Every constructor of ship models know how difficult it would be to “bind” the motor with a screw. Especially when we are talking about models up to 50 cm

Every constructor of ship models know how difficult it would be to “bind” the motor with a screw. Especially when we are talking about models up to 50 cm

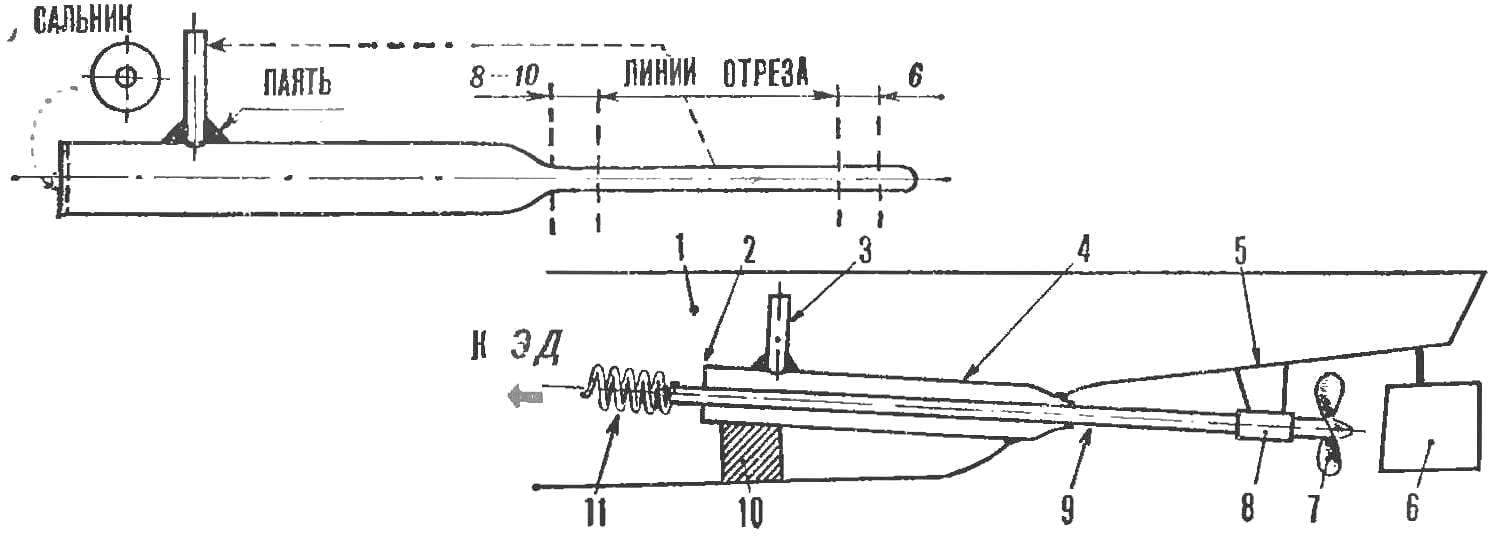

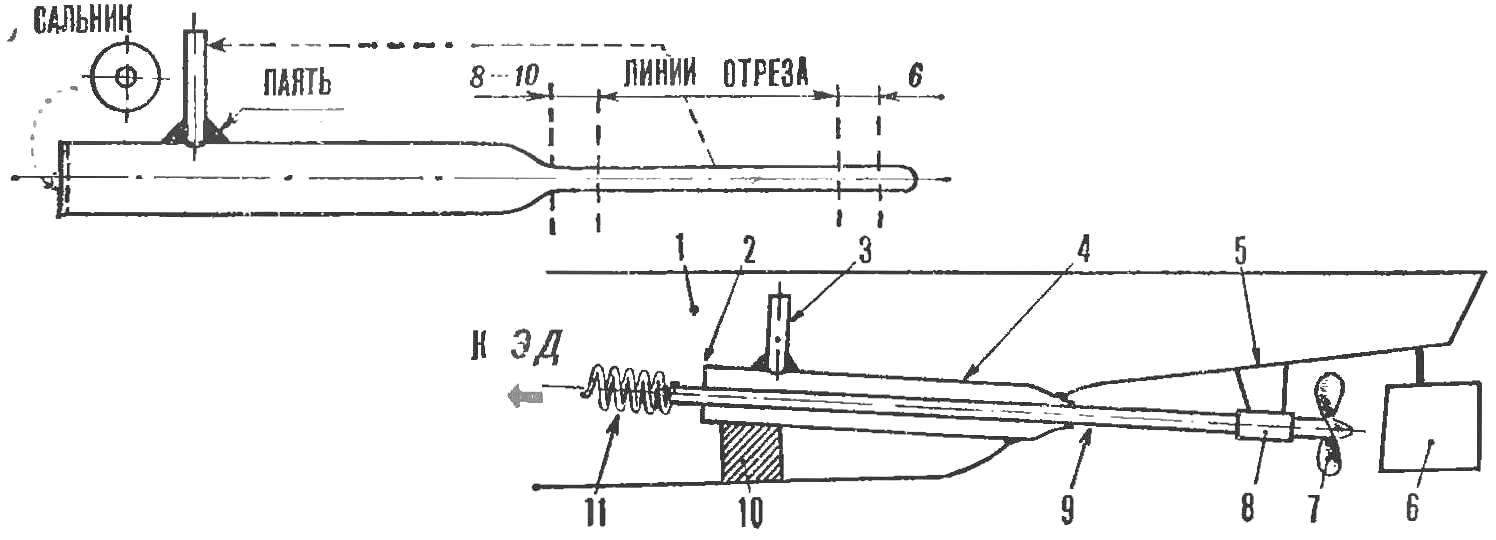

Dadude doing all sorts, and yet many of them miss the water. To improve this knot can be a simple and reliable way. Take the metal rod from the “thick” of refills for a ballpoint pen and cut a thin part at a distance of 8-10 mm from the hull (see figure). (Pre-fill stem acetone to remove the remains of the paste.) To the end of the widest part of the tin solder at the bottom, in the center punch hole, equal to diameter of steel knitting needles (future tree). One end of the spokes connect to the motor by a spring, and on the other solder screw.

Deadwood of rods from ballpoint pens:

A diagram of the manufacture of deadwood; B — installation of deadwood on model: 1 — body 2 — seal-washer, 3 — fuel tube, 4 — deadwood 5 — bracket, 6 — wheel, 7 — screw, 8 — hub, 9 — shaft (needle), 10 — housing mounting bracket, 11 — prugna.

If the shaft screw is much longer than the deadwood, make an additional bracket, the outer nonet which solder to the leg in the same tube (its thin part with a length of about 6 mm). Through the filling tube, fill the system with grease. Reliability is guaranteed. Water will not penetrate into the housing.

A. DOROSHENKO, g. Gaysin