I’m a longtime, or rather, hereditary subscriber of the journal “modelist-Konstruktor“. First (1972) the journal was written by my father – Galkin Grigory Petrovich (he is now 80 years old), and then myself. Since the beginning of the output of the app “Aviacollection” – sign on him.

I’m a longtime, or rather, hereditary subscriber of the journal “modelist-Konstruktor“. First (1972) the journal was written by my father – Galkin Grigory Petrovich (he is now 80 years old), and then myself. Since the beginning of the output of the app “Aviacollection” – sign on him.

How many can remember, our yard has always been the vehicles. Love for her father has passed and my brother and me. In his youth are still fascinated by aviation. Under the influence magazine chose and the profession: graduated from Vyborg technical school and got the specialty of aviation mechanic. Worked for 21 years with a touch of 7,000 hours of on-Board engineer for the Mi-8 helicopter in the far North.

At the end of 1990-x years the father retired (although he worked another 7 years – 8 at the request of the leadership – he was a good crane operator). At the same time he built the tractor, so that it can serve the readers of “M-K“.

The construction of the tractor laid the old bell truck, which my father bought one of zakresevskis units. True, and it came in handy only a four-cylinder diesel engine, front drive (pull) the bridge so some minor units and components – for example, fuel tank, instrument panel. And if the engine was incomplete (without injectors) and quite worn, the bridge was a real find: with planetary wheel reduction gears and differential lock. The tractor has also become a leading (but pushing) the rear axle.

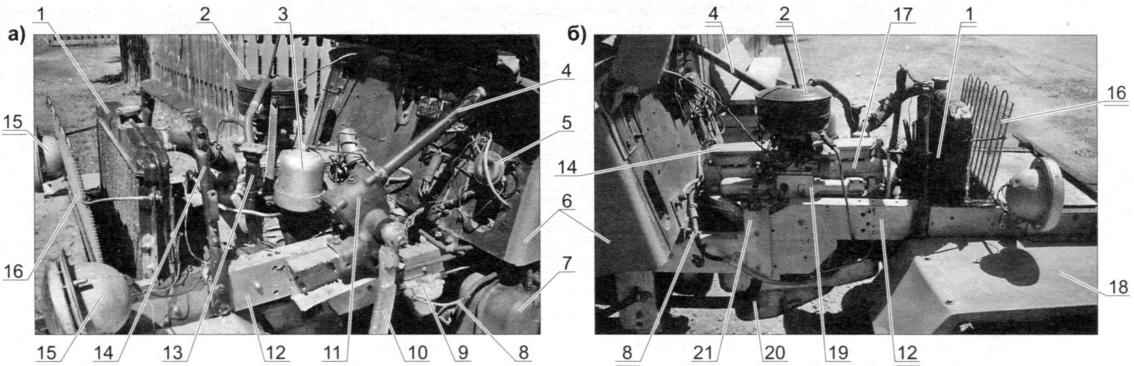

Engine compartment (a pitchfork to the right; b — left):

1 — the radiator (from a car GAS-52);

2 — air filter;

3 — oil centrifuge;

4 — steering shaft (from the GAZ-52);

5 — sound signal (VAZ);

6 — front shield;

7 — fuel tank (V=57 liters);

8 — fuel line;

9 — the fuel filter;

10 — a Pitman arm (long);

11 — steering gear (GAZ-52);

12 — frame;

13 — filler neck of engine oil;

14 — strut-mount hood;

15 — headlight (2 PCs.);

16 — protective grille;

17 — engine (GAZ-52);

18 — front fender (2 PCs.);

19 — intake manifold of the engine;

20 to the sump;

21 — stand wire rope

Injectors and a different fuel system for the engine adapted from the skidder T-40 (later replaced them with equipment from Swedish timber, which came with almost no alterations).

Tractor frame – welded, is relatively simple – it is of a slightly trapezoidal shape is slightly wider at the rear relative to the front end. Cooked on a flat floor. The frame consists of a pair of side members and several cross members. The spars made of channel number 15 dimensions (shelf x wall height x wall thickness) 52х150х4,8 mm with a step (down) in the middle part – in order to contact patch of the tires different front and rear wheels were on the same level in the horizontal position of the frame. Place ledge welded lapped and reinforced with gussets and plates. The crossmember is made of a channel No. 12 dimensions (flange width x wall height x wall thickness) 52х120х4,8 mm. While the front and rear crossmember are and the bumpers. Behind the front bumper welded from bottom area of a width of 600 mm stainless steel 5 mm sheet. To the pad welded two spacers from the channel number 12 700 mm length also with a platform, which is attached to the hinge sleeve swing of the front axle.

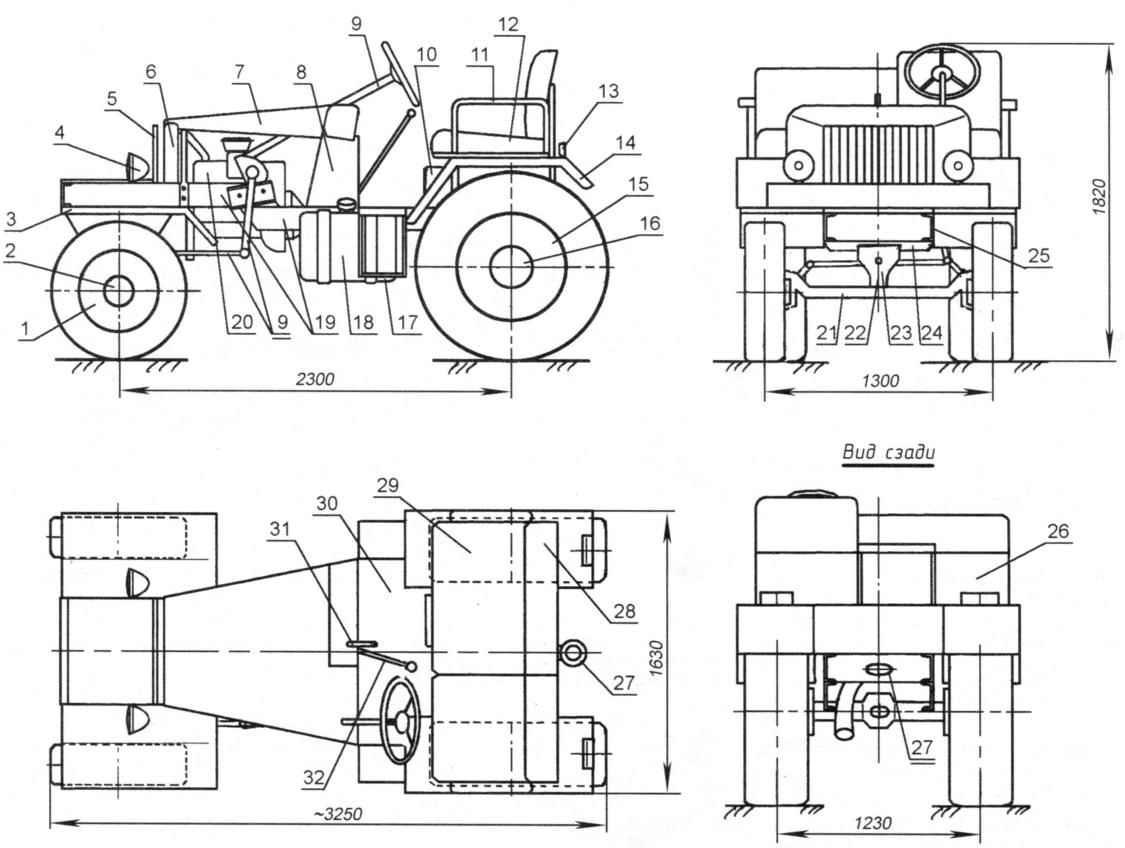

Tractor truck:

1 — front wheel (tire and rim from the car UAZ-469, the drive from the farm);

2 — front wheel hub (farm equipment, 2 PCs.);

3 — the front wing (the panel from the refrigerator, 2);

4 — headlight (ZIL-157);

5 protective grille (radiator cooler);

6 — radiator (from a truck GAZ-52);

7 — the hood (of the car GAZ-69);

8 — front shield (loader);

9 — steering (from the truck GAZ-52);

10 — battery;

11 — holders;

12 — the driver’s seat;

13 — rear signal lights (VAZ-2101);

14 — rear fender (the panel from the refrigerator, 2);

15 — rear wheel (tire and rim from truck tractors To-700, disk-from agricultural machinery, 2 PCs.);

16 — hub rear wheel (farm equipment, 2 PCs.);

17 — tripping (2 PCs.);

18 — fuel tank

19 — frame;

20 engine;

21 — beam front axle (from the truck GAZ-52);

22 — swing axis of the axle;

23 — bracket of the axle beam to the frame;

24 — support plate;

25 — spacer (2 PCs.);

26 — rear shield;

27 — CZ;

28 — passenger seat back;

29 — seat passengers;

30 — floor (sheet s4);

31 — Parking brake handle;

32 — shift lever

Over ledges of the side members are welded thereto a cross member from the same channel, and to her – shield. To the panel mounted control pedal tractor steering shaft bracket, and from the engine compartment:.

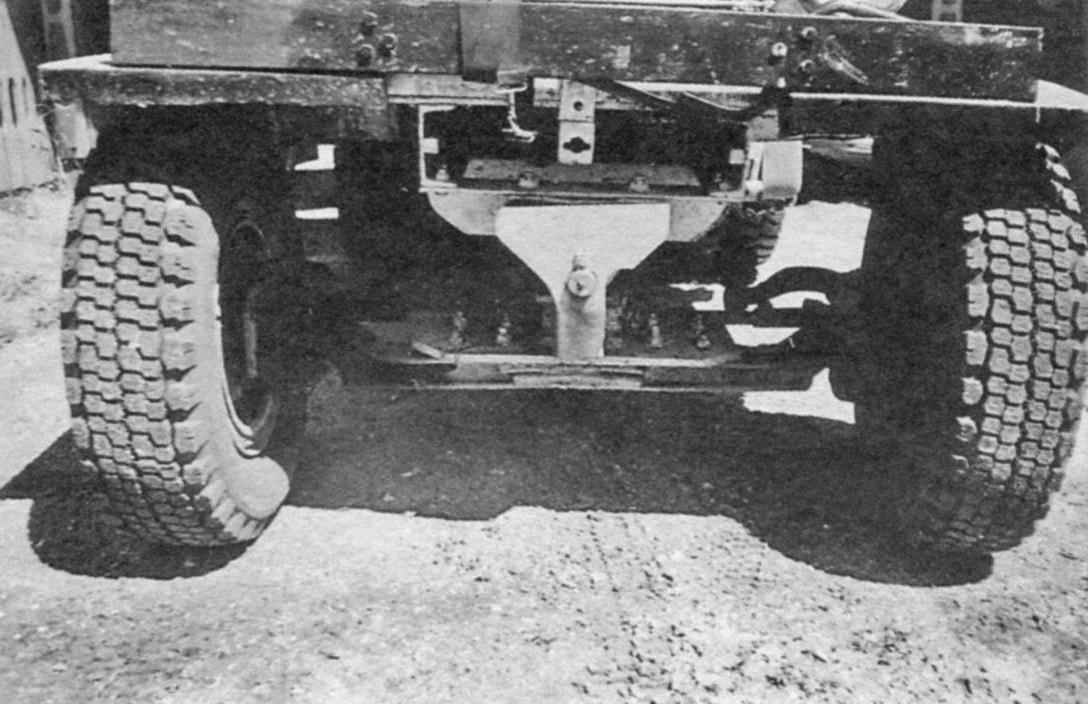

To the rear ends of the side members, bottom, welded the cradle mounts to the frame beam of the rear axle.

Front axle (with steering-swivel) adapted from the truck GAZ-51. To the frame it is attached at the Central hinge, there is a bridge – swinging. Front wheel hubs – from truck truck tractor T-40, but the wheel and tyre from the car UAZ-469.

Suspension of front axle

Rear axle podstegivaet to the locating blocks of the frame through the rubber lining and is secured with ladders – a pair on each side. Directly to the bridge is welded tow – it’s even safer than to the frame – because earlier, when the bridge was on the lift, on these brackets is attached to the boom, and all loads are carried directly by the bridge.

Rear wheel homemade. Their rim – of the wheels of the vehicle ZIL-157 and the hub part (drive) from the wheels of a forklift. The disc was cut by electric welding, and machined on a lathe. Then the disk inserted into the rim, and, after adjustment of their relative position, the parts were welded: continuous weld inside and outside – intermittent. Bus from ZIL-157 for wear replaced with identical tires, but agricultural equipment.

In the transmission box changes gear and the clutch basket from used truck ZIL-130. Next to the host bridge, the torque is transmitted through a tandem propeller shaft with two slotted couplings.

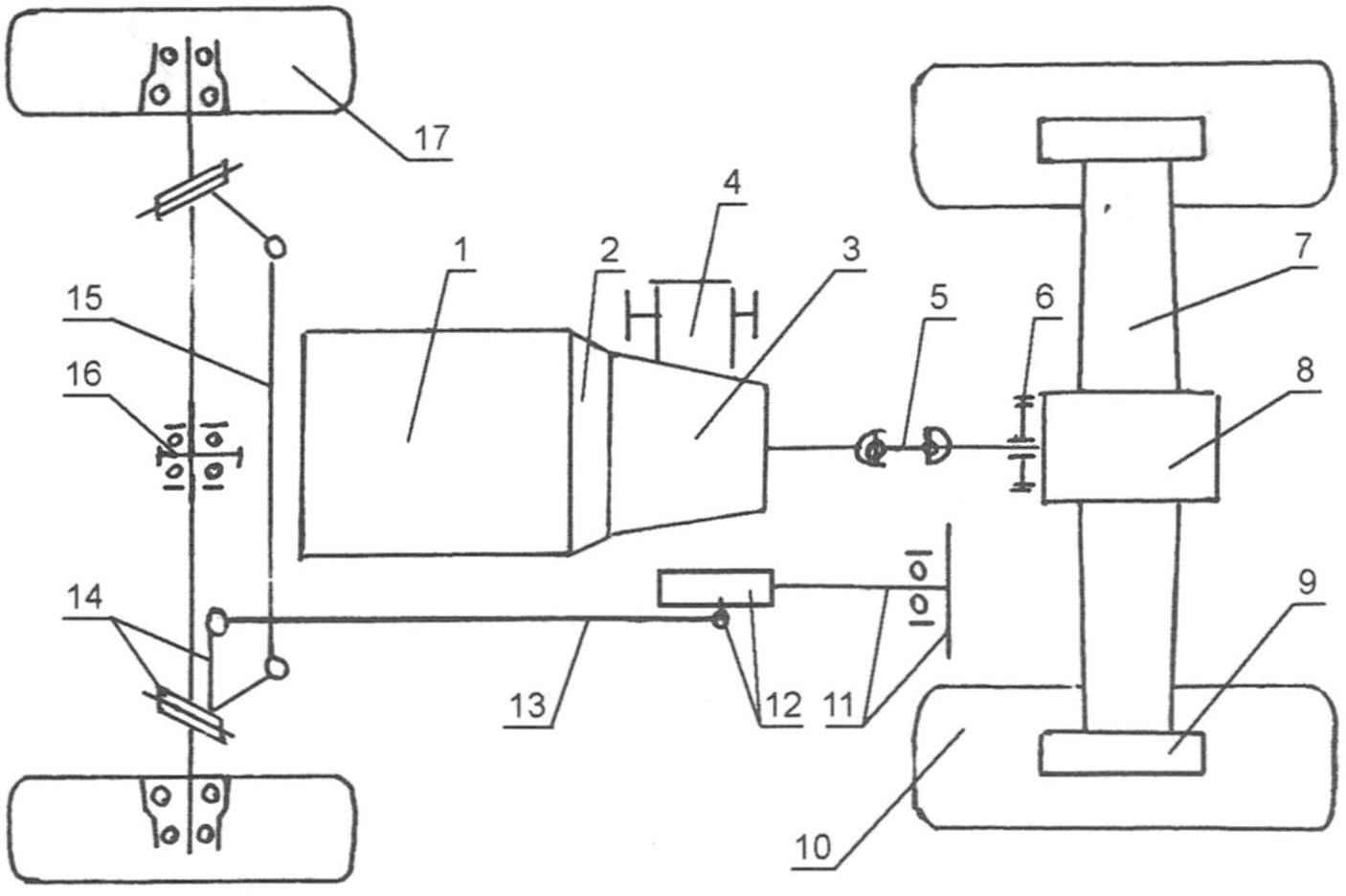

Diagram of the powertrain and steering of the tractor:

1 — engine;

2 — the clutch basket;

3 — gear shift;

4 — reducer power take-off;

5 — twin driveshaft;

6 — disc brake;

7 — rear drive axle;

8 — Carter, the main transmission with limited slip differential;

9 — the case of the planetary gear wheel hub (2 PCs.);

10 — front drive wheel (2 PCs.);

11 — steering wheel with a steering shaft;

12 is a worm gear with a bipod;

13 — longitudinal thrust;

14 — the rotary fist with the lever (2 PCs);

15 — steering knuckle;

16 — the axis of swing of the front axle;

17 — front control wheel (2 PCs.)

Electrical equipment on the tractor is assembled, that is, “every little helps”: lights – from ZIL-157, front “turn signal” from GAZ-53, the rear lights from the VAZ-2101. The engine start is carried out from ignition switch electric start (and kick-starter, but how much I remember – it’s never been used). Battery – 72 Ah, under the passenger seat and closed the front cover on the spring locks.

The hood of the engine compartment – GAZ-69. Driver’s seat – the tractor To-700, but no suspension. The passenger seat is a double, self-made: the frame is from a steel angle 25×25, the base is made of thick plywood, gasket – foam rubber, upholstery – leatherette.

After working on the tractor about ten years, diesel forklift from “kicked the bucket”. Boring cylinders and the crankshaft journals helped briefly. It was all about the lack of “native” replacement parts from other engines they did not fit. Have a question about the replacement motor.

At this time, once again, there was a reduction in the army, and was disbanded near the located repair battalion. There was a sale of equipment. That’s where I bought the engine from BTR-60 84 HP with all equipment: shielded wiring plugs, starter, generator, carburetor, and clutch basket and gearbox. This inline six-cylinder engine used truck GAZ-52, so the missing equipment (for example, liquid cooling system) borrowed from him. When installing the motor had to alter the mount to the frame. Now he’s attached to the front on the rubber cushions in the U-shaped (inverted) suspension, and rear – the struts for Carter the gearbox. But the shifting was immediate, and it was kwintessential.

Tractor brake mechanical, disc. Located on tail shaft gear (around the gearbox axle). Drive brakes – dual pedal through the rod and lever (located under the instrument panel) – with the help of a rope.

Power assisted steering (gear, column, steering wheel) – the car GAS-52. The alteration has undergone a Pitman arm: extended stay welded square steel rod. Rod coming from the Pitman arm to the knuckle, home – made, with tubular tips.

The instrument panel is used from GAZ-52. It is an ammeter, the pointer of the coolant temperature, oil pressure, fuel level, speedometer. Under the dash hidden mechanical disconnect switch (toggle switch) – it performs the functions of anti-theft devices.

The tractor performed crudely but securely – operation for two decades for transporting goods, and to work the land proved it. Largely successful design of the tractor was through the rear axle from a Bulgarian truck. He proved to be reliable and copes with ensuring the patency of the tractor in difficult road conditions and high-torque on farming. In the case of slipping of one of the wheels of the rear axle by rectilinear motion, it is immediately locked with the other. On the turns in the bridge start to work wheel planetary mechanism, but when turning the steering wheel to stop the tractor can turn around one wheel skidding of the front. But this is extreme, and so turn sharply undesirable.

The dashboard and controls of a tractor

By its capabilities the bridge from the truck surpasses even the bridge from the truck of the vehicle GAZ-66, which, besides, as for the tractor it is necessary to shorten (zawjati track).

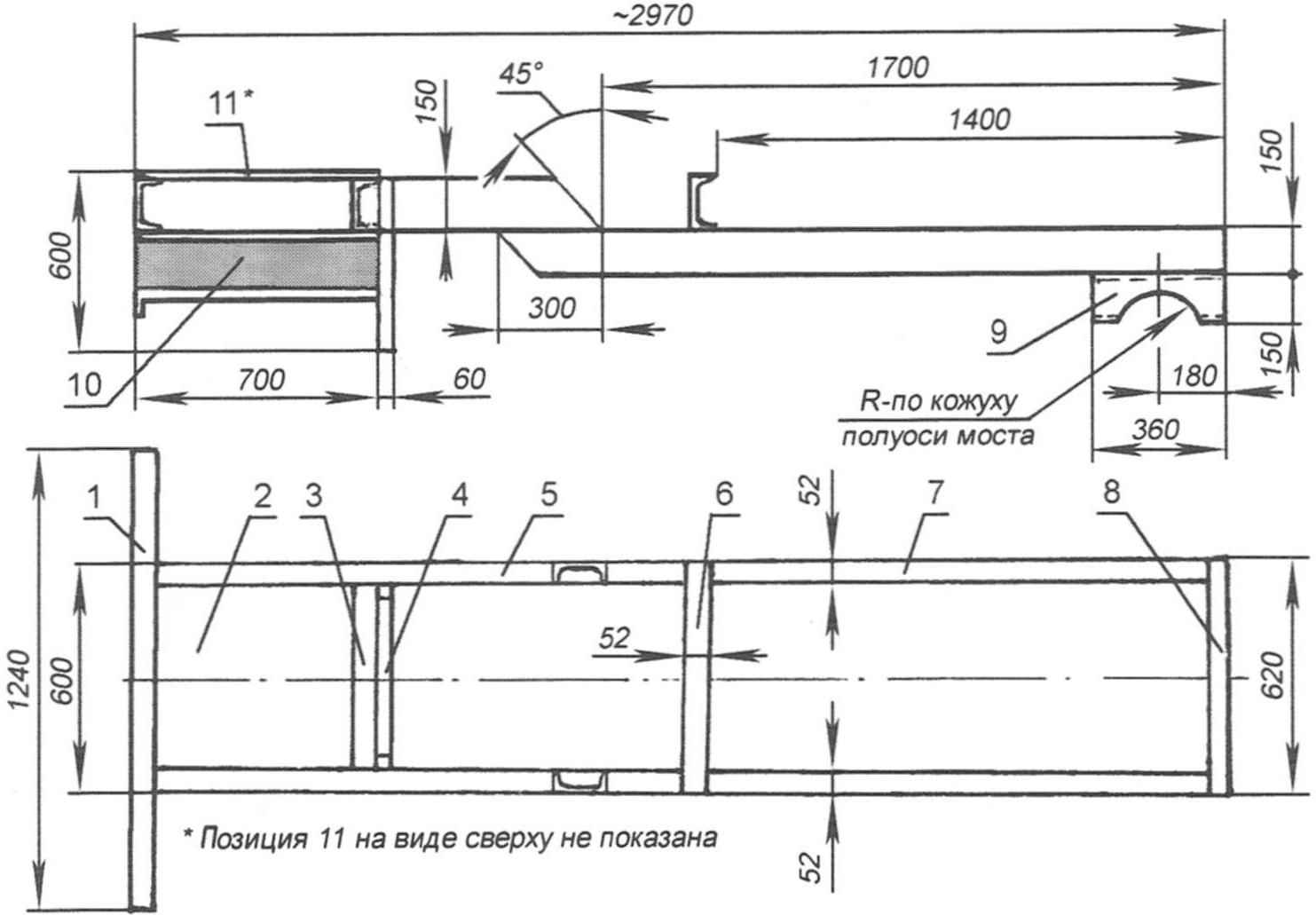

For the transport of goods to the tractor clings also homemade single axle truck. It is the third in a row – from one to another, increased capacity, and design were similar.

Bogie frame is welded from the same channel that the frame of the tractor (No. 12). Axle and wheel hubs – from agricultural machinery, leaf spring suspension of the truck GAZ-53. The body frame is welded from steel angle 25×25. Cladding made from floorboards of the “twenty” attached to the frame with bolts. The front and rear sides of the trolley – folding (horizontal hold circuits), which allows to transport lengthy cargoes.

Frame:

1 — front cross member (channel No. 12);

2 — medium area (sheet s4);

3 — front cross member (channel No. 12);

4 — mounting bracket front engine mounts (L-shaped profile of the steel sheet s4);

5 — the front part of the spar;

6 is a Central cross — member (channel No. 12);

7— rear of spar (channel No. 12,2 PCs.);

8 — rear tie bar (channel No. 12);

9 — place the rear axle (channel № 12, 2);

10 — spacer (channel № 12, 2);

11 — upper pad (sheet s4)

Tractor trailer single axle truck

“Modelist-Konstruktor” No. 9, 2011 | A. GALKIN, New Urengoy, Yamalo-Nenets A. O.