Among the expense of building a traditional models, the class b-1, includes construction on an oversized fuselage, equipped with a rubber motor, is in artistic terms, perhaps, of greatest interest. They are built and young modelers, making only the first steps in small aircraft, and celebrated masters — participants of competitions of the highest rank.

Among the expense of building a traditional models, the class b-1, includes construction on an oversized fuselage, equipped with a rubber motor, is in artistic terms, perhaps, of greatest interest. They are built and young modelers, making only the first steps in small aircraft, and celebrated masters — participants of competitions of the highest rank.

The model we offer to you today, on forces not to everyone. A number of its elements requires very careful handling and must be manufactured to a high accuracy class. It is mainly refers to rotor group (in the manufacture of screw we recommend to use our tips, see “M-K” № 3, 1977), And yet, according to the designer rezinomotornaya, the master of sports of the USSR V. ROZHKOVA, the difficulties should not be afraid: try it and cruise model will justify your work reliable stable flights.

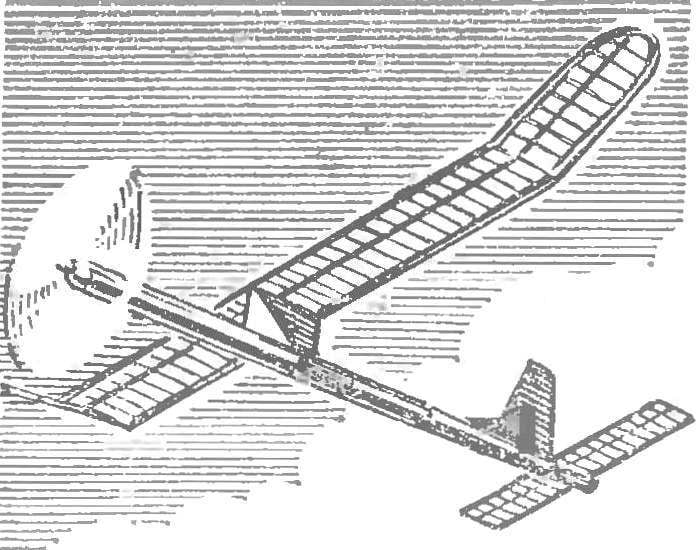

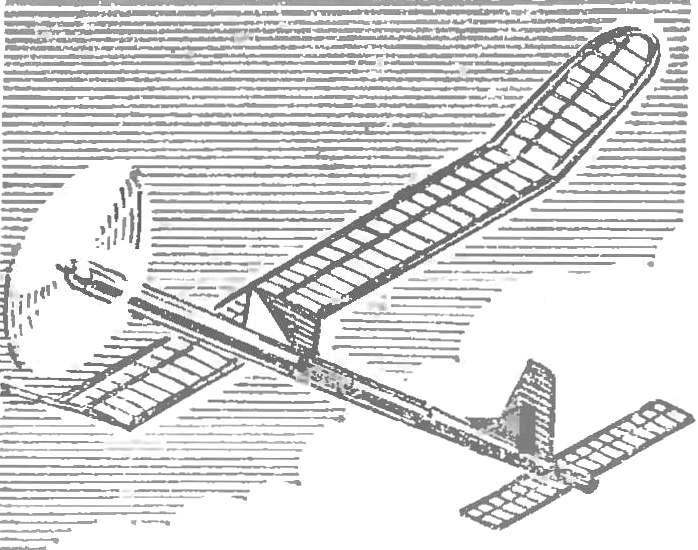

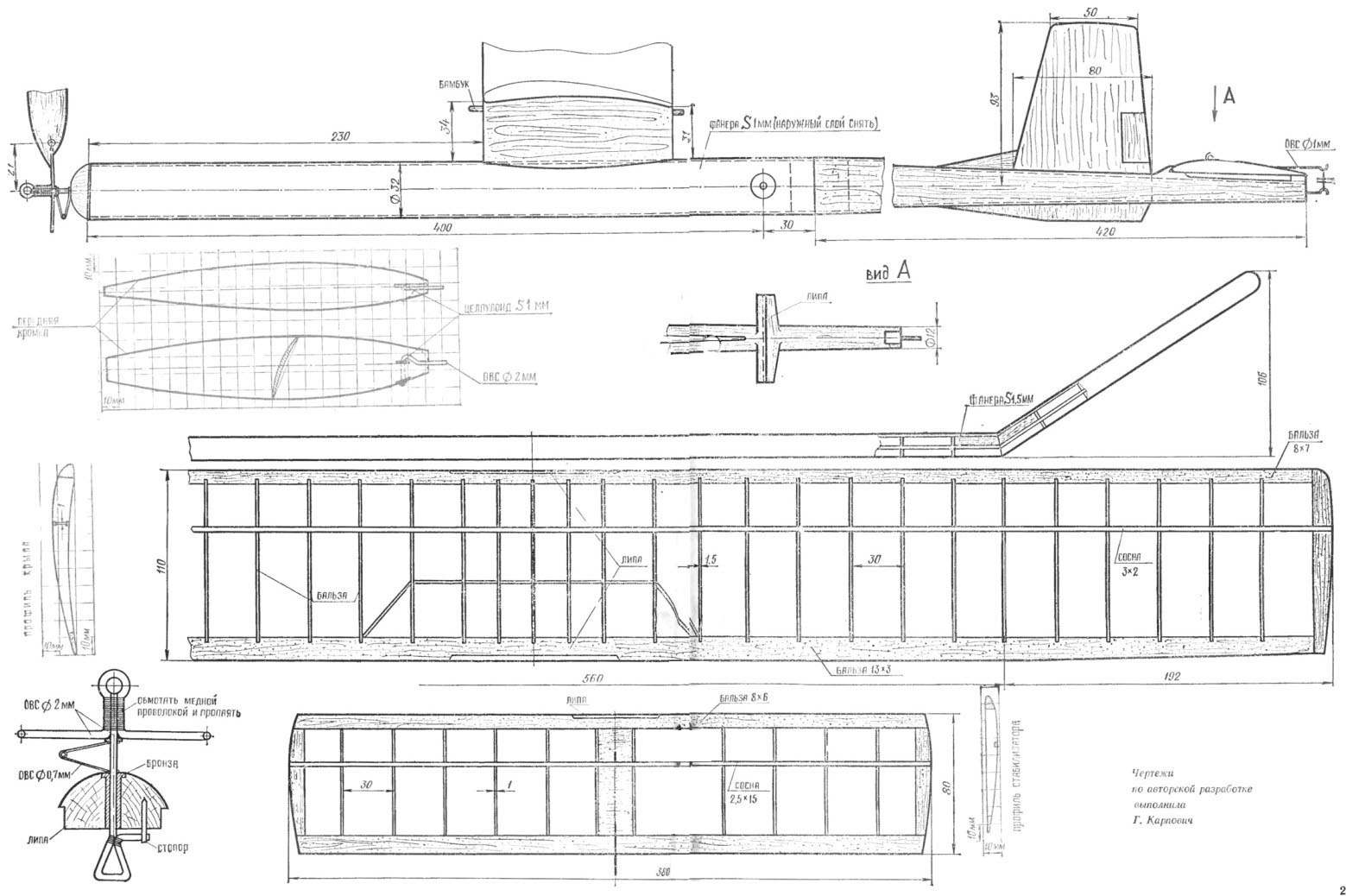

Rezinomotornaya model airplane is made according to the classical scheme.

The FUSELAGE is from the engine (power) parts and tail boom connected to the boss. The first is made of plywood with thickness of 1 mm in the following way. A sheet of plywood 450X110 mm steamed in warm water and tightly to the disc Ø 30 mm rubber strap. After drying, the seam cut down on “us” together. Do not forget to wind up on disc two layer of tissue paper, glued to the fuselage was easy to remove. Giving to dry the glue, clean off with a file one sing that will reduce the weight of the resulting tube up to 15-20 g Inside her twice to cover Amalita.

TAIL boom made of balsa wood with a thickness of 2 mm on the tapered mandrel in the same way. On the thin end of the glued plate of the Pipa with a thickness of 2 mm for attachment of the stabilizer. Rear hook-twisted steel wire Ø 1 mm.

PYLON — the balsa block with a profiled upper surface is glued to the fuselage. Front and back it is fixed by the two pins of bamboo for winding rubber thread wing mounting.

KEEL — balsa plate thickness of 2.5 mm. is inserted into the slot of the tail boom of the fuselage and is fixed on the glue. Assembled weight 7,7 g

WING — stacked design. Edges, tip and ribs from balsa. You can run them from Pipa, however, care should be taken that she was dry and seasoned. The thickness of the parts it is necessary to reduce by about half. Ribs (balsa 1.5 mm thick or polovye — 0.7 mm) are cut from the solid, profiled bar, cut with a thin knife and emery paper are handled, and to increase the rigidity of the sides are covered with Amalita.

SPARS (two of them) — from pine slats with a cross-section 3×2 mm. Central part of the wing is a straight wing. Angle of transverse “V” made by the wing tips in the form of “ears” formed by the cantilever parts. Longerone of each console are connected With the spars of the wing parts out of plywood with a thickness of 1.5 mm. the Space is filled with balsa plates. The front and rear edges in the middle of the increase of fake accents. Wing glued long-fibre paper and covered with Amalita: top three times and four times from the bottom. Weight 28 g.

The STABILIZER design is similar to the wing: the front, the rear edge of the ending and 12 ribs from balsa. The longitudinal section 2,5X1,5 mm — one top only. Hooks for attaching to the fuselage is made of steel wire Ø 1 mm. Stabilizer attached to the tail boom plate rubber thread, which rejects it for a “parachuting” at a 45° angle, it is held in this position a thin fishing line.

The stabilizer is glued with paper and three times covered with liquid enamel. Its weight is 8 g.

GROUP-ROTOR model consists of a two-bladed propeller with folding blades, bushings and rubber motor. Hub and shaft screw wire OVS Ø 2 mm. Hub is curved so that at both sides is formed by the axis of oscillation of the blades. The boss is machined from Linden, it is based on epoxy resin sticker bronze bushing serving as a bearing for the shaft of the screw. Between the boss and the hub — spring of a pin type wire OVS Ø 0,7 mm. the Blades from balsa. In places of attachment to the hub is thickening, it is drilled hole Ø 2 mm: additional reinforcement serve as a celluloid overlay. On the outer contour of the blade need to turn over a strong thread, glue long-fibre paper, and six times to cover Amalita. The weight of the blade is 3.5 g With the inner side of the boss screw is fixed with a wire pin (stopper), which, after unwinding of the rubber motor stops the propeller in a horizontal position. Under the action of the incoming air flow to tend to fold along the fuselage, reducing drag. Screw diameter 400 mm, weight 30 g.

The rubber motor is dialed from a round rubber Ø 1 mm, length — 400 mm, weight 20 g.

All up weight 163 g.