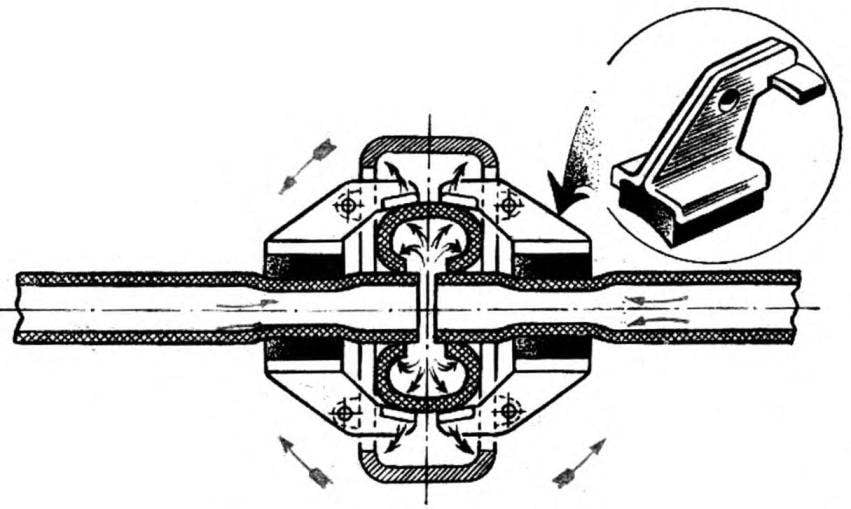

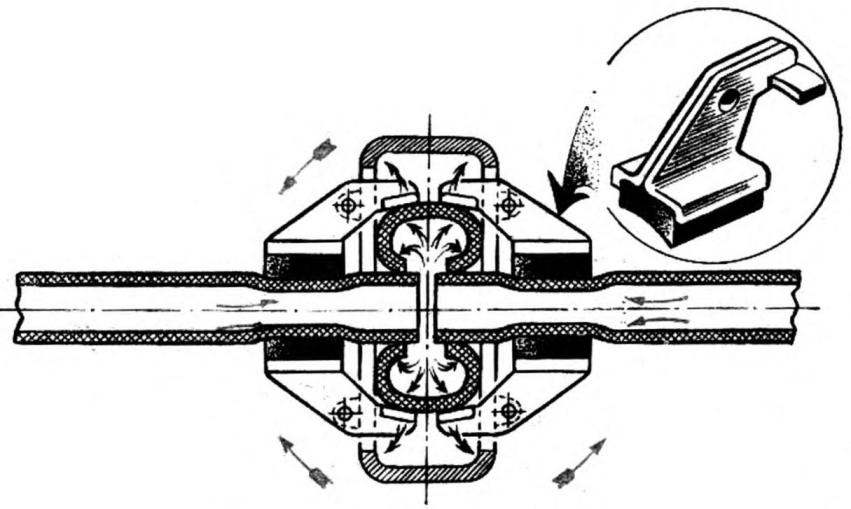

Like it or get a hose clamp or wire the ends of pneumology, no one can guarantee the strength of the connection: the internal air pressure will do the trick. And if force this pressure to use to secure the hoses to each other? This idea I have embodied in a specific construction of the clutch. It is based on the building, reminiscent of a car tire (made, of course, of metal). In the case of slotted radial grooves into which is inserted four levers. Inside the case is another “car tire” — this time from elastic rubber.

Like it or get a hose clamp or wire the ends of pneumology, no one can guarantee the strength of the connection: the internal air pressure will do the trick. And if force this pressure to use to secure the hoses to each other? This idea I have embodied in a specific construction of the clutch. It is based on the building, reminiscent of a car tire (made, of course, of metal). In the case of slotted radial grooves into which is inserted four levers. Inside the case is another “car tire” — this time from elastic rubber.

The clutch works well.

Two hoses into it on each side in those holes, and the system serves pressure. Elastic tire, swelling, first, tightly compresses the hose ends and, secondly, pushing on the levers, the opposite ends of which compress the tubing, preventing them from slipping from the clutch. When removing pressure hoses can be removed. I hope that my proposed coupler will be used on the plants where you need to quickly and securely connect the hoses to connect to the main line of pneumatic tools.

N. TATARINOV, Chelyabinsk oblast