An old but wise folk saying goes: “Bread is the head of everything.” However, storing it in advance is a hopeless task. It goes stale and dries out very quickly, or even gets moldy and becomes unfit for consumption. And as is known, fresh bread is especially tasty. But people have not yet found a way to store it for a long time without losing its taste qualities — except perhaps by drying it into rusks. But housewives use the latter method more out of desperation.

However, to avoid baking (or buying) bread frequently (if not daily), people still managed to extend the fresh state of bread: some wrapped loaves in clean towels, while others stored them in a dark wooden chest. Industry eventually adopted the latter idea — began producing tabletop or wall-mounted bread boxes: wooden or surrogate steel ones. Our family also wanted to have a wooden bread box. But we just couldn’t manage to buy one: either such items were not available in stores, or the money was needed for something else at the moment when a bread box could be purchased.

Then I decided to make a bread box myself — to gain experience in carpentry and save money at the same time. Besides, the task turned out to be fascinating.

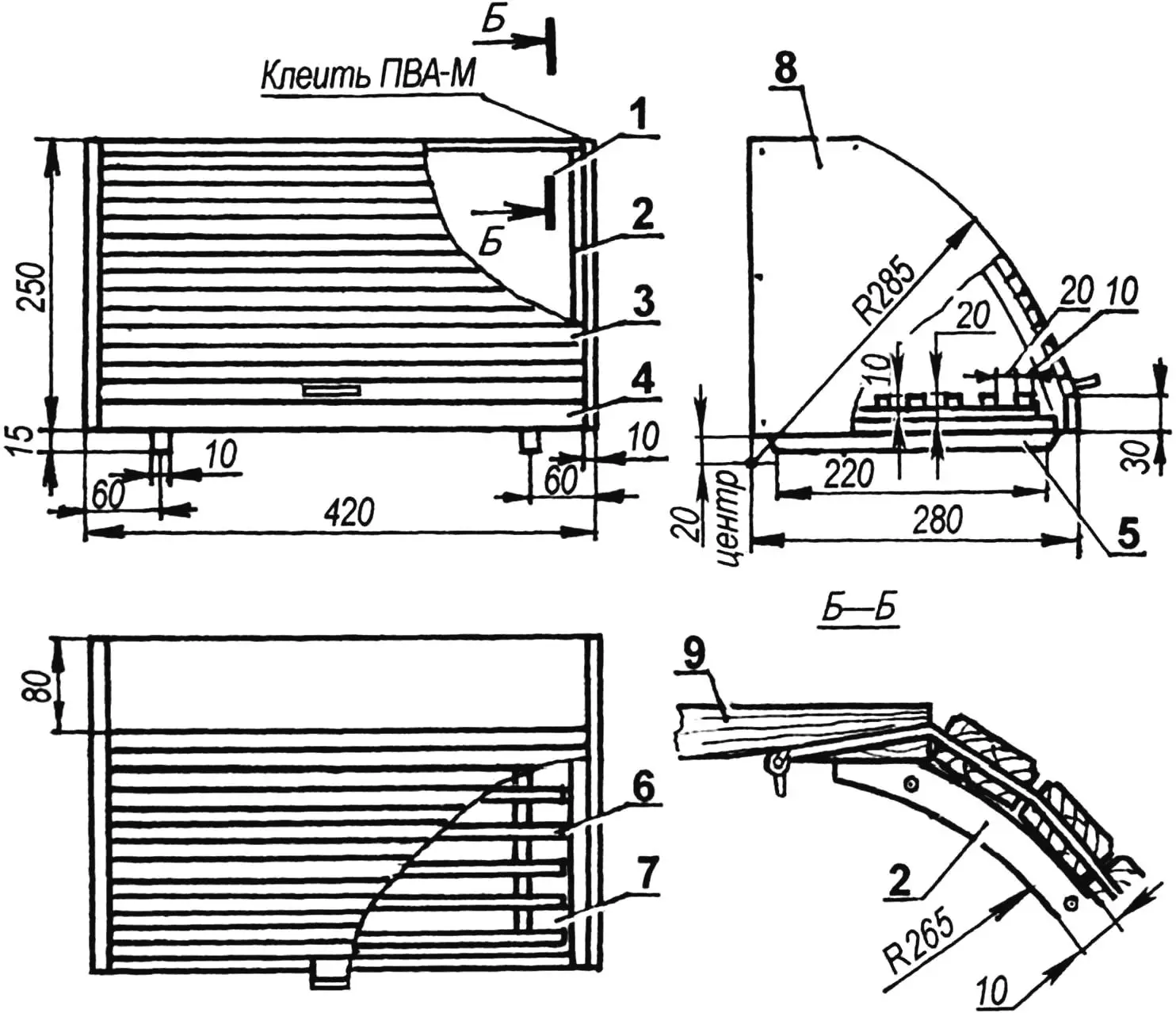

1 — back wall (glued panel from boards s10, 2 pcs.); 2 — support (curved block 10×10, 2 pcs.); 3 — curtain door; 4 — threshold (slat 400x30x10); 5 — runner leg (block 15×10, 2 pcs.); 6 — grid 350×240 (block 10×10, as needed); 7 — bottom (glued panel from boards s10); 8 — side wall (glued panel from boards s10); 9 — lid (board s10)

As material for the bread box, I used small boards of hardwood from crates discarded by a grocery store. I carefully disassembled the crates and stacked the boards near the heating radiator. After about a week of drying, I more precisely fitted the edges of the boards together using a hand plane and, after applying PVA glue, joined three or four pieces into small panels. I tightened the boards in the panels with a cord, and placed the panels on a flat table one on top of the other and pressed them with a stack of heavy books.

The next day (after work), I planed the surfaces of the panels with a plane and, after marking the contours of all the bread box parts, cut them out with an ordinary (children’s) hand jigsaw. At that time, we lived in a private apartment. The landlady appeared and warned that she would evict us for noise and mess. I had to finish the bread box on other evenings secretly and quietly.

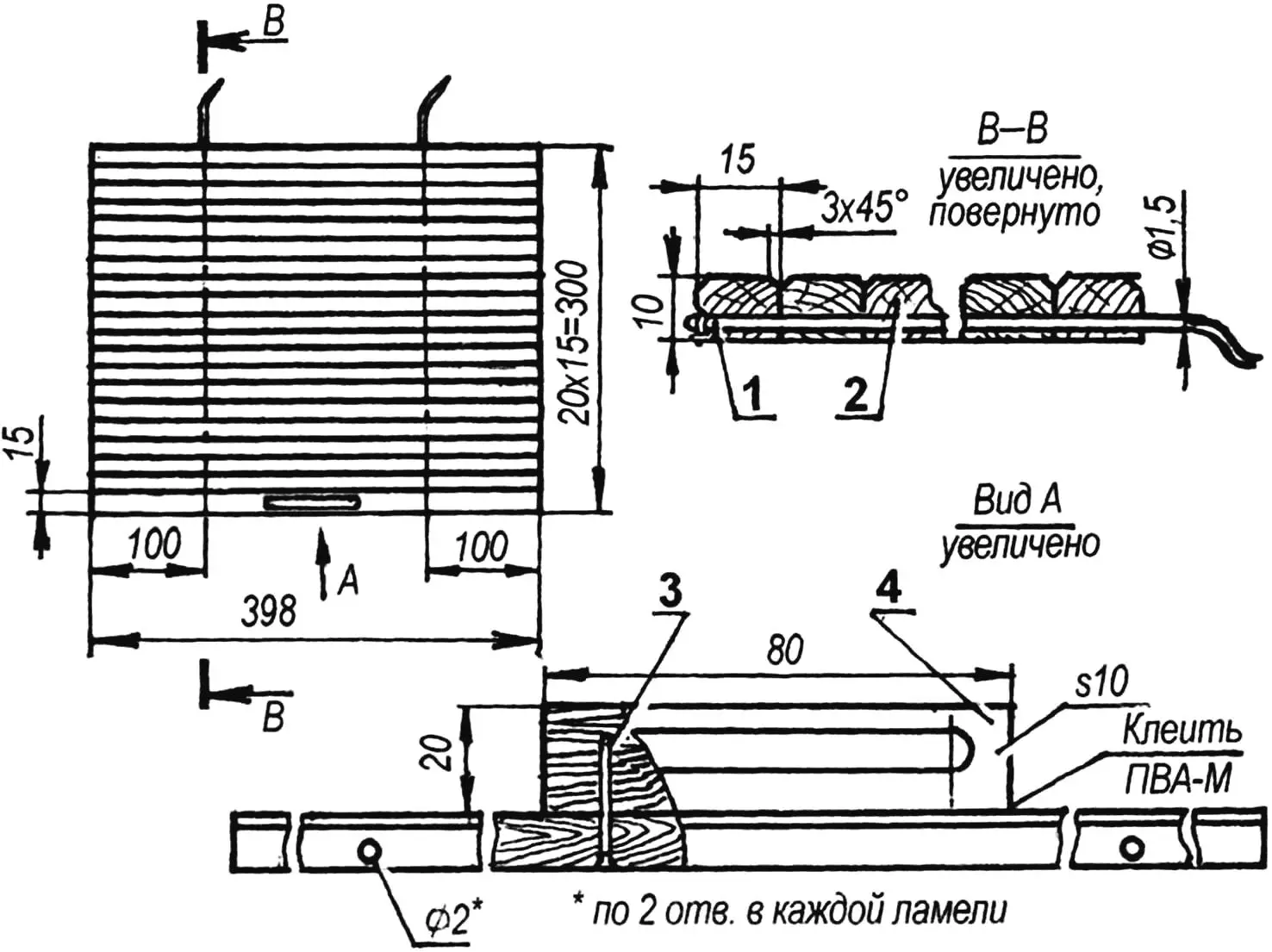

1 — nylon fishing line Ø1.5 (2 pcs.); 2 — slat (15×10, L398, 20 pcs.); 3 — nail Ø1.2×25 (as needed); 4 — handle (slat 80x20x10)

I assembled the bread box parts into a single structure using PVA glue and small nails. After the glue dried, I carefully sanded all joints and surfaces. I assembled the curtain door of the bread box from slats — 15×10 mm cross-section slats on two pieces of nylon fishing line. To pass the line through, I drilled two holes in each slat. To attach the curtain to the bread box, I also drilled two corresponding inclined holes in its lid — inserted the ends of the line pieces into them and tied them firmly. After that, I attached a handle (with glue and small nails) to the door, and runner legs to the bottom. I also installed a grid on the bottom inside the bread box, made from the same slats as the curtain. Finally, I coated the bread box with colorless varnish on the outside.

When the landlady came to us again for rent, she saw the finished bread box and… asked me to make the same one in exchange for part of the future rent.

And our simple bread box still serves us to this day — for more than twenty years now.

A. MATVEYCHUK