The tillers built in circle of “Technical creativity” Yakovlevskaya Polytechnic. Designed for ploughing all types of soils – both light and heavy. Ease of management makes the job tiring. The design turned out well, the care required is minimal and the performance and quality is excellent, and therefore how to repair and improve are required.

The tillers built in circle of “Technical creativity” Yakovlevskaya Polytechnic. Designed for ploughing all types of soils – both light and heavy. Ease of management makes the job tiring. The design turned out well, the care required is minimal and the performance and quality is excellent, and therefore how to repair and improve are required.

The reliability of the gear allows you to plow effortlessly and virgin. The life of the gearbox before overhaul, at least, ten years. The number of gear 4 forward, 4 backward.

Time plowing 6 acres with an average hardness of land -25 mins

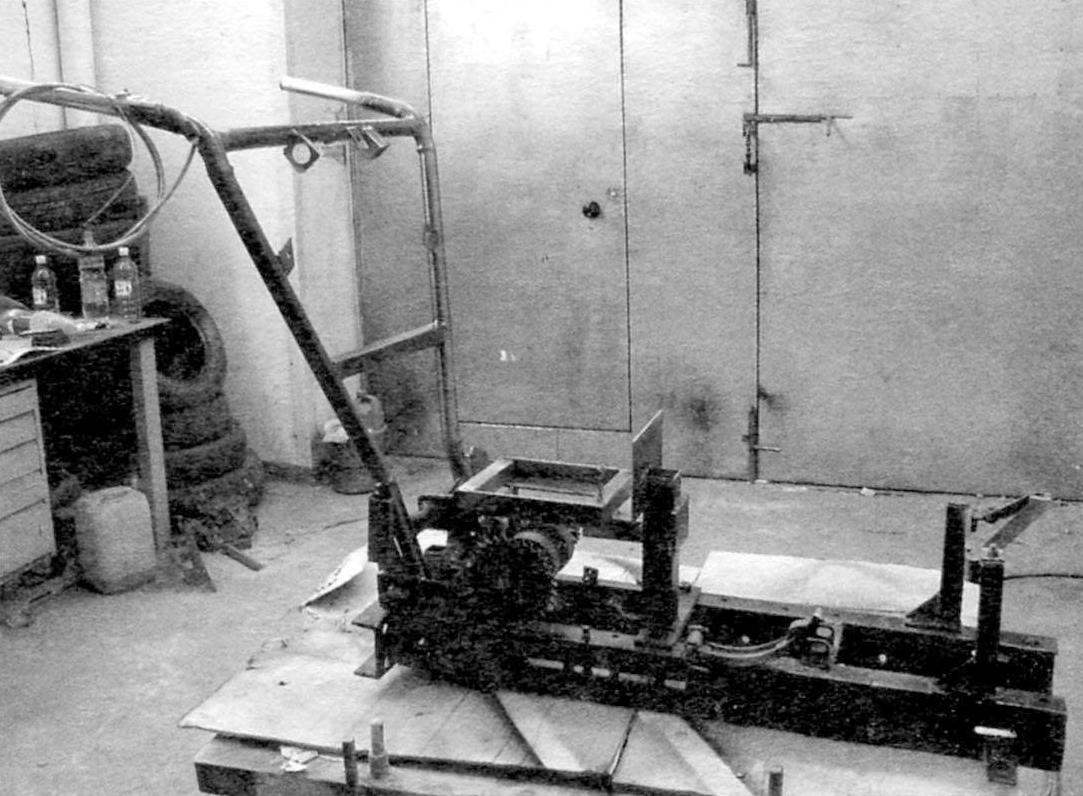

At the design stage tillers a big help to us was given publication in the journal “modelist-Konstruktor” of yesteryear. We chose from them the most valuable. Thus was developed the concept; a two-wheeled walk-behind tractor frame structures using transmission gearbox from a written off scooter “Ant”. To increase traction to the drive wheels of the cultivator, have developed the intermediate shaft with a common ratio of 4.5.

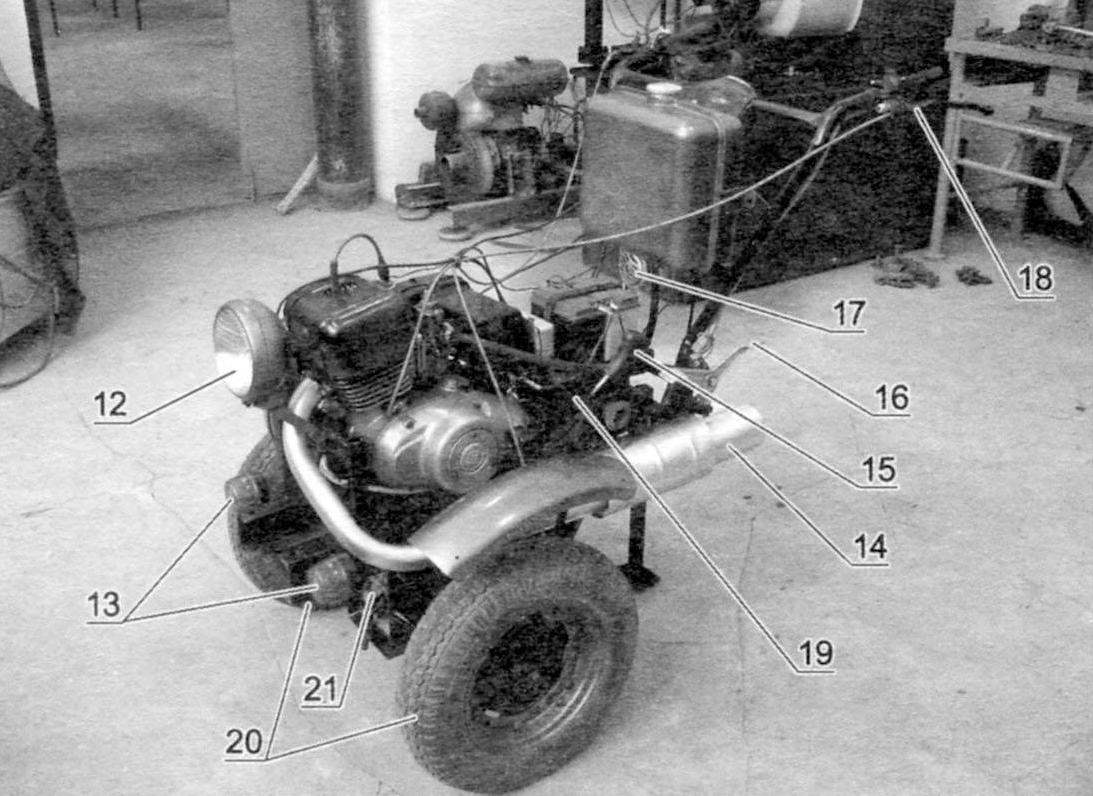

Of the existing features of the mechanism, we note, first of all, the use of relatively powerful powerplant – engine of the scooter Muravey with forced air cooling. Control arms – standard. And finally, another distinctive feature is the braking device which is necessary for operation of the trailer-truck that turns a walk-behind tractor in the cargo vehicle.

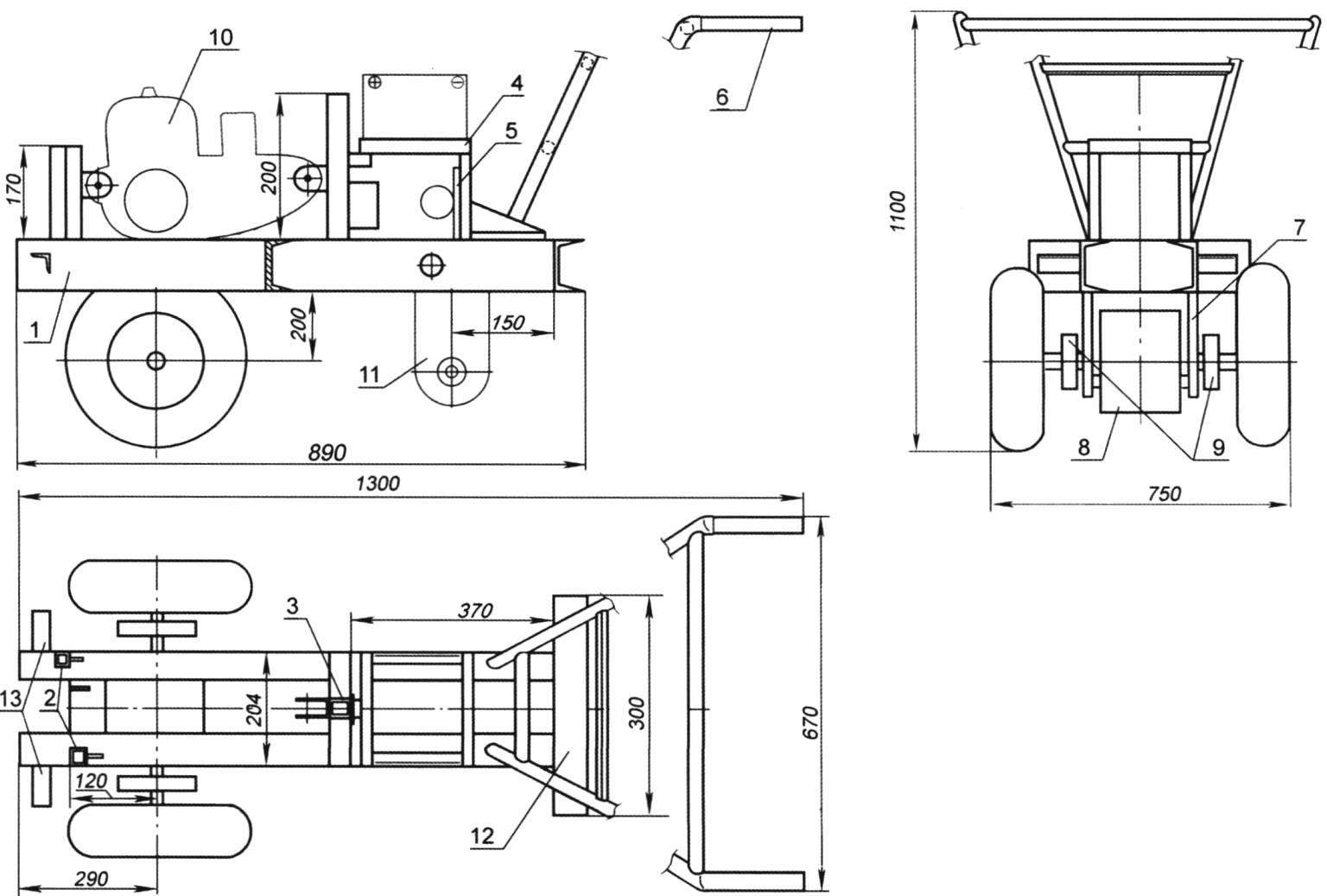

Motoblock “Vostok-1”:

1 – motor; 2 – tank; 3 – battery; 4 – the lever of the brake control; 5 – the case of the milling mechanism; 6 – a control lever differential; 7 – housing Vozduhoflotsky engine; 8 – relay-controller; 9 – guard circuit; 10 – handle throttle control of the carburetor of the engine; 11 – the protective wheel well; 12-searchlight; 13 – blinkers; 14 – muffler; 15 – kick-starter; 16 – lever control transmission; 17 – sound signal; 18 – lever clutch control; 19 – intermediate shaft; 20 – drive wheels; 21 – differential

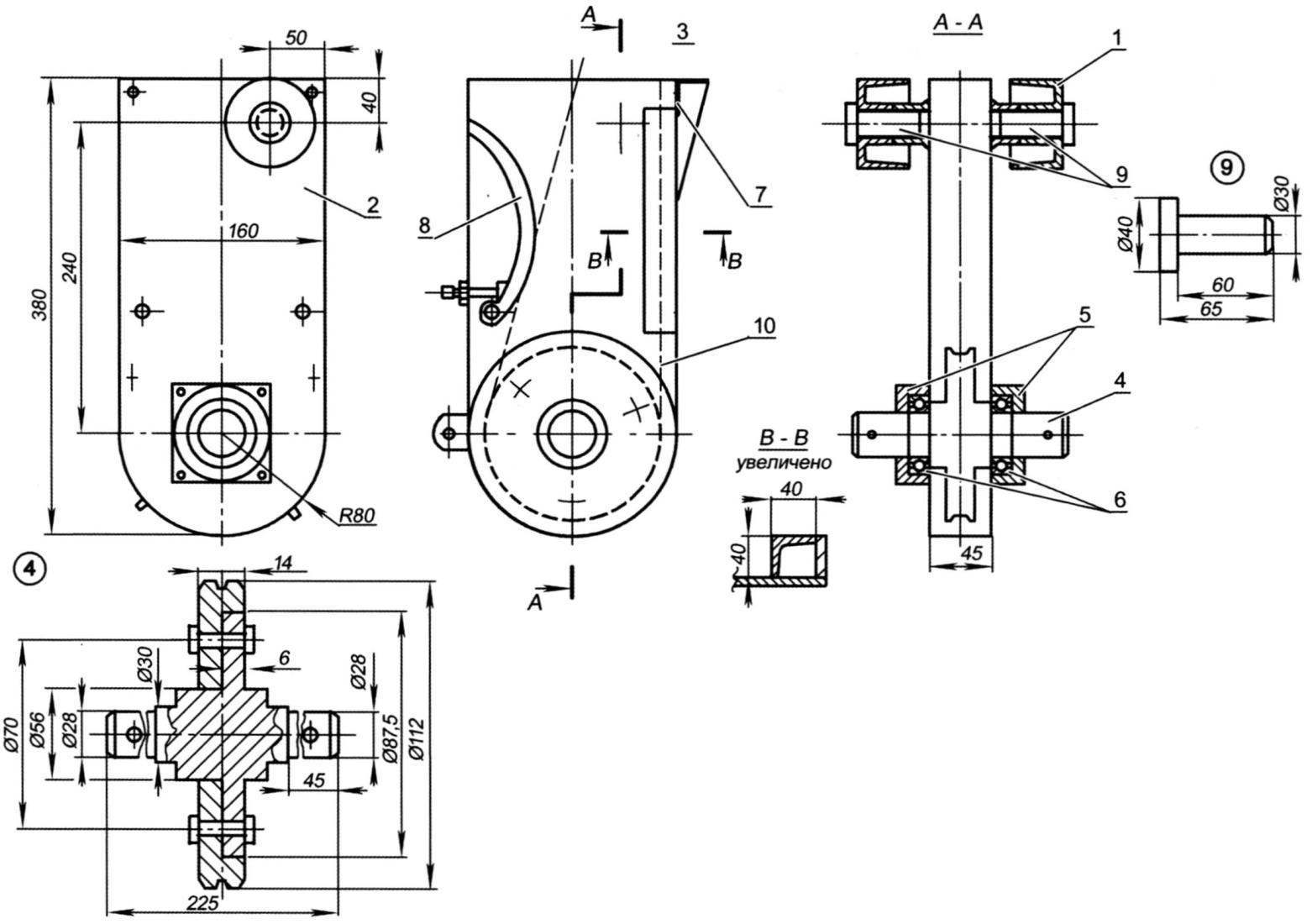

The frame of the cultivator with intermediate shaft

When plowing through the cutters for the majority of the tillers of the drive wheels are removed and in their place installed the cutter, and the depth of plowing is regulated by a braking device. On our tillers different scheme would be applied mills drive; differential gear set to the neutral position and the drive of cutters is provided from the intermediate sprocket to the shaft milling cutters with double-row chain from VAZ (timing).

Milling shaft when not in use with the housing removed from the clamp and into transport position without interfering with the work of tillers in other modes.

Transmission of tillers is a two-stage chain transmission with step 15,875 mm and the intermediate double row chain for the drive of the cutter shaft and the differential. The differential is connected with driving wheels through two flexible couplings. The intermediate shaft is mounted on two sealed ball bearings 206. To tension all chains in the walk-behind used device used in the timing mechanism of automobiles. This device is simple and easy.

Chassis of walking tractor:

1 – longeron (channel 80×40, 2); 2 – front brackets; 3 – back bracket; 4 – frame batteries; 5 – bracket, intermediate shaft; 6 – control knob; 7 – a plate of fastening of a reducer; 8 – gear differential; 9 – elastic coupling drive; 10 – engine T-200 (situation); 11 – milling shaft Assembly (furnished); 12 – cross member for attachment; 13 – bracket front

Milling shaft in the housing:

1 – longeron; 2 – housing cover; 3 – housing shaft (cover removed); 4 – gear shaft (gear timing VAZ-2101); 5 – bearing housing (rear axle VAZ-2101); 6 – bearing 180306; 7 – mounting bracket (40×40 area, L120); 8 – chain tensioner Assembly (tensioner VAZ-2101); 9 – axle housing mounting; 10 – timing chain (GRM VAZ-2101 – length in a place)

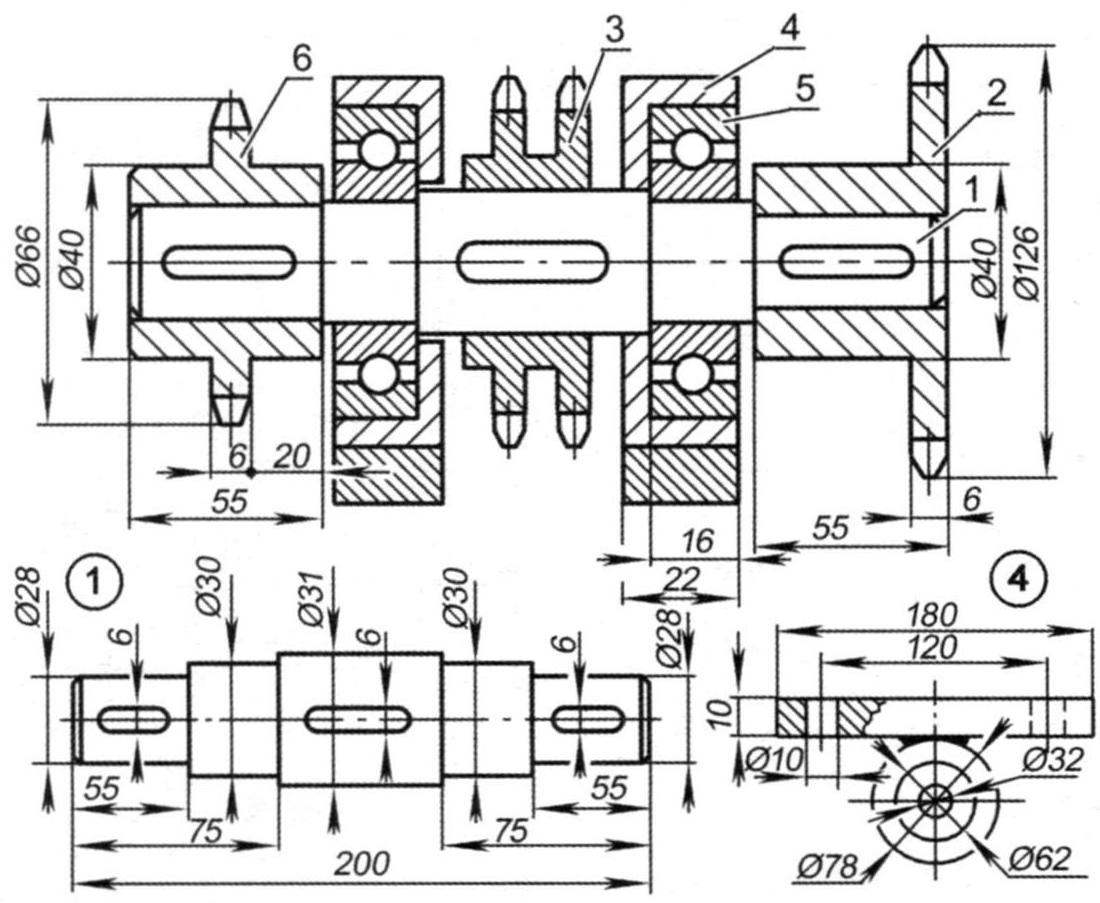

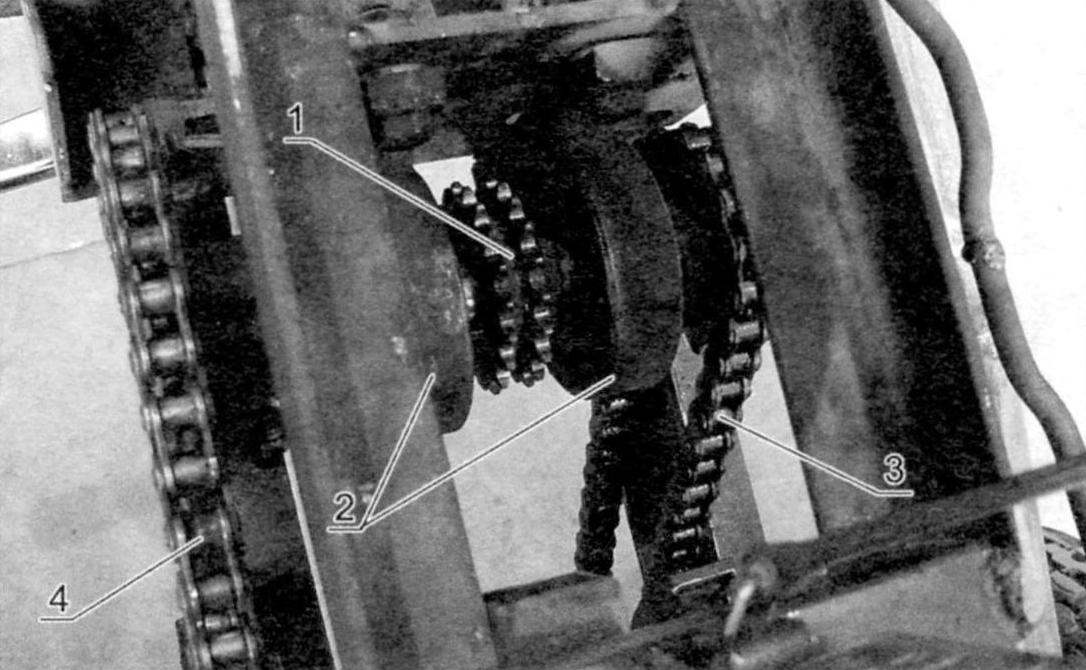

Intermediate shaft Assembly:

1 – intermediate shaft; 2 – the driven sprocket z30; 3 – sprocket milling shaft z19 (GRM VAZ-2101); 4-bearing; 5 – bearing 80206; 6 – sprocket z16

Differential taken from a cargo scooter “Ant”. It is good that it has the reverse: forward, reverse and neutral position, this is what we used when constructing a walk-behind tractor.

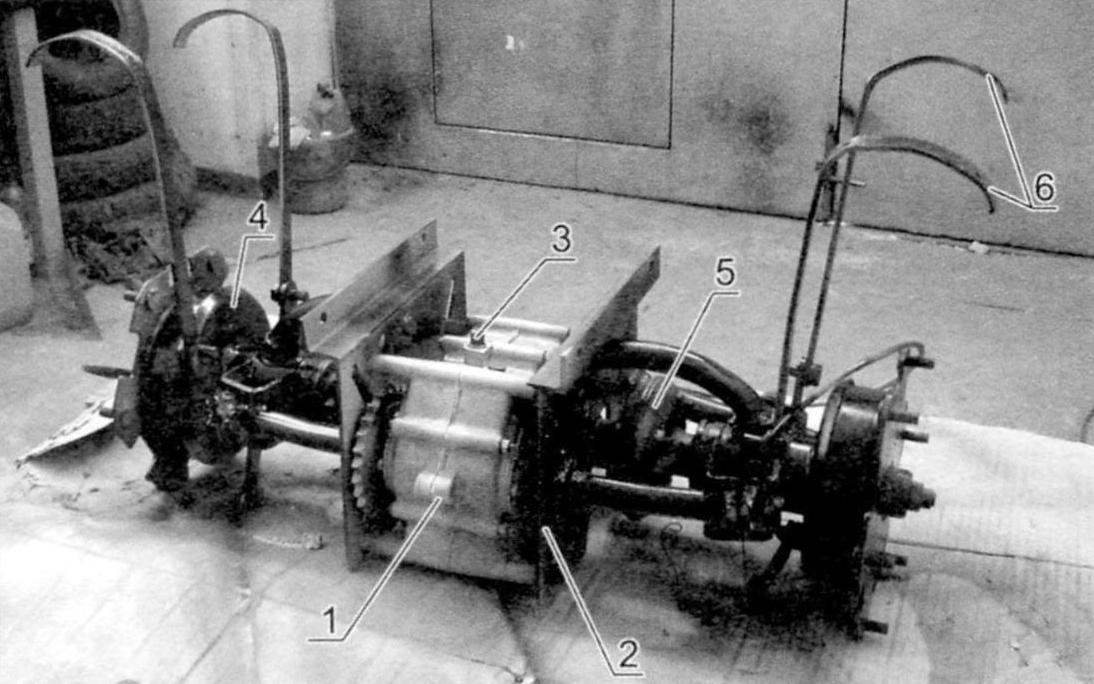

During operation of the cultivator as motoriz use the standard wheels of the scooter “Ant”, and to work with attachments set of wheels from the sidecar with improved cleats. For plowing, there is a set of special metal wheels with cleats in the form of metal plates.

The engine will not start unless you use the kick-starter, it is planned to equip denotation.

The drive axle of two-wheel tractor:

1 – differential housing; 2 – differential housing cover; 3 – the control shaft of the differential; 4 – brake drum; 5 – elastic coupling; 6 – mounting brackets flaps wheels

Intermediate shaft:

1 – sprocket milling shaft; 2 – bearing; 3 – chain drive differential; 4 – chain drive intermediate shaft

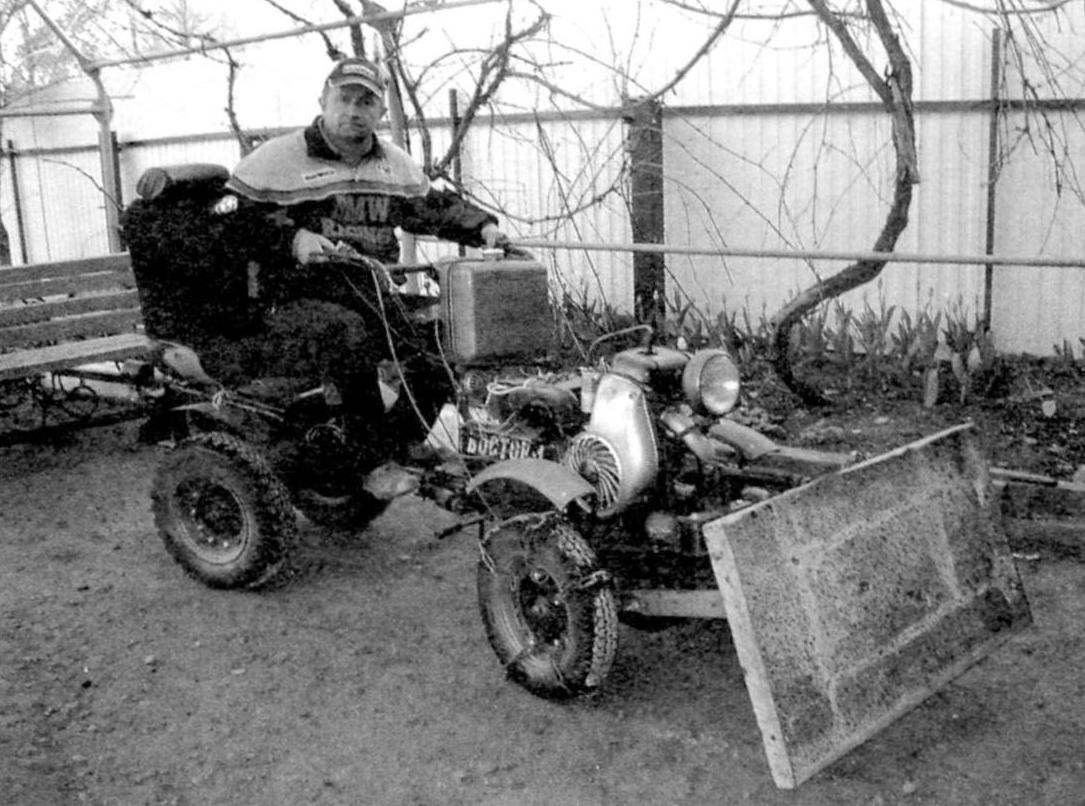

The tillers trailed seat on wheels and a blade front

To work in conditions of poor visibility and during dark time it is equipped with illumination device – a headlamp finder.

Further to the tillers have produced the frame with the seat and want to make a trailer truck for transportation of goods.

Our tillers was named in honor of the spacecraft “Vostok-1” on which Yury Gagarin in 1961 made his unprecedented flight in outer space.

SPECIFICATIONS

Band width of plowing, mm………………………………………………800

The diameter of the cutter, mm……………………………………………………………380

Plowing depth, mm…………………………………………………..20 – 200

Weight without motor and cutters, kg…………………………………………………30

Mass mills, kg…………………………………………………………………….20

Engine……………………………………………………………….”Tula 200″

Motor weight, kg………………………………………………………………….36

Rated power, HP…………………………………………………13

Fuel……………………………………………………………………AI-76

Fuel consumption on 6 acres, l……………………………………………….1,2

Fuel tank capacity……………………………………………………….6

V. SHKARIN, Stroitel, Belgorod region.