Mechanical hand inertia starter, which we want to offer a very simple. For its production it is not necessary to engage the gear works to make gears and toothed wheels for multiplier. Currently there are several manual sharpening with different gear ratios gear — 10 RT-10 and 16 at RT 16. For an inertia starter will need gear from two such tools. It is important that the total gear ratio of the future fixture was 30-40.

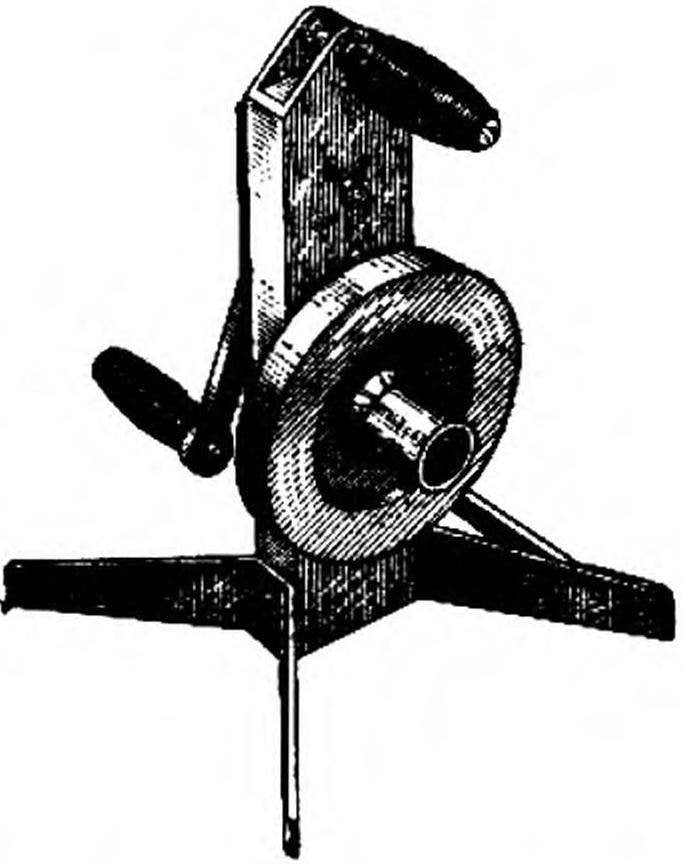

Look at figure 1. To start the engine, the flywheel and the starter spins the spinner of the model airplane is pressed against the friction bushing.

The friction bushing is made of rubber tube, hose or a monolithic cylinder having at one end a conical hole is deaf. The initial diameter of the cone in the sleeve 12 to 14 mm. it is Necessary that the friction torque generated on Koke was sufficient to turn the screw. Ensure that the surface coke did not get oil or fuel.

The flywheel is a battery of kinetic energy, accumulating it during the promotion. It is installed on very high-speed — output shaft. The flywheel can be manufactured in the form of a solid disk or a lightweight, with a groove in the Central part. You can do composite, vytachiv its Central part is made of aluminum, and peripheral — in the form of steel rings. Note that the flywheel must be carefully balanced — it is best to do “that by inserting the smooth shaft and installing the two pregnant ground line. Balancing is done by drilling out the material of the peripheral part of the circle.

Fig. 1. Inertia starter:

1 — heel (D16T. strip 4 mm thick). 2 — the case (D16T, sheet thickness 5 mm), 3 — flywheel (steel) 4 — friction bushing (rubber), 5 — Bush (D16T), 6 — M4 screw (steel), 7 — pin 0 4 mm (steel), 8 — a radial-thrust bearing 9 — bearing housing, 10 — cap (D16T), 11 — spacer (D16T), 12 — knob (PCB). 13 — axis (D16T), 14 — way clutch. 15 — washer (D16T), 10 — lever (D16T), 17 axis (steel), 18 — stick (PCB). 19 — M4 screw (steel), 20 screw M6 (steel).

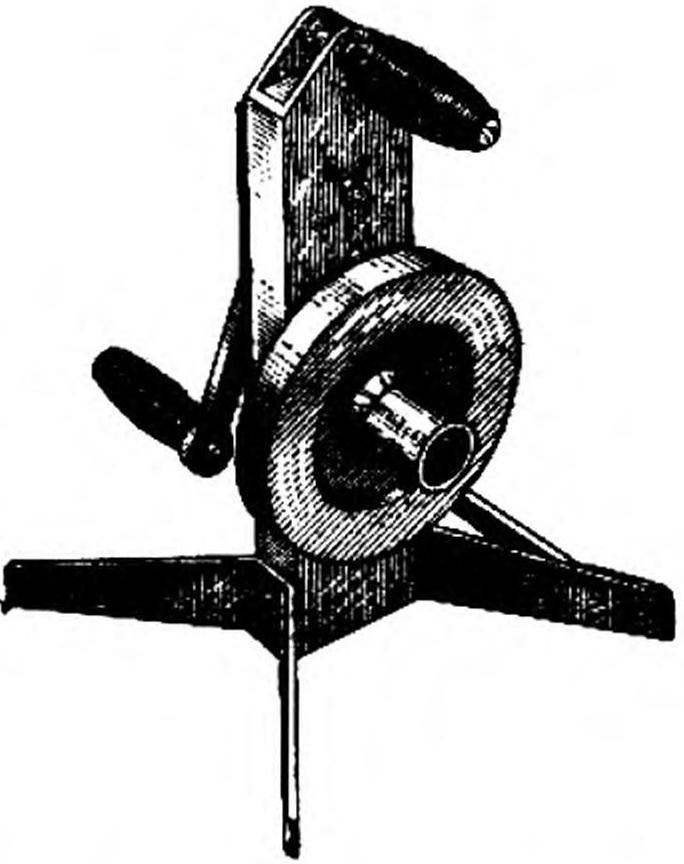

Fig. 2. The ratchet mechanisms (A — gear B — roller):

1 — sleeve, 2 — led bushing, 3 — rollers. 4 — toothed wheel. 5 — shaft of the multiplier, 6 — spring, 7 — dog.

The multiplier has a gear ratio of about 40. When choosing gear, keep in mind that their modulus should be not less than 1, otherwise inevitable chipping of teeth.

Actuator lever has a shoulder equal to 200 mm. With a multiplier it connects by using a ratchet or roller clutch mechanism. Schemes both one-way clutches shown in Fig.

Heel starter constructively is chosen such that the device was stable and ke is overturned in the promotion of the flywheel. The heel needs to be provided for sites on which the promotion and launch of advancing feet, holding the mechanism to the ground.

In the design and manufacture of starter strive to ensure that he was perhaps easier because they have to and during the competition. Makes sense the heel starter to make removable or folding when the device becomes more transportable.

V. НАЙД0ВСКИЙ, head of airmodelling mug, Kharkov

Recommend to read MINI DRILL This device (see figure) is used for drilling holes of small diameter, which is often required in the manufacture of small structures, models, repair of printed circuit boards. For... FROM CATAMARAN TO TRIMARAN In my previous article (see “M-K” No. 12-2019 and 1-2020 ) I talked about the experience of building and operating a collapsible planing catamaran of the Craig Cat type. Such a craft can...  Every year the competition is less you can see modelers who runs the micro internal combustion manually, without the aid of special starter. Often using mechanical devices, electric starter with battery to use is not very convenient — too heavy batteries, and to recharge them is not always possible in “field conditions”.

Every year the competition is less you can see modelers who runs the micro internal combustion manually, without the aid of special starter. Often using mechanical devices, electric starter with battery to use is not very convenient — too heavy batteries, and to recharge them is not always possible in “field conditions”.