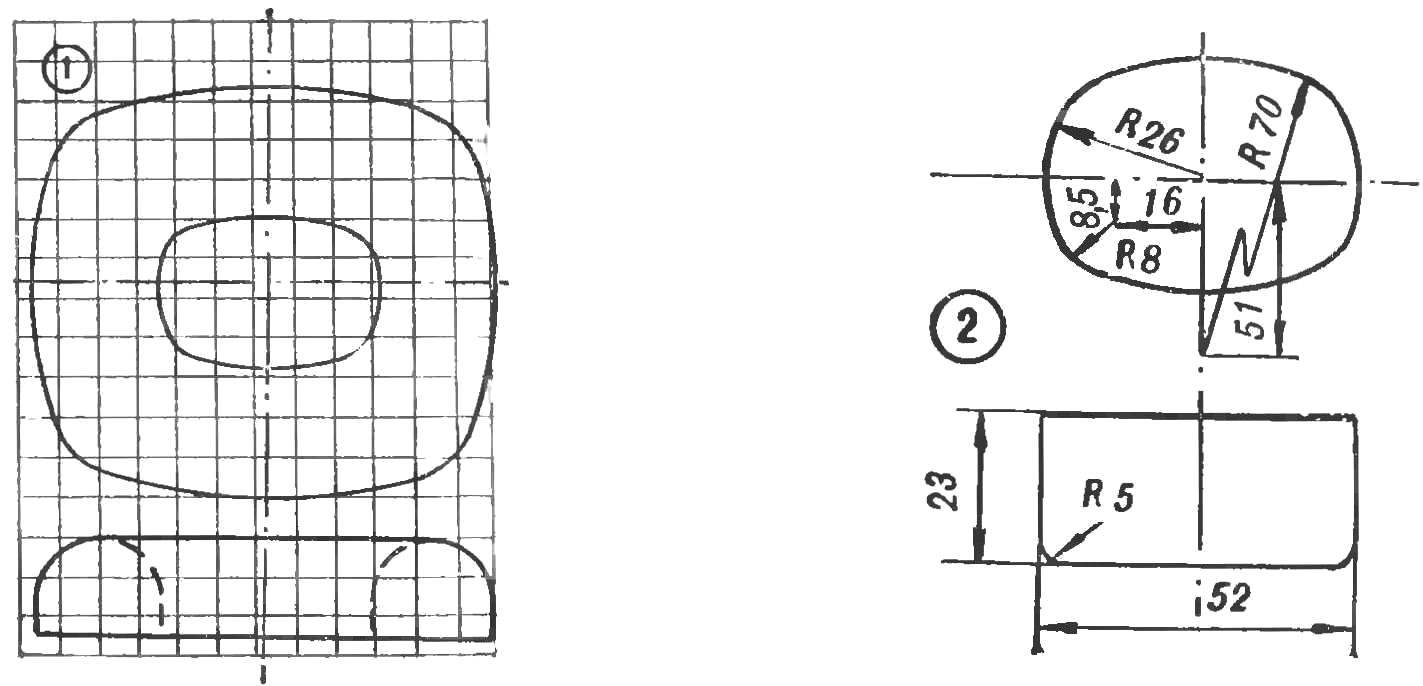

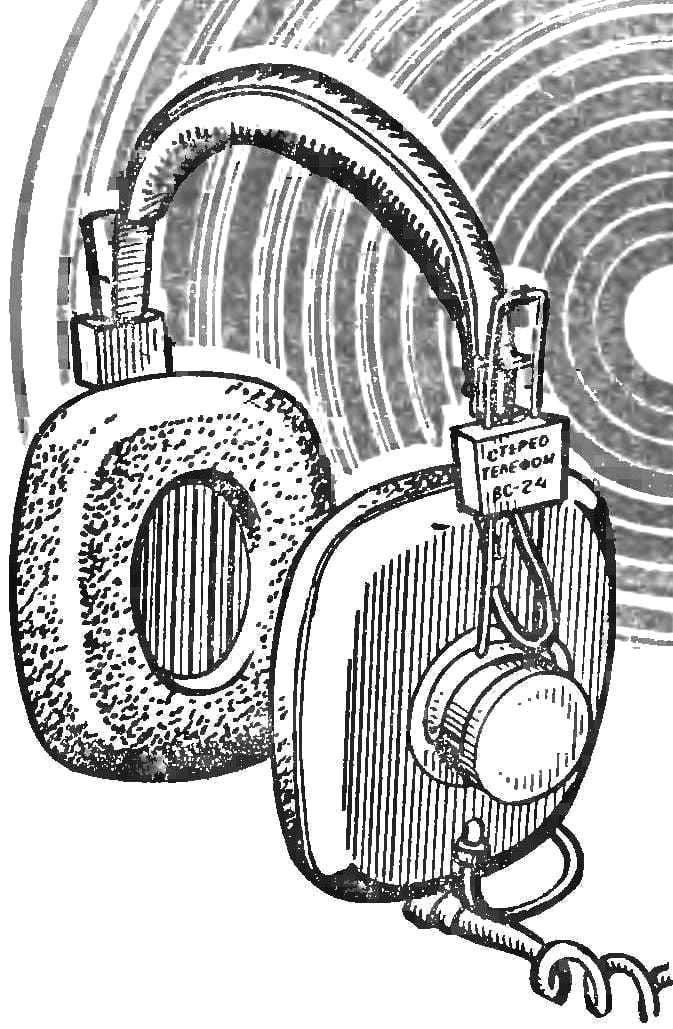

(The end. The beginning in № 4, 1976) the design quality of stereoleto, the description of which we offer readers, the outer shell of the ear cups made of artificial leather of black color. They are made on a wooden model-the matrix (Fig. 1). The hole is carefully cut out with a jigsaw, and the cut portion is used as a punch. Faux leather cut out a rectangle the size 180X160 mm, remove the knitted lining and evenly stretch the skin on the model, fixing the lower side of the stationery buttons. Then the product is heated to 70— 90°, push in and a punch in the matrix, stand in this condition until cool. Then punch with the buttons removed and the shell removed. On retinectomy frame (Fig. 2, POS. 2) glue 88H glued the foam and cut it in the shape of the ear pads. Thereafter, the sheath is stretched over the foam and glued to the bottom of the frame with glue BF-2, first external perimeter and then the inside. Decorative grille — from pocket radios. Glue it to the frame last.

(The end. The beginning in № 4, 1976) the design quality of stereoleto, the description of which we offer readers, the outer shell of the ear cups made of artificial leather of black color. They are made on a wooden model-the matrix (Fig. 1). The hole is carefully cut out with a jigsaw, and the cut portion is used as a punch. Faux leather cut out a rectangle the size 180X160 mm, remove the knitted lining and evenly stretch the skin on the model, fixing the lower side of the stationery buttons. Then the product is heated to 70— 90°, push in and a punch in the matrix, stand in this condition until cool. Then punch with the buttons removed and the shell removed. On retinectomy frame (Fig. 2, POS. 2) glue 88H glued the foam and cut it in the shape of the ear pads. Thereafter, the sheath is stretched over the foam and glued to the bottom of the frame with glue BF-2, first external perimeter and then the inside. Decorative grille — from pocket radios. Glue it to the frame last.

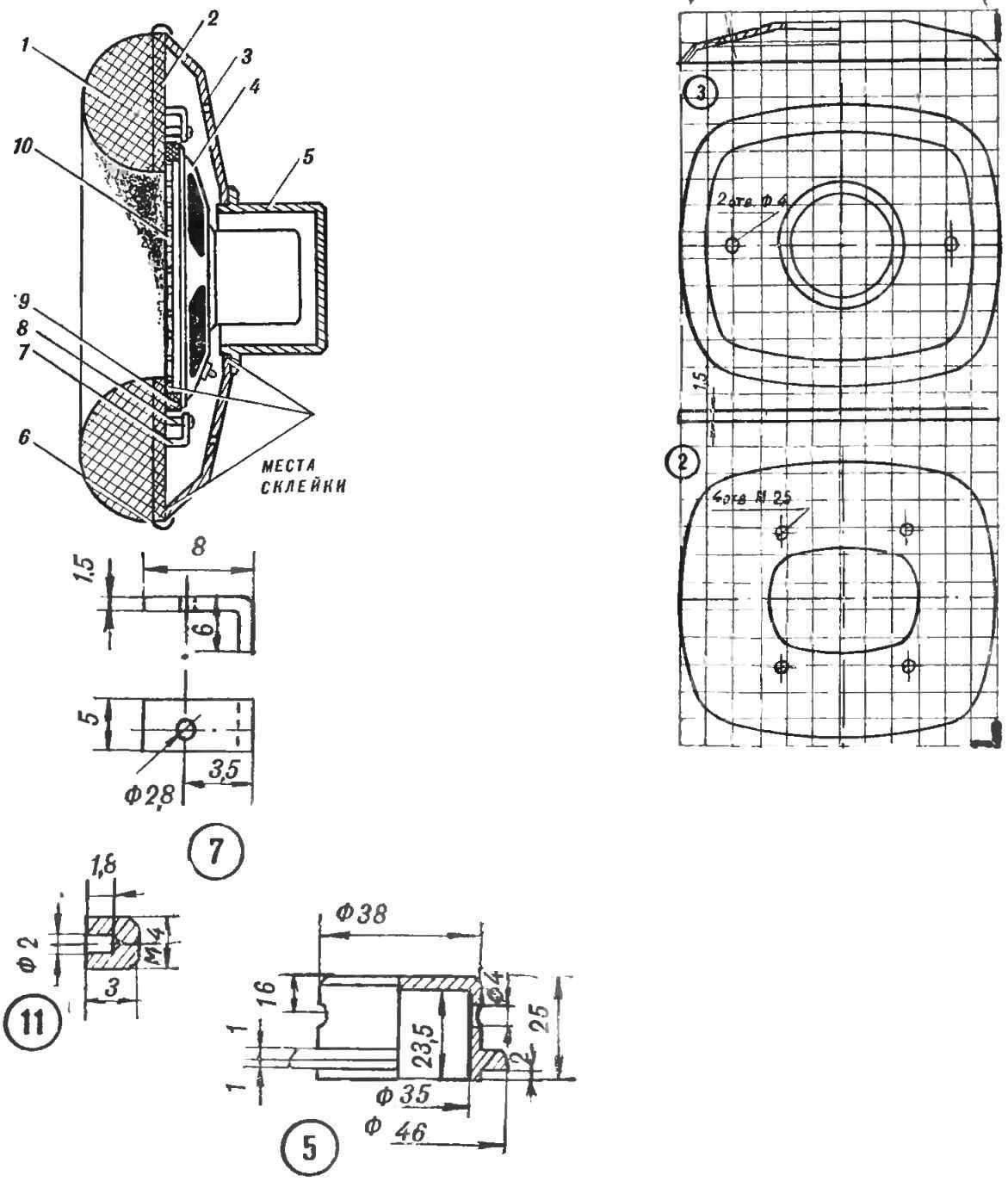

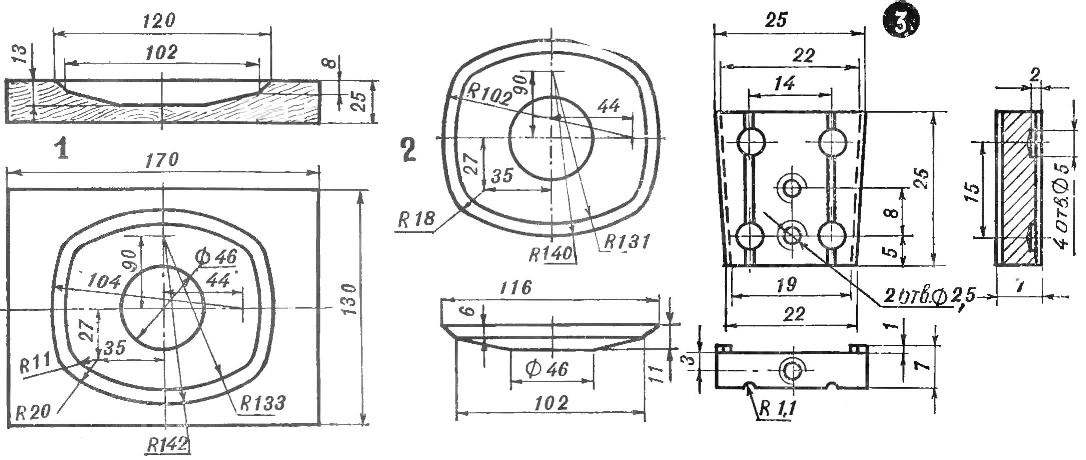

The phone is out of the box (POS. 3) and cover (POS. 5). Box stamped with the stamp and punch (Fig. 3) of thermoplastic plastic or organic glass (must be painted). The box and cover are glued together with epoxy. When gluing these parts cover set that to the side holes were located along the minor axis of the box.

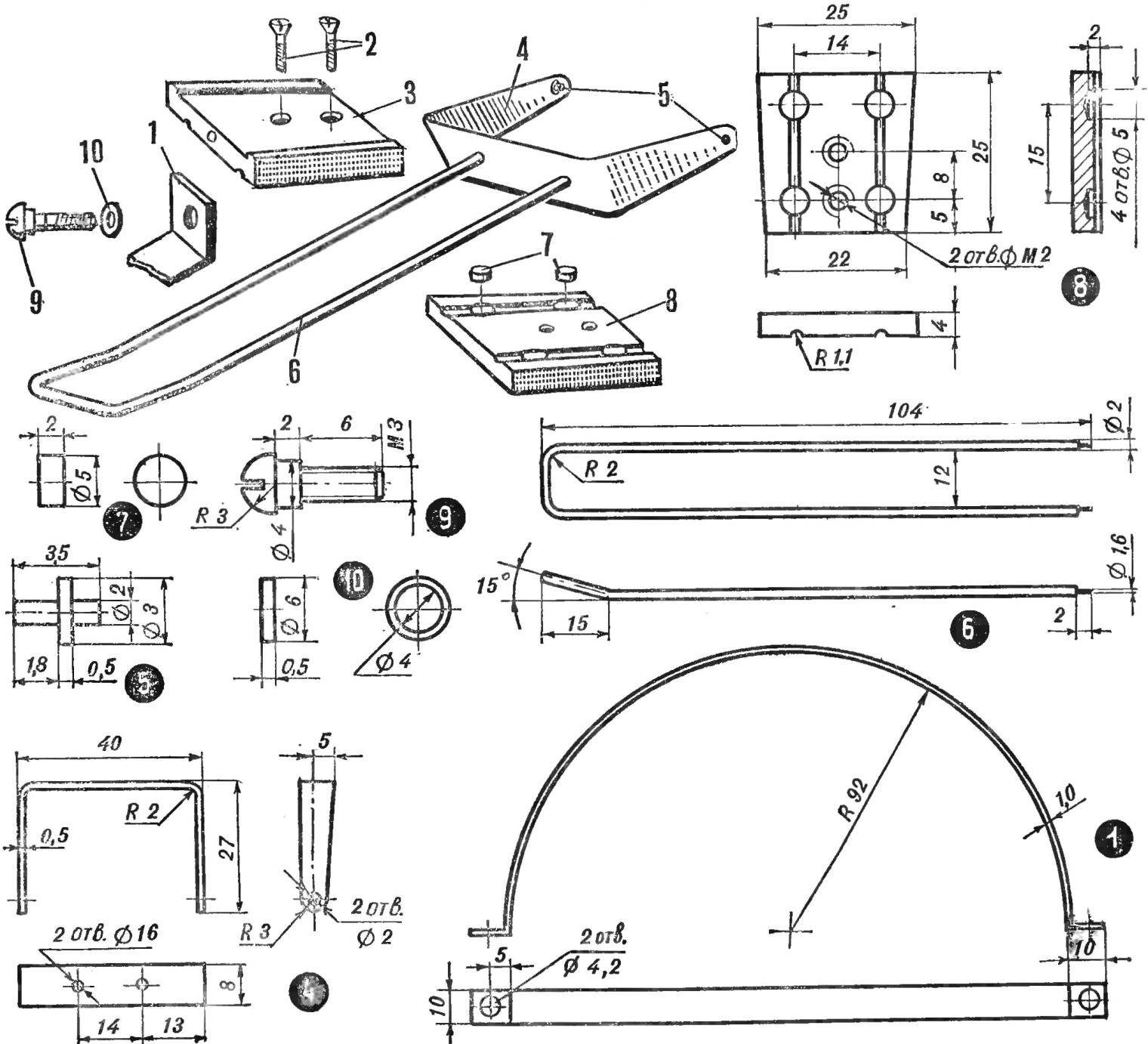

Headband can be done by yourself or use from industrial phones. It should press firmly the phone to the ears and to have the adjustment under the head of the listener. Headband design — figure 4.

The spring on both sides adhered to the foam thickness of 6-8 mm and cased with leatherette. On the inner side of the spring lay wire to connect the phones (both ends should be left on 12-14 cm wire for installation).

Fig. 1. Matrix and a punch for the manufacture of ear pads:

1 — model of the embouchure (wood), 2 — punch (wood).

Fig. 2. Phone design:

1 — Cup, 2 — frame (Micarta), 3 — box (plastic), 4 — head 0,25 GD 10-290, 5 — housing cover (aluminum), 6 decorative trim, 7— corners for attachment of the head (aluminum), 4 PCs., 8 — screws M2.5X 10, 4-piece, 9 — sealing ring (rubber), 10 protective grille, 11 — bushing (brass), 2 PCs.

When assembling the headband in the side and top holes of the bracket respectively, the pins inserted and the guide plug, which then rivets. In the holes of the base and lid glued (glue 88Н) felt panels. They are necessary for smooth movement of the guide plugs in the grooves of the base, when adjust the size of the headband. The Cam plug is installed in the grooves between the base and the lid by affixing the two screws. Last close trim. With both sides on the pad, it is desirable to make the inscription: “left”, “right” or color coded: right — red and left — white, yellow or blue.

The spring is fastened to the base with a screw. Between them laid the washers which allow the base to rotate slightly around the screw. It helps to install the phones on the head of the listener.

Fig. 3. The matrix 1 and the punch 2 for manufacturing the box body.

Fig. 4. Headband:

1 — spring (St. 65G), 2 — screw M2, 3 — base (made of anodized aluminum, anodizing), 4 — clip (brass, chrome-plate), 5 — pin (brass), 6 — guide rail plug (wire OVS, chrome-plate), 7 — insert (fetr), 8 — a cover (made of anodized aluminum, anodizing), 9 — screw (brass, chrome-plate), 10 — washer (PTFE).

After manufacturing all the parts start assembling phones. Head (see Fig. 2) is attached to the frame using the four corners and screws. If the casing head 0,25 GD-10 has four mounting holes, the need for corners is eliminated. Clamp the headband (Fig. 4, POS. 4) is connected with a cover (Fig. 2, POS. 5) use pins that are enclosed in the sleeve (POS. 11), screwed on the glue in cap. In the upper housing holes pass the wires from the headband to connect to external devices (cable MMC-2 or three-core flexible cord with a length of about 2 m). Filling the entire inside of the hull with mineral wool, glued it to the frame with glue BF-2. The top is glued a decorative edging of cut the vinyl chloride pipe. About how to connect the phone and check the quality of their work, narrated in the second issue of the magazine this year.

V. SKLYAROV, engineer

Recommend to read

TRACTOR AS THE TRACTOR

TRACTOR AS THE TRACTOR

F. Slavin from the village Malesina Kurgan region gathered his hands, using the components and mechanisms of various scrapped or abandoned motor equipment. Engine—DT-25 diesel,... PIONEER SCHEMATIC MODEL OF THE AIRFRAME

PIONEER SCHEMATIC MODEL OF THE AIRFRAME

The most important thing: the Artek pioneer simple, easy to control and good flying. And the material always at hand: cardboard, pine or lime bar, tissue paper, rake, a few small studs,...

(The end. The beginning in № 4, 1976) the design quality of stereoleto, the description of which we offer readers, the outer shell of the ear cups made of artificial leather of black color. They are made on a wooden model-the matrix (Fig. 1). The hole is carefully cut out with a jigsaw, and the cut portion is used as a punch. Faux leather cut out a rectangle the size 180X160 mm, remove the knitted lining and evenly stretch the skin on the model, fixing the lower side of the stationery buttons. Then the product is heated to 70— 90°, push in and a punch in the matrix, stand in this condition until cool. Then punch with the buttons removed and the shell removed. On retinectomy frame (Fig. 2, POS. 2) glue 88H glued the foam and cut it in the shape of the ear pads. Thereafter, the sheath is stretched over the foam and glued to the bottom of the frame with glue BF-2, first external perimeter and then the inside. Decorative grille — from pocket radios. Glue it to the frame last.

(The end. The beginning in № 4, 1976) the design quality of stereoleto, the description of which we offer readers, the outer shell of the ear cups made of artificial leather of black color. They are made on a wooden model-the matrix (Fig. 1). The hole is carefully cut out with a jigsaw, and the cut portion is used as a punch. Faux leather cut out a rectangle the size 180X160 mm, remove the knitted lining and evenly stretch the skin on the model, fixing the lower side of the stationery buttons. Then the product is heated to 70— 90°, push in and a punch in the matrix, stand in this condition until cool. Then punch with the buttons removed and the shell removed. On retinectomy frame (Fig. 2, POS. 2) glue 88H glued the foam and cut it in the shape of the ear pads. Thereafter, the sheath is stretched over the foam and glued to the bottom of the frame with glue BF-2, first external perimeter and then the inside. Decorative grille — from pocket radios. Glue it to the frame last.