SIDE — DUMP TRUCK. To deliver the current grain from working in the field combine to drive if the feed to the farm building materials to the rising walls of the new building is everywhere in the village the required on-Board the vehicle. Such popularity is due to universality of his body fit for any cargo. One bad — unloading process, requiring considerable manual labor. Whether it is a truck! In a matter of seconds this “scoop on wheels” takes an inclined position, and the cargo already on the ground. Not accidentally, rural innovators are constantly find the most simple solution: how to get side car “samoraspustitsya”.

SIDE — DUMP TRUCK. To deliver the current grain from working in the field combine to drive if the feed to the farm building materials to the rising walls of the new building is everywhere in the village the required on-Board the vehicle. Such popularity is due to universality of his body fit for any cargo. One bad — unloading process, requiring considerable manual labor. Whether it is a truck! In a matter of seconds this “scoop on wheels” takes an inclined position, and the cargo already on the ground. Not accidentally, rural innovators are constantly find the most simple solution: how to get side car “samoraspustitsya”.

The options offered are different — from rolling front-side, which ropes moves on the body and, like a scraper, it pushes the load up to put under the bottom of the accordion from old inner tubes filled with exhaust gases and raises the body.

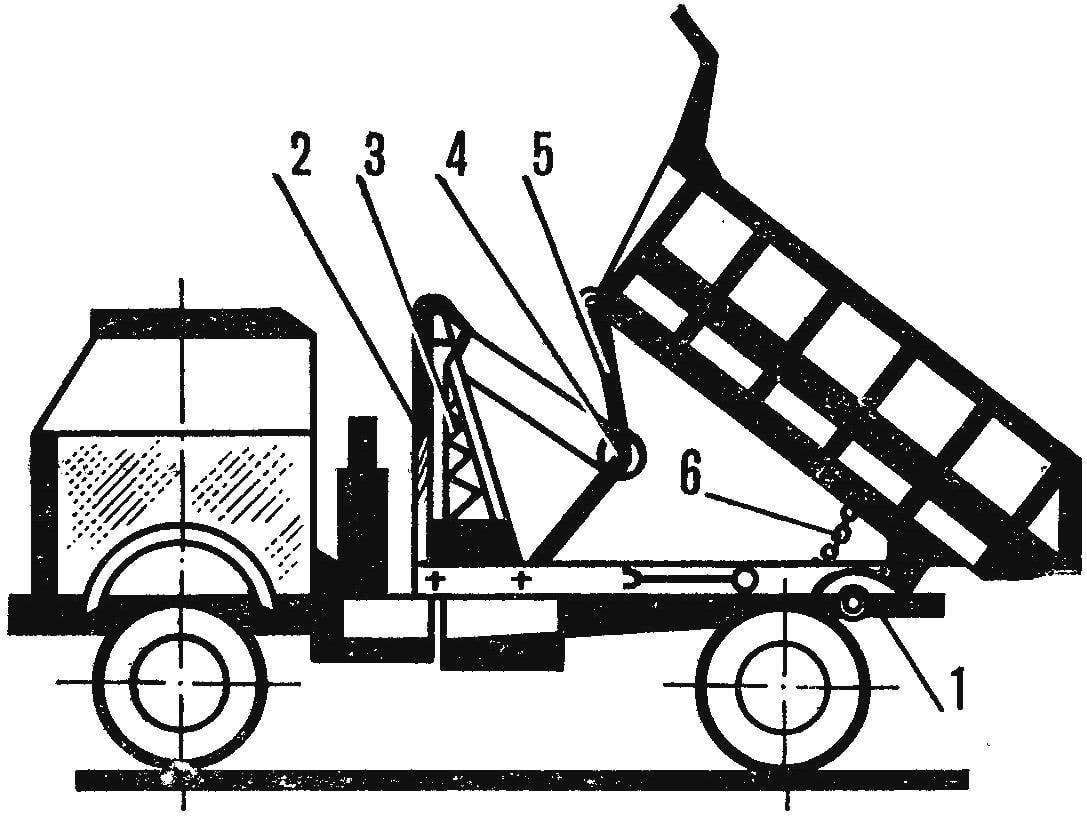

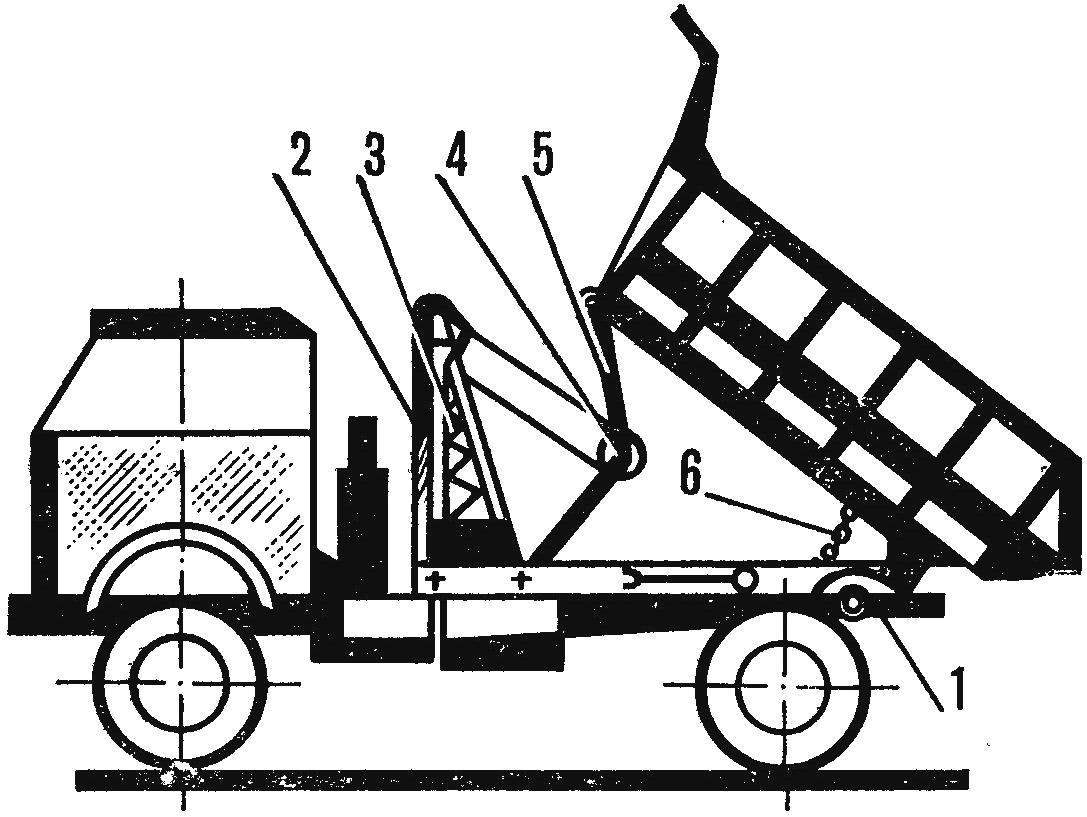

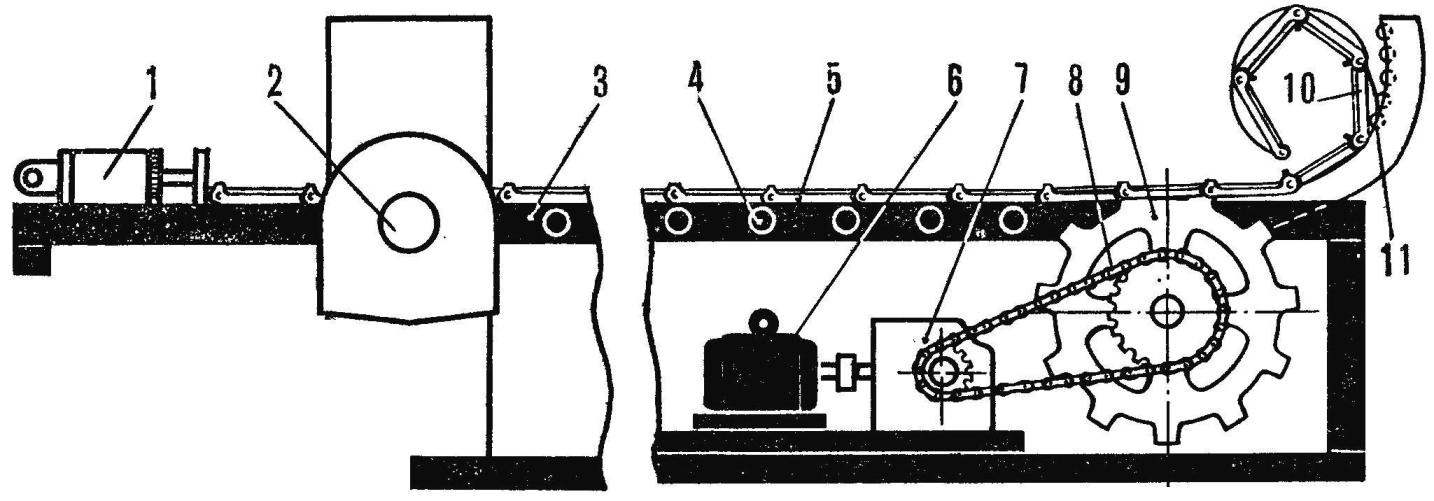

Innovators of the Tula Association “Allergological” found the option of upgrading conventional vehicles ZIL-130. Securing the body to the rear of the frame on the hinge, they are summed up under the middle part of the simple hitorijanai lifting system — and the body was breaking. Schematic diagram of the device shown in figure 1.

Fig. 1. Hitorijanai lift:

1 — the frame of the car, 2 wooden beam, 3 — frame lift, 4, 5 — hinges, 6 — arm, 7 — rod hydraulic cylinder, 8 — cheek lever, 9 — frame body.

Conversion, as can be seen from the diagram, is the following. On frame 1 of the vehicle with the wooden beams 2 is mounted stationary lift frame 3 with the hinge 4 to the lower end of the linkage 6 and the second hinge 5 mounted on the moving part, the frame body 9.

Before the rollover .the body turns on the oil pump; the rod of the hydraulic cylinder 7, advancing, pushes through the cheek 8 on the lever 6, and that, in turn, on the frame 9, installing it at an angle of 40°, sufficient for cameras-grusinia.

Tests showed that the conversion of airborne vehicles into trucks not only simplifies and reduces process discharge, but three times reduces the number of machines required to perform the same amount of work.

Kurgan cargo authored the company No. 1 the same cars made self-discharging by utilizing existing platforms, tipper semi-trailers from 1-PTS-9 or W-PTS-12, shortened by 850 mm. the Working bodies of the platform lift are two cylinder, oil which serve pumps NSH-32 or GP-46 driven from the power takeoff of the vehicle ZIL-MMZ-555 mounted on the gearbox upgradeable machines. Dividing the tap in the hydraulic system allows you to attach to the vehicle a tipper with a lifting capacity of 4.5 t, which further increases the efficiency of the use of the ZIL-130 after conversion.

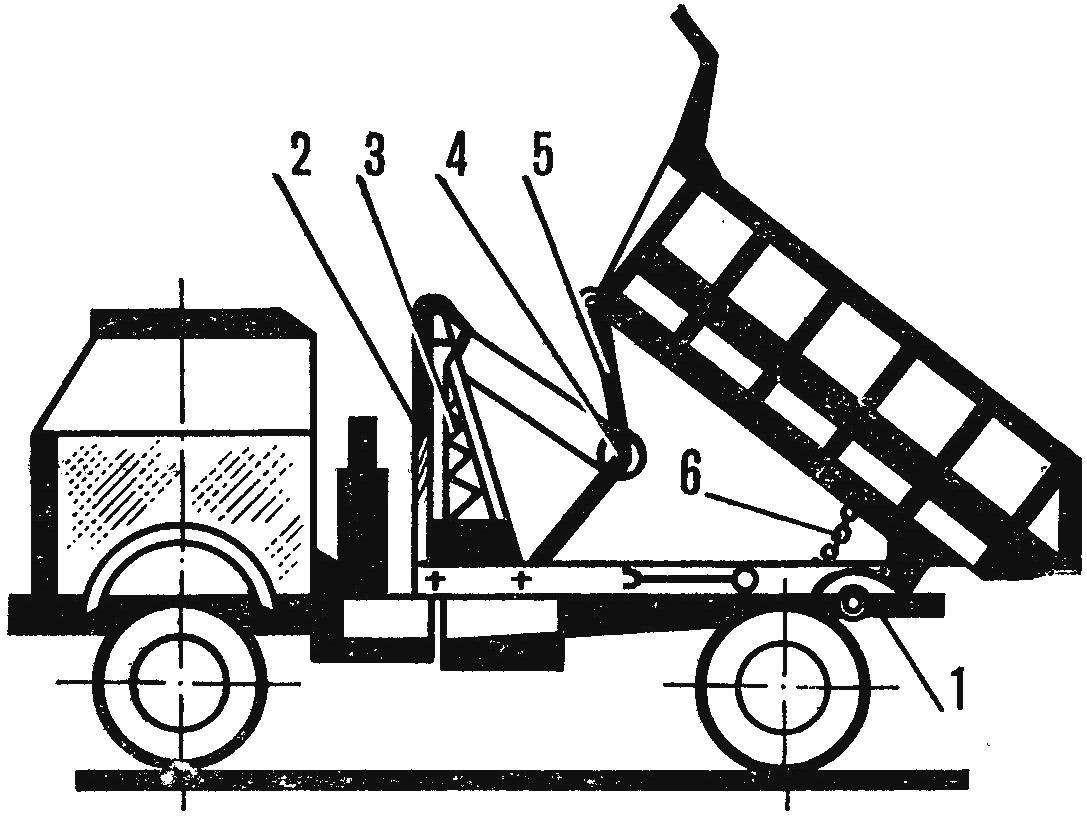

A different principle is applied at Vologda tractormeter plant. Here at MAZ-509 is installed removable tipping device with manual lifting body (Fig. 2), based on the folding lever and acting on it block system with a rope from the winch.

Fig. 2. Cable lift:

1 — winch 2 — cable, 3 — strut, 4 — unit, 5 — lever, 6 — chain stopper.

The cable lift works as follows. When you turn on the winch 1 cable 2 via the stand unit 3 and unit 4 linkage 5 decompresses folded under the body of the lever, slowly lifting the body up to the angle of bounded chain stopper 6. After unloading the winch handle is rotated in the opposite direction, the cable is unwound from the drum, gradually releasing unit 4, and the lever is again formed below the descending body.

Thanks to this modernization by reducing costs of manual labor and improve the efficiency of car usage achieved savings of up to 1000 rubles per year for one car with dump device.

CATERPILLAR IN THE ROLL. Probably, each tractor had to experience the brunt of the work with a broken caterpillar. No easier to cope with it at the repair station, even if it is equipped with a special stand, as, for example, in the shop of recovery tracked link in the Novgorod district Association “agriculture”. To roll the finished section of the caterpillar and roll, two workers had to spend a lot of time and physical effort.

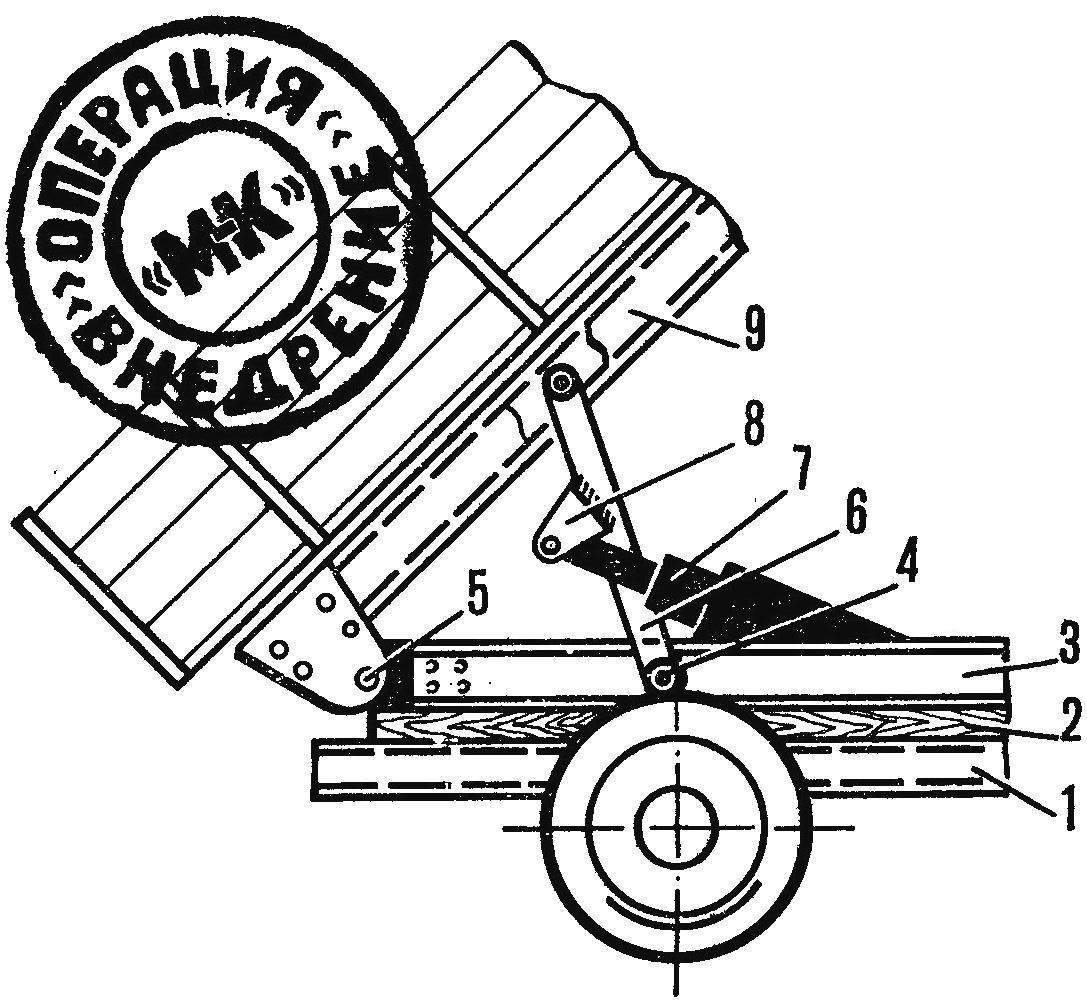

Local innovators decided to improve the stand and cause the tape to curl up without the use of manual labor — like the way she moves on the tractor. This stand was modernized and equipped with an additional mechanism for “rolling” caterpillar roll (Fig. 3).

Fig. 3. Conveyor belt for caterpillar:

1 — pusher, 2 — spontaniczny node, 3 — guides, 4, 11 clips, 5 — band, 6 — motor, 7 — reducer, 8 — chain 9 — sprocket, 10 — turn portion of the tape.

At the beginning of the stand, where the Assembly of the parts, mounted the pusher 1, which establishes the link exactly on the axis spirtovodnogo node 2. Before this operation often had to do with a crowbar and sledgehammer.

Between the rails 3 of the stand placed the 4 rollers that reduce the force required to move the tape on the stand. And feed her to the area of collapse is now with the drive sprocket 9 from the tractor driven by the electric motor through a reducer and chain transmission.

Work on the stand after the modernization has not only become easier — increased productivity. To make this mechanism because of its simplicity can be in any village workshop.

TRUMPET QUINTET. As at the time of the inalienable honor of the rural landscape of steel posts and wire, as now, domestic and industrial buildings in the villages is unthinkable without pipes. This water and gas supply, steam heating in homes, various slurry pipelines, karmapolice and milk on the farms, the irrigation systems on the fields, hydroponics in greenhouses — just to name a few.

It is therefore natural that rural innovators created a lot of different devices and tools to work with pipes. Here we present five of them.

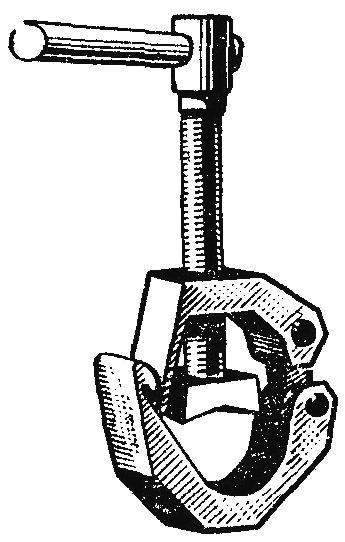

Where to connect pipes do not need welding or threaded elements, an indispensable tool can become just a simple installation swage (Fig. 4). It consists of a two-piece clamp, in making the joint, and a screw with a clamping plate. The swage is designed for Assembly of tubular components and systems of so-called respriatory method. It is designed for diameters from 15 to 50 mm.

Fig. 4. Mounting swage.

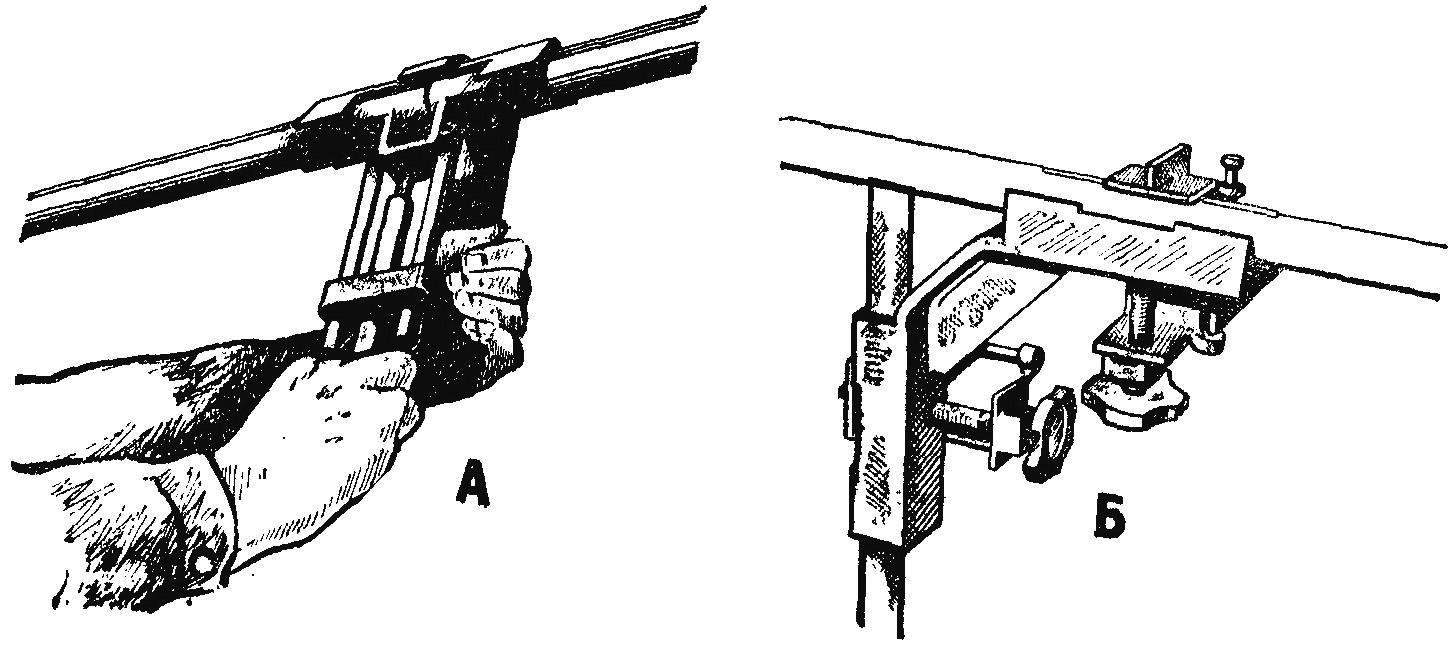

Fig. 5. Devices for joining pipes:

But — end connection; B — perpendicular.

Figure 5 shows two devices that facilitate the welded connection of the pipes And alignment of the abutting ends before welding, Used — to install them at the right angle. In both cases, fixation of the joint is achieved through the fixed and movable brackets; clamping is carried out with the screws.

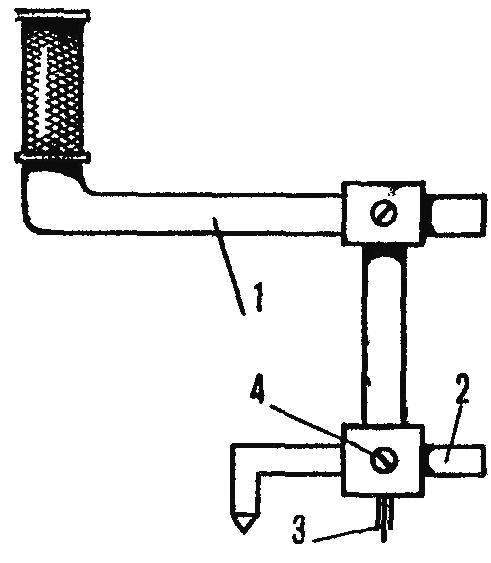

Sprinkler pipes are connected is usually a locking means and require a large number of rubber rings and gaskets at the joints. For their manufacture Isilkulsky district Association “Rosselhozbanka” apply the simple but effective “rotation” with a movable center (Fig. 6). Installing the rod 2 required radius, clamp it with the screw 4 and rests with a sharp leg fit in a rubber billet. One turn of the handle 1 and the two-edged knife 3, fixed in a special holder, cut a circle, then the ring itself-gasket.

Fig. 6. Brace for rubber:

1 — rotary lever with handle, 2 — guide rod, 3 clip blade, 4 — screw of the slider.

Fig. 7. Brush-machine.

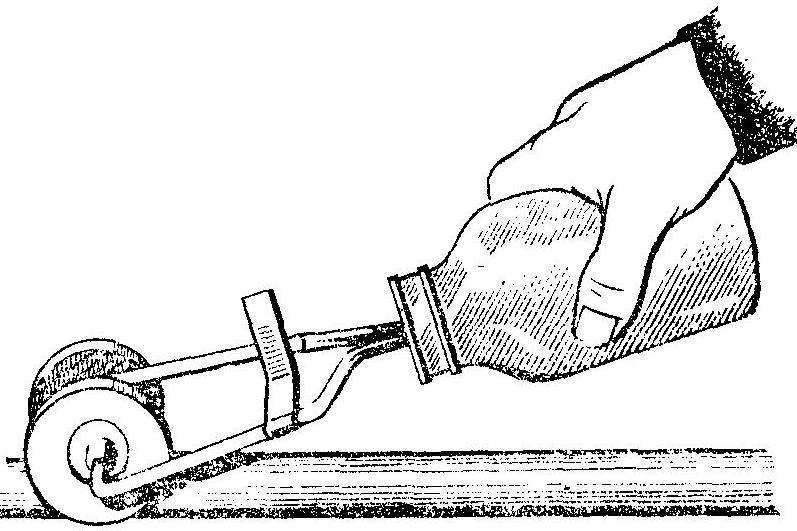

However, there is little to connect the pipes — it is necessary also to protect them from rust. And it is no less time-consuming work. Faster and easier it will allow the original roller brush (Fig. 7), connected the feeding tube with a balloon that performs the role of the handle. Spray paint fed through a tube in foam or fur cushion.

The work will be especially productive if you have a set of replacement rollers corresponding to the profile of the treated surface.

A. KISELEV