All this is arranged on the frame of the cultivator, which is a hard cover with the side members. The frame is made of 4 mm sheet steel by welding. Previously in the side walls of the enclosure cut the holes for the bearing housings of the intermediate and driving shafts. Additionally the inner edges of the holes are reinforced with steel rings 5 mm thick. Total thickness of the wall and rings are sufficient for threading M8 bolt fastening the bearing housing. All housings are equipped with gaskets and, except for the upper left (in the direction of movement of the tillers), rotary shaft seals.

The upper housing machined with an offset axes of the bearings, so they can be rotated to adjust the tension of the chain running gears. These enclosures have 32 mounting holes for M8 bolts, but use of them is only four.

Scheme of transmission:

1 — drive sprocket (z = 14,t = 12,7); 2 — the intermediate chain of transmission (t = 12,7); 3 — an asterisk of an intermediate, external (z = 40, t = 12,7); 4 — sprocket intermediate the inner (z = 14, t = 19,05); 5 — chain running gear (t = 19,05); 6 — asterisk running gear (z = 27, t = 19,05)

The layout of tillers MP-2:

1—the engine (from a motorcycle MMVZ-C 112); 2 — air filter (MMVZ-3.112); 3 — ignition coil (B-300); 4 switch (CAT-1A); 5 — fuel tank (from a moped “Riga-12”); 6 — rod steering levers throttle and clutch; 7 — the lever of a gear box of the engine; 8 — strap adjustment rods (2 pieces); 9 — bracket auxiliary support; 10 — support the Parking; 11 — wheel (2 piece scooter “Ant”); 12 frame walking tractor; 13 — bolt-timing chain tensioner drive; 14 — silencer (from the pumps MP-800); 15 —the lever start the engine.

Frame walk-behind:

1 — the emphasis of the bolt-chain tensioner intermediate transmission; 2 — side rail (2pcs); 3 — eyelet of the adjusting strap (2 PCs); 4 — ear mount the electronic switch (steel, strip 20×3, 2); 5 — a casing running gear transmission; 6 — flange; 7 — eyelet tie rod (2 PCs); 8 — tube oil level monitor (bolt M14); 9 — ring reinforcement.

The principal dimensions of tillers.

Carrier group walking tractor:

1 — the frame of the engine; 2 — frame fuel tank with shroud cover transmission suspension; 3 — earring trailer; 4 — finger connector; 5 — auxiliary support bracket; 6 — a stopper of the Parking support; 7 — pole Park; 8 — frame walking tractor; 9 — bolt-tensioner M10x1,5 (L100); 10 — stud M16 (L1З0) securing the motor frame.

Frame engine:

1 — the standard frame of motorcycle MMVZ-3.111 with the fixing points of the engine; 2 — bushing mount frame; 3 — a nut of the tensioner chain; 4 — mounting bracket of the muffler; 5 — bracket installation the ignition coil.

Frame fuel tank:

1 — mounting bracket tank; 2 — reinforcing plate; 3 — frame; 4 — bracket tank; 5 — stand; 6 — casing cover suspension of the transfer; 7 — a plug with breather (bolt М14х1,5)

Intermediate shaft:

1 — a casing running program; 2,10 — bearing; 3 — M8 screw (2×4 PCs); 4 — shaft; 5,8 — bearings 206; 6 — dowel prismatic; 7 — inner sprocket (z = 14); 9 — asterisk external (z = 40, a motorcycle MMVZ-Z. 111); 11 — a sealing cuff; 12 — flange; 13 — shear segment; 14 — nut М18х of 1.5.

The intermediate shaft carries two sprockets: outside a large, number of teeth z=40 and step t = 12,7 mm (motorcycle MMVZ-3.111) inside lower with the number of teeth d = 14 and step t = 19,05 mm Suspension shaft has one sprocket z= 27 and t = 19,05) which runs in an oil bath. Transmission oil is filled into the casing from the top, the level is controlled via the hole in the rear wall of the housing (with the cover removed, and inverted threaded tube). The difference in air pressure arising from the operation of the chain transmission, is leveled by means of a throttled hole-breather in the other tube, threaded into the casing cover. The latter is a complex combination of the actual lids that eight M6 screws attached to the flange of 5 mm steel sheet on the top of the cut casing, welded to her frame fuel tank. This combination is advantageous in that, first, saves space, and secondly, fuel from the high tank is fed by gravity into the engine.

The side members of the frame of the cultivator, made in the form of angle profiles with remote vertical walls at the joints with tilted cover, welded flush to it. The side members carry several features: front — support bolt-on-Tagetes intermediate chain of transmission, in the middle of the ears attaching strips regulating the position of the steering rods; behind — the lugs for fastening of the rods themselves. In addition, the horizontal shelves there are seven threaded holes M6 for mounting of the wings.

On the same line with the axis of the bolt, the tensioner rails are four groove for fastening pins of the frame of the engine, allowing these pins to move forward and backward within the grooves and thus change (adjust) the chain tension.

Behind the shelves in the vertical spars drilled holes for mounting hook-on earrings. This earring, attach it to the bracket base plate and the plate in the description, perhaps, do not need, everything is clear from the drawings.

The frame of the engine is a part of the frame of the Minsk motorcycle, complete with two sleeves for fastening pins, mounting bracket for silencer, nut chain tensioner and bracket installation the ignition coil.

Steering rods of the welded pipe sections with a diameter of 27×1 mm and plates-пер1е-micek of steel sheet of thickness 2 and 5 mm. the Left rod carries a lever clutch control, the “stop” button engine, bracket for adjusting strap; right — arm “gas”, the adjusting device cable tension control, and bracket for adjusting the second strap. In addition, the ends of the rods are equipped with rubber handles.

Chassis shaft:

1 — M8 screw (2×6 pieces); 2 — seal lip; 3 — shaft; 4 — the bearing housing (2); 5 — the bearing 206 (2); 6 — a casing running transmission; 7 — an asterisk of running gear (z = 27); 8 — dowel prismatic.

The hub of the wheel.

Steering rod:

1 — handle (rubber); 2 — the lever of the clutch control; 3 — stop button for the engine; 4 — lever “gas” (from the snowmobile “Buran”); 5 — rod steering (tube 27×4); 6,7 — jumper; 8 — lugs for tensioning the control wires; 9 — eyelet of the adjusting strap (2 PCs); 10 — the end of the cable in the shell (second cable not shown); 11 — bolt M8 adjusting (lock nut not shown); 12 — clamp (bushing Ø10×4 with screw M5).

Wings:

1,3 — wings right and left (steel sheet s to 1.8); 2 — loop fastener to the frame tillers (steel, sheet s).

The cutter (shown right; left — reflected-view):

1 — case (pipe 40×5); 2 — incisors inner; 3 — cutters external.

Trailed earring:

1 — case (steel, sheet s5); 2 — ring (21×2 tube, L120); 3 — cheek mounts to the frame tillers (steel, sheet s5).

Bracket support Parking:

1 — body (steel, sheet s5); 2 — cheeks (steel, sheet s5); 3 — the eye (rod Ø10); 4 — elektroskripka (8 PCs); 5 — spacer (rod Ø14. 2); 6 — lock the Parking supports (rod Ø10, sizes place).

Parking leg.

Strap position adjustment of steering rods.

The shift lever of the gearbox of the motor has a length of 250 mm. First, the transfer switch arm by means of a special lever and rods, placed on the left rod. But later I abandoned this clutter. It turned out that the transmission of the switch… foot!

On the way to the garden or traction version of the walking tractor moves on wheels scooter cargo “the Ant”. The wheel hubs machined from steel billets of appropriate size and mounted on a shaft running only a single bolt M10 each.

Before processing a vegetable garden, for example, before cultivation, the tillers “change shoes” — instead of wheels on the ends of its driving shaft to put on a homemade cutter. They are made of welded housings, machined from lengths of pipe 40×5 mm diameter, and welded them criss-cross cutters, cut out from the leaves of a leaf spring car GAZ-69. Passage width including milling of the soil is approximately equal to 1 m.

The finished walk-behind I carefully prepared for painting: so file all the sharp corners, treated surface “skin”, was degreased. Then double-dyed. After that, my MP-2 for several years now, looks like factory. Good tillers not only externally— in the processing of our gardens, it is simply irreplaceable.

V. PETROV, S. P s b n o e, Krasnoyarsk Krai

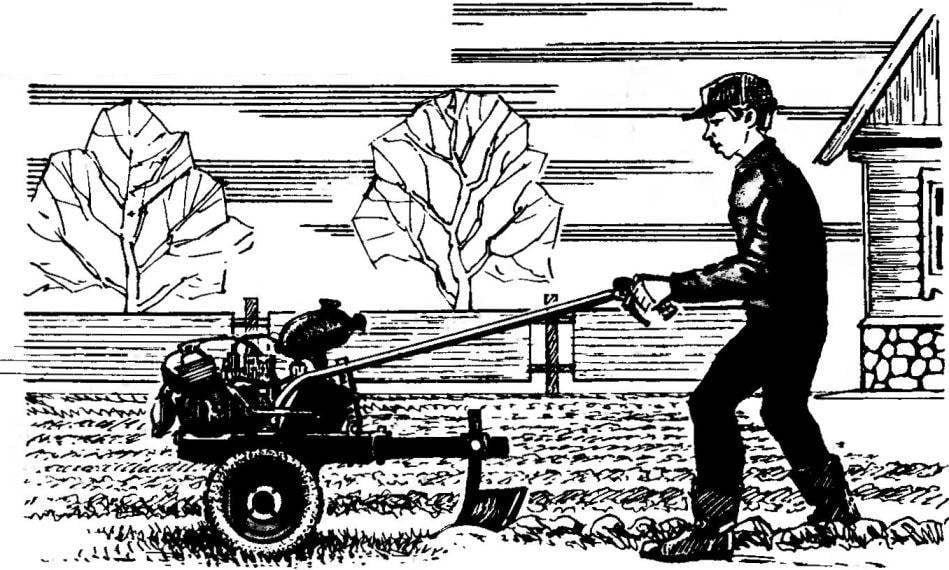

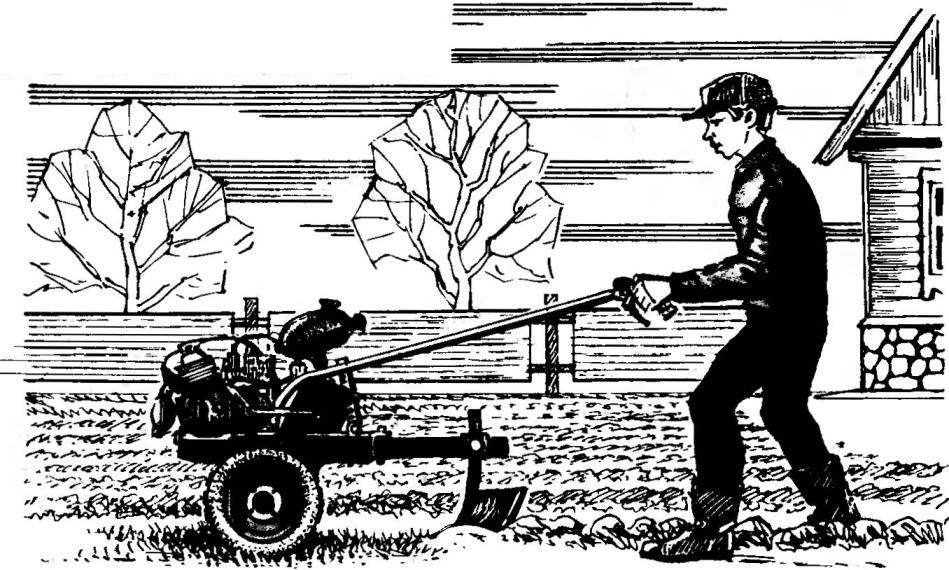

Recommend to read AMPHIPOD Diverse and numerous family water bikes, but they all have a major flaw: transport them by land very difficult. Another thing — ampipe, on land he feels as confident as on the water. The... ROTATES FIELD In a previous article under the heading "electronics for beginners" (see "M-K" № 8, 1979) we understand how magnetic field is formed it Turned out that, in particular, generates supplied...  Accurately process small parcel of land on which “serious” technology closely, except that the tillers. Therefore, the prudent farmers, deciding to get a similar unit, first choose the make and weigh its capabilities. And then think about the truck, mounted and trailed equipment that will be needed for your specific job. So was the case with me. The only difference is that I decided not to buy ready-made tillers, and build it yourself. For the sample took the industrial design “the meadow”, Podkopayeva its simplicity. But only a sample because I have assemblies and parts which are markedly different from standing on the prototype. They had to fit, and many components and parts — manufactured again.

Accurately process small parcel of land on which “serious” technology closely, except that the tillers. Therefore, the prudent farmers, deciding to get a similar unit, first choose the make and weigh its capabilities. And then think about the truck, mounted and trailed equipment that will be needed for your specific job. So was the case with me. The only difference is that I decided not to buy ready-made tillers, and build it yourself. For the sample took the industrial design “the meadow”, Podkopayeva its simplicity. But only a sample because I have assemblies and parts which are markedly different from standing on the prototype. They had to fit, and many components and parts — manufactured again.