“Eureka” is a centerboard boat of simplified construction, designed for home building technology.

The boat’s hull is wooden, lightweight, with a membrane-type skin. It consists of three built-up frames, a keel, and four stringers. The midship frame is reinforced, since the mast and centerboards are attached to it. The mast is made of duralumin tube or wooden, pivoting. The sail is a lateen sail, with a mainsail area of about 3.2 m2. The plywood centerboards are pivotally secured in a duralumin tube glued into the midship frame.

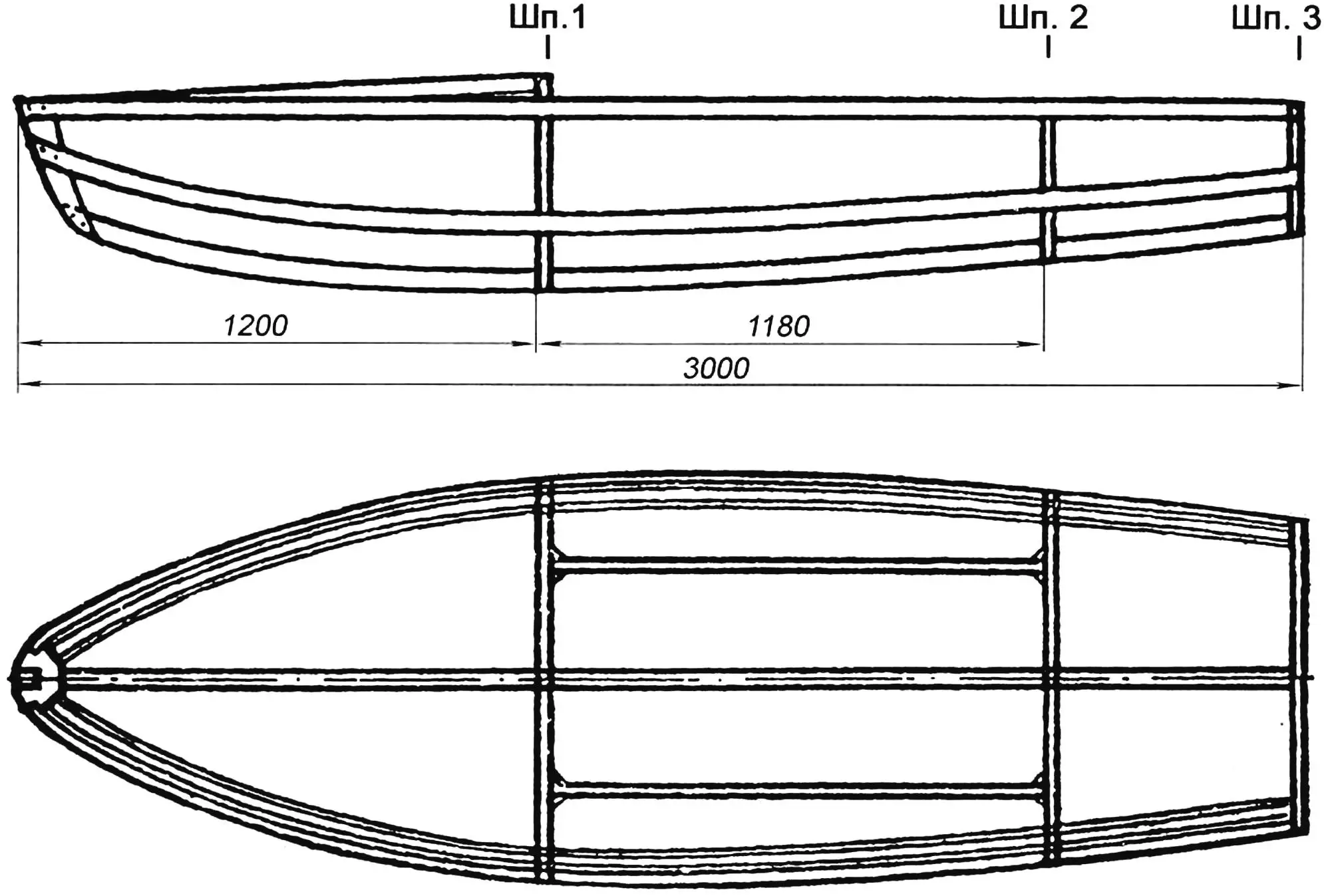

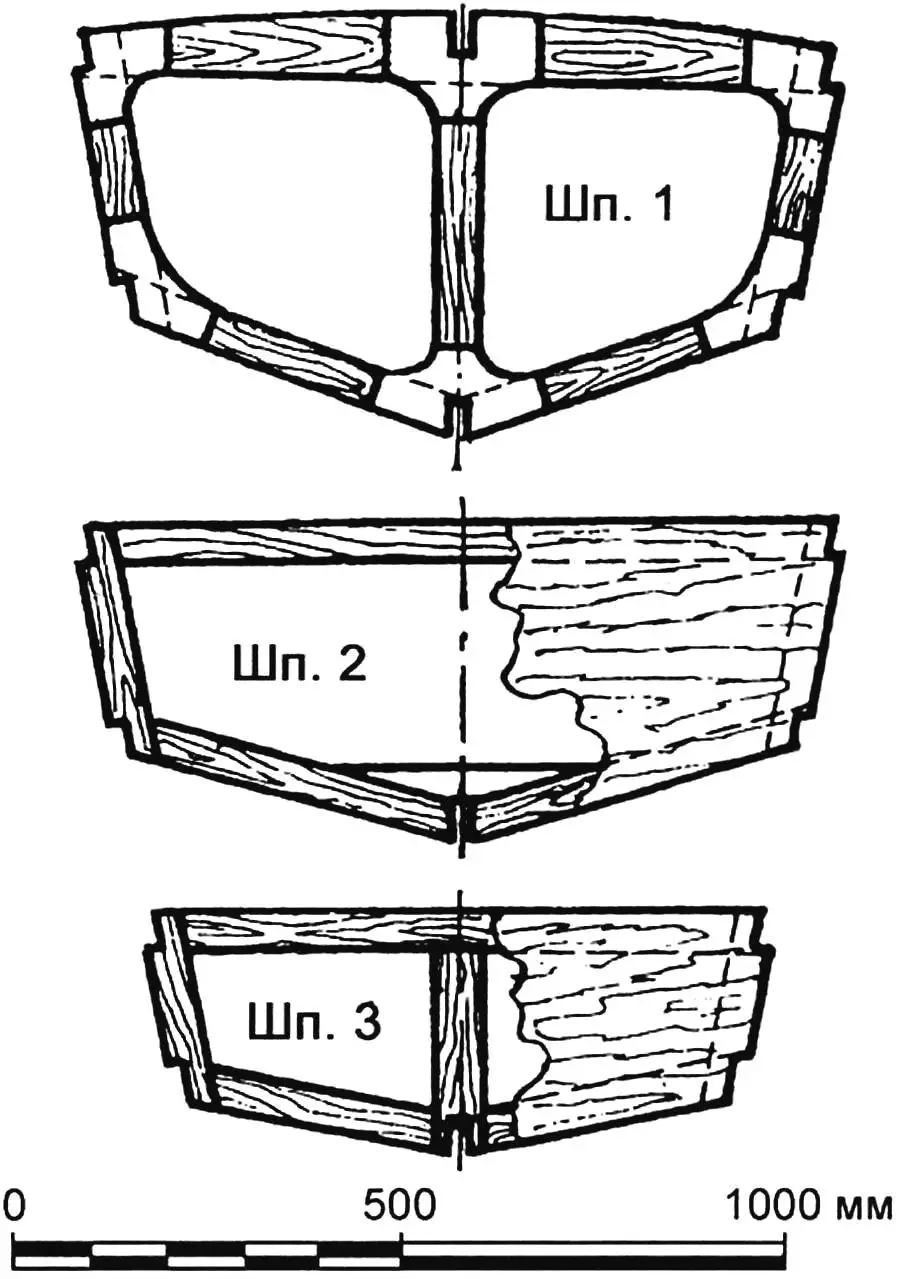

For the frames, pine battens with a cross-section of 50×20 mm and 3-mm plywood will be needed. The frames are assembled on a plywood sheet with the outlines of the theoretical frames drawn on it. After mutual fitting of all parts, a plywood sheet is placed on top and attached to the frame blank with nails and epoxy glue. On the other side, the joints are reinforced with plywood gussets. The transom board has double-sided plywood sheathing.

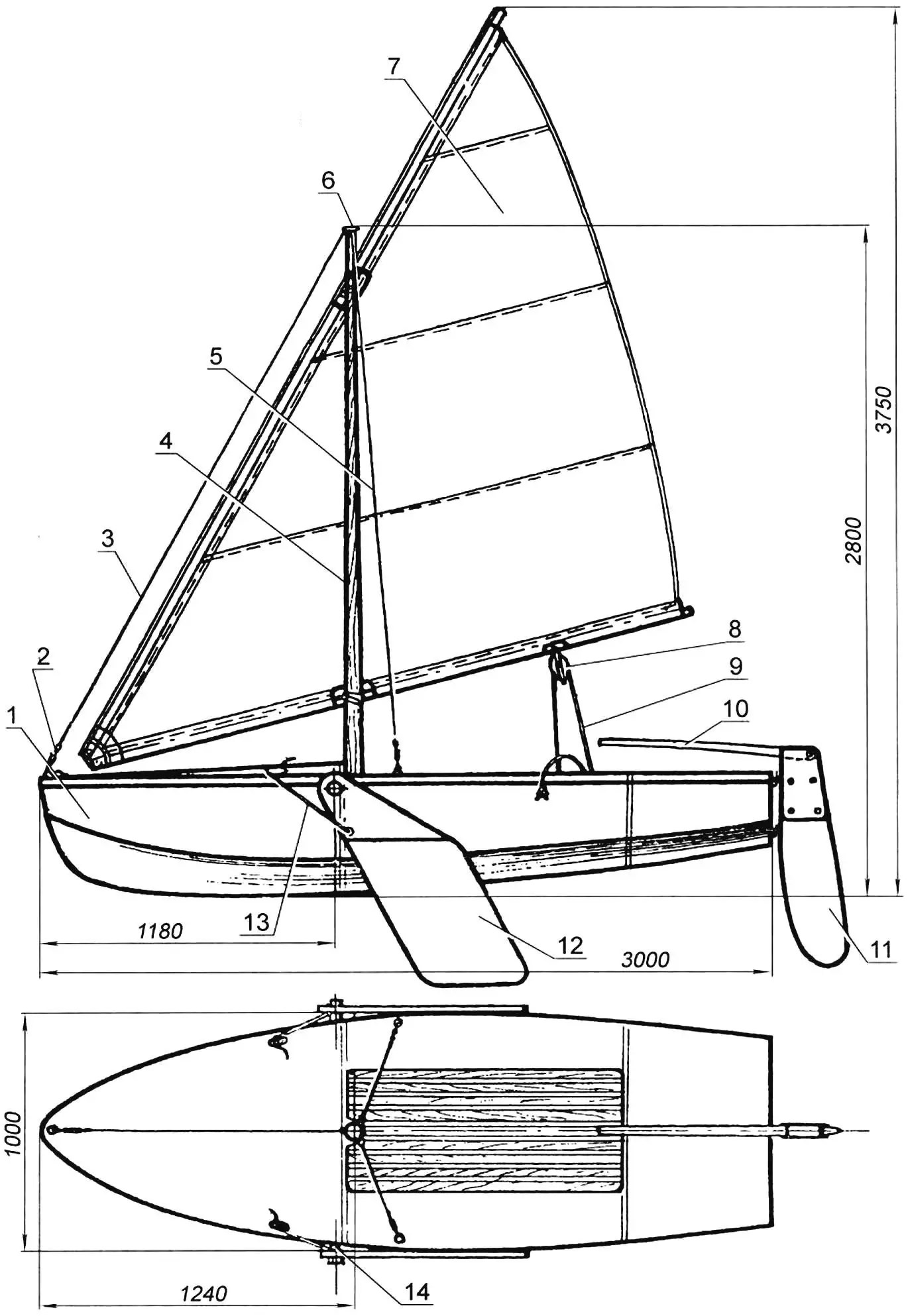

1 — hull; 2 — turnbuckle; 3 — forestay (steel, wire Ø3); 4 — mast (duralumin, tube 50×2 or wood laminate); 5 — shrouds (steel, wire ОВС Ø3); 6 — mast fitting; 7 — mainsail (area 3.2 m2); 8 — boom sheet block; 9 — boom sheets; 10 — tiller; 11 — rudder blade; 12 — centerboard (2 pcs.); 13 — downhaul; 14 — centerboard axis (steel, tube Ø22×2

The frame assembly is performed on a level floor — the frames, transom board, and stem are temporarily fixed on it, and then the keel, stringers, and other longitudinal members are attached to them with screws and epoxy glue. After the glue cures, the frame is leveled with a plane, rasp, and sandpaper.

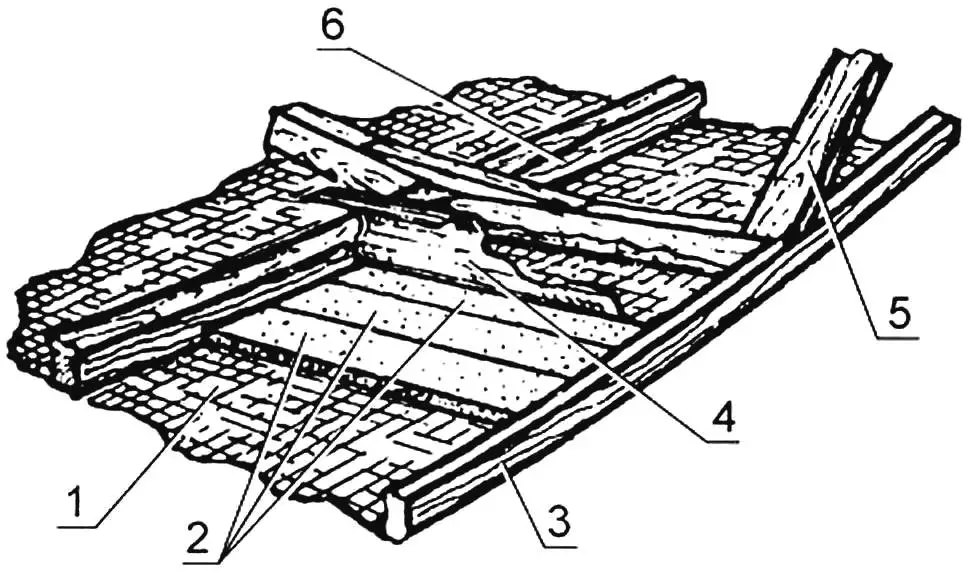

The next stage of work is obtaining the skin. For this, the frame is tightly covered with fiberglass using small nails, after which the skin is impregnated with epoxy resin diluted with acetone. Be sure to use a respirator or gas mask, and it is advisable to work outdoors. For the next two or three layers, the resin is not diluted.

The resulting skin is lined from the inside with foam plastic (construction or packaging). It is pre-cut into plates 10 mm thick and 100 mm wide with a heated nichrome wire stretched over a chipboard board on two porcelain insulators. It is best to press the foam plastic to the skin with polyethylene bags filled with dry river sand. After gluing, the foam surface is leveled, puttied with a compound of epoxy resin and wood sawdust, and lined from the inside with one or two layers of fiberglass.

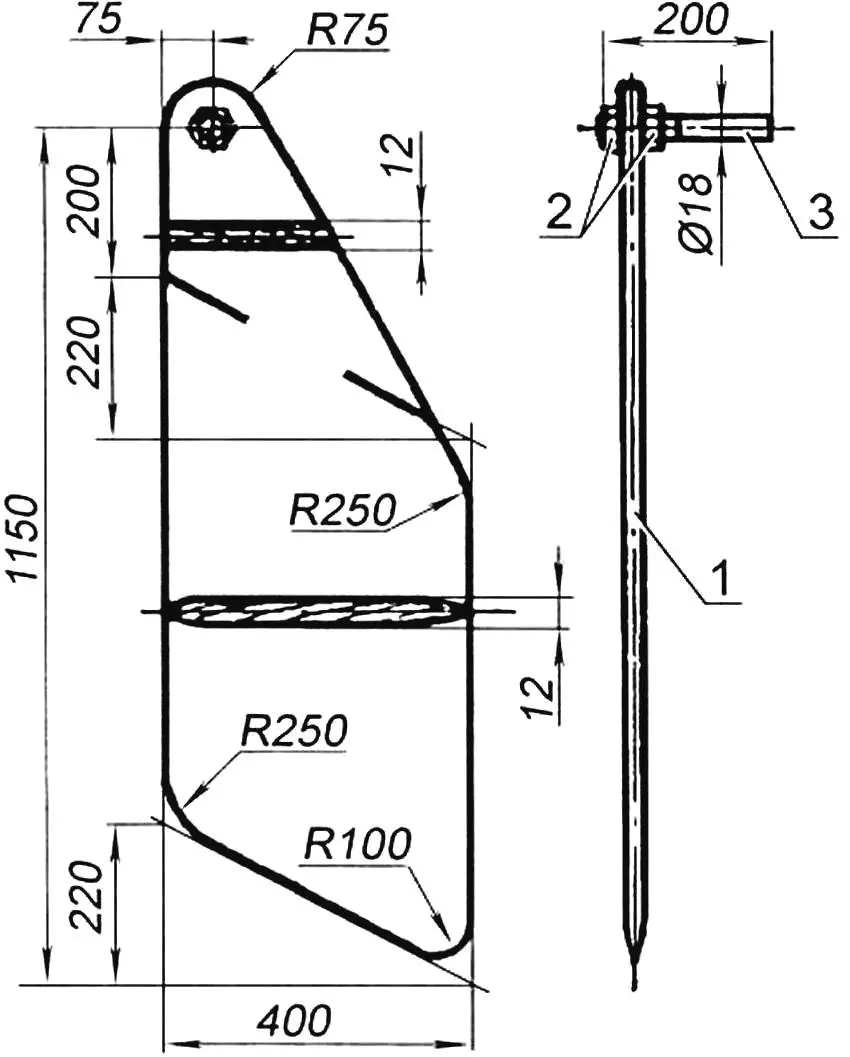

In the upper part of the midship frame, a duralumin tube with a diameter of 22 mm is attached using a nylon cord and epoxy putty made from wood sawdust — the side centerboards will be secured in it. The boat’s deck is made of plywood or hardboard.

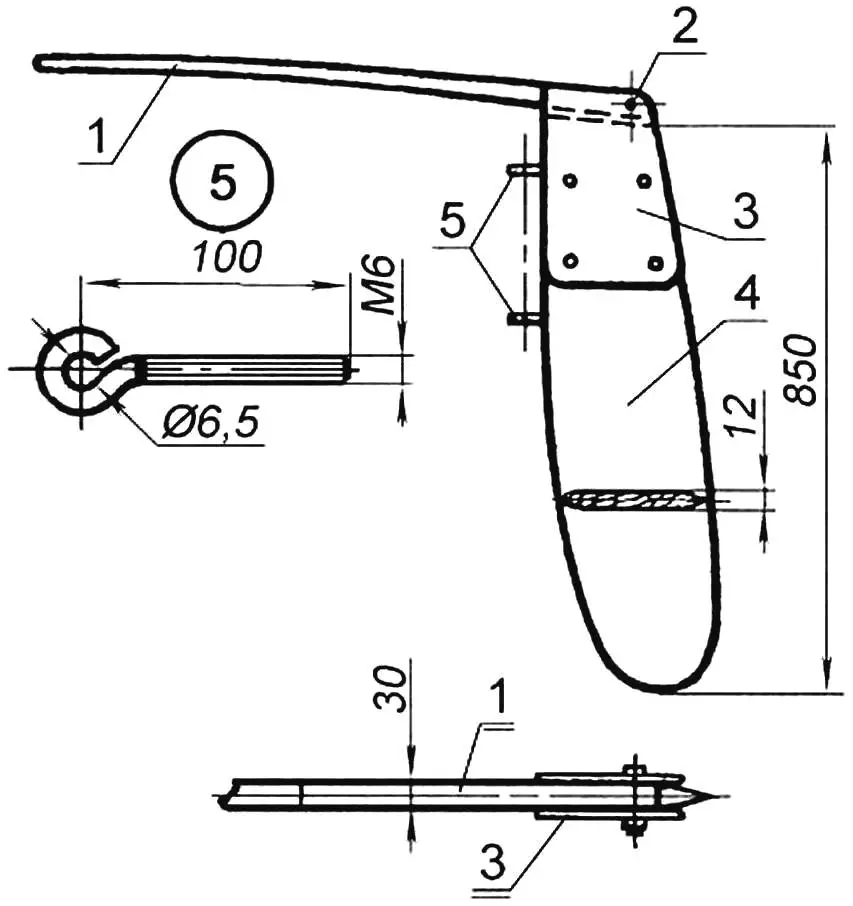

The centerboards and rudder blade are cut from 12-mm plywood, covered with fiberglass, and after sanding, primed and painted with bright nitro enamel.

The centerboard’s pivot axis is a duralumin stud with a thread on one end. The centerboard is secured in it between two nuts. The centerboards are fixed in the tube using a nylon lanyard, which is attached to a cleat.

1 — fiberglass sheathing; 2 — filling (foam plastic); 3, 6 — longitudinal members; 4 — inner fiberglass sheathing;

5 — frame

The rudder blade is secured to the transom using hinge brackets — one-sided threaded studs bent in the shape of the letter L and secured to the transom board with nuts and washers. The corresponding parts of the hinges, resembling pins with rings in shape, are also bent from the same studs. In the rudder blade, they are secured in drilled holes with epoxy glue. The tiller is made of oak or beech batten, pivotally connected to the rudder stock.

Inside, on the hull’s keel, near the midship frame, a mast step socket is installed, and flush with the deck — a collar made of 3 mm thick steel strip: they form two supports for the pivoting mast.

1 — tiller (beech or oak, block 30×30); 2 — tiller hinge (bolt with self-locking nut); 3 — rudder stock box (duralumin, s2.5); 4 — rudder blade (plywood s12, covered with fiberglass on epoxy resin); 5 — mounting hinges (stud M6)

The yard and boom of the lateen sail are planed from straight-grained wood and joined at the front with a duralumin plate that provides their pivot connection.

The yard and boom are secured to the mast with nylon lanyards, which are wrapped in “figure-eights” around these spars. The sail height is fixed by passing the securing lanyard through a hole in the mast.

1 — centerboard (plywood s12, covered with fiberglass on epoxy resin); 2 — nuts; 3 — stud (duralumin)

For the sail, fabric of the “bolon” type or pillow ticking is best suited. Tent fabric will also work. The sail is connected to the yard and boom using “pockets” cut from fabric denser than the sail itself. All corners of the sail are reinforced with fabric patches — cringles.

On the first trips to the water, tune the centerboard boat. The main thing is to align the centers of sail and lateral resistance. Misalignment can be noticed immediately: the sailboat with the rudder in neutral position will either luff (sail closer to the wind) or bear away (sail more off the wind). To balance the centerboard boat, you need to either move (forward-backward) the sail relative to the mast, or deflect (forward-backward) the centerboards. A well-tuned sailboat has a slight tendency to luff; this helps in squalls or emergency situations to bring the centerboard boat into irons — head to wind.

I. SERGEYEV