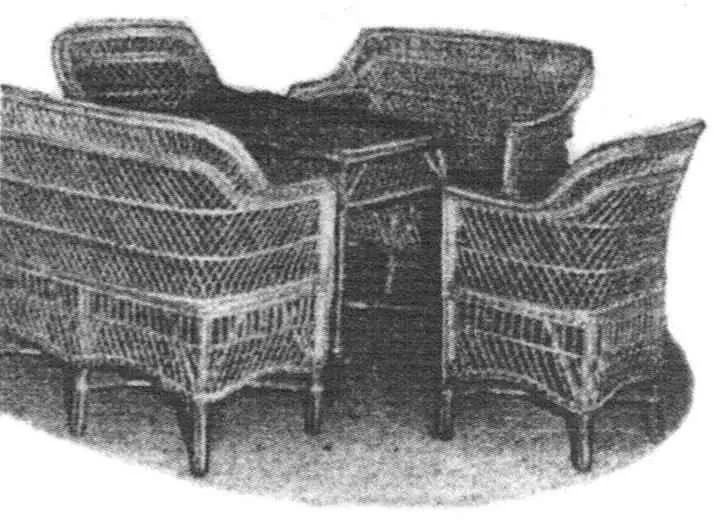

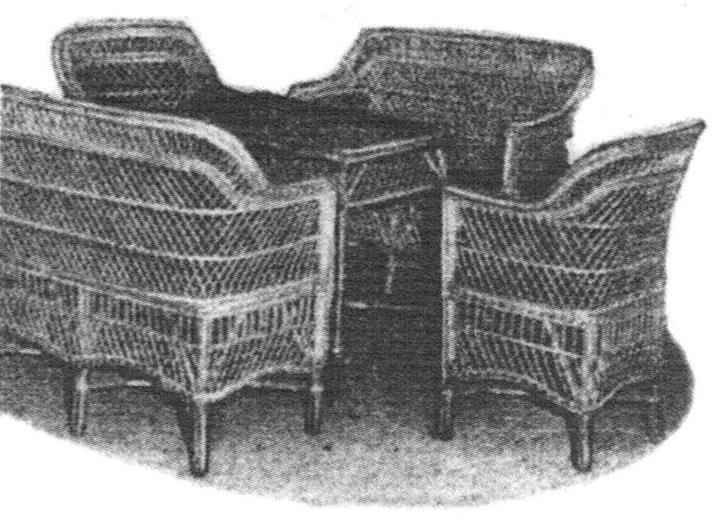

Seluga gives a rod average quality. And the red (Caspian) Verba – a thick one – and two-year shoots. So use the latter mainly for furniture.

Seluga gives a rod average quality. And the red (Caspian) Verba – a thick one – and two-year shoots. So use the latter mainly for furniture.

Harvest every one of the above mentioned materials can be almost any time of the year. Note, however, that in the summer during the period of rapid shoot growth (of vegetation) the wood is quite fragile. The rod is not as flexible and gives up to 30% of breakdowns. Therefore, the best for harvesting twigs is the time from late autumn to early spring, when intense movement of SAP is not observed.

When harvesting vines should be cut as straight shoots (minimum length 60 – 70 cm), without painful growths, damage and knots.

Moreover, the quality of the entire batch can be judged by the cut of one escape (after all, the physical and mechanical properties of branches per plant is about the same). If the wood is cut has a reddish-brown tinge, while the heartwood is big and loose, you harvest the twigs from this Bush is hardly appropriate due to excessive brittleness of the starting material.

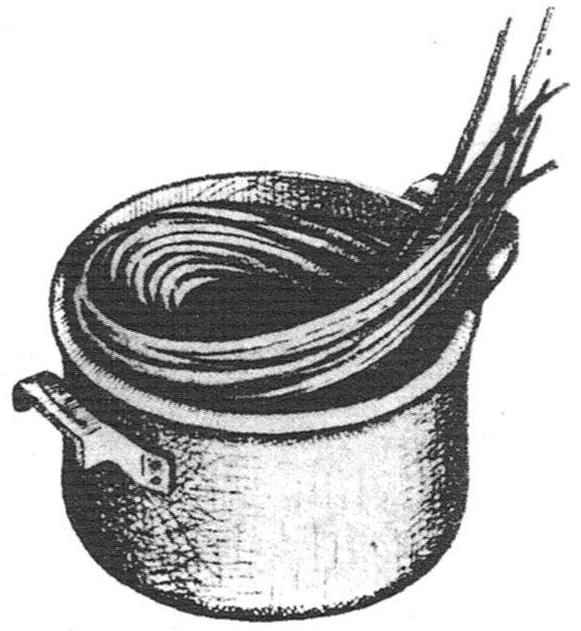

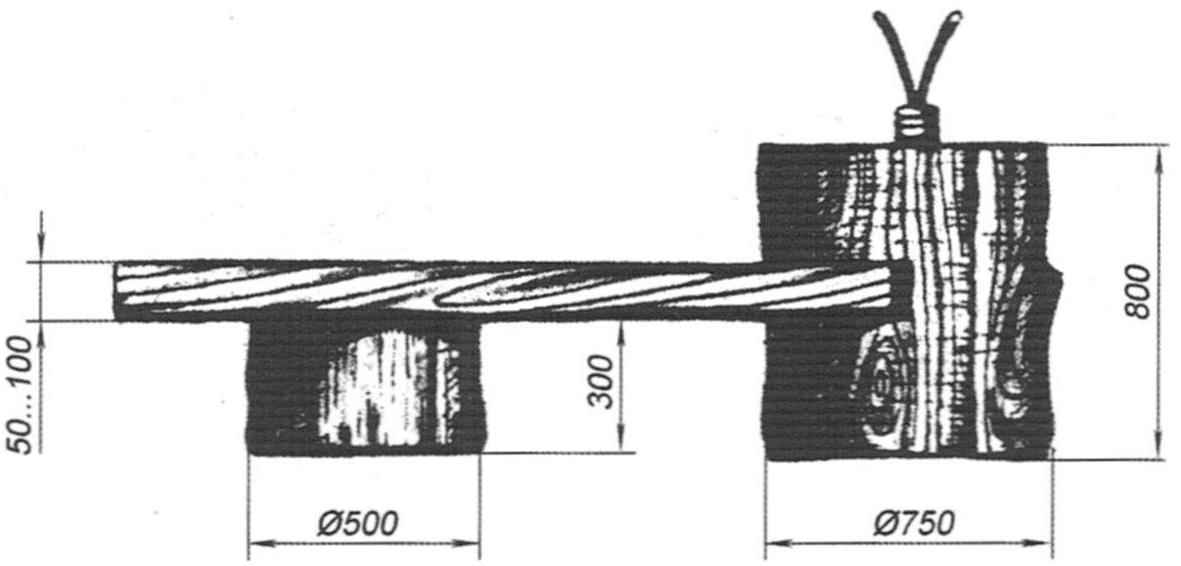

The vine, cut in late autumn or early spring, prior to working with it for 3-4 hours to soak, and then (0.5 h) – steamed for easier removal of the bark (so-called lubki or debarking). To do this conveniently, turning long rods one by one (or in small bundles) in the form of a ring along the side walls of the pan a suitable container, see Fig.

The vine, cut in late autumn or early spring, prior to working with it for 3-4 hours to soak, and then (0.5 h) – steamed for easier removal of the bark (so-called lubki or debarking). To do this conveniently, turning long rods one by one (or in small bundles) in the form of a ring along the side walls of the pan a suitable container, see Fig.

After. the vine is cooled in cold water and proceed directly to the debarking. To perform this operation better using semilly – homemade spring clamp in the form of a stake with a hole. Sche-Milka hammered into the ground or reinforce the ridge with a bench (the bed). The butt of the rod is inserted into the spring clip. Then, holding the left hand semelka, pulled right vine. If the first pulling the bark is separated, not completely, the rod is rotated around its axis and passed through semelka second time.

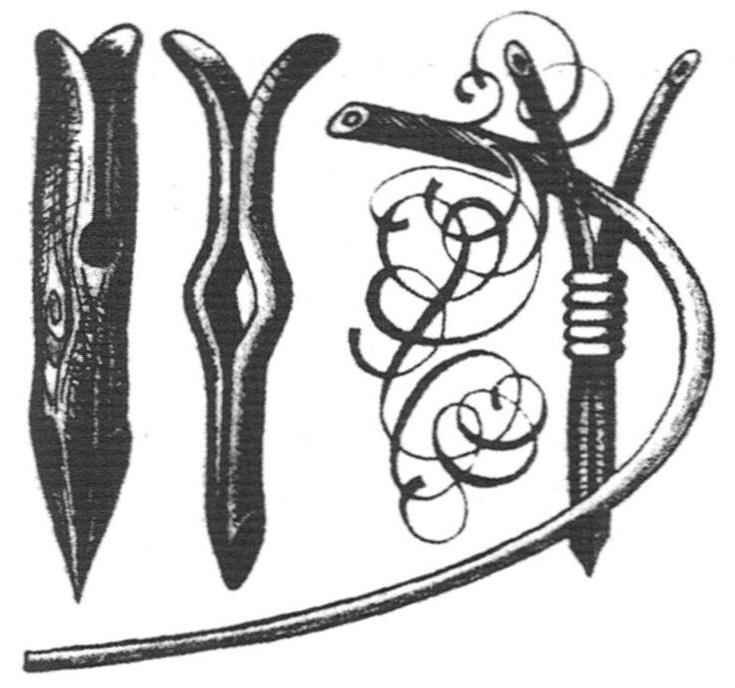

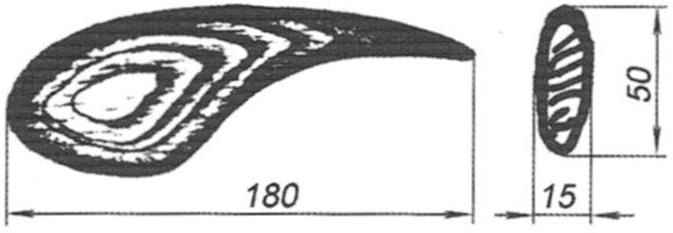

But for weaving, in addition to the round rods often require so-called bus (tape). Essentially this is the same vine, split it lengthwise into two, three, or four parts. The blank of such material is usually carried out using kolenkow, made of solid wood or of bone, plastic, metal (see ill.). At the end of the rod with a knife to produce the appropriate incision, in which is inserted the wedge-shaped projections, Colunga. When driving past along the core rod is split into equal parts. Well, if the pulp is to remove, get another kind of material for weaving the seam or plane.

Part of the harvested material master korsinsky, specialists in wicker furniture and skilled DIY subjected to coloration. But before that, remove contained in the vine prevent uniform absorption of paint tannins. Achieve this by soaking material (several hours) in a hot alkaline solution (per liter of water takes 40 – 50 g of potassium carbonate, or potassium carbonate, which can be purchased in a camera store). Soaking often make a simple “rustic” way, placing the workpiece from the vines in a bucket of water where previously lowered to 1/4 – 1/3 of hour while boiling the cloth bag with wood ashes.

Part of the harvested material master korsinsky, specialists in wicker furniture and skilled DIY subjected to coloration. But before that, remove contained in the vine prevent uniform absorption of paint tannins. Achieve this by soaking material (several hours) in a hot alkaline solution (per liter of water takes 40 – 50 g of potassium carbonate, or potassium carbonate, which can be purchased in a camera store). Soaking often make a simple “rustic” way, placing the workpiece from the vines in a bucket of water where previously lowered to 1/4 – 1/3 of hour while boiling the cloth bag with wood ashes.

Thoroughly soak harvestable plaiting material, alkaline water is drained. And rods (as well as bus, plane) for 3 hours immersed in the dye solution from time to time moving their them with a stick to obtain a uniform coloring on all sides.

Bright bright colors give the aniline dyes used in the home for dyeing. Consumption in our case is: one package per 3 liters of water. And that painting became more profound in staining solution add 1 – 2 tablespoons of acetic acid.

The types kolenkow and their use for splitting the rod into two equal parts:

1 – Phillips;

2 – Y-shape;

3 – chisel kolonki;

a – performing a cut on the end of the rod;

b – the splitting of the rod to the required workpiece

As already mentioned, after 3 hours, the dye solution is drained. And the material is rinsed in cold clean water. And change it to until the drained water will not cease to be painted.

Instead of aniline dyes are often used and various mordants. They are not afraid of moisture and do not fade in the sun. And the range of tone coloring give a fairly wide. From light gray or, say, light brown to black or dark brown with reddish, greenish or bluish hues.

Instead of aniline dyes are often used and various mordants. They are not afraid of moisture and do not fade in the sun. And the range of tone coloring give a fairly wide. From light gray or, say, light brown to black or dark brown with reddish, greenish or bluish hues.

To obtain a gray color using a solution of iron sulphate. And the tone of color depends here on three factors: the concentration of the solution, the time spent in it the source material and the degree of presence of tannins in the wood. Black achieve by replacing 1-2 hours a solution of iron sulphate with a thick decoction of willow bark. The one that remains after lupke (clean) rods. Well the color brown get any key, placing the source material to weave into a solution of potassium permanganate.

Keep prepared for weaving material is completely dry (in the wet state in a day can appear in the mold on the wood and it will turn black), tied in bundles. But before applying – soaked. The elasticity in the course of the netting support, avertive temporarily “committed” to the work of the rods, tapes and the plane in a wet cloth.

Keep prepared for weaving material is completely dry (in the wet state in a day can appear in the mold on the wood and it will turn black), tied in bundles. But before applying – soaked. The elasticity in the course of the netting support, avertive temporarily “committed” to the work of the rods, tapes and the plane in a wet cloth.

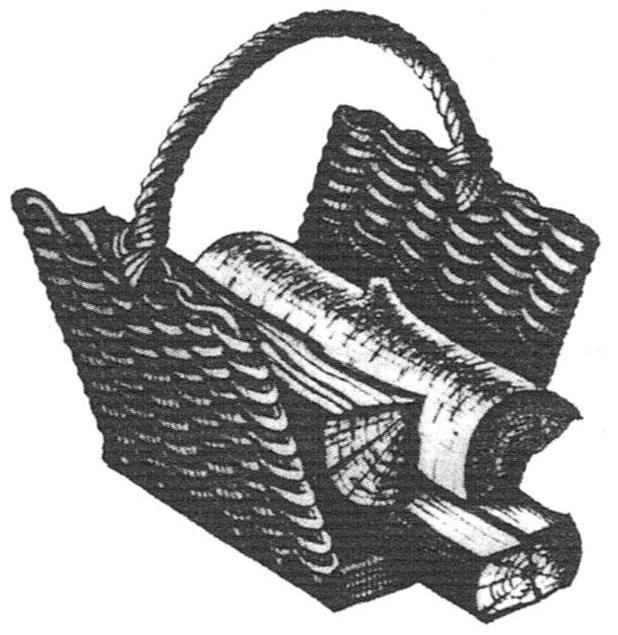

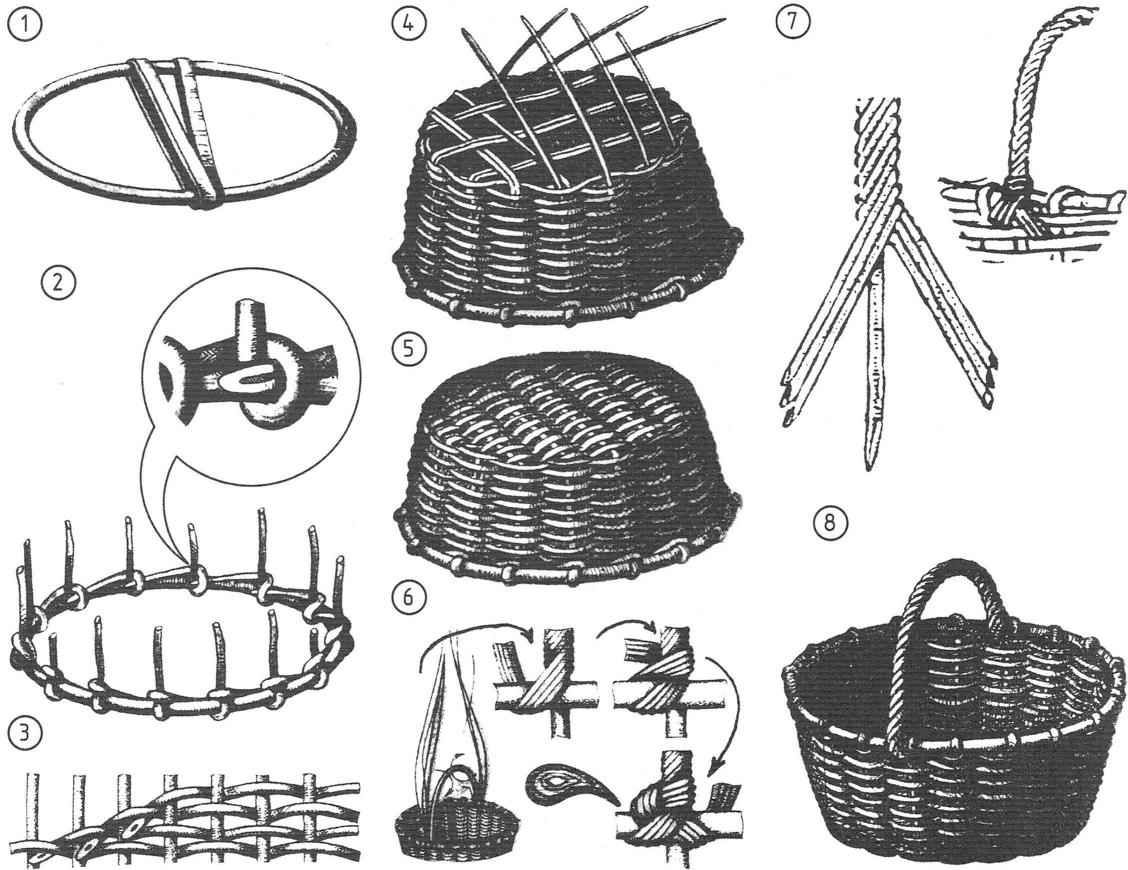

Basket weaving with the wrap is used in cases when the finished product is required to obtain as soon as possible (in a hike in the woods or on the river). The work begins with the manufacture of the Hoop. Bend it out of wicker with a thickness a little less of the little finger. The ends of the workpiece cut with a knife “on condition” that bring them together and tightly tie the satin ribbon or twine with each other. If the basket must be oval, then wrap pull together on a mutually antithetical sections of the long flexible rod or rope.

Ridge with a bench (bed) – comfortable working place of the master of weaving furniture and other various products of the vine

Then move to the interweaving of foundations – vertical rods of the uprights at a right angle to the Hoop at the same distance from each other. Each such rod is pre-cut at an acute angle from the butt to the length of the palm. Turns out the light and flexible “tail”.

He twisted around Hoop, round rod-riser and press to wrap the fingers of your left hand. In a similar sequence to weave the following rod-risers. Only so do it to the previous tip rod is firmly pressed them to the Hoop. But the end of the second rod is pressed against the third, etc. On the same principle, as is done in weaving a wreath of wild flowers.

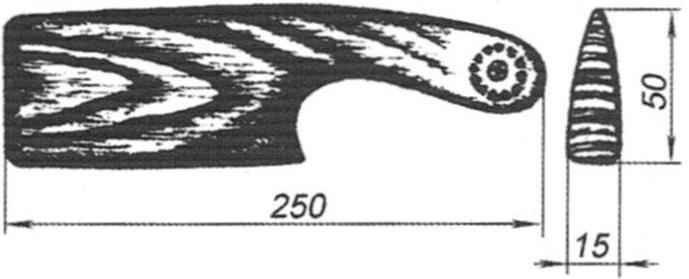

Now the future basket reminiscent of a fisherman’s Creel only very rare. Begin to braid rods as rural fence. And he’s “lagging with potyczki”, i.e. with the largest possible compression of the rows of rods to each other. To do this conveniently with a special mallet (see Fig.). It is usually cut from oak, birch, larch or dried stem of lilac. It should be quite massive, heavy and durable. At the same time, it is desirable that the beater this could pass freely between two adjacent racks of netting, would be narrow and easy to use.

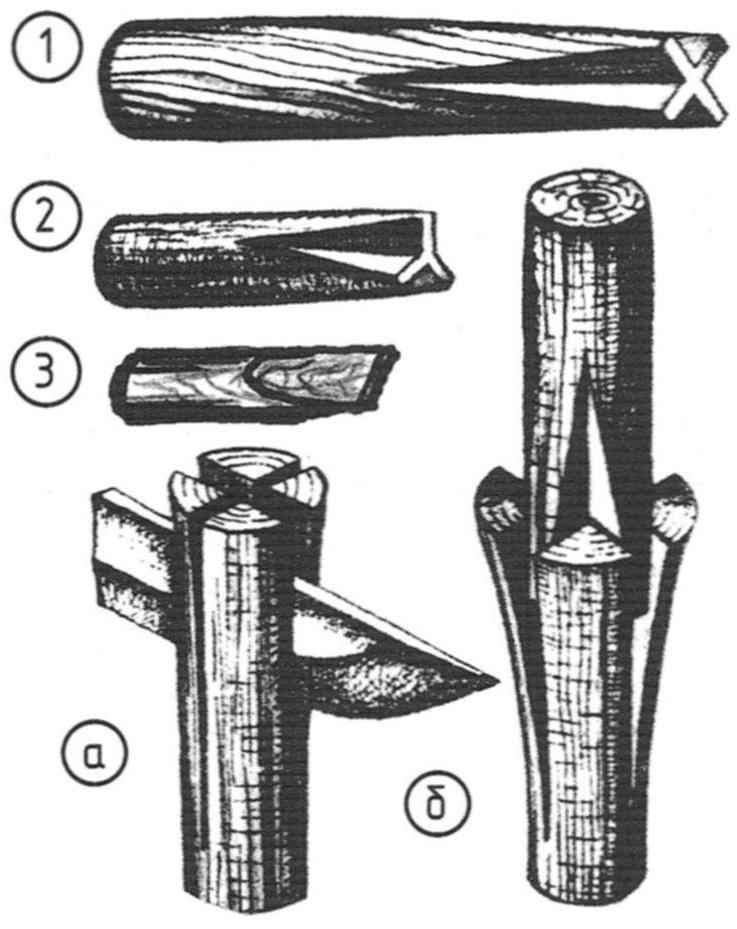

Stage of weaving baskets wrap:

1 – the manufacture of a Hoop;

2 – addition of base (vertical rods-racks);

3 – perform simple netting on the sides of the basket;

4 – bending the bars of the racks, making the frame bottom;

5 – twining of the bottom of the basket;

6 – the sequence of the handle;

7 is a variant of the braiding of the handle of the basket;

8 – the finished product

Moving Boca to the plastic, bent the bars-risers. To cut them the extra length to hide the ends of each in the appropriate place on the opposite side of the wall. And perform

operation uprating by pinning. That is, jamming the end of one rod between the bars on the opposite side, bent it, and then firmly braid the bottom of the vine thinner.

The handle is executed from a thick rod-knitting needles, pointed at both ends, is inserted in the side of the basket and braided bundles of thin rods in one of the illustrations by the way. For example, each of the beams curve around the bow and tying the ends firmly with a knot on the opposite side.

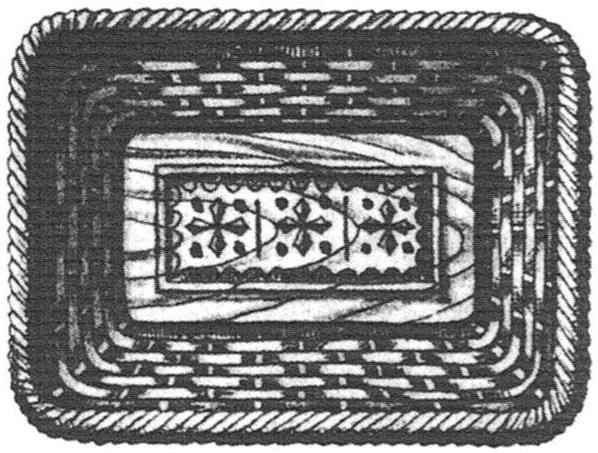

The basket can be done and appropriately decorated. For example, using to weave not only debarked (white) rods, but untreated. Such contrasting combination of the dark series plateua with light looks quite impressive and elegant.

TITOVA, Moscow oblast (Continued).