There is an element of design, which can be found probably in any moving models. It is the bearing. Often a pair of “shaft — hole” presented in the form of passing through the wall of thin sheet metal or metal wire axis. This couple meet on the microplane in the system control cord the aircraft or in the nose bearing rezinomotornaya, and the boat, built by children’s hands, — the bearing of the prop shaft or hub of the rudder, not to mention the suspension of the microcosm novice automodellista.

There is an element of design, which can be found probably in any moving models. It is the bearing. Often a pair of “shaft — hole” presented in the form of passing through the wall of thin sheet metal or metal wire axis. This couple meet on the microplane in the system control cord the aircraft or in the nose bearing rezinomotornaya, and the boat, built by children’s hands, — the bearing of the prop shaft or hub of the rudder, not to mention the suspension of the microcosm novice automodellista.

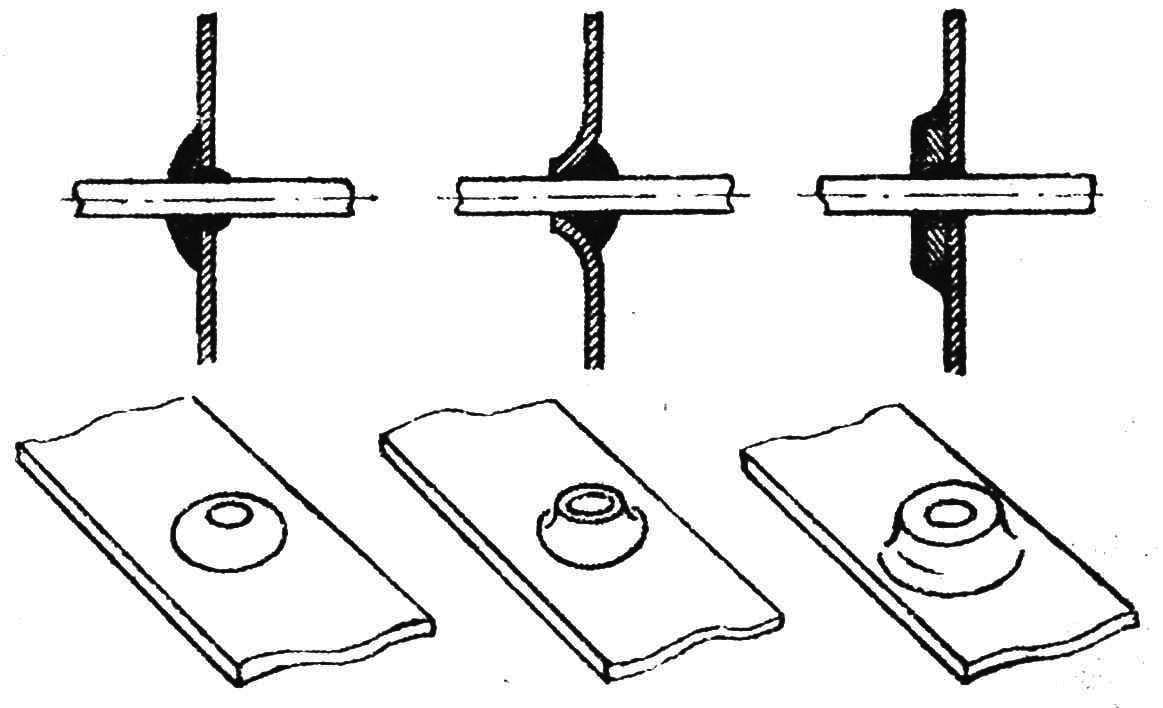

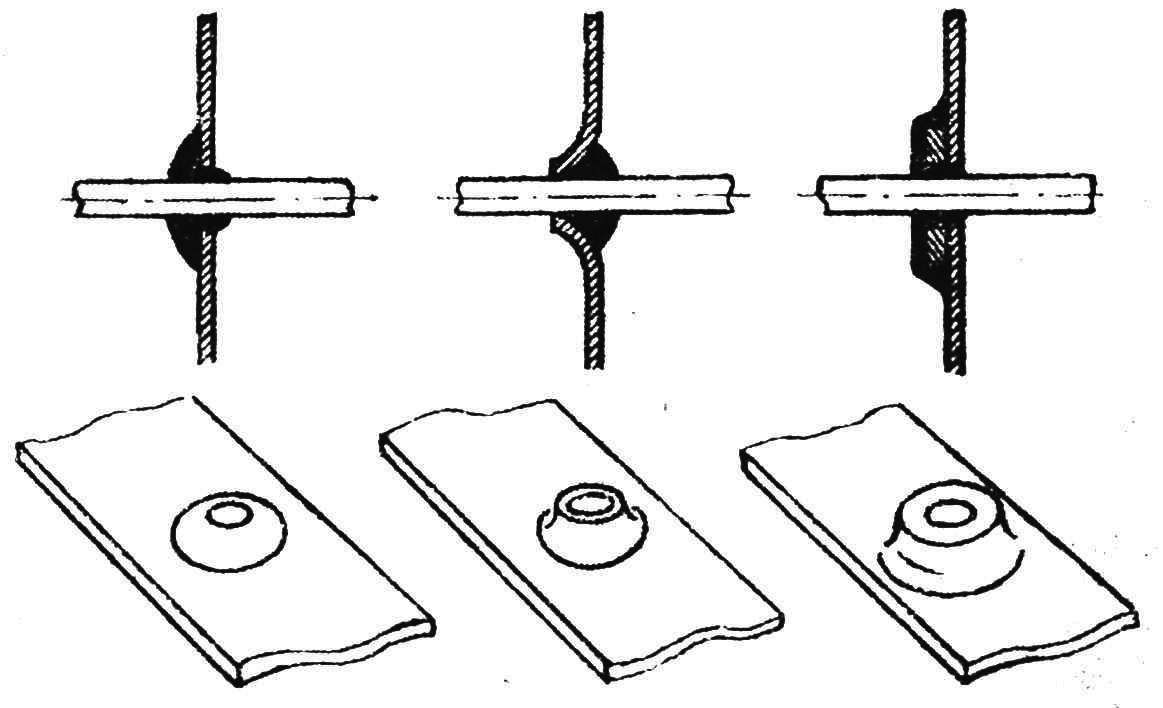

In all such cases will be useful recommendations P. Konstantinova from the city of Kursk. He proposes to improve the friction pair “shaft — hole” due to the increase of the bearing surface. This can be achieved, causing the holes a drop of solder. Even better, putting the item on a scrap Board, pre-tin to push the blow core. In the formed recess and filled with’ molten solders.

The bearing would be safer if the “reinforce” tin, Bay them (and probav so) steel or brass washer of suitable diameter so that when drilling for the bearing it turned out to be framed by this goal. Now the random misalignment of the axis will not cause crushing of the relatively soft friction surface.