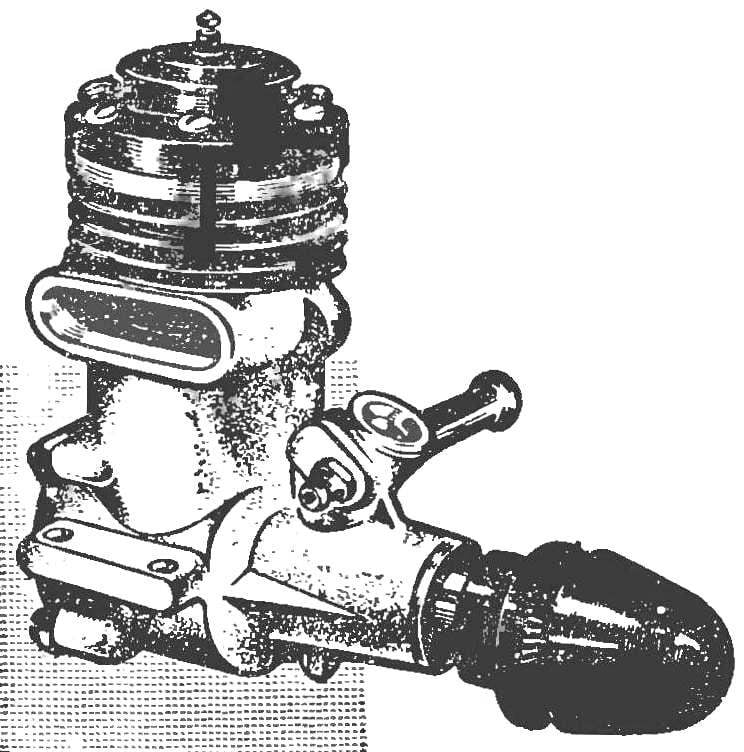

The need for easy to operate, the engine for aerobatic cord models-copies and the lack of compression engines of large cubic capacity prompted Novosibirsk modelers from CUT SB as USSR to the idea to alter the pre – “Flight” in the compression option.

The need for easy to operate, the engine for aerobatic cord models-copies and the lack of compression engines of large cubic capacity prompted Novosibirsk modelers from CUT SB as USSR to the idea to alter the pre – “Flight” in the compression option.

This engine starts easily and has adequate power. All operations on the adaptation made in aeromodelling circle.

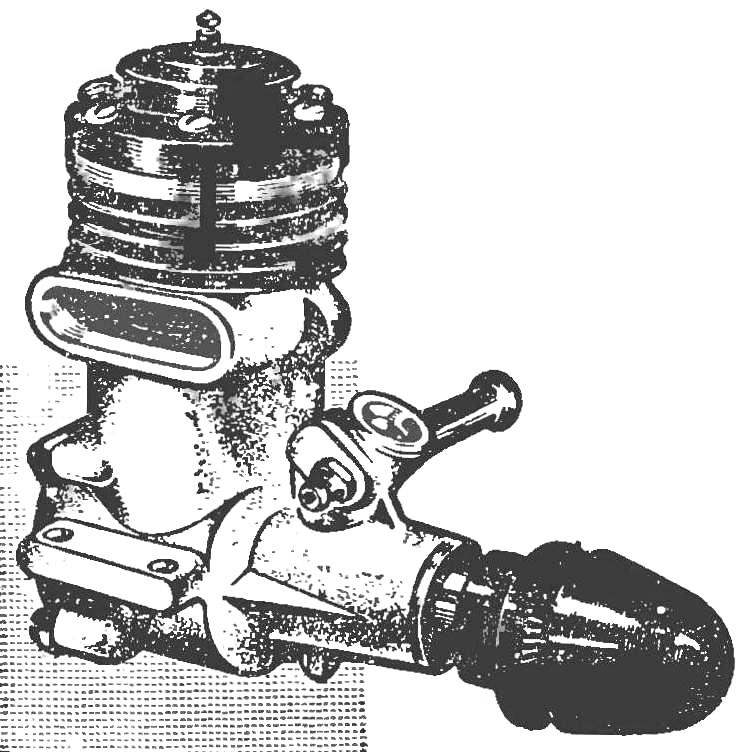

Blow controlling (Fig. 1) made of grey cast iron of any brand, began the top 10 or 20. Then modify the cylinder liner, as shown in figure 2. The bypass window solder steel liner (solder POS-40). The inner diameter of the sleeve in the lower part with the help of lap increase is 0.008—0.01 mm. below the top collar of the cylinder put a ring thickness of 0.5 mm. It will increase the phase of exhaust and bypass 6°. There have been attempts to increase the phase at 10 to 12°, but then the engine got worse. Final timing is shown in figure 4.

To reduce the volume of the crankcase and to reduce the resistance to gas flow cavity of the crankshaft to fill in epoxy resin, as shown in figure 3. To the bridle on the epoxy, attach the two balsa segment also covered with epoxy resin. As the weight of the segments is negligible, this operation requires no additional balancing of the crankshaft, at the same time, the volume of the crankcase is much reduced. (The author claims that after two hours of no bonding defects were found. — Editor’s note.)

A piston (Fig. 5) cut off the deflector. The rod will zakruglenie sharp edges and Polish it. Sealed one of the holes in the nozzle of the carb, as if there are two holes occurs perezaliv motor during charging, and also difficult to adjust the speed and mode of operation unsustainable.

The engine works well in a mixture of ether, kerosene and oil MS-20 (33.3%). With a screw diameter of 280 mm and spacing 150 mm, it develops up to 10 thousand Rev/min.

Yu. a. GORSHKOV, head of the aircraft modeling lab CUT USSR Academy of Sciences,