Car-truck individual in the household – an indispensable means of transport even for those who have a mini-tractor or motoblock with a trailer. Its main advantages – environmentally friendly and quiet, but because the car can even be used indoors.

Car-truck individual in the household – an indispensable means of transport even for those who have a mini-tractor or motoblock with a trailer. Its main advantages – environmentally friendly and quiet, but because the car can even be used indoors.

And I in my lifetime have made these trucks a lot for yourself, relatives, friends, and, as I remember – all different.

When overhauling the archive in the workshop found a sketch of the two-wheeled carts made several years ago by the order of priest or temple, or monastery. Someone from local residents, who knew me as an engineer and homebrew, sent it to me. As it turned out, cars, what he needed was not on sale in the local construction markets. Industrial enterprises with a single order too did not want to communicate – as for the manufacture of cars had to be developed, and drawings.

After listening to the wishes of the priest on the question of his claims to the car, made a sketch (it caught my eye), agreed with him and proceeded to fulfill the order.

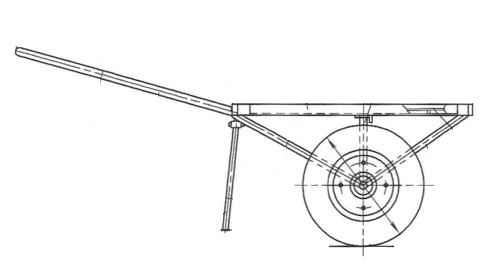

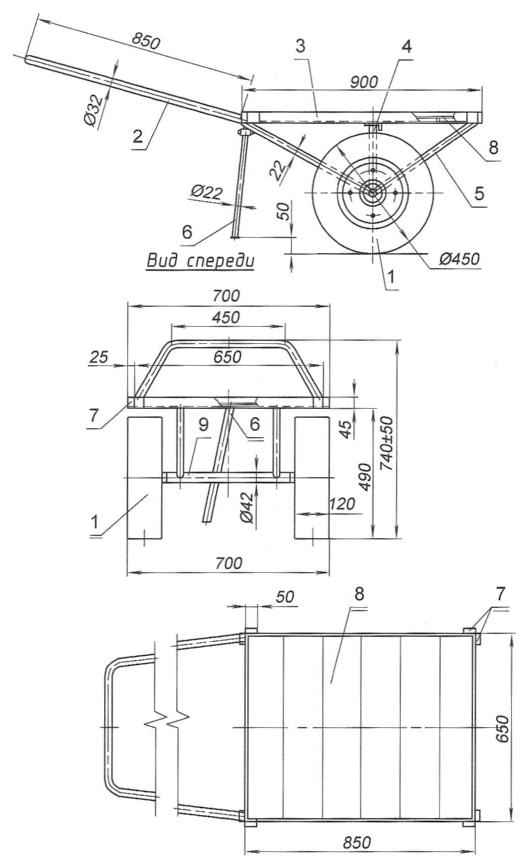

Design cars: single-axle, two-wheeled. Its peculiarity is that the axis of the wheels passes across the loading platform under her middle. With this arrangement, almost the whole weight falls on the wheel, and the carrier remains the only car to push.

Two-wheeled wheelbarrow with a Central axis position:

1 – wheel (drills, 2 PCs.);

2 – handle (tube d32);

3 – frame platform of the body (area # 4 and # 5);

4 – front (tube d22,2);

5 – brace (pipe d22, 4 PCs.);

6 – folding legs (pipe d22);

7 – brackets for installation of boards for the carriage of bulk cargo (steel sheet s, 8 PCs.);

8 – deck platforms (decking, wall paneling s16);

9 – tubular beam (pipe d42х5)

In the proposed attention of readers of the journal of design applied to the wheel Assembly (tires, wheels with rims, hubs and even the axis) from the agricultural implement.

The car was made individually in a single copy without the use of any jigs, fixtures and machines.

The schematic outline of the General appearance of the cars using hand hacksaws for metal were cut from the pipes and corners necessary details.

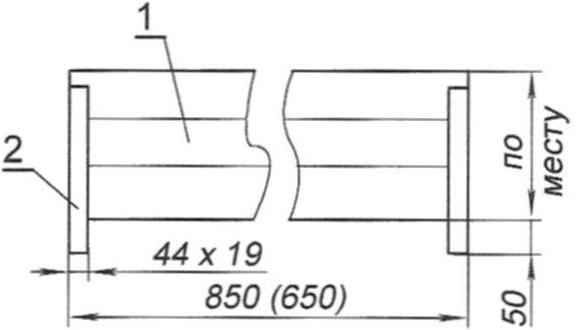

The build begins with welding the axles to the tubular beam (d42x5 mm), keeping the size of the track.

Then welded the frame body of the cargo platform is placed in the racks at the desired height on assembled wheels and secured with struts.

Finally, from the pipe d32 was bent the handle and welded to the frame body at a convenient height (for your height) so that the load platform was tilted in the working position forward by 5 – 10°.

Side Board cars:

1 – shield (grooved Board, wall paneling s16);

2 – rack (wooden block 50×25, 2 PCs.)

After welding, the entire structure is set folding legs and gets the wooden flooring of the platform body (loading platform). In the illustrated embodiment, the decking is constructed of siding (grooved Board), 16 mm thick crosswise of the platform. But this is done because at that time there was at hand a longer scraps of lining. But in fact flooring is better to make along – it is easier to dump loose loads.

Feature of this design is a flat platform (platform) to the carriage of goods located at a convenient loading height.

This design is practical when transporting hay bales, bags, furniture.

For bulk cargo and wood planks are welded brackets, which are inserted in a rack of boards. Roll, according to customer’s requirements, I did not. But they are easy and quick to put together in the form of boards of the same siding, and flooring, cementing between a pair of cross-struts of wooden bars of suitable section. Stand have to do with projecting ends, which are inserted in brackets.

Ready truck for delivery to a “place of residence” was uploaded to the car “Oka”.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.