The internal combustion engine (ice), however, had a few to modify. With revision to subjected to nothing like the cooling system with forced circulation of coolant. To enter the last available in each of the two cylinders was carried out separately, and circulation is improved. For this I recommend to do the following.

First of all, remove the regular aluminum patrol(OK, connecting the cooling jacket of the cylinder heads of internal combustion engines. Then remove from the holes in the heads of the studs — the ones which were dismantled fasteners pipe on the engine. Then in the holes (on each head) to cut the tap M22 thread under pre-new fittings (see Fig.). Complete work on the cylinder heads that are installed in its place a new fitting durotoye connect the hoses with the radiator hose. Now all of a silencer. Not to interfere, it is simply removed. Then, departing from the lower connector 45 mm, in the jacket of each cylinder of the drill hole 15 mm. 0 don’t forget about pin holes for the water pipe. Tap cut into the MV thread, fix these pins. And crafting from STZ flanged nozzles, set last in the prepared space with the use of sealing rubber gaskets and M8 nuts. These inlets is connected to the fuel (water pump), what is it used for again durotoye hoses.

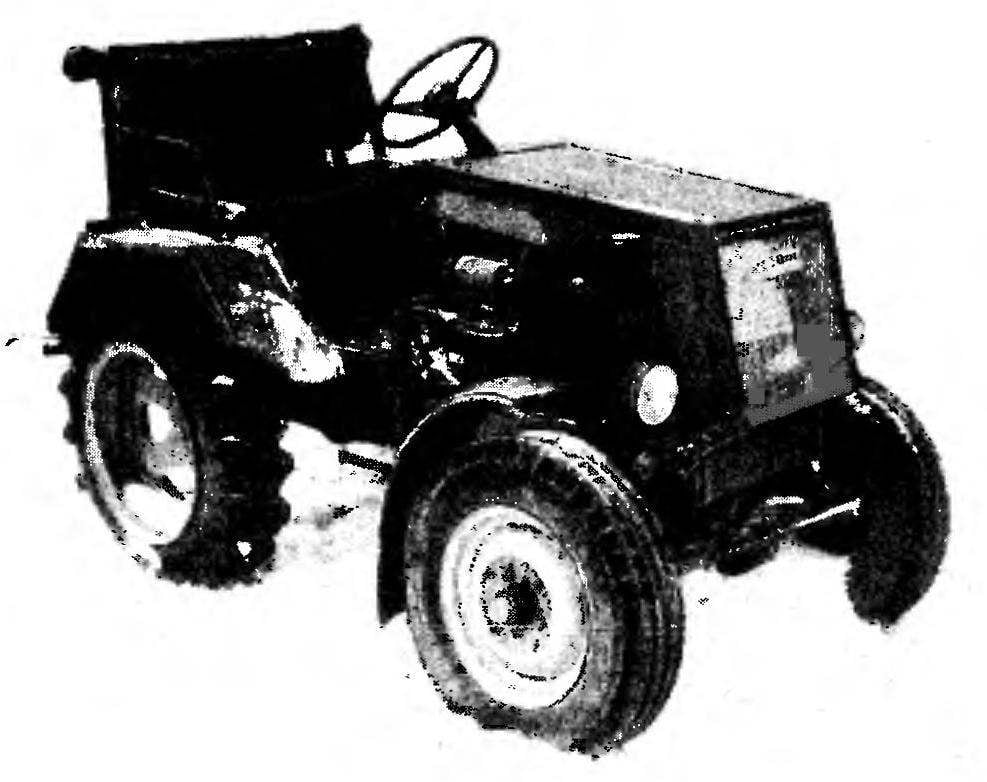

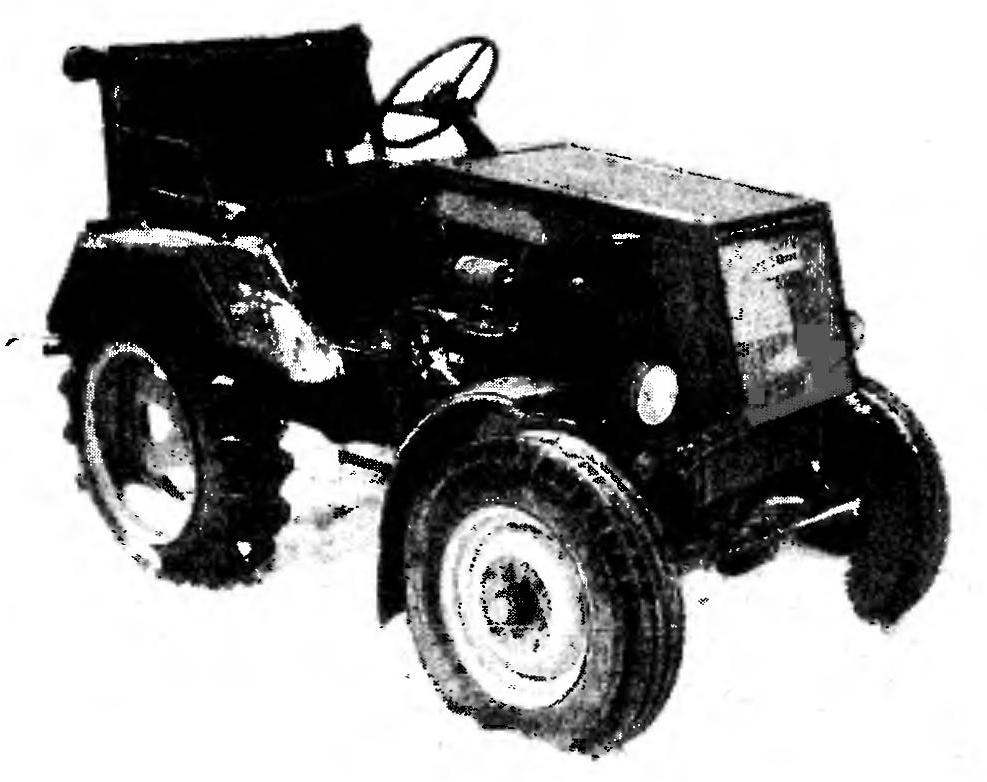

The layout of the mini-tractor:

1 — rear (driving) wheel (2 PCs.), 2 — rear fender with splash guard (2 pieces), 3 — seat and underneath hydraulic tank capacity 7 l, 4 — rear of the cab with the back, 5 – signal light unit (light-turn signals, brake and marker lamps, 2 PCs.), 6 — shift gearbox, 7 — steering wheel, 8 steering column (UAZ-452), 9 — brake pedal and clutch, 10 — instrument panel, 11 a radiator, 12 generator, 13 — motor, 14 — oil filter 15 — the hood turning a homemade, 16 — crank start the engine !7 front light unit (lamp, light turn signal, 2 PCs.), 18 — front (driven) wheel (2), 19 — welded frame, 20 front fender with splash guard (2 PCs), 21 — the front of the cabin, 22 — the gas pedal.

Kinematic scheme of transmission:

I – the front wheel (6.0 to 16″, 2 PCs.), 2 — the engine (motor pumps MP-800V, modified), 3 reducer-made with gears from the starter ІІ350 (SMD-62), 4 — flywheel and clutch (of a car ZAZ-966, modified), 5 transmission (from the vehicle GAS-52, modified), 6 driveline (two flange cardan shaft GAZ-52, is connected ing a cross-piece), 7 rear axle (from the electric vehicle EP !03К, zarabotany), 8 wheel rear (8,3-20″. 2).

Revision of the cooling system:

1 – shirt engine cylinder (2 PCs), 2 — fitting (alloy АЛ5, 2), 3 – engine cylinder head (2 PCs.), 4 – pin with M8 nut (4 PCs), 5 — nozzle input (STZ, 2 PCs.).

,

Diagram of engine cooling:

1 – radiator (exhaust tractor DT-20). Durnoye 2 hoses (coolant o of the cylinder heads to the upper radiator tank), 3 – cylinder engine, 4 — durotoye hoses high pressure (coolant from the water pump into the jacket of the engine cylinders), 5 water pumps NSH-10, 6 — fan (tractor DT-20), 7 — gauge pointer coolant temperature. 8 — tee (STZ), 9 the connection of the pump (connected daretowin connecting hose of the radiator).

The driveshaft cylindrical transmission rear axle:

1 — flange driveline (from the car GAS-52), 2 – slotted part of the shank of the rear axle (from the car GAS-52), 3 — cuff, 4 — bearing (auger header), 5 — flange housing cover (motor-power transmission of the electric vehicle EP-10ЗК), 6 — ball bearings No. 208, 7 — bearing housing drive axle of the electric vehicle (no change), 8 — weld part “of the shaft-shank” (Steel 45).

The driveshaft cylindrical transmission rear axle:

1 — flange driveline (from the car GAS-52), 2 – slotted part of the shank of the rear axle (from the car GAS-52), 3 — cuff, 4 — bearing (auger header), 5 — flange housing cover (motor-power transmission of the electric vehicle EP-10ЗК), 6 — ball bearings No. 208, 7 — bearing housing drive axle of the electric vehicle (no change), 8 — weld part “of the shaft-shank” (Steel 45).

To improve circulation holes in the head gaskets, cylinder diameter increased to 10 mm. the circulation of the coolant delivers water pump (UAZ-452). Strictly speaking, the exact place of installation of fundamental importance here is not. But it is better, apparently, to strengthen the water pump to the tide head of the second cylinder is removed, the vacuum device pumps. Is the pump belt drive from the gearbox output shaft of the internal combustion engine.

A number of features. In order to maximize the compaction of the layout, simplify the whole structure itself… the engine is placed ahead of the radiator, the inlet of which is mounted a tee. And the last is screwed up the gauge pointer coolant temperature. On the frame the engine is mounted on two cross members. And the launch is done by hand, from the right (facing) side of the tractor, which is located here upright arm, driven by the sharp turn it down. Moreover, the starting sector and the ratchet washer — factory, and the arm is made of half-inch segment of pipe.

Gear motor — probably the most complex node of the power transfer from those who will have to make. Gear, single stage, with a gear ratio of 1.0. The need to enter it into the kinematics MT (see Fig.) due to a number of reasons. And especially the fact that our mini-tractor — dual main gear. So, we need a change of direction of rotation of the shaft. There is no doubt that the absence of the kinematics of the drive (connecting directly) it would impede the PTO. In addition, it would rule out the possibility of running the engine manually using the factory trigger. A splice variant of the “directly” requires after you install the magneto in reverse. And most importantly, in addition would be loaded with the motor shaft from axial forces arising from the inclusion of a clutch.

The gear case welded. Made of 4 mm steel plate (STZ) with two tightly welded the supports of the bearings. Has a screw-top air vent and bottom drain plug. Lid with welded thereto a bearing support N9208. Located within two spur gears taken ready (gear-starting engine P-350, or SMD-62). But the hub of improvised, made of Steel 45.

The flywheel and clutch from the ZAZ-966. Went pretty well, fit into the design of MT. However, the heel of the releaser had had to counterbore diameter 35 mm free passage of the primary shaft of the gearbox. And for fastening the flywheel to the flange of the gearbox output shaft of the internal combustion engine — use the three bolt M14 (see Fig.).

Gearbox taken from the car GAS-52, with subsequent revision. And

the essence of the latter in that the glass vizinova bearing 20 mm are pruned. Perform this operation for the creators of the improvised techniques. As, however, and cutting malagoni threads of opposite rotation, which should be with all the accuracy to perform.

Well, the main gear modified KP connects u-joint. Moreover, it consists of two flnew propeller shaft, taken from the same GAZ-52, connected by a crossbar.

Rear axle (and leading) from the electric vehicle (electric forklift)

EP-103K. This solution allows without any special tricks to achieve not only a sufficiently large ground clearance, the MT, but greatly simplifies the kinematics of the whole machine, without reducing its performance.

The thing here is in the design of the used node. After all, in a single unit with the axle from EP-USC is a traction motor, the rotor shaft of which is mounted the gear first-stage main transmission (dual). So, enough to do a small revision, and we can build this bridge on our mini-tractor!

As regards the specific operations in the remake is so important for reliable operation of the transmission node, that their essence consists in cutting on a lathe of the motor housing, previously removed from the transaxle EP-10ЗК, up to 70 mm and the installation (instead of rotor) specially made homemade shaft welded structure.

The latter will be nothing more than a cylindrical shaft transmission to rear axle. It consists (see Fig.) two parts: Phillips (taken from the shank of the main gear of the GAZ-52; ensures reliability flange “driveline”) and weld-on, pre-machined from Steel 45. After connection of the two parts obtained by welding the shaft is subjected to heat treatment (quenching and tempering).

In addition to the short case, from the previous standard electric loader EP-103K in the design of the drive axle MT also used the bearing shields (flange-cap). And rear — after completion under the bearing support of the auger from a combine harvester (see figure).

Himself rear axle of the forklift EP-10ЗК (final drive bevel gears and differential) used in the construction of the mini-tractor without modifications. In principle, you can do without shortening the hull gutted of the motor, if there are severe restrictions on the layout of the tractor, mainly related to an undesirable increase in the length of MT. It is sufficient in this case to make himself “shaft-shank” under the enclosure dimensions of the “motor”.

Brake system in question . MT — hydraulic, rear-wheel. Moreover, any changes in the original design of the drive axle EP-10ЗК for its successful operation is not required. Especially if the master cylinder from the car GAS-52 ( 32 mm diameter).

N. GONCHAROV

Recommend to read DOOR WITH PUMP… To the front entrance door slammed I equipped them with shock Bicycle pump. Now they close almost silently. The pump is mounted pivotally in brackets. mounted on the door and the... THE KEY IS “HOW MUCH”? Even the person far from technicians, often have to Unscrew-screw the screws, bolts, nuts (hardware — so often referred to in abbreviated form these metal products) are designed for this...  Among the difficulties which beset the creators of the homemade mini-tractor (MT) at every step, or three, judging by editorial mail, nesereznaya: the complexity of vehicle development is quite reliable and strong engine, compact transmission and rear axle, whose design is largely determined by the mobility of the machine, and its appearance, and maximum ground clearance…

Among the difficulties which beset the creators of the homemade mini-tractor (MT) at every step, or three, judging by editorial mail, nesereznaya: the complexity of vehicle development is quite reliable and strong engine, compact transmission and rear axle, whose design is largely determined by the mobility of the machine, and its appearance, and maximum ground clearance…