Held in 2013 in the suburban town of Zhukovsky the International aerospace salon (MAKS-2013) successfully demonstrated their work to the young “rocket scientists”. Very popular with the audience enjoyed the exhibition of rocketmodeler of Elektrostal in Moscow region called “missiles of the Fatherland.” In this work, young technicians syut clearly demonstrated in the models in scale 1:25, the initial stage in the development of a missile shield of our country.

Held in 2013 in the suburban town of Zhukovsky the International aerospace salon (MAKS-2013) successfully demonstrated their work to the young “rocket scientists”. Very popular with the audience enjoyed the exhibition of rocketmodeler of Elektrostal in Moscow region called “missiles of the Fatherland.” In this work, young technicians syut clearly demonstrated in the models in scale 1:25, the initial stage in the development of a missile shield of our country.

It should be noted that some models of this exposition has already been described in the article “M-K”: R-1 (No. 6 of 2012), R-2 (No. 7-2012 g) and R-5 (No. 6-2014).

Today our publication is about R-12 and its model counterpart.

Ballistic medium-range missile R-12 (designer M. K. Yangel) was the first strategic missile. She received index 8K63. The first launch took place on 22 June 1957. The missile has received 4 March 1959 in the newly created strategic Rocket forces (RVSN). 8K63 was the most mass-produced (produced 2300 units). For many years it was in service with the strategic missile forces, and the last of them were destroyed in may 1990.

Rocket R-12 (Fig. 1) for the first time had a fully Autonomous inentionally control system. The rocket consisted of a warhead, transition, skirt, blocks, oxidant magbabago instrument compartment, fuel tank and tail section with placed on it the starting graphite supports and gas rudders, which are carried out flight control.

Rocket R-12 was a further development of the already established R-5 and R-5m and for its production was used and the same processing equipment. Use for R-12 engine RD-214 altered the appearance of the rocket – had to do a conical skirt in the tail section that improves stability in flight. The same purpose was served by the four fixed aerodynamic stabilizer.

Subsequently, after the elimination of missiles R-12, based on them were developed the rocket series “Cosmos”.

TECHNICAL DATA OF R-12 MISSILE

Length – 22 100-22 770 mm.

Diameter – 1652 mm.

Sweep the stabilizers – 2003 mm Starting weight – 41 700 – 42 200 kg warhead Weight – 1300 – 1640 kg. the motor is running – 140 C. and Range up to 2100 km.

The proposed model is a copy of the R-12 (Fig. 2) scale is 1:25. It is called, – dual-use: as the subject of the exhibition and as a sport “shell” for a speech at the event on the model rocket in the S7 category – on realism of the flight. Her designer – Vitaly Pirogov – eighth-grader of the Lyceum № 7 in the town of Elektrostal.

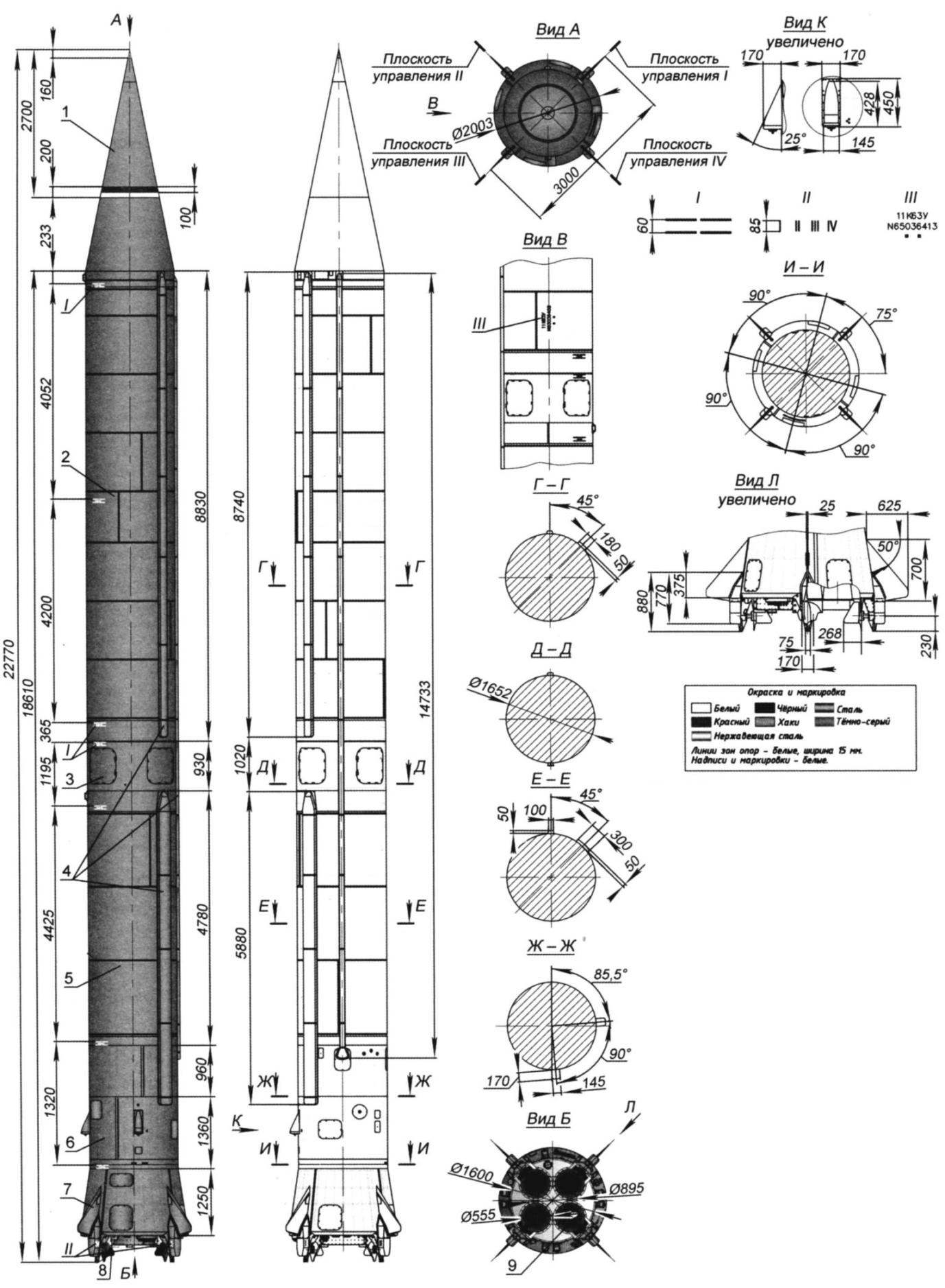

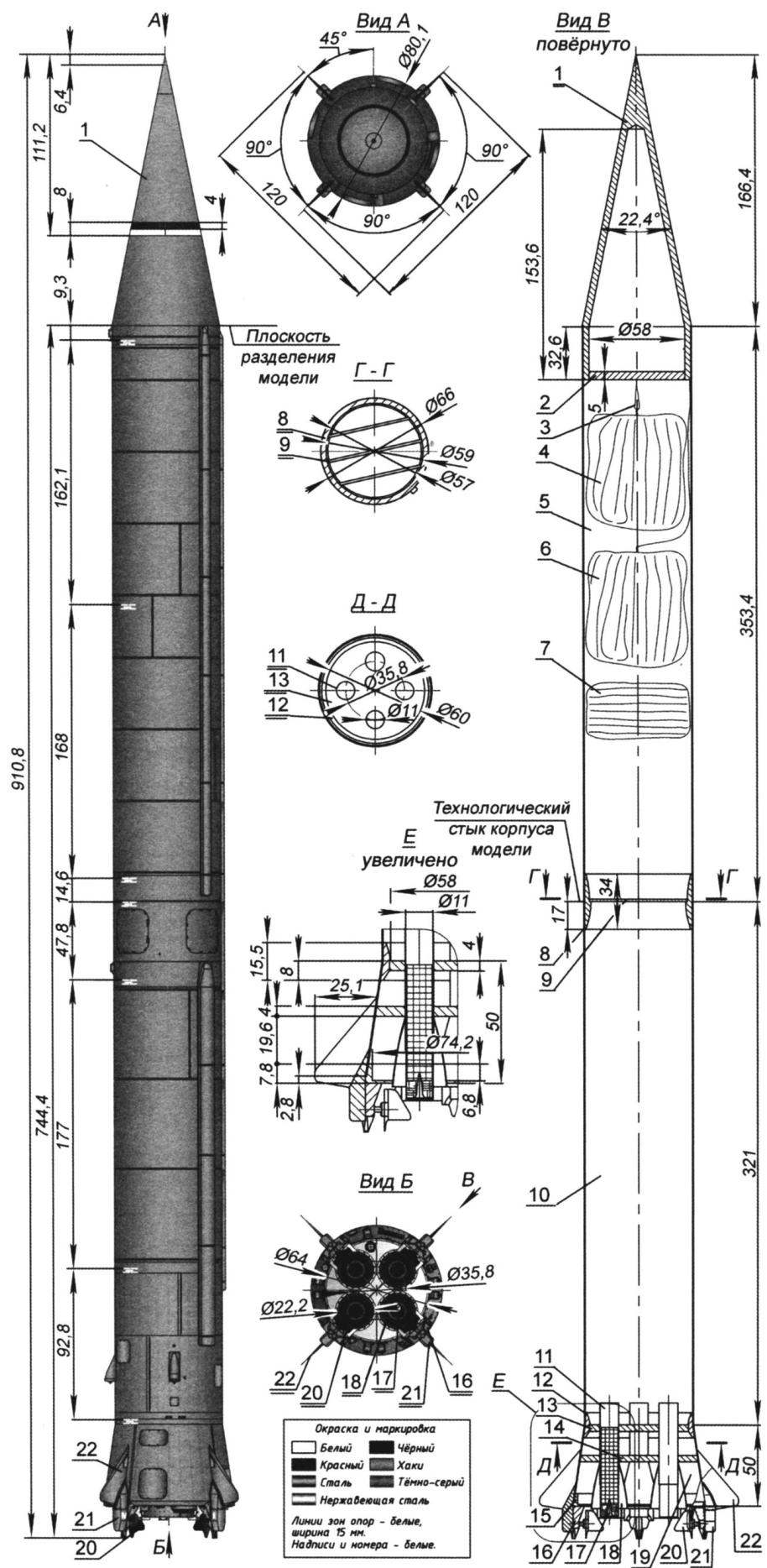

Fig. 1. Ballistic medium-range missile R-12 (8K63 index):

1 – head; 2 – the block oxidizer tanks; 3 – instrument compartment (libacovea); 4 – gargrot; 5 – fuel tank; 6 – the rear compartment; 7 – aerodynamic stabilizer; 8 – gas drive; 9 – nozzle engine, the RD – 214

Fig. 2. Model-a copy of the R-12 missile:

1 – fairing; 2 – frame; 3 – loop parachute suspension of the head part; 4 – parachute head part; 5 – upper element of the shell model; 6 – parachute corps; 7 – wad; 8 – connecting sleeve elements of the case; 9 – retaining bars; 10 – the bottom element of the case; 11 – container MRD; 12 – connecting bushing of the tail cone; 13,14 – frame; 15 – soft-frame; 16 – bearing; 17 – MRD; 18 – simulation of the nozzle; 19 – conical skirt; 20 – gas-dynamic drive; 21 – fairing of the rotary mechanism; 22 – aerodynamic stabilizer

The main “building” material for the creation of this copy extra – ordinary drawing paper with a thickness of 0.22 – 0.23 mm, PVA glue or “Moment” (“Joiner”) necessary for its production will need two mandrels, cylindrical – with a diameter of 65 mm and a length of 450 mm and taper – length of 75 mm and a cone angle of 15°. The most suitable material for the mandrel metal. For cylindrical can be successfully applied and plumbing pipes. Pipe an outer diameter of 65 mm that is sometimes found in stores.

Model-a copy of the R-12 missile as a prototype – single. For the flight demonstration of a lot of points with her “didn’t earn”. But a good estimate can be obtained on a “stand” for quality workmanship, as well as mnogovektornosti during the flight, using all four engines pulse of 2.5 or 5 n·C. But this entails complication starting “complex” for successful start-up, which somewhat reduces guarantee simultaneous ignition of all MRD.

Our attentive regular reader may have noticed the length of the mandrel of the shell model. Yes, she really became twice shorter. And here’s why. While working on this copy we first made a mandrel length of about 650 mm. But in the process of manufacturing faced a problem – to remove from the mandrel such a blank has proved impossible, even using all sorts of tricks: and hydration, and the taper of the mandrel. But the truth was much simpler – to make the body of the two elements, and then combine with sleeve, pre-attornevs connecting plane.

It should be noted that we in the circle have a lot of experience with models-replicas of missiles. But each new one has its own characteristics. And the guys-members each year, gaining experience flying design, join the ranks of copyists, bringing the process of making the product something, new.

The proposed technology of making flying models-copies of the R-12 – further perfection of work of young modelers-the”rocket guys”. Conventionally, this model can be divided into two parts: the main body (length 710 mm) and a fairing (length 199 mm). The procedure of production is irrelevant and is only dictated by the availability of material and working conditions.

Fairing carved from basswood on a lathe. Billet with a diameter of 70 mm and a length of 210 mm is clamped in the Chuck of the lathe and process from the outside, reducing the diameter to the cartridge. Then gradually rassverlivajut inside to a depth of 150 – 152 mm drills of different diameters – from 10 to 25 mm and do the internal conical bore (the angle of 22.4°) long cutter. And to a depth of 32 – 33 mm – bore cylindrical (diameter 58 mm). After that take it out of the Chuck of the lathe, clamp a new billet and make the frame for the fairing and fix it reamed part. The junction (for safety) coat with glue dots. After it dries on the outside treated with the cutter set at an angle of 11.2°, cleaned with sandpaper and coated with nitrocellulose lacquer. Plywood machined the bulkhead with a diameter of 58 mm and tightly inserted into the end of the fairing, pre-vkliw it a loop for attaching a parachute. Then, after loading the fairing when balancing the finished model, it is necessary not to forget to attach the frame tightly.

The case of the model-copy of the R-12 missile is made of two cylindrical elements: the upper – 353,4 mm in length and the lower length of 321 mm, Each element glued from two layers of drawing paper on the mandrel with a diameter of 65 mm. After drying, the resulting blank is treated with the seam with sandpaper and coated with a single layer of nitro lacquer – so removed the pile after Stripping the skin. Then mark with a pencil the location of the welds and paste over each element of the hull with strips of thin paper (thickness -0,13 mm), making them knurled rivet joints with a gear of the clock in increments of 2 – 2.5 mm. Width strips of paper at the same two locations, that is, 86 -88 mm. After drying, the joints of the strips are pasted over with strips of width 1.2 – 1.5 mm. It will be an imitation of the welds.

Then the mandrel with the wound preform is placed in a bucket of water, add 2 – 3 l of hot water and cover the entire “design” plastic bag – make a steam bath. After 20 to 30 minutes, the glued element can be easily removed from the mandrel. Similarly vyklevyvajut and bottom element. After drying, the removed elements of the case are put on the fixed wooden frame and butt length, respectively 353,4 mm and 321 mm.

Tail section (skirt) vyklevyvajut the same technology. But for pasting the outer layout will have to make a special template (jig) to fit in place and then trim the length of 50 mm. the Connection of the skirt with the bottom element of the housing is carried out using a bushing, carved from basswood. But first glued it in the rear compartment.

Motor (power) unit model R-12 – generic. It has two options for the placement of the engines – two and four. This model is equipped with two MRD momentum 5 n·s). The power unit consists of four containers mrad with a diameter of 10.5 mm and three balsa frames with a thickness of 3 to 4 mm, made of plywood. Fix the unit in a skirt after gluing the bushings and assembling the lower element of the body.

Fig. 3. Mandrel for the manufacture of housing elements-models of R-12 missile:

1 – tail; 2 – the Central part

The connection of the upper and lower housing parts produced with the help of the sleeve, which is simultaneously holding the bars for wadding and parachutes at the start of the model. To do this, it glued a few spacers made of bamboo slats with a diameter of 1.5-2 mm. All of this allows not to disturb the alignment model at the time of launch. For reliability, the mechanical bonding of the elements of the case on top of the time necessary to put weights (150 – 200).

Stabilizers (four of them) are cut from glass fiber plastic with thickness of 2 mm, profiled and fastened tight with a Bobby pin to the tail compartment. Put them only for evaluation and flight.

The final stage in the work on model gluing all the external elements: boxes, racks, pads and painting. Main color – khaki. Simulation of nozzles of the bottom part is silver.

Before you fly, determine the DH model (MRD). It needs to be in the region of the connecting sleeve. From experience, fairing need to load 20 -25 g. of lead and equip the model in flight condition.

The starting weight of the model is around 145 g.

V. ROZHKOV