Thermoresin is, for example, for harvesting belt of sheet rubber or an old Bicycle inner tube, removing the PVC insulation from the wires and coaxial cable, for cutting a thin sheet of vinyl plastic, Plexiglas, foam.

Insert a knife suitable for the pattern of patches of rubber, and also for preparation of films to various physical devices.

Roller knives. This tool is very convenient for cutting off the films from rubber or polyethylene. The knives represent the copper pipe or rod with a pointed rotating roller on the end.

The processed material is placed on a smooth (preferably wooden) surface and pressed with a wooden ruler. Along it are warmed up the soldering iron roller. If this is a double plastic film, it is not only cropped, but also welded. Therefore, this knife is easy to make packages for sealing a variety of objects and materials.

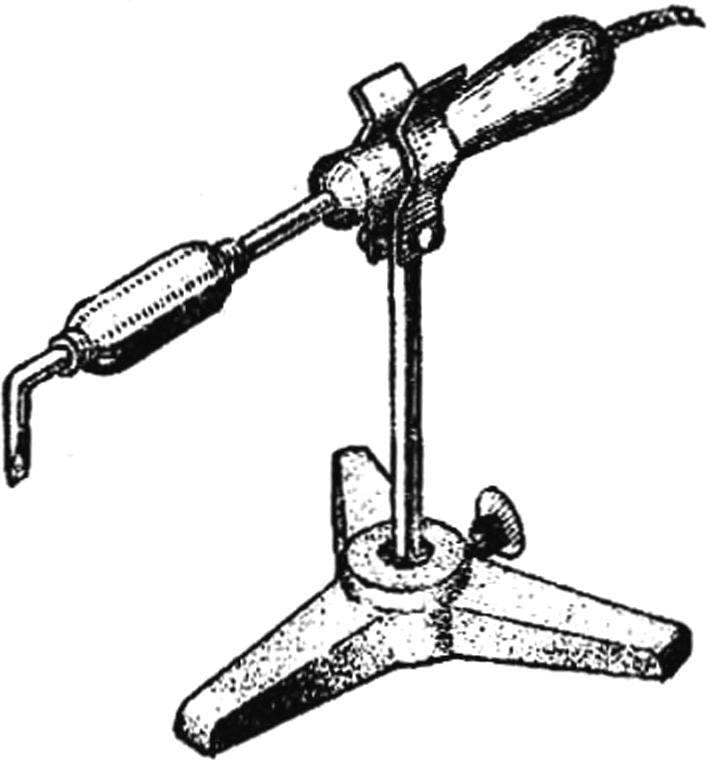

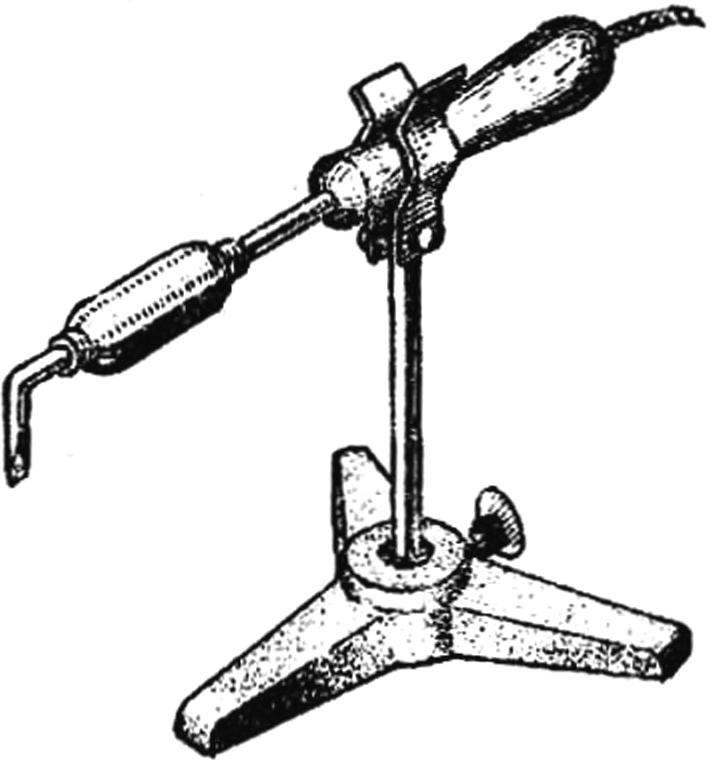

Soldering iron and tips to him:

1 — stripes drill, 2, 3 — torch 4 — roll knife 5 — press welding, 6 — vulcanizer, 7 — “crucible”, 8 — uncooperatively.

The tool is convenient and to work with the plexiglass. Vyplavin them first grooves with one side of the sheet, then another, successively bend the plexiglass on the planned lines — get a transparent box, for example, the aquarium fish tank. Roller blades, in addition, allow to cut out people^ a hundred or foam letters for stands.

You can make a single-purpose termoindurente, for example, welding, roller press, which serves for gluing plastic films in bags or pouches. It differs from previous devices that movie from his flat and grooved rolling.

Vulcanizer. Used in schools, electrostatic, magneto-electric machines, projectors, tape recorders have the belt. During their operation often have to connect the broken rubber ring manufacturing new or existing stretched.

Reliable bonding of the two ends of the belt are obtained via vulcanization. This would require two mold-nozzle for electric soldering iron and vulcanizing rubber.

Molds are made of two equal size copper plates of thickness not less than the diameter of the welded belt. The plates are superposed upon each other and the corners are connected by M4 screws. Then, the resulting package is clamped in the vise and in front of the drill socket for a rod, and along the lateral — hole Ø 6, 4 and 2 mm of the belt is most common. The distance between the holes must be not less than the thickness of the plate — otherwise, warm up the place curing will be uneven and its quality will deteriorate.

Preparing the ends of the belt to the mix, remember that slanting slices run them directly before vulcanization. Paving between them a thin piece of rubber vulcanizing appropriate form, both ends clamped in a mold and put it into a copper rod into the soldering iron. The optimum heating time is determined by experiment, using the same cut belt.

The nozzle-“the crucible”. It is a hollow copper cylinder, into which put the slices of tin, lead or zinc. After they melted, the metal is poured into a form or a glass of water, oil: so you can get the balls for experiments.

The same nozzle is suitable to demonstrate the working steam cylinder is filled halfway with water and plug the tube — formed pairs after a while with the noise pushes it.

The device helps to make the through holes in the foam or foam rubber, for example, a cylindrical socket for coils of film strips.

Uncooperatively. To conserve reagents when carrying out practical work in chemistry in the schools widely practiced semi-micro, the essence of which consists in experiments, not in test tubes and small volume cells. Stands with the cell industry doesn’t. However, they are easy to fabricate from Plexiglas plates using a soldering iron with a nozzle uncooperatively.

First on the plate of Plexiglas with a thickness of 12 mm or other synthetic material, make markings with a pencil, then center punch, mark the cell and next, the heated nozzle is extruded holes of different depths, they are obtained with pure spherical shell does not require additional processing.

V. SHILOV, F. PRONIN

Recommend to read

“UMBRELLA” IN THE GARDEN

“UMBRELLA” IN THE GARDEN

A kind of umbrella made of sharpened timber th a plywood "roof", will help protect the tomato seedlings from hot sun or a sudden hail. GEAR RACK ON THE LATHE

GEAR RACK ON THE LATHE

We offer you a simplified method of manufacturing a cylindrical gear rack. It can be done with a conventional tap, picking up the thread profile in accordance with your existing gear....

The conventional electric soldering iron (100 watts, voltage 220 V) through the use of technological replacement of nozzles turns into a versatile tool that allows you to perform several additional operations. Here is a description of several tools and ways to apply them.

The conventional electric soldering iron (100 watts, voltage 220 V) through the use of technological replacement of nozzles turns into a versatile tool that allows you to perform several additional operations. Here is a description of several tools and ways to apply them.