My neighbors, United in a gardening partnership, alternately using an agricultural machine with electric and… mechanism on the basis of an old, battered “poscache” — PD-10M, which converts rotary motion to reciprocating: he “gives life to” working bodies: the saw cleaver, the nose-“subete”.

The kinematics are so simple that you can draw it, a separate circuit is hardly appropriate. Any saadeldin and tan understand what was happening. Will be able, undoubtedly, to appreciate and fruitfulness of the idea of using the same nodes to parts, it would seem, absolutely different purposes.

With the engine, I think, all each very clearly. You can use any asynchronous electric motor with a power of about one kilowatt. The recommended option is a three-phase motor 1.1 kW to be included in the single phase alternating tone voltage is 220V on the circuit with the starting and working condensers. The details of such inclusion has been repeatedly considered in publications of the journal (see for example, pp. 8-9 the twelfth issue of the journal for 1991).

Of course, if you wish, you can successfully replace on electric internal combustion engine of appropriate power and size (at a remote location plots for diarrhea). But, as already noted, for our gardening partnership, it was preferable to make a reliable “lumberjack-mower” on electricity.

“Highlight” of the proposed technical solution is the use of “poscache” as a mechanism, well-sostikuemsa with the motor and converting rotational movement of the shaft of the latter in the reciprocating movement of the implement. However, the underlying PD-HUME had a few padiament.

Should get hold of your domin part with the land and animals type cows, as memorized from childhood tongue Twister “In the yard — grass, grass — wood” begins sometimes to acquire particular urgency and relevance. In fact, it is a mini-program of preparations for the winter.

But for the oven heating is necessary in an average of 8-9 cubic meters of firewood. And cut (the size of the furnace) and pinned! At the mere recollection of this back sometimes whining begins. And then there is worries associated with hay…

My neighbors, United in a gardening partnership, alternately using an agricultural machine with electric and… mechanism on the basis of an old, battered “poscache” — PD-10M, which converts rotary motion to reciprocating: he “gives life to” working bodies: the saw cleaver, the nose-“subete”.

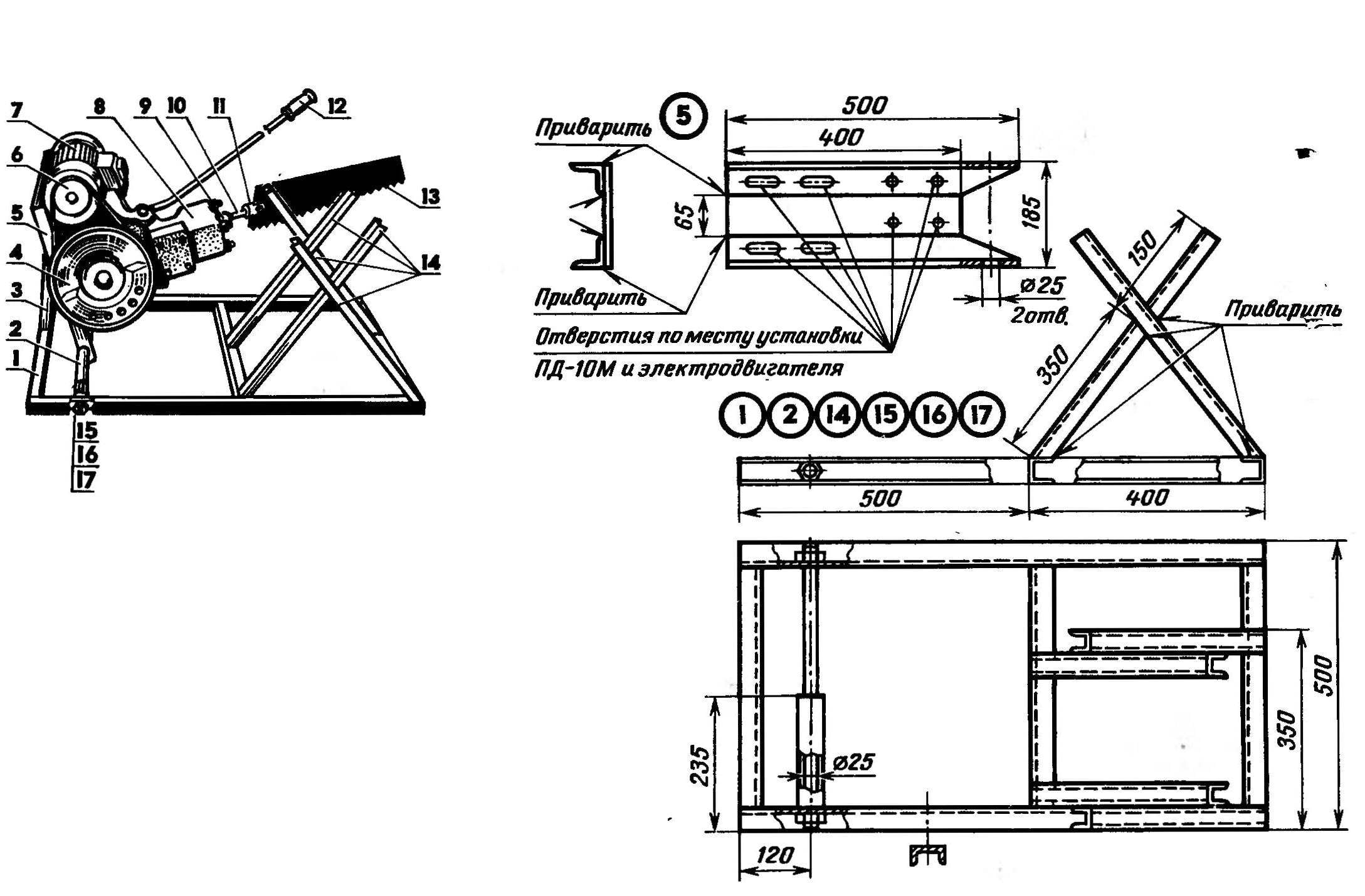

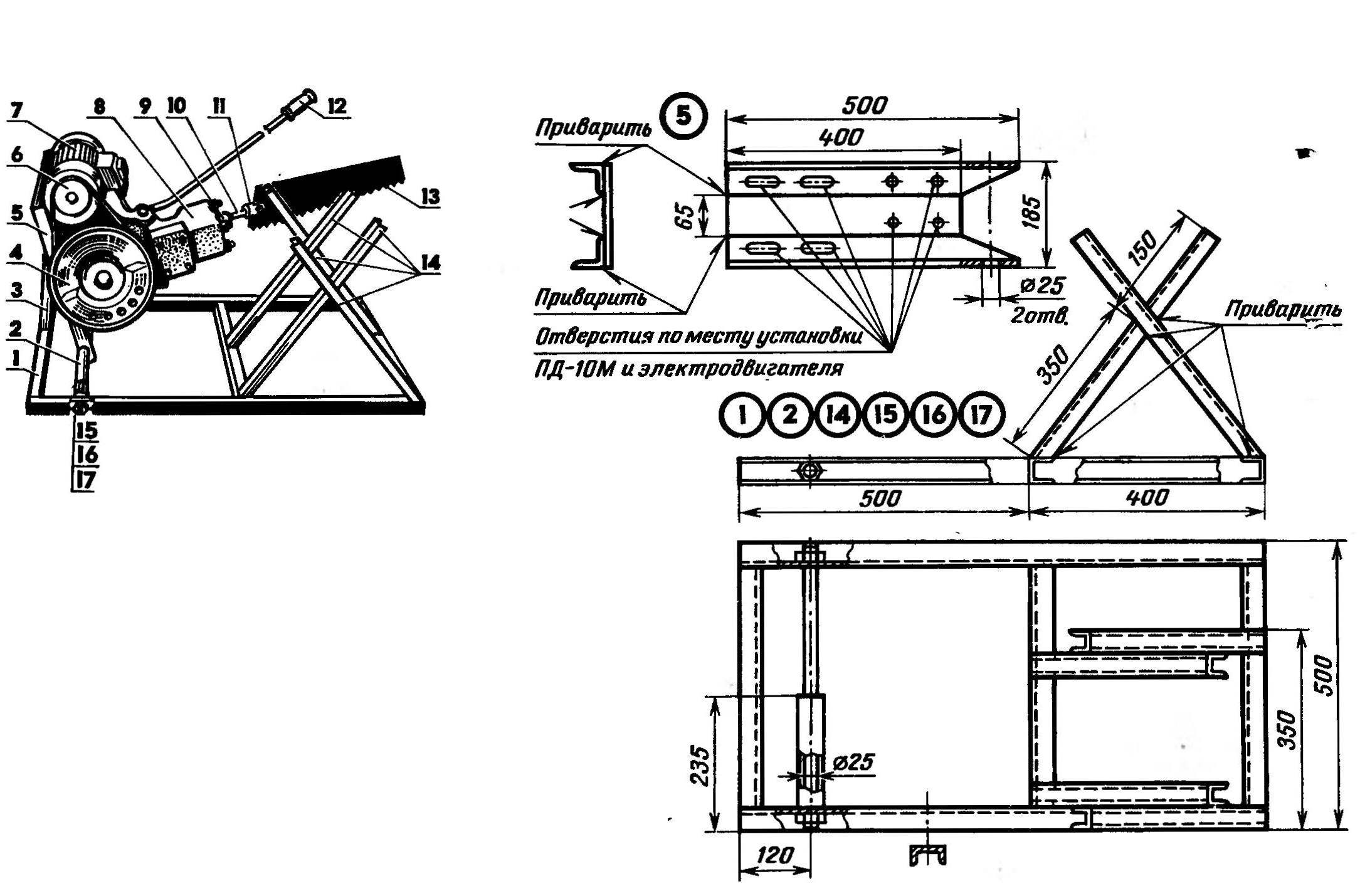

Electric Sawyer — woodcutter (option):

1 — frame (welded construction of segments channel number 8), 2 — spacer (cut 34×4 steel seamless pipe, length at the installation site, 3 piece), 3 — end stop (cut from channel No. 8), 4 — pulley-flywheel (from a decommissioned tractor engine D-37), 5 — plate mounting swivel (6-mm sheet St3 with welded bottom two lines of steel area 60×60 mm) 6 — lead pulley (automotive), 7 — asynchronous motor power 1.1 kW, 8 — crank mechanism (deducted from the starting engine PD-10M, revised), 9 — bushing, bronze (mounted in place of candles) 10 — stem (Steel 45), 11 — fixing unit of the working body (saws) to the stock, 12 — crank (cut from water-gas supply pipes with a rubber knob on the end), 13 — working on (cut canvas and hand saws), 14 — goats (welded construction of sdres-cov on channel number 8), 15 — the axis of the turntable with the M24 thread on the ends (ST5), 16 — M24 nut (2 PCs), 17 — grower washer (4 PCs). Mount cleaver and guides for logs conventionally not shown.

Crank out “poscache”:

1 — crankcase cover improvised (St3), 2 — crankshaft gear 3 — finger intermediate gear, 4 — gear with intermediate bearing assemblies, 5 and 7 — locking ring, 6 — ball, 8 and 10 — roller bearings 9 —connecting rod 11—seal 12 —strip, 13 — flywheel 14 — crankshaft, 15 seal bushing, 16 — plate flywheel housing, 17 — plunger 18 — M12 nut with cotter pin and washer, 19 — lock washer, 20 — cylinder, 21 — cylinder head gasket, 22 — cylinder head with Central hole (bored to a diameter of 30 mm), 23 of stock (300-mm rod diameter 16 mm, Steel 45), 24 — bushing (bronze) with cable gland, 25 — locknut M16, 26 — holder of the working body (in particular saws, Steel 45), 27 — the working body (for example, 400-mm cut leaves from hand saws), 28 — bolt M16 with nut and washer grower 29 — filler faucet (you can substitute homemade plug from St3), 30 — M30 nut (shaped), 31 — a stub reinforced (St3), installed the carb, 32 — Carter, 33 — gasket blow-by.

Electrocautery (option):

1 — wheel bearing (from a scrapped farm), 2 — movable knife (of the 13 segments of the movable knife from the header of a forage harvester), 3 — timber finger bearing (two backrest knife forage harvester, welded for greater rigidity at 90 degrees from the back side), 4 — teeth of the fixed knife (7 sections of the fingers of the harvester combine harvester written-off fixed bolts M12 on the support beams), 5 — panel, 6 — clamp, (3-mm St3), 7 — rod-arm (pipe 33,5×3,25 water and gas) with remote enable, 8 — wheel steering ellipsoid (cut 25×3 steel seamless pipe), 9 — a main wheel (of a motor scooter, 2), 10 — asynchronous motor 1.1 kW mounting plate, 11 — V-belt transmission with the host (0=85 mm) pulley to the driven (0=260 mm), 12 — socket, 13 — crank mechanism on the basis of “poscache” PD-10M, 14 — frame base (6 mm STZ), 15 — bronze sleeve, 16 — rod.

The kinematics are so simple that you can draw it, a separate circuit is hardly appropriate. Any saadeldin and tan understand what was happening. Will be able, undoubtedly, to appreciate and fruitfulness of the idea of using the same nodes to parts, it would seem, absolutely different purposes.

With the engine, I think, all each very clearly. You can use any asynchronous electric motor with a power of about one kilowatt. The recommended option is a three-phase motor 1.1 kW to be included in the single phase alternating tone voltage is 220V on the circuit with the starting and working condensers. The details of such inclusion has been repeatedly considered in publications of the journal (see for example, pp. 8-9 the twelfth issue of the journal for 1991).

Of course, if you wish, you can successfully replace on electric internal combustion engine of appropriate power and size (at a remote location plots for diarrhea). But, as already noted, for our gardening partnership, it was preferable to make a reliable “lumberjack-mower” on electricity.

“Highlight” of the proposed technical solution is the use of “poscache” as a mechanism, well-sostikuemsa with the motor and converting rotational movement of the shaft of the latter in the reciprocating movement of the implement. However, the underlying PD-HUME had a few padiament.

The power plant leads and the movement of the scythe-“catfish” made from end, it would seem, parts of agricultural machinery. Again, the simplicity of the kinematics. And so high reliability of the whole mower as a whole.

For the manufacture of a cutting apparatus used here, segments of blades and parts of backs, as well as sections of the fingers from decommissioned machines. In particular, the carrier finger rail is made from the back of the knife silage farm machinery. Moreover, for greater rigidity design this reinforced the same part that is welded on the back side at a right angle. And required for electronically 7 sections of toes taken from “decrepit” harvester grain combine harvester (stationary teeth, of course); they are fixed with bolts M12 on the support beam.

Details for moving (cutting) part of Tangier. taken from the header of a forage harvester. To capture our makeshift machine was about a meter, had to use the 13 segments of “factory” knife. As for the presser foot, they are “handwritten” production.

Purpose wheels (borrowed, again, from a scrapped farm equipment) dual. Set at the edge of the cutter bar, it largely facilitates the operator the management electromusical. In addition, the support wheel helps to maintain a constant height of mowing. The one that is optimal for the conditions.

The whole kinematics of electrocoil arranged in such a way that ensures the equilibrium of the structure even under light pressure of the operator on the steering wheel. Moreover, the latter does not differ from the technical solutions found by the inventor of Vlasovka (near Kremenchug), V. Yakovlev (see # 5’91).

Done carefully, electrophotonic knows no failures. But when it is necessary to strictly follow safety rules, have a connector on the cable, use only well protected from a “breakdown” electrical equipment, to prevent accidental touch to live parts and parts. To work in a dry, preferably with rubber of the hand mittens. And the legs have protective tested for electric strength, bots. And nourish your elektromashyna not directly from the mains AC voltage of 220 volts, and via an isolation transformer.

It is highly desirable to equip this machinery device audity disabling type 3010.2.010 UHL, manufactured by Gomel plant “Elektroapparatura” (it is designed for tone load up to 10A) or other similar specified machine. Including homemade, description and principle electric scheme which had been previously published in the journal.

Recommend to read THE GRIP IN THE CLIP No manual clutches are difficult to handle small parts. However, they are not all easy: "the production process" occurs on weight, what kind of accuracy. What if to fix the vise?... MINI-SLIDE FOR CUPS In any locker in the kitchen is not so much space under the dishes. To use it more efficiently will allow you to cut the plastic mass of the bottle or bottles of suitable diameter.... Scroll back to top

Should get hold of your domin part with the land and animals type cows, as memorized from childhood tongue Twister “In the yard — grass, grass — wood” begins sometimes to acquire particular urgency and relevance. In fact, it is a mini-program of preparations for the winter. But for the oven heating is necessary in an average of 8-9 cubic meters of firewood. And cut (the size of the furnace) and pinned! At the mere recollection of this back sometimes whining begins. And then there is worries associated with hay…

Should get hold of your domin part with the land and animals type cows, as memorized from childhood tongue Twister “In the yard — grass, grass — wood” begins sometimes to acquire particular urgency and relevance. In fact, it is a mini-program of preparations for the winter. But for the oven heating is necessary in an average of 8-9 cubic meters of firewood. And cut (the size of the furnace) and pinned! At the mere recollection of this back sometimes whining begins. And then there is worries associated with hay…