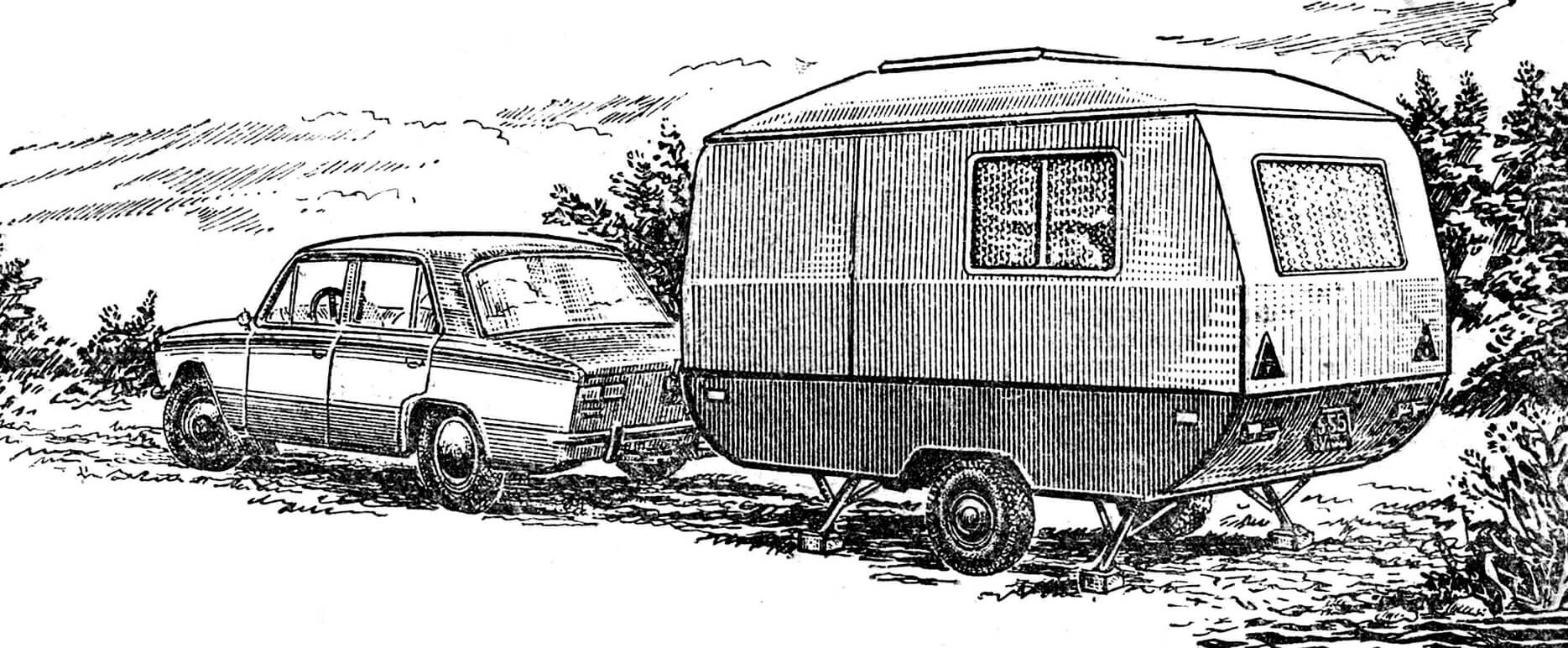

M-K has repeatedly published descriptions of car trailers. And industry produces them, for example, “Skif”. However, I decided to build it to my own taste. And since then, the traveling dacha has been reliably serving my family for many years. All its components turned out to be quite durable and efficient, and the interior provides comfort for four people.

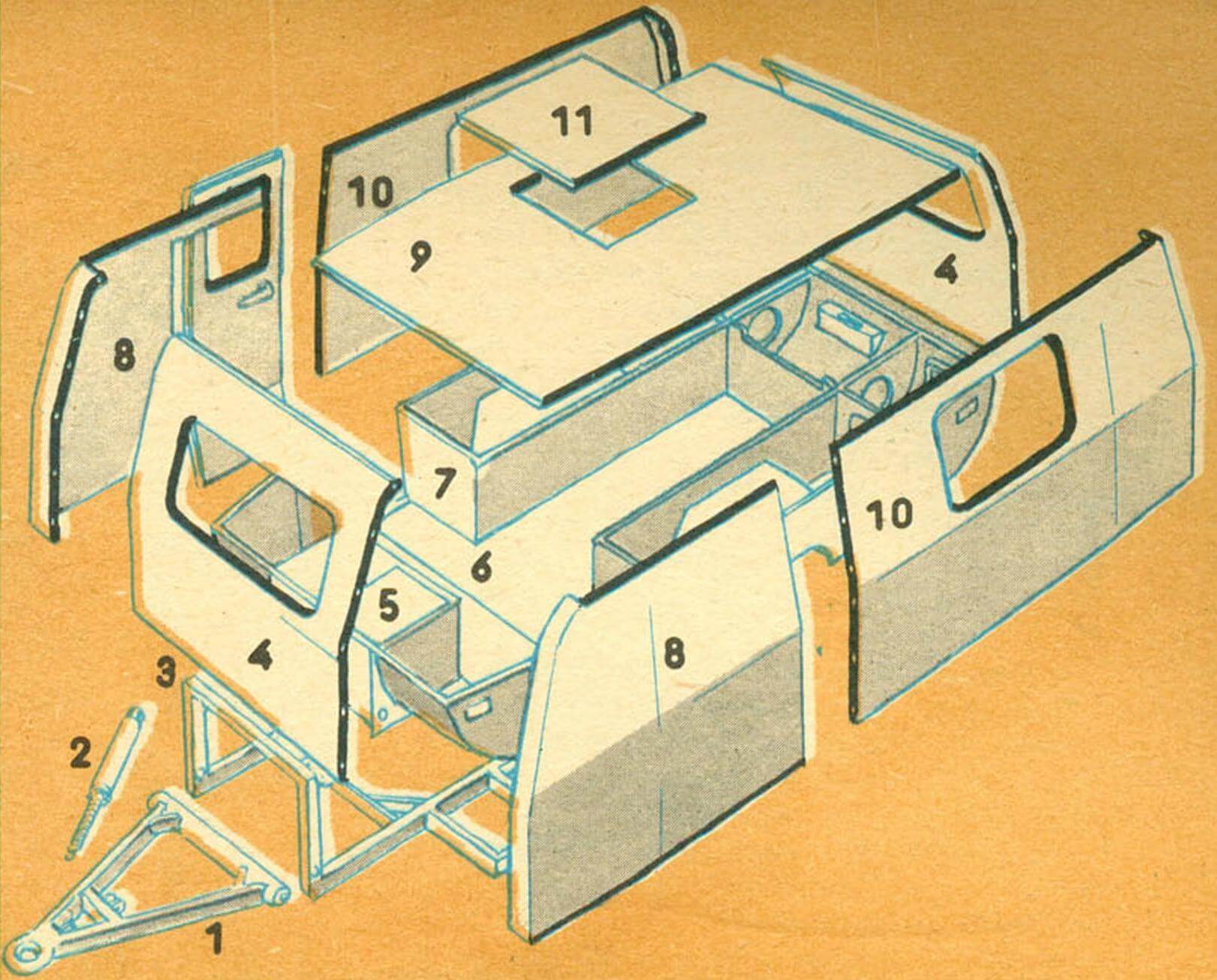

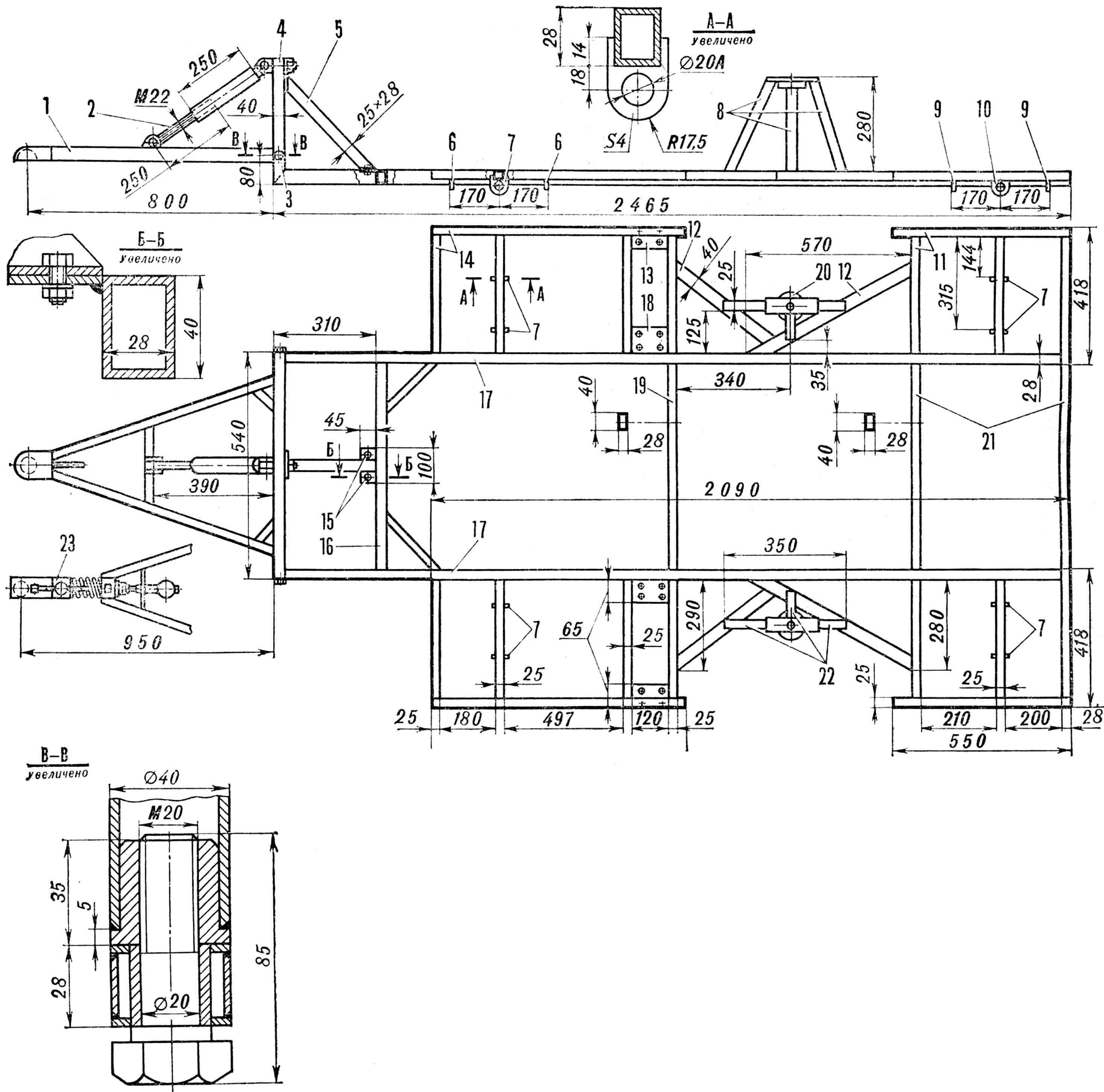

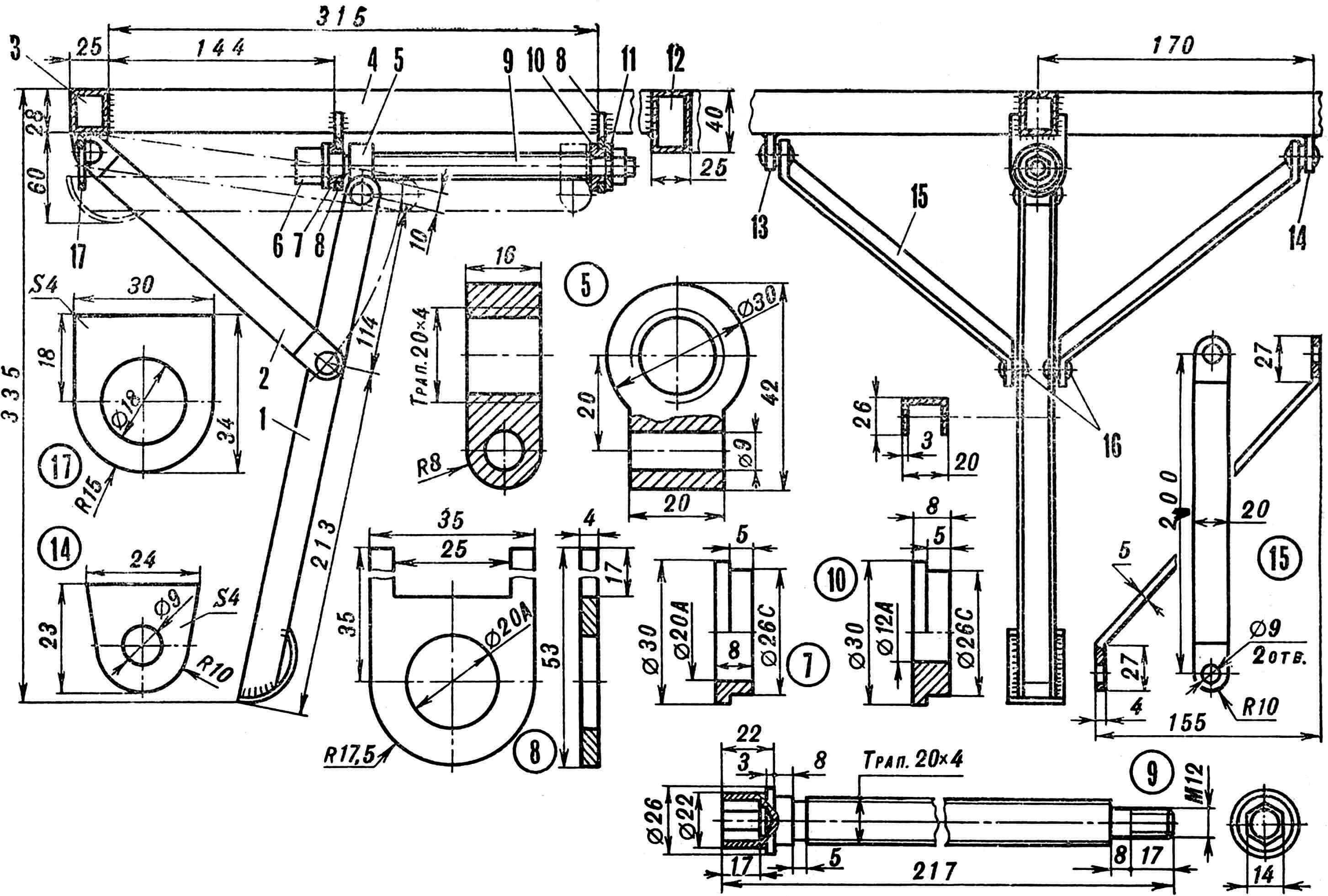

The trailer—I called it “Lada-V”—is dismountable and mounted on a steel frame, the main load-bearing element. To connect to the vehicle, a triangular drawbar is used, fastened to the frame with two M20X85 bolts and an adjustable rod. The latter allows you to insert the Lada-V frame horizontally or raise its rear part when driving on uneven roads.

The base of the body is fixed to the frame with M6X12 bolts. In its front part there is a sealed section for two five-liter gas cylinders. Access to them is through the seat (section cover).

The front and rear walls with windows are attached to the base with M6X12 bolts. Small side panels are attached to the first, large ones to the second.

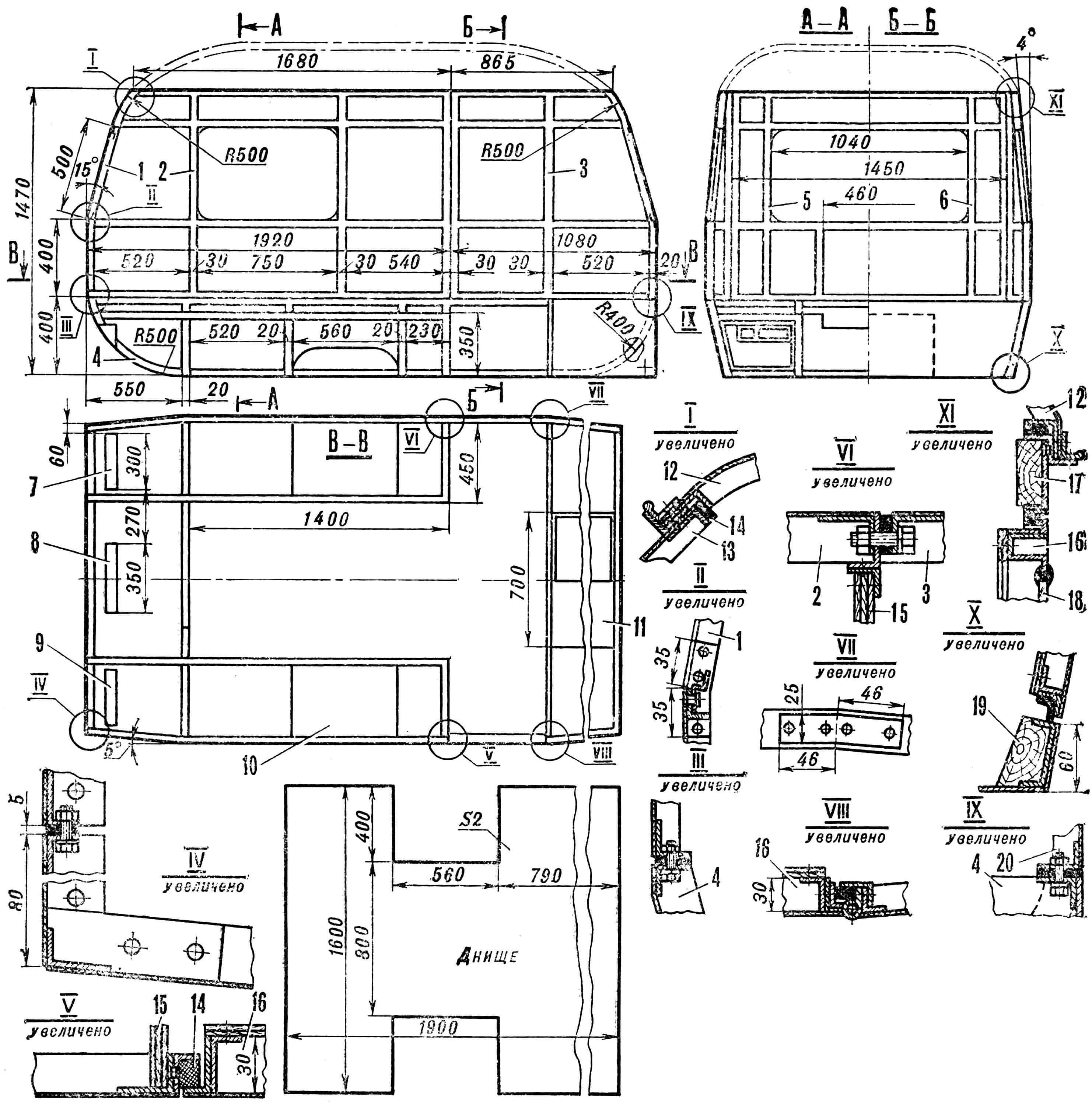

The body base is solid-riveted, with a flat bottom and openings for the wheel arches. Attached to it are transverse and longitudinal partitions, reinforced with 30X18 mm aluminum corners and connected with rivet seams to the outer panels.

The contours of the front and rear parts of the body are made of sheet duralumin, reinforced with curved corners. At the rear there are knockouts for the sidelights and the state license plate.

The windows in the trailer are car windows, with standard frames, glass and seals.

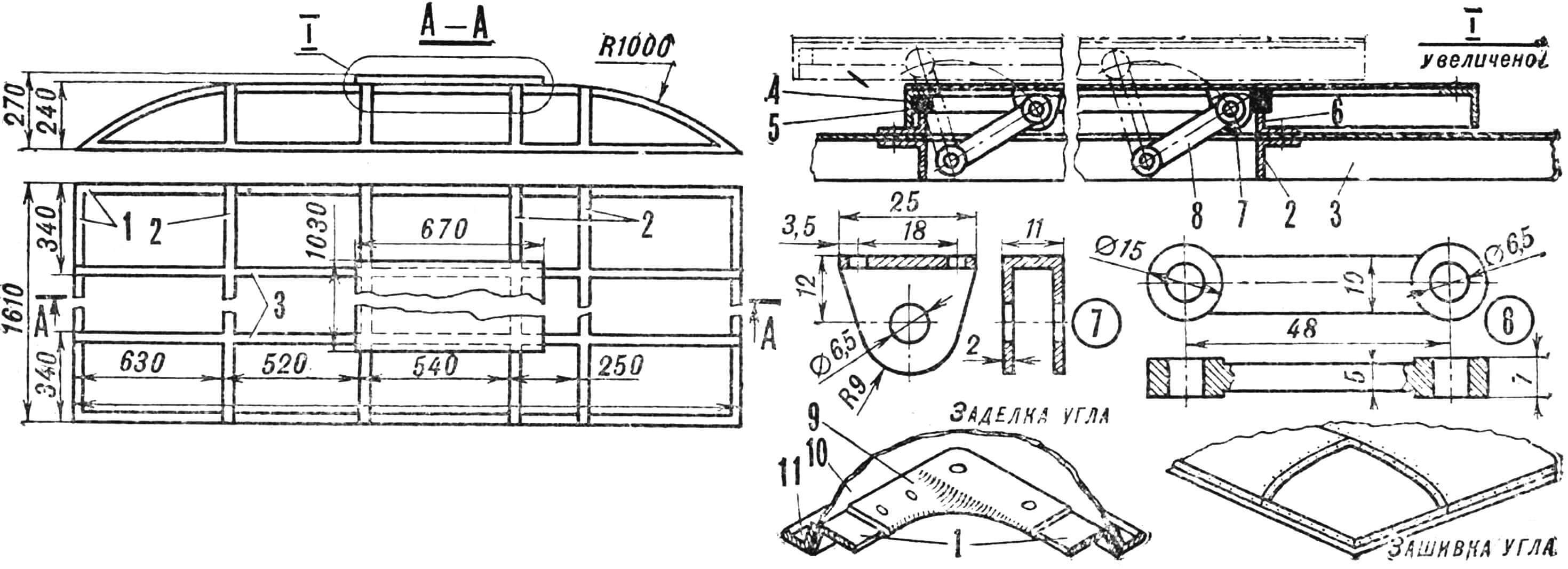

Roof structure. The longitudinal, rear and juice frames are assembled in the same way as the base. The casing is made of sheet duralumin riveted with corners. First, the frame was assembled, on which the longitudinal and transverse frames were fixed with rivets. The corners of the strapping are reinforced with rigid pads. Particular care should be taken when cutting the sheathing in the corners of the roof: here the rectilinear trim elements are connected to frames of various curvatures. After attaching the aluminum sheet to the frame, no additional stamping of the corners was required.

To discharge water from the roof, grooves are provided along the contour. There is an opening in the middle of the roof for a ventilation hatch. Its lid rises on four rockers.

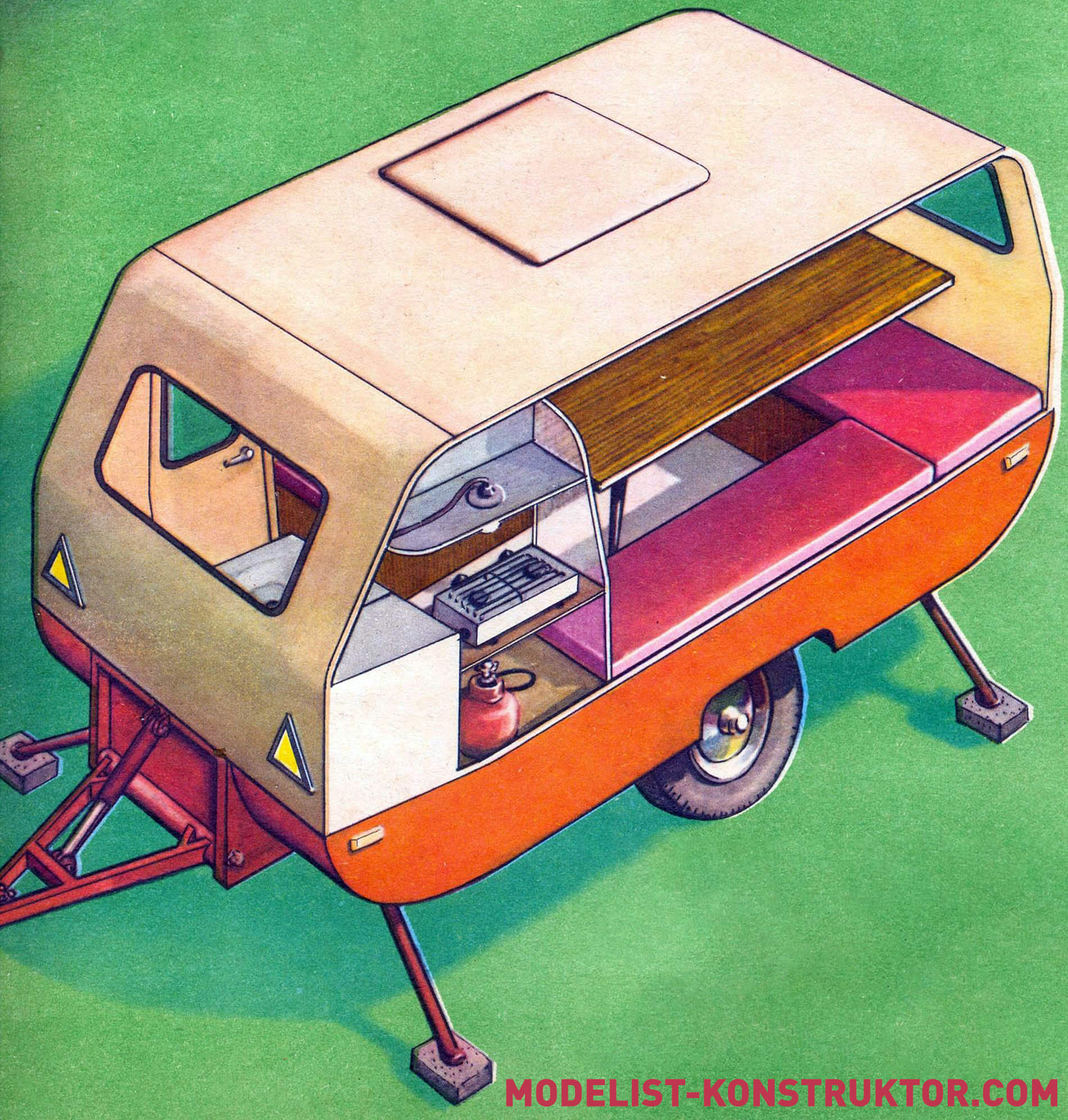

All body panels are filled with 18 mm thick foam sheets. They were covered with paper and covered with light gray plastic. The partitions under the sofas, the kitchen block, the hanging shelf and the plywood partitions are finished with a synthetic film to imitate wood.

The backs and seats of the sofas are made of seven-millimeter plywood and sheet foam rubber 40 mm thick. The top is covered with decorative fabric. The salon is equipped with lampshades powered by the car battery. To use the cargo compartments located under the side sofas, the table in the salon can be raised on hinges, with which it is attached to the rear wall. The table stand fits into a niche on its lower plane.

The trailer interior is divided into two functional areas: recreation and household. The first is equipped with a table, which can be removed for the night and placed between the side sofas. It turns out to be a kind of ottoman. In front, in the living area, another sleeping place for a child can be equipped.

The limited area of the cabin dictated the placement of the kitchen unit – compact, but at the same time convenient. We even managed to place a sink (polyethylene container 450X450X150 mm).

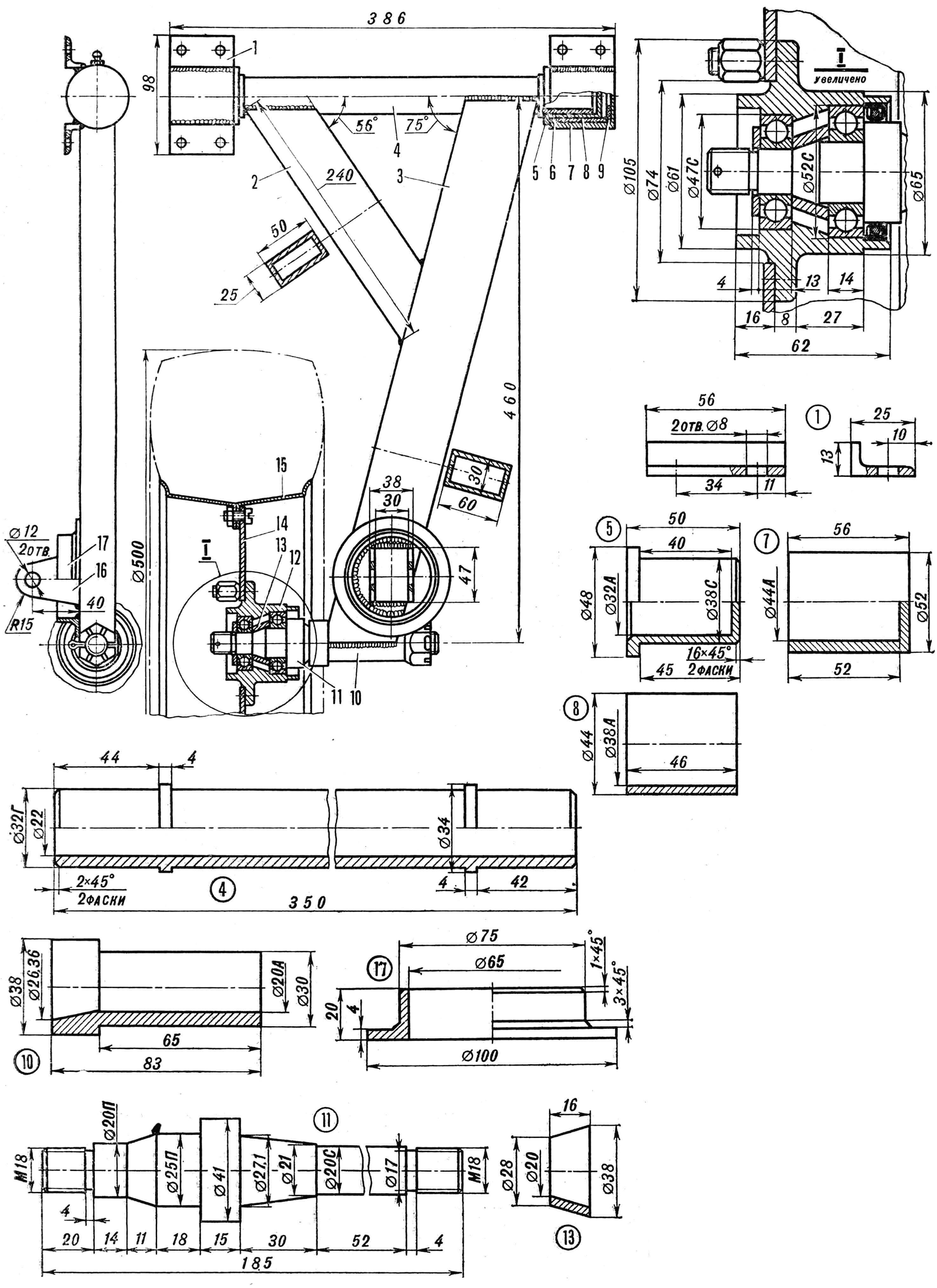

The main load-bearing element of the trailer – the frame – is welded in a slipway with clamps to prevent residual thermal deformations.

Its main part is a power rectangle made of steel pipes with a cross-section of 40×28 mm: two spars and four cross members. A U-shaped front end is welded to it in front, to which a drawbar, an adjustable rod and a front strut are screwed, and on the sides there are elements of the front and rear trim (longitudinal and transverse pipes 28X-5 mm), intended for attaching parking jacks. Between the frames, on the rear struts made of steel pipes with a cross-section of 40X28 mm, there are tripods (pipes 28X25 mm) with brackets (eyes) for shock absorbers and support rings for the wheel suspension springs.

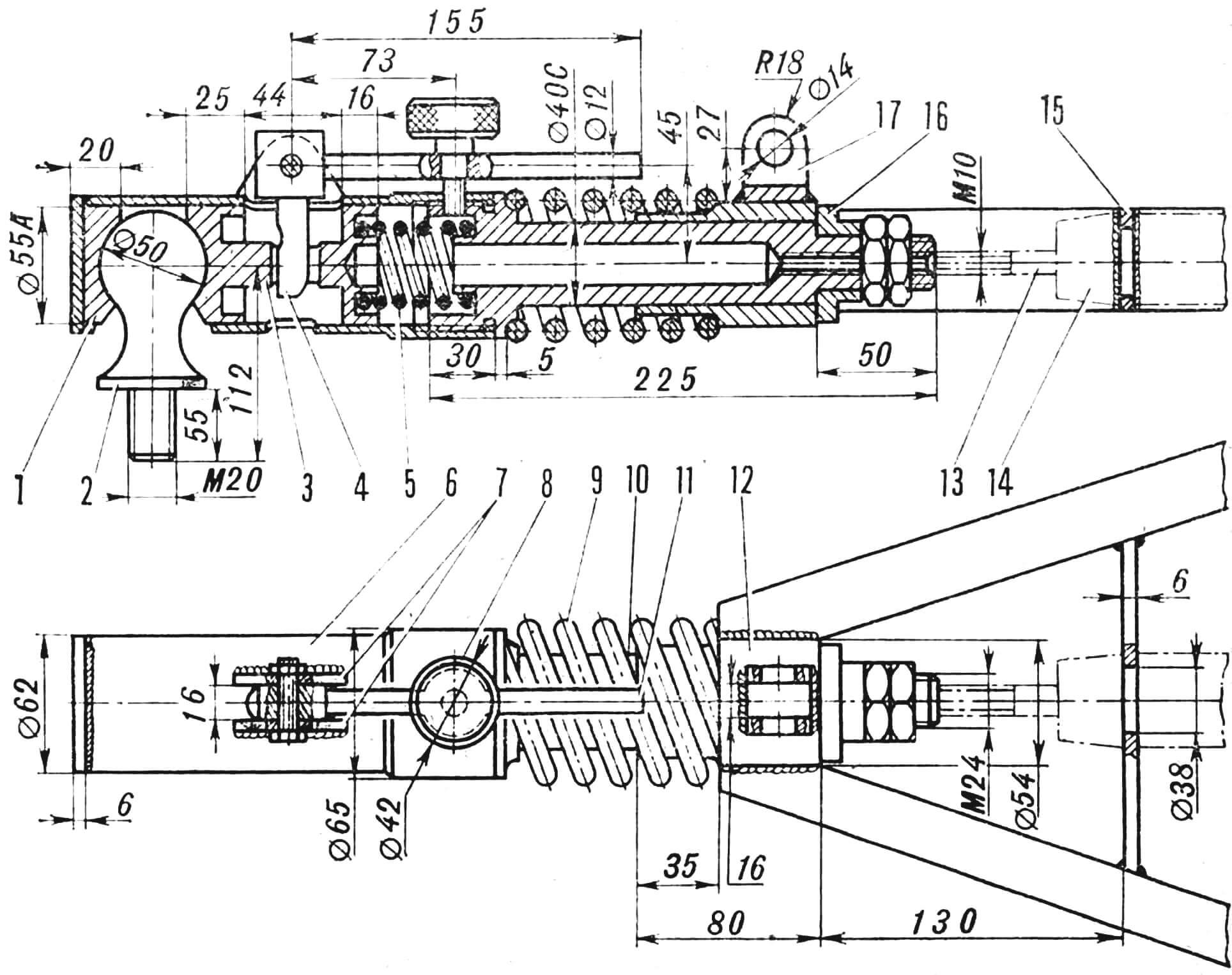

To connect the trailer to the car, at first I used the Skif coupling mechanism, but then replaced it, in my opinion, with a more advanced, homemade one, which allows me to create a braking force in the wheels proportional to the weight of the trailer and its speed. This drawbar is a movable spring-loaded unit. At the front it has a body with front fixed and rear movable stops with a spherical surface for the hitch ball pin. The back stop is pressed by an internal spring and held by a hook secured to the body with a screw. A cylindrical slider is also connected to the same body, at one end of which there is an external thread M60X2, at the other – an internal thread M10. The slider moves inside the damper housing, pressed by an external spring. A rod is screwed into the internal thread of the slider, connecting to the main brake cylinder from the Moskvich car, mounted on the drawbar bar.

The braking force of a trailer’s wheels depends on its weight and travel speed. The larger they are, the more the damping spring is compressed, and the rod presses on the cylinder. Hence the braking force.

The wheels are from a C3A motorized stroller. The rims come from it, connected to the hub with steel discs Ø 230 mm. The wheel suspension is pendulum, with front suspension shock absorbers from the S3A stroller and springs from the ZAZ-968 car. The wheel on the axle shaft rotates at the end of a V-shaped pendulum, welded from two struts, which, in turn, are welded to a crossbeam suspended in sliding bearings to the supporting platforms of the trailer frame.

On the large strut, near the axle sleeve, there is a support ring for the suspension spring and a shock absorber mounting bracket. The response units are on the trailer frame, on tripods.

When parked, the trailer can be detached from the vehicle. To give it stability and a horizontal position, jacks are provided. There are four of them – two on each side. They are moved from the marching position to the parking position with a special key, similar to a crank. At the end of the wrench there is a hexagonal end, which is threaded into the lifting eye of the jack and inserted into the head of its lead screw. By rotating counterclockwise, the paw is lowered all the way into the ground.

The outside of the Lada-V is painted as follows: the top is light, the bottom is dark to match the color of the car. The bottom of the trailer is covered with a 5 mm thick fiberboard sheet and covered with enamel.

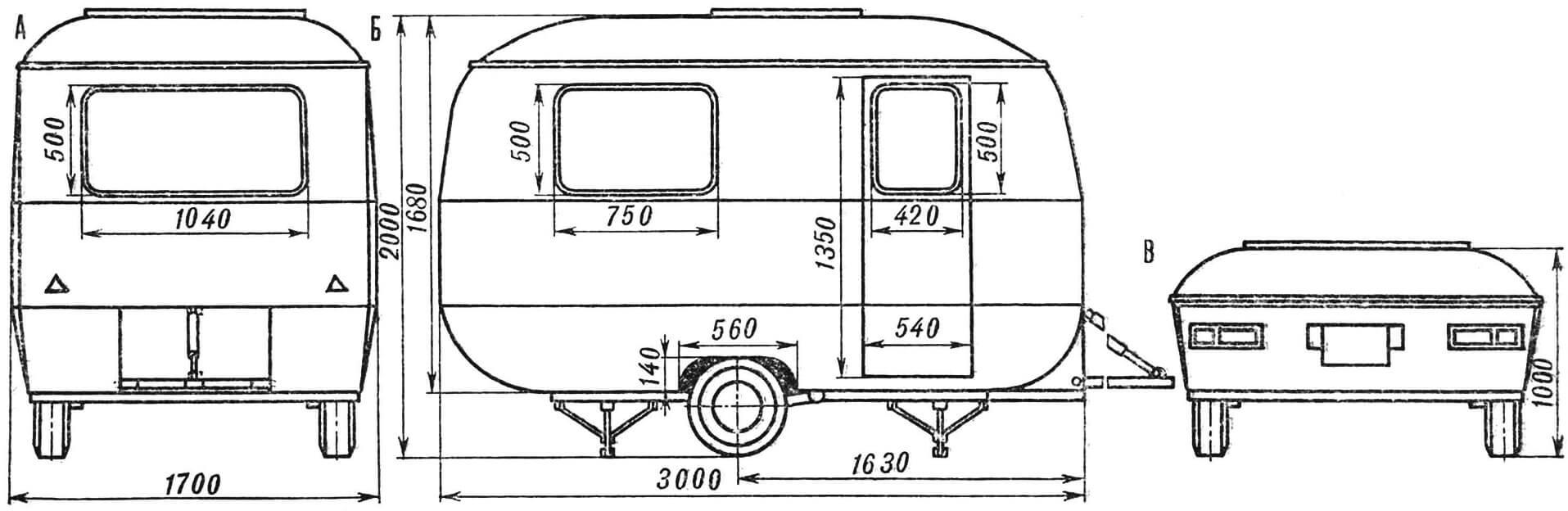

TECHNICAL CHARACTERISTICS OF “LADA-V”

Length with drawbar, mm — 3850

Width, mm — 1700

Height, mm – 2000

Interior height, mm — 1680

Weight, kgf – 200

Load capacity, kgf – 200

“Lada-V” is equipped with electrical appliances from the “Zhiguli” VAZ-2101 (rear lights). There are two white triangular reflectors installed on the front wall, and red ones on the back wall.

The trailer is stable in movement and maneuvering, and is quite aerodynamically streamlined. This can be judged by fuel consumption – no more than 10 liters per 100 km. You can also transport a caravan trailer in packaged form, if it is not currently intended for housing. The time to pack and prepare for movement in this form does not exceed two hours.

A. VASILIEV, Vitebsk