As described below, the thresher works on the principle of rolling corn cobs in the progressively narrowing gap formed between the cylindrical drum and concave with rubber surfaces. Cob, salinitas between the drum and the cover, rotates around its axis, while it is separated from the grain.

As described below, the thresher works on the principle of rolling corn cobs in the progressively narrowing gap formed between the cylindrical drum and concave with rubber surfaces. Cob, salinitas between the drum and the cover, rotates around its axis, while it is separated from the grain.

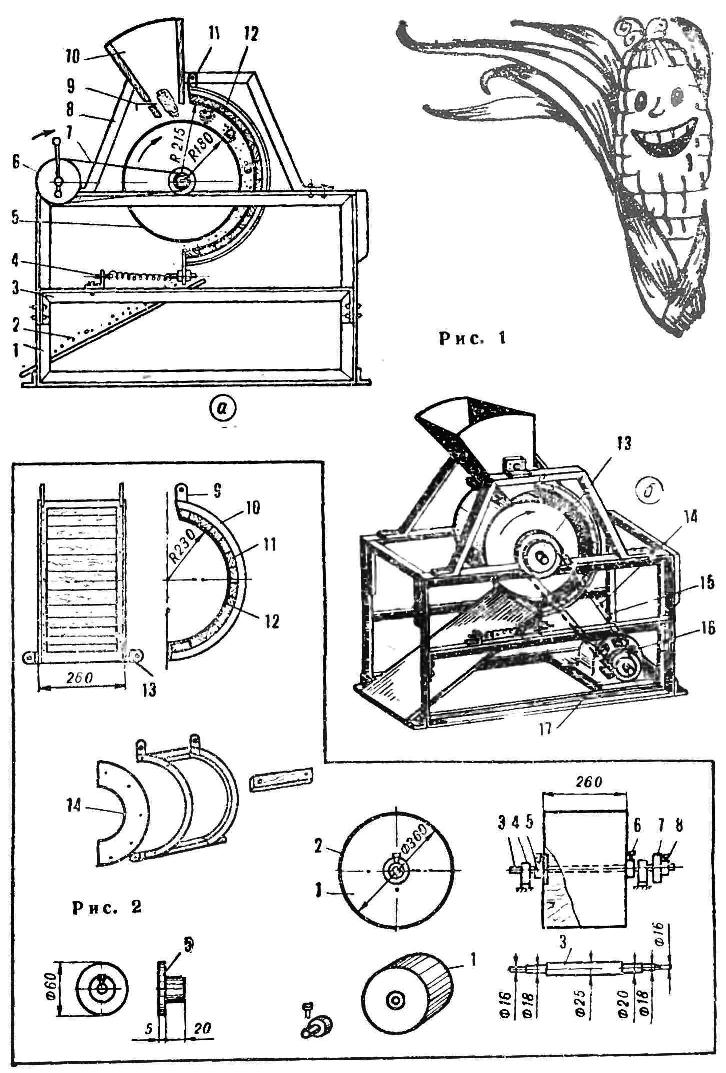

The thresher consists of the following main parts: the frame with the upper bracket, a hopper with a valve, a drum, a soundboard with tension device, manual or mechanical drive.

The frame can be made of angular steel size 35X35X4 mm or wooden bars section 60×60 mm.

The drum (Fig. 2) are made of dense wood chocks Ø 360 mm and the length by the width of the frame. To balance the centrifugal force the drum must be carefully balanced.

The cylindrical surface of the drum is covered with two or three layers of rubber with a total thickness of 8-10 mm. Steel shaft Ø 25 mm is passed through the drum and is connected with a wooden cylinder steel hubs with wheel bolts.

The frame of the deck (Fig. 2) are made of angular steel size 30X30X4 mm and wooden bars with a thickness of 15 — 18 mm. the Surface of the bars covered in the same rubber layer as the drum. The inner radius of curvature of the deck must be greater than the radius of the drum 45 to 50 mm.

Fig. 1. Thresher for threshing of corn cobs:

a) with manual transmission: 1 — frame, 2 — pitched Board, 3 internal adjustable bracket, 4 — tensioner 5 — reel, 6 — manual gate 7 — transfer-to-reel, 8—upper bracket, 9 — valve, 10 — hopper, 11 — upper hinge decks, 12 decks; b) electric: 13 — pulley drum 14, the belt to the drum 15, and a protective cover (shown in phantom), 16—electric motor; 17 — bracket of the motor.

Fig. 2 (in the frame). The threshing machine:

drum: 1 — wooden frame, 2 — rubber layer, 3 — steel shaft 4 — bearing, 5 — hub, 6 — bolt hubs, 7 — pulley, 8 — bolt pulley.

deck: 9 — eyelet deck, 10 — frame of angle steel, 11 — wood, 12 — rubber layer, 13 — lug tensioner 14 and a side flap.

In the upper part of the soundboard is pivotally connected to the upper bracket and the lower part with the tension device. The gap between the drum and the upper part of the deck is constant, the size of cobs in a transverse position, and the bottom part is regulated by the springs to the threshing of corn cobs occurred without damage to the grain.

The drive can be done from an asynchronous motor with power 1 kW. For an intense thrashing of the ears of corn, the drum speed should be between 650 — 800 rpm In the bracket of the electric motor make the grooves for adjusting belt tension.

The mechanical drive must have protective casing that ensures full safety.