With the help of electric iron, you can quickly and safely fix Velocimetry, warmers, Pasika recorders, inflatable toys, etc. m by putting patches and connecting them vulcanized. The connection is so strong that when you try to separate the rubber patch will not break at the bonding, and in a new place.

With the help of electric iron, you can quickly and safely fix Velocimetry, warmers, Pasika recorders, inflatable toys, etc. m by putting patches and connecting them vulcanized. The connection is so strong that when you try to separate the rubber patch will not break at the bonding, and in a new place.

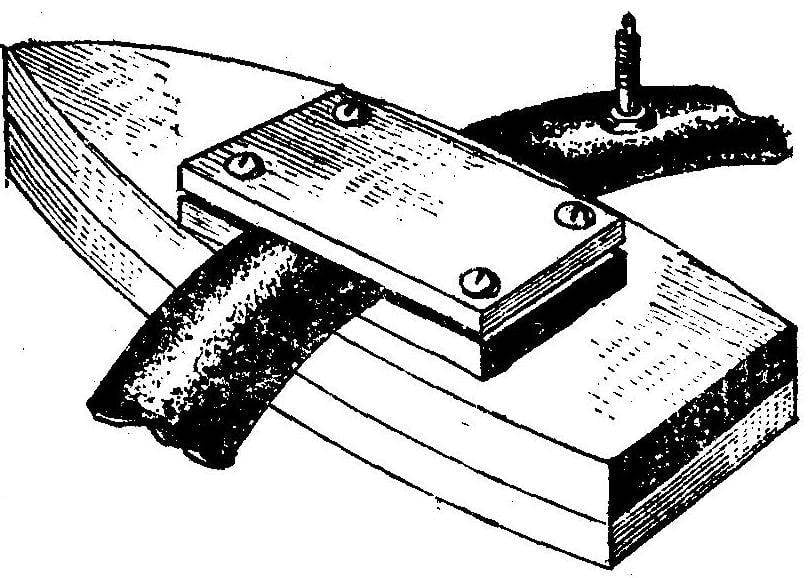

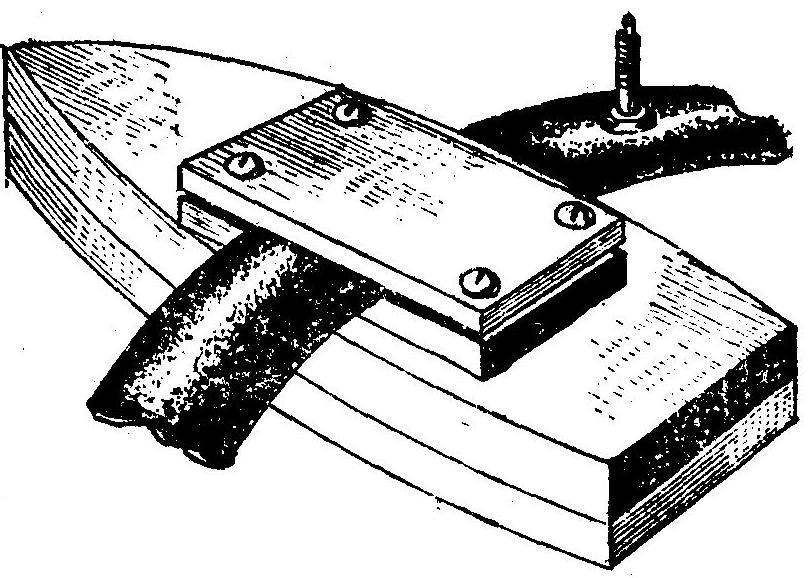

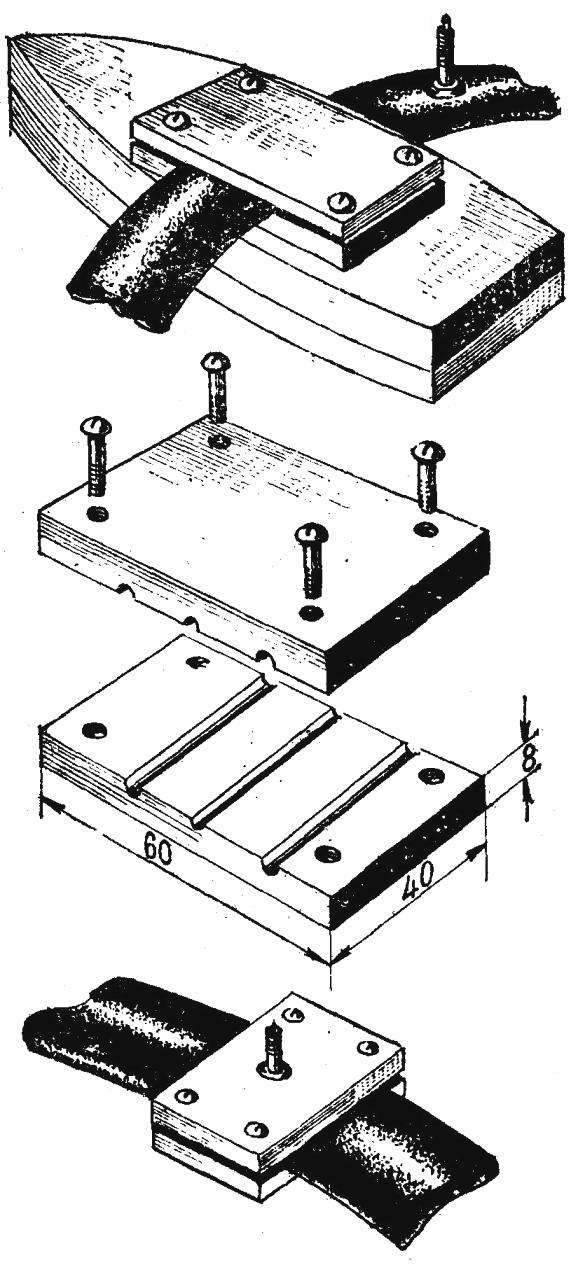

For work, in addition to break up (raw) rubber from weloveourdick, you need a simple mold, which is made of two steel plates with a thickness of 6-8 mm and size of 40 X60 mm. At the corners, drill four holes and cut thread M4 for tightening halves with screws. The inner edges of the plates slightly worn down that the edges don’t hit the rubber. In the case of complex configuration of the repaired parts plates attach the appropriate form or make additional holes and grooves.

Before starting, thoroughly cleaning the treated location (region pasikov is cut at an angle of 45°) and degreased with light petrol (B-70). Then to the repair place put a patch, the desired size of the raw rubber, put in a mold and firmly tightening the screws. Put on a heated iron so that the entire plane of the lower half of the mold concerned heating surface, provide exposure for 10-15 min. During operation, ensure that the rubber does not touch hot parts of the iron.

Grooves for bonding pasikov drill when tightened the halves of the mold, and the drill diameter should equal the diameter Pasika. In one mold, drill several holes for different diameters pasikov, however, the distance between them should be not less than the thickness of the workpiece. Otherwise, heating of splices will be uneven and the quality of curing will be impaired.

The sweep of the places of gluing or cutting the ends of the Pasika do before operation, and raw rubber is applied in a thin layer — so the connection will be stronger.

The quality of work can be significantly improved by applying iron with thermostat. Setting the knob to “silk” (120-140°), can not be afraid that the mold will overheat.

According to the proposed technology, having made appropriate molds to make various small parts: a shank for models, cuffs, rubber seals, etc.

The exposure time for parts of the conventional raw rubber (not ipomoeeae) should be not less than 1 h.