About ten years ago I read in “M-To” article that described the design of the spear gun. Decided using the same principle — a spring as a battery, to make the gun more simple, easy, and good combat. Numerous experiments and fine-tuning have produced the desired result.

About ten years ago I read in “M-To” article that described the design of the spear gun. Decided using the same principle — a spring as a battery, to make the gun more simple, easy, and good combat. Numerous experiments and fine-tuning have produced the desired result.

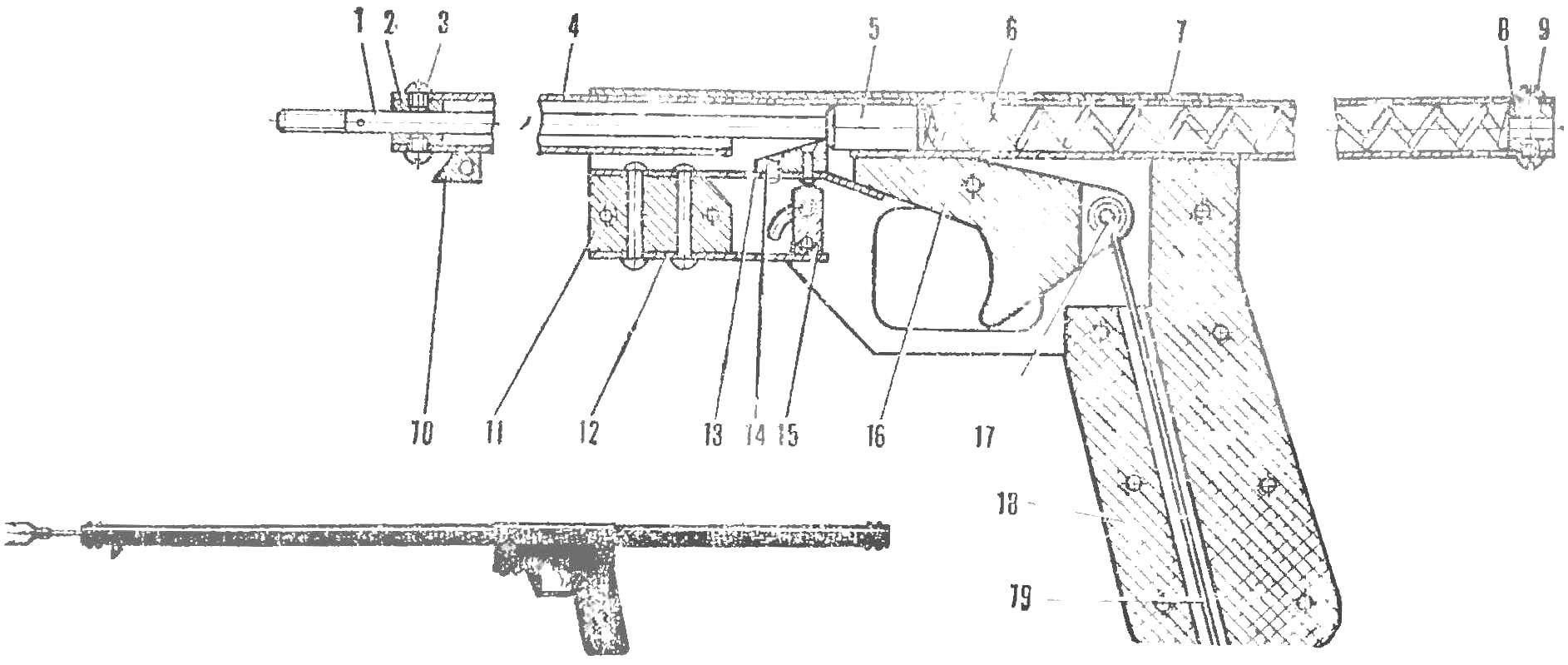

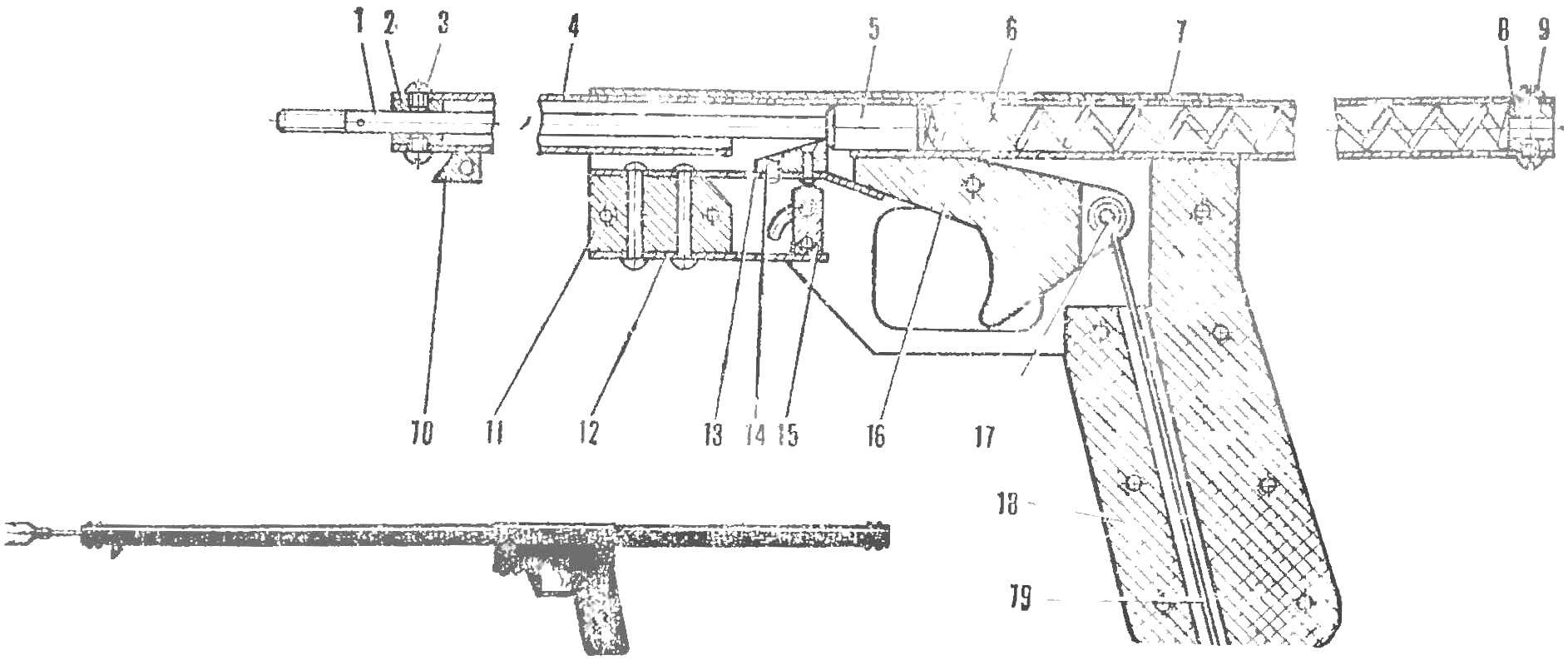

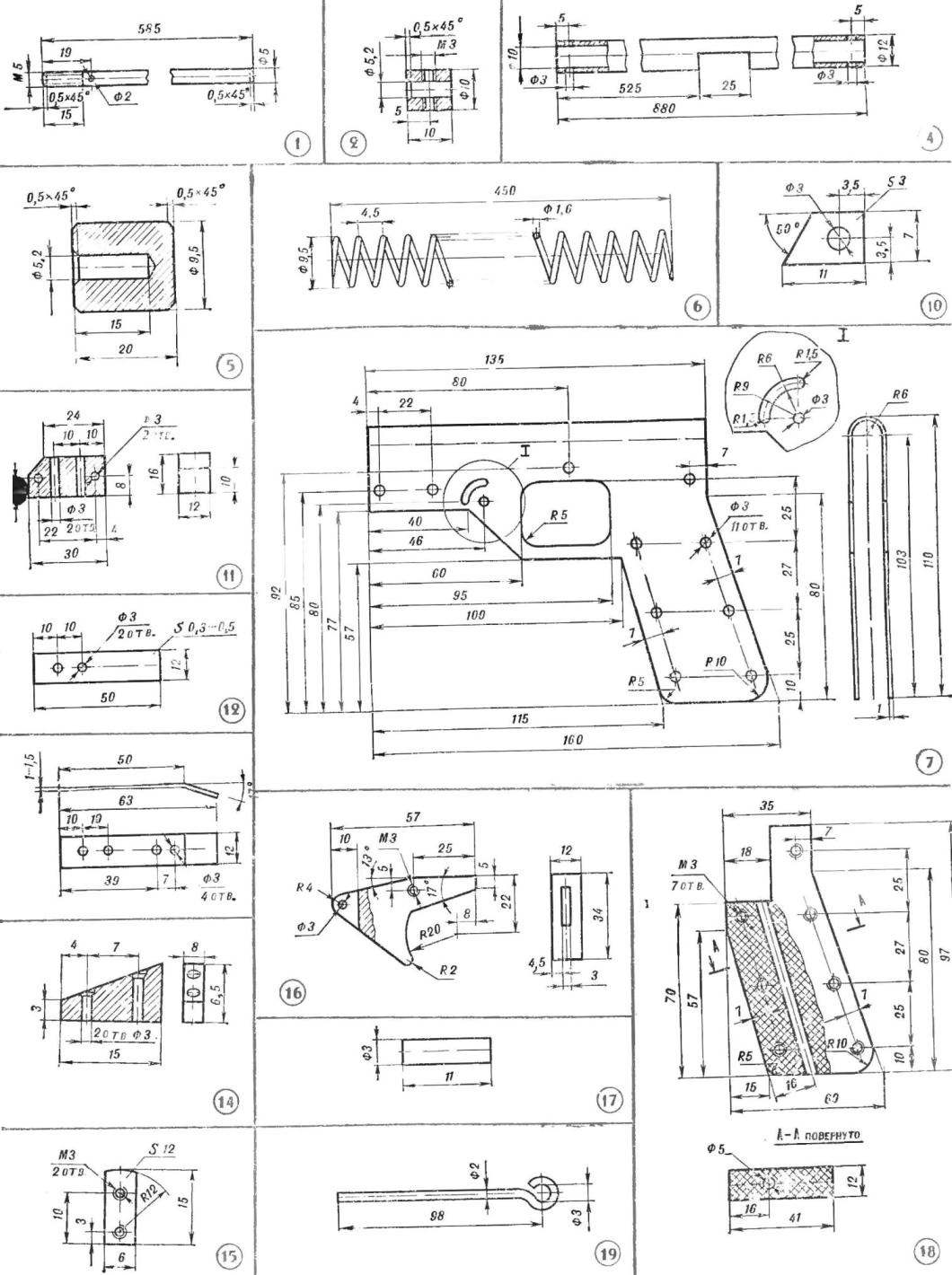

The figure shows a section of a spring crossbow.

The HARPOON consists of a steel rod Ø 5 mm (“silver”). On one of its ends threaded M5 and drilled a hole for Lin. After machining the harpoon quenched. Sleeve — bearing harpoon — machined from stainless steel or aluminum.

The BARREL is a tube 12X1 mm Material — brass or stainless steel. For the free passage of water at a shot or charge across the surface of the trunk nastelivaetsya hole Ø 4-5 mm in increments of about 10 mm. Piston is machined from stainless steel or aluminum.

Fig. 1. Spring-loaded spear gun:

1 — harpoon, 2 — sleeve, 3 — M3 screw, 4 — barrel, 5 — piston 6 — spring, 7 — holder, 8 — Bush 9 — screw M3, 10 — hook 11 — insert, 12 — spring fuse, 13 — spring, sear and 14 sear, 15 — fuse 16 — trigger, 17 — axis thrust winding Lin, 18 pen, 19 — pull winding Lin

By the way, and sleeve, and the piston can be made from segments of tubes 10X2,5 mm, which will completely eliminate the lathe work in the manufacture of guns.

The action SPRING is wound from wire grade optical fiber Ø mm. 1,6 Initially for rod Ø 6 mm turn to turn the circumferential wire, which is then stretched until the desired step is 4.5 mm. To the processing of the spring was not residual deformations, the wire must be let go, that is heated to about 300° and allow to cool to room temperature. End turns having heated red hot, it is necessary to bend in such a way that their plane was perpendicular to the axis of the spring.

The CLIP is cut from sheet brass or stainless steel with a thickness of 1 mm. Openings on its lateral surfaces, it is desirable to saw placing the plank of suitable size after the workpiece is bent. This will avoid errors in the location of the holes on the right and left cheeks of the cage. During Assembly the clip is brazed to the barrel, focusing on the position of the slot.

The HOOK is designed to reel in his harpoon line. He sawed out of brass or stainless steel and is soldered to the end of the barrel.

LINER textolite, it is designed for mounting flat return springs. Liner priklepyvayut to the clip, spring also priklepyvayut to the liner. Rivet is desirable to use steel, in a pinch you can use ordinary nails.

SPRING GUARD is designed to fix the fuse in two stable positions. Material is steel tape thickness of 0.5 mm 65G or U10A. Attach the springs to the cage may be better with screws or rivets.

CRAVING for winding Lin is a piece of steel wire with a thickness of 2 mm. One of its ends bent into a ring, which is attached to a pull of the trigger.

A. RAKHMATULIN