For many years, I have been mounting my amateur radio homemade devices in universal cases made according to a single scheme. This is a frameless construction consisting of two U-shaped parts: a base and a cover. They are made from sheet steel of the required thickness (usually from 0.3 to 1 mm), which when connected form a closed volume. The cases are light and strong enough. Their sizes can vary from a matchbox to the dimensions of a refrigerator.

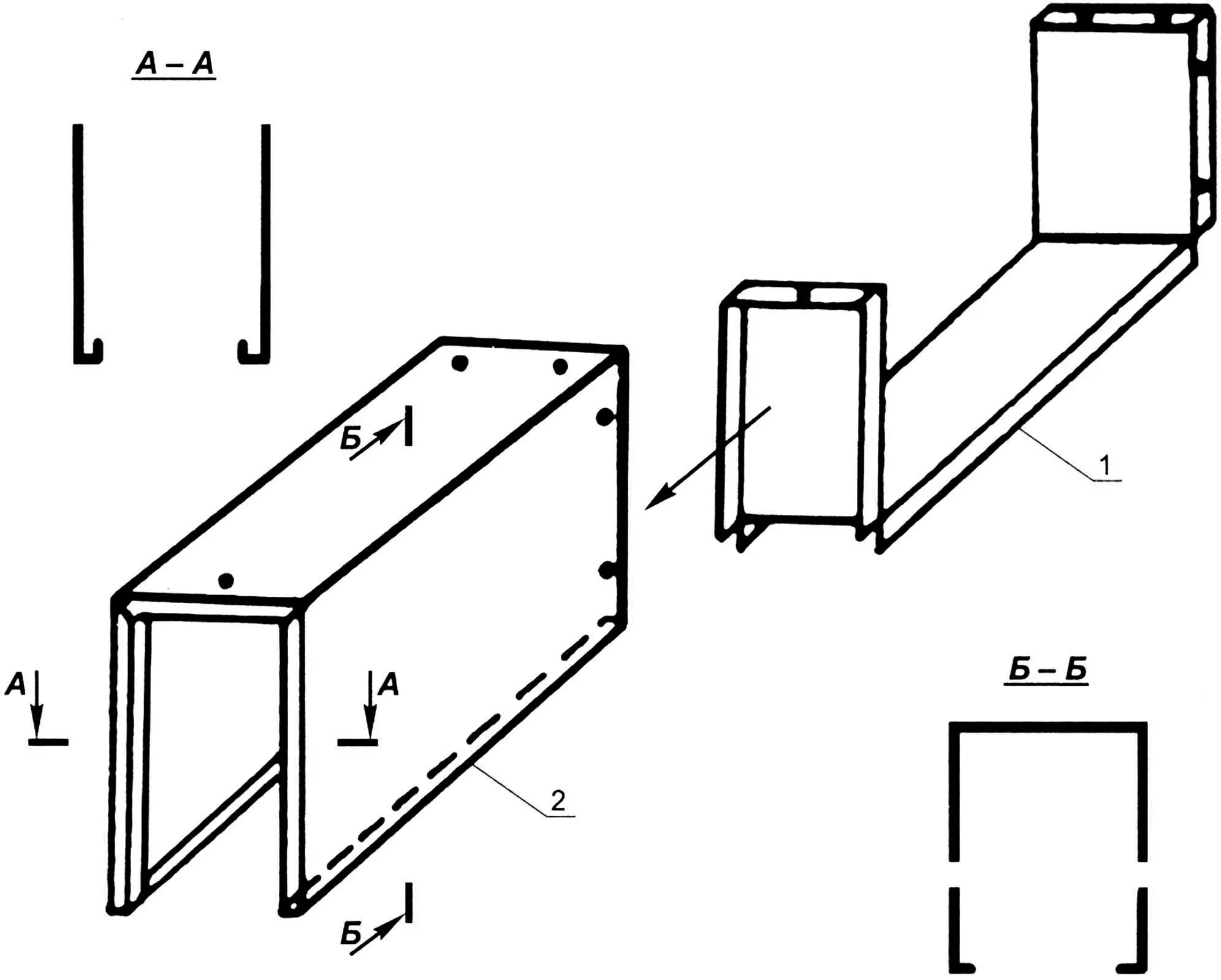

Universal case:

1 – base; 2 – cover

The process of creating a case begins with drawing the corresponding development on a sheet of paper, which is then transferred to metal. The marked blank is cut along the contour, all necessary holes are made, then – bending and flanging.

Various options are acceptable for connecting the base and cover: using angles or with flanges. To make the front panel look “professional”, the front edge of the cover should be flanged inward. And the carrying handle should be attached not at the geometric center of the cover, but at a place that will be convenient when carrying the device, taking into account its weight distribution. After a test assembly, the cover and base are painted with hammer or colored enamel.

«Modelist-Konstruktor» No. 4’2025, Alexander SHIMANAEV