There was a time when a cracked handle of radio, split arm shift lever of the car has forced me to look for a replacement in the stores, and, frankly, often unsuccessfully. I tried to carve them out of various plastics or metal, but this was laborious and time consuming. In addition, not always possible to bring the home up to full compliance with the lost original.

There was a time when a cracked handle of radio, split arm shift lever of the car has forced me to look for a replacement in the stores, and, frankly, often unsuccessfully. I tried to carve them out of various plastics or metal, but this was laborious and time consuming. In addition, not always possible to bring the home up to full compliance with the lost original.

The search for an appropriate method of recovery of a variety of plastic parts eventually led me to the idea to use for “that purpose epoxy resin. It was the perfect source material: “cast” almost every part of it is not a difficulty. The best shape-forming material was a conventional plaster.

When making forms, I adhered to the following technology. For a start I picked up a box of metal or plastic — most often it was a bar of soap. Then they filled it (pre-grease the inside surface with a thin layer of technical vaseline) to half plaster of Paris and was immersed in it until about half naselennyu detail, which was backed up. Without waiting for complete curing of the plaster on its surface a thin metal blade was doing two or three wells.

After the final setting of the plaster the surface again smeared with vaseline and poured a new batch of plaster that completely covers the item sample. Before the last fill put in the form of a plastic insert forming the sprues and vapory.

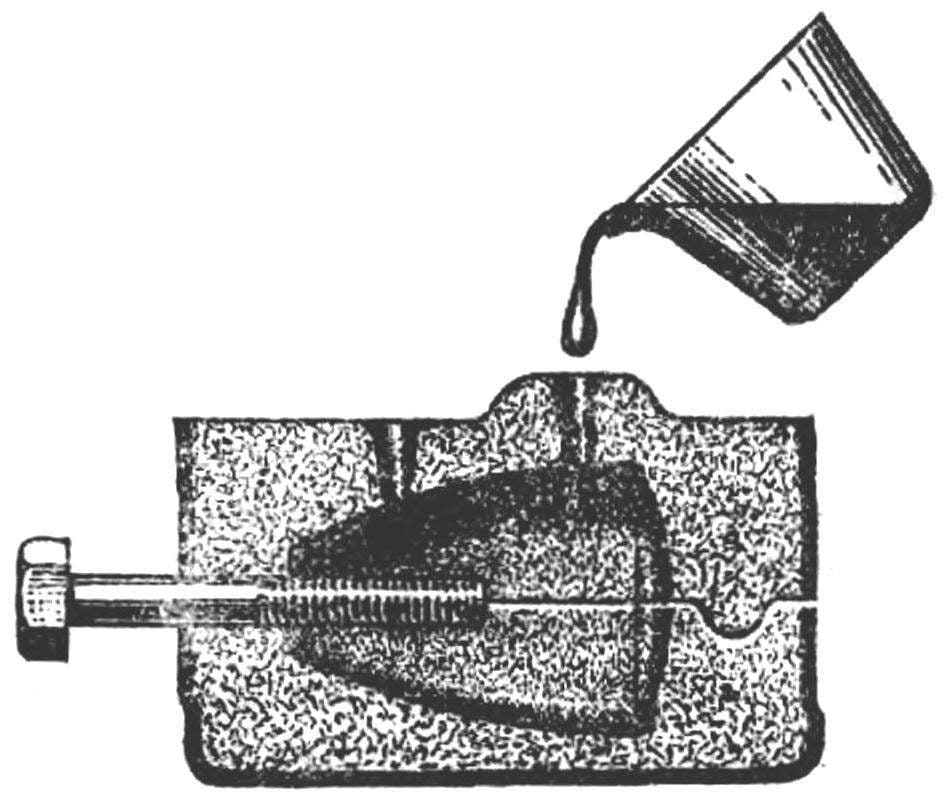

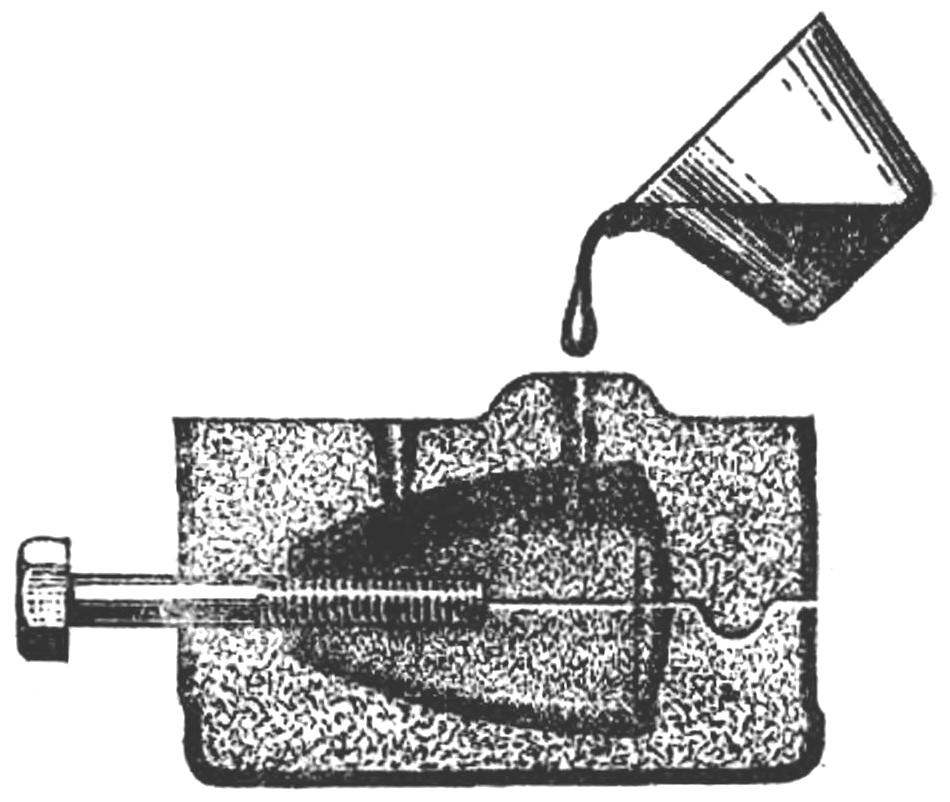

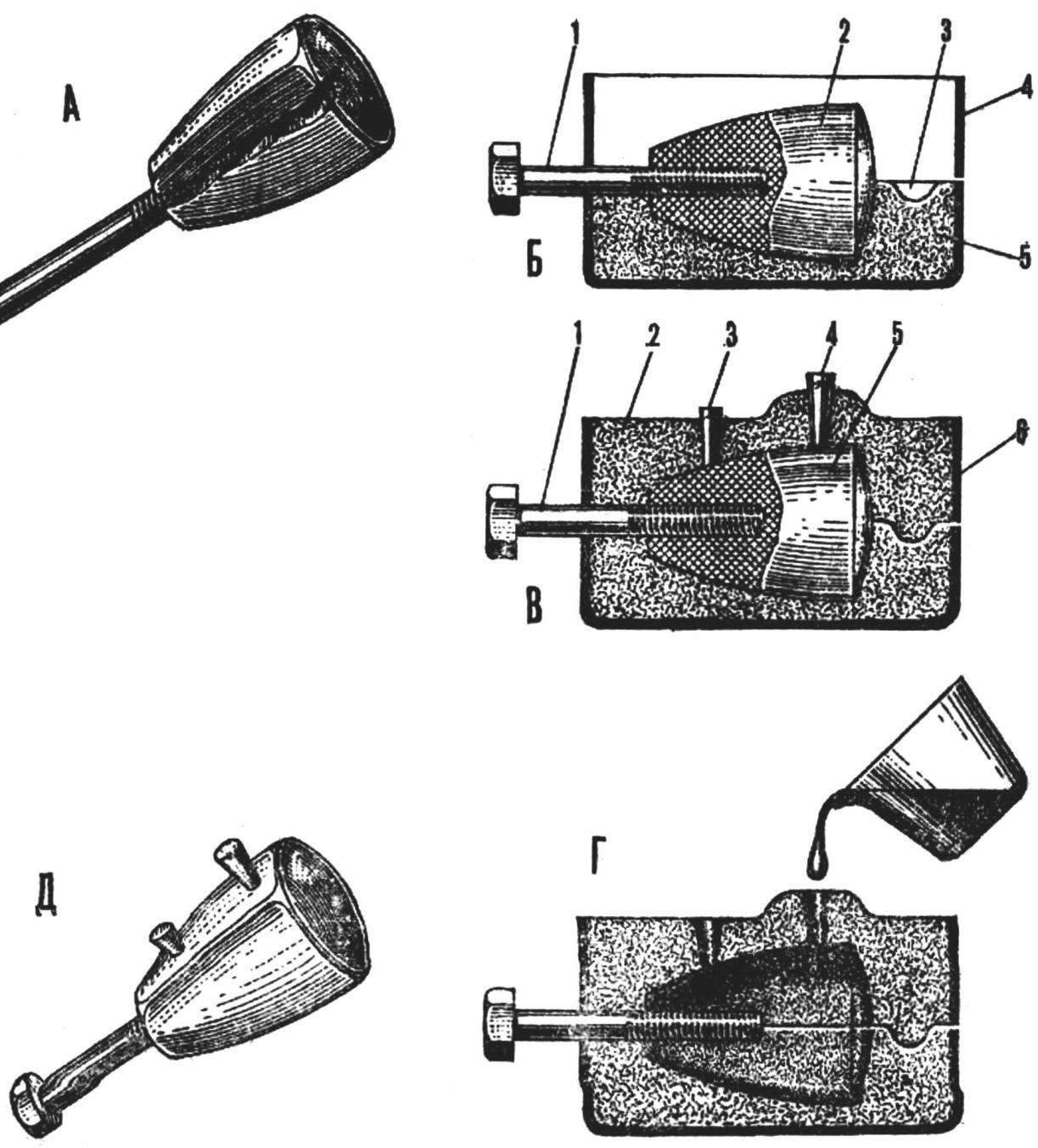

Fig. 1. Manufacturer of epoxy resin lever to change gear.

And a cracked arm.

B — fabrication of the lower mold halves: 1 — bolt, 2 — arm-standard, 3 — hole latch, 4 — box, 5 — gypsum.

In the fabrication of the upper mold halves: 1 — bolt, 2 — gypsum, 3 — insertion, heaving, 4 — panel below gate, 5 — arm-standard, 6 — box.

G — fill epoxy resin into the form.

D — ready “casting”.