When Gennady Kulish arrived in Kirovohrad Institute of agricultural engineering, engineering, it, recent rocketmodeler, and in a head could not come that an important part of modern aviation and rocketry — radio location — will find application in agriculture. And that the range of agricultural machinery, he will experience no less exciting moments than with their launching of rockets.

When Gennady Kulish arrived in Kirovohrad Institute of agricultural engineering, engineering, it, recent rocketmodeler, and in a head could not come that an important part of modern aviation and rocketry — radio location — will find application in agriculture. And that the range of agricultural machinery, he will experience no less exciting moments than with their launching of rockets.

…— Ready! Mechanic has fixed the steering and moved away from the harvester. All expectantly looked at the car.

The harvester is not interested in them: in my lifetime they’ve seen enough of beet harvesting technology (it took place at a testing station in Dnipropetrovsk combine plant, and the participants were experienced specialists of agriculture). Took all of the semi-cylindrical box attached to the front of the combine.

The roar of the engine broke the silence. It was evident, however, that the driver does not touch the control levers. And the car smoothly pulled away. Harvester was exactly between the rows of beets. The impression was that he kind of sniffs to lush foliage plants, a “nose” is this little box.

Harvester went smoothly, beets flew into the bunker. Someone watching applauded, followed by the rest. Broke down and Leo G. Sakaly, although the external manifestation of emotions he is not inclined. But then a special case: the world’s first combine harvester, driven by a radar device out on the course.

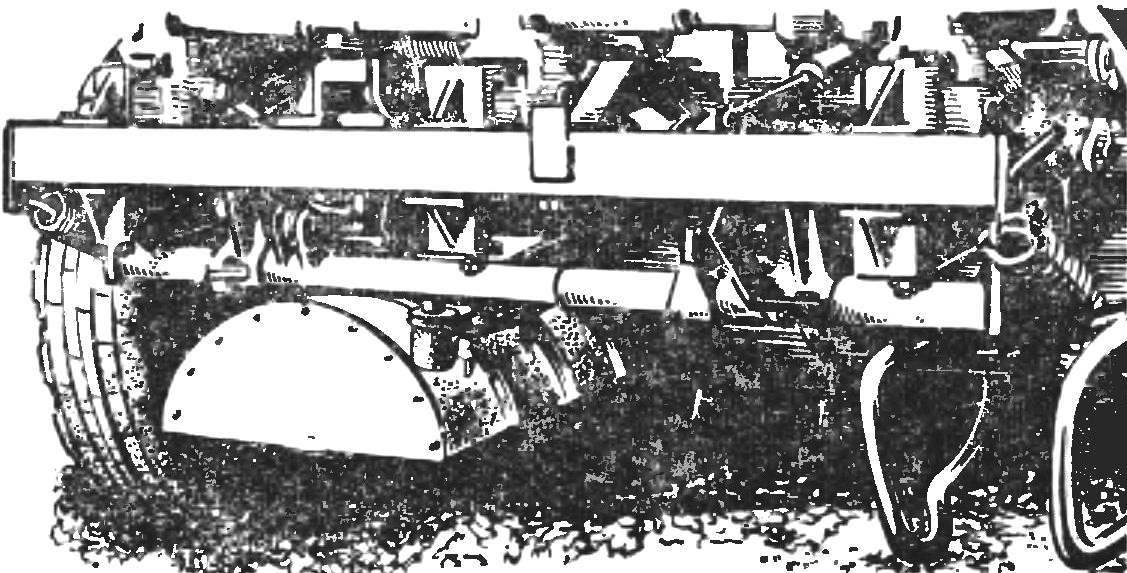

At first glance — what is special? There are devices for automatic driving in other technical fields: aviation, railway transport. But for agriculture they are of little use — a dust and jolting, as in the field or on the rails, nor even in the skies there. And accuracy requirements of the movement even tougher. If sugar beet harvesting machine, for example, is on the field along the axis of the row of beets, the deviation from this axis should not be more than 25 mm. Strange at first sight requirement. the same field! Inch right inch left, is it a big problem? Yes, so great that the working body (something like a fork, see Fig.) will pass by the root or it will shred it. The cultivators should also have a similar accuracy, or together with the weed machine will destroy the plant.

The problem of automatic driving agricultural machines standing in front of scientists for quite some time. Attracts here a lot. First of all, the opportunity to dramatically increase working speed, therefore, increase the productivity is approximately two times. Further, a significant reduction of crop losses: damaged plants will be smaller. And all together will lead to a significant increase in agricultural production. And another aspect: the transformation of the tractor operator or the combine operator, the replacement of labor, requiring great physical effort, maintenance of fine mechanisms. Hence, women will be able to work on these machines as operators. This is important in social terms.

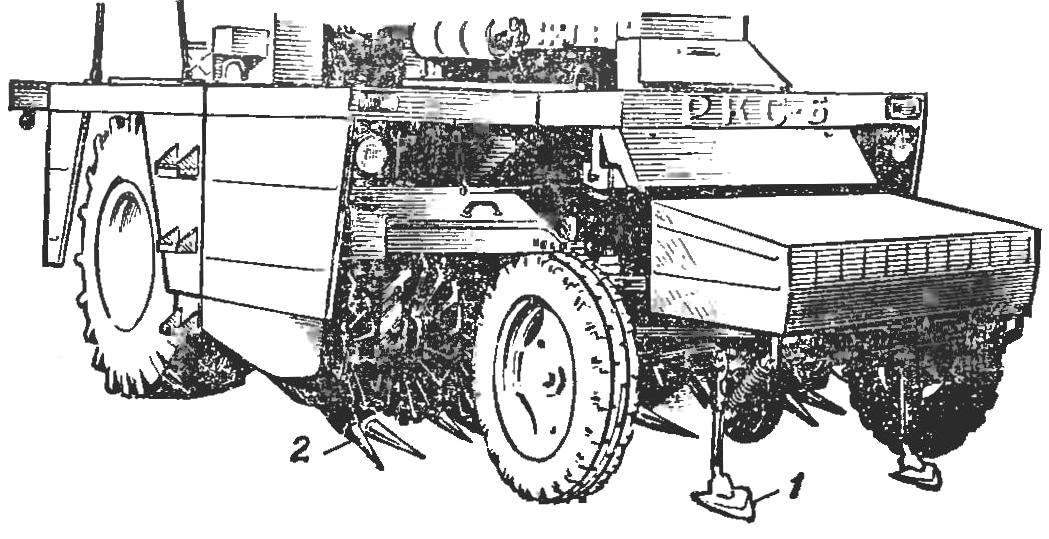

Beet harvester RKS-6:

on the left, with mechanical probes 1 and 2 working body for digging beets;

to the right is a prototype of the same harvester: instead of a mechanical probe on the front — high frequency device enclosed in a half-cylinder.

Automation control of machines — the problem is perhaps most relevant to sugar beet harvesters. Cleaning sweet root — the process is very time consuming. For automation it. along with other organizations, undertook Dnipropetrovsk combine plant and Kirovohrad Institute of agricultural engineering. Of what importance was attached to this work, says already that fact that scientific supervisor was the rector of the Institute, delegate of the XXIV Congress of the party, doctor of technical science, Professor Gregory R. Nosov.

Direct work on the problem headed by candidate of technical Sciences Lev Grigorevich Sakaly, a scientist from the breed of “fans”. At its creative account of a few tens copyright certificates on inventions. And the region where this uvlechenii people completely new: the use of electricity as a direct tool in agricultural processes. For example, he has several patents for a method of killing harmful insects and weeds by electric discharge. And when faced with the problem of automating the process of beetroots, it was decided to use the principles of radar. But this idea did not come immediately.

The process of machine harvesting of sugar beets a few years ago looked like this: on the left a tractor, he was fastened by a sugar beet harvester. The driver of the tractor could be inexperienced boy; the driver of the combine — as. It was strictly to ensure that the working parts were exactly at the rows of beets.

Therefore, the first stage of automation was the fact that the harvesters have supplied probes. Probes are walked along the row of beets, and if slightly deviated to the side, this meant that the working body has deviated. Immediate command on the hydro-mechanical device and the frame with the working bodies adopt the desired position.

Here is the first stage freed up for other farm work about 70 thousand people, has brought about one million cut of the savings allowed by a few percent (nationwide, the figure may be huge!) to reduce yield losses.

The second stage — beet harvester is released from the tractor of the tractor and becomes self-propelled. Dnipropetrovsk and Ternopil factories began to mass-produce combine harvesters KS-6 and PKC-6. These machines can drive and automatically — using the above-described probes, and manually. And they were given the opportunity to improve harvesting beet steel Bender, automating another, is extremely time-consuming operation.

It used to be: the harvester attached to the tractor, walked, beets dug. But this is not the product: about the piles of dug up beets women sitting and knives, she cut off the tops. The knife in his hands after the combine is complete failure in the process chain automation of cleaning. And there was a special batobalani processor, which “shaves” the field, cutting the tops from beets (it is then’ used to feed livestock). And then immediately beet machine digging up from the ground roots.

This technology, introduced in recent years, allowed more than 30% increase in working speed and efficiency. The total economic effect from the use of new equipment exceeded the previous year, 20 million rubles, and it is expected to be even greater.

But just as the fairy dragon in place of a severed head grew a new one, so the solution to one technical problem inevitably creates another. After all, if the beets cut off the tops, the root tip will be flush with the ground or even deeper, lightly sprinkled. As it is, then, to find? Mechanical probe are not very reliable assistant.

Noses, sakaly, and other employees of the Kirovograd agricultural undertook the solution of the problem. The idea was downright daring: put on a beet harvester, a sort of radar. The device, which probed using high-frequency electromagnetic waves in soil, differing in the ground the roots of the beets.

If we send in the ground an electromagnetic wave of high frequency, the intensity of the received signal will be determined not one but two characteristics: conductivity and dielectric constant, different for tuber and soil. It becomes possible to adjust the device so that the signal obtained from the soil, are only the characteristics of the tuber. Characteristics of the soil in the signal will not be counted, it will be as if transparent, and the root of device “will appear” as clear as we could see him if he was on the surface. Well, to pass the signal through the amplifier and other devices on the mechanism that controls the position of the digger so the digger stood up strictly along the axis of the row, this is, as they say, a trick.

We spoke with Lev Grigorievich Sakaly, and at this time in the audience brought a small — sized transistor radio — box.

— That is the amplifier is one of the most important elements “of the radar at the combine,” said Lev Grigorevich. — Completed integrated circuit. They will adapt the recognition system to a lower sensitivity to the soil.

— Such devices are already widely tested?

— In large quantities.

— Participated in their creation and testing students?

— Well, it would be possible to undertake such a great work on designing, debugging and testing all these new devices, if we hadn’t relied on students? Take the test. Forty students departed last summer across the country with new appliances. They can be found in the Caucasus, the Volga region, Kazakhstan, the Kuban, Ukraine, in other places. “Radar” for agricultural machines, it was important to test in different conditions of soil and climate. The guys did a great job, which helped to debug the device.

The Institute has created such a creative atmosphere in which able, interested guys from the beginning drawn into the work, greatly widening the horizons of their chosen profession. In the great creative process the students were full participants. Isn’t that encouraging? Peter selkin, for example, collecting scheme, soldered, debugged the hardware, went to testing, then did a report on this subject at the Institute. Another student, Vasily Smirnov also an active participant in this work, has made automation the topic of his diploma. The use of radar in agriculture has fascinated and Gennady Kulish, many other students.

After a new device visited the exhibition NTTM at the Institute, he was sent to the Republican competition of student works.

I must say that the administration, party and Komsomol organization of the Institute, do all to the creativity, charge enormous forces, which the students receive at the Institute, is not lost in subsequent years, did not dissolve would nd the weekdays. The Institute works closely with the Dnepropetrovsk combine-harvester factory. The chief of the Bureau of machines in this enterprise Vadim Georgievich Kuzmin co — wrote a lot of proposals. Here, the plant is supported by creative research in the field of automation of agricultural work.

By the way, students leave the Institute with a warning to do: this is because the new name of the specialty, which they get by — design, installation and commissioning of automated agricultural systems.

Together with the Ryazan design Bureau on machinery for cultivation and harvesting of potatoes, Poltava agricultural Institute and other organizations have developed two versions of high-frequency devices, which recognize the potato tubers among the stones and lumps of soil.

You can call the other organizations working on this problem. But the dispersal of works for implementation among different organizations leads to a dissipation of resources and effort and reduces their effectiveness.

Now at the Kirovograd Institute organized branch of all-Union Institute of agricultural machine building (VISKHOM). The theme will be exclusively automation of agricultural works. This is the first of its kind, the prototype of the future large enterprises. Enthusiasts from the student environment will continue to work as employees of KB branch Vishama.

R. YAROV, our special. korr., Kirovograd