At the Moscow city competitions on indoor models in 1975, first place went to Evgeny Ermakov. His model is a copy of the “blériot XI” rubber engine showed in the three games great duration: 60, 64, and 50 C. None of the Soviet airplanes have not demonstrated a flight duration rezinomotornaya room-models. How is “micro-Bleriot XI”?

At the Moscow city competitions on indoor models in 1975, first place went to Evgeny Ermakov. His model is a copy of the “blériot XI” rubber engine showed in the three games great duration: 60, 64, and 50 C. None of the Soviet airplanes have not demonstrated a flight duration rezinomotornaya room-models. How is “micro-Bleriot XI”?

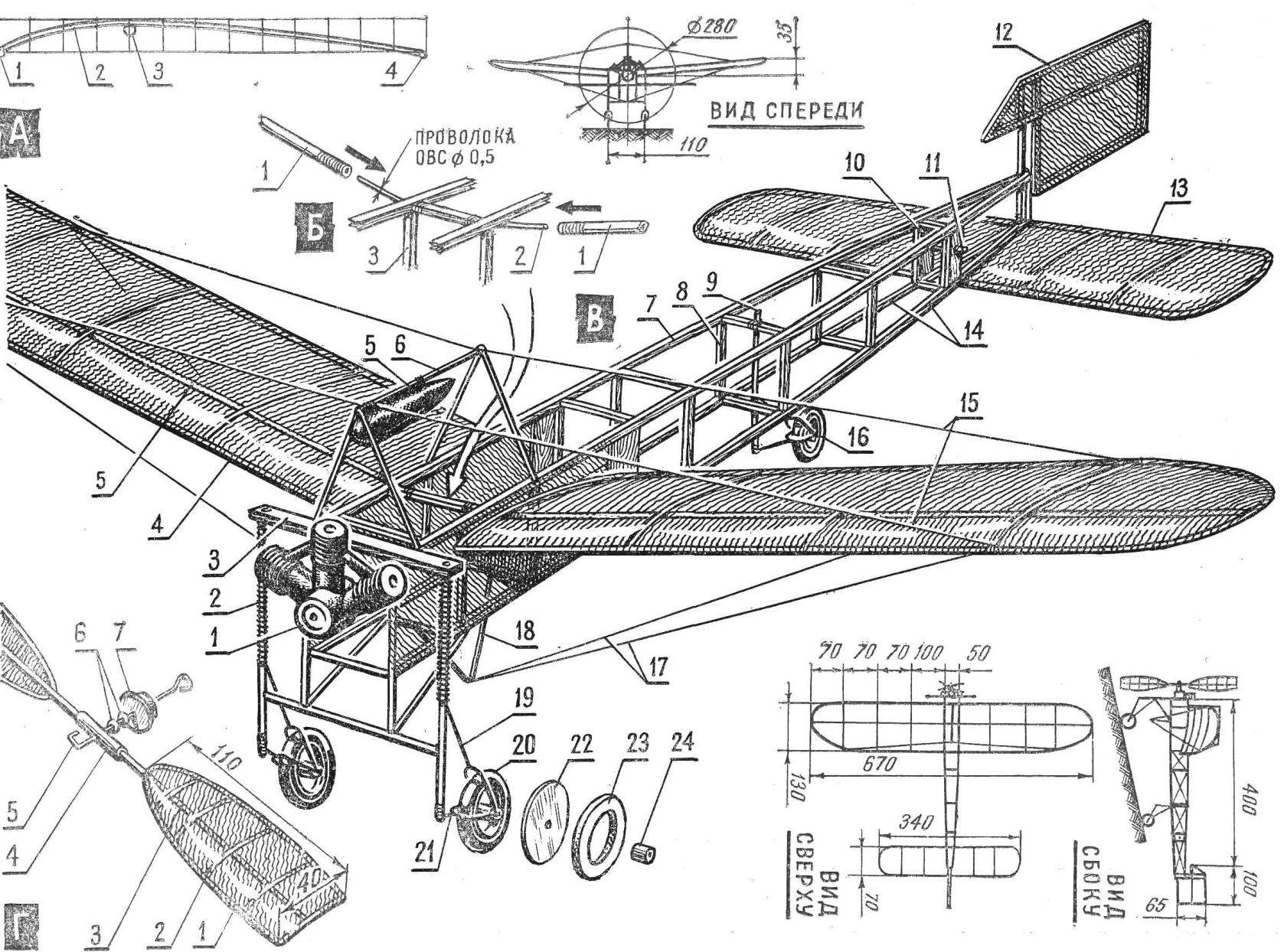

The fuselage is glued emalita of the longitudinal and transverse balsa strips a cross section of 3X3 mm. Left and right side panels are collected separately at the Plaza, and then joined cross struts. In the rear fuselage directly behind the last frame reinforced two plates with holes for the bamboo pin on which is fixed a rubber motor. To the front of the fuselage attached to the frame of the balsa slats and 2X2 mm 3X1 mm, which is struts and struts made of steel wire Ø 0,5 mm forms a chassis. The upper horizontal strut of the front frame, two strips of 1X2 mm, which are attached to the front transverse strut of the frame. Around the vertical side bars of the chassis wound thread, simulating a spring-loaded depreciation. Wheel carved from balsa wood with a thickness of 1 mm with slots to simulate spokes. In the hub of each wheel is glued on both sides celluloid washers.

In the locations of the tires of the wheels thickened annular plates. In the front part of the fuselage strengthened the layout of the three-cylinder engine “Anzani”, painted black. Through the front of the engine is removable nasal boss of circular shape with the shaft of the screw from a thin steel wire Ø 0,5 mm. from the Top of the front fuselage is located the “wild boar” for braces. To simulate the cockpit of the upper horizontal strut of the fourth frame of the fuselage are curved, and the second frame top spacer is missing. On the sixth frame of the fuselage bottom on a wire rack strengthened tail wheel, the rim of which is carved out of balsa wood with a thickness of 1 mm, four spokes glued from balsa plates of 0.5 mm and the hub is formed of two celluloid plates 1 mm. Side front part of the fuselage pasted the usual tissue paper and painted yellow. The tail part of the fuselage sides has a brace of black threads, running crosswise.

The wing consists of two halves — left and right; each is assembled from two edges, curves and ribs. For making all of these parts are used dry grass stems Ø 1 mm for edges and 0.6 — 0.7 mm for radii and ribs.

For the correct placement of the wing on the fuselage follows with a sharp steel needle to carefully make holes on both sides of the fuselage, observing the dimensions shown in the figure. In these holes the pins will enter the edges of the wing, and it thus becomes under the required angle. After the wing is thus located on the fuselage, it rusclimat thread to the upper triangular “boar” and the bottom flat of the pyramid. In addition, the bottom pyramid for hardness should be fixed by additional braces from threads.

ROOM MODEL IS A REPLICA OF THE PLANE “BLERIOT XI”:

A rib of the wing (the square grid is 10 mm): 1 — front edge, straw Ø 1.5—1.8 mm; 2 — rib, straw Ø 1.5 mm; 3 — spar, straw, Ø 2-2. 5 mm; 4 — trailing edge, the straw Ø 1,5—1,8 mm. B — the attachment of the wings to the fuselage: 1 — wing spar, reinforced at the root with thread No. 30 with adhesive; 2 — wire pin; 3 — samotna frame. In General the model: 1 — model three-cylinder engine “Anzani” (foam); 2 — strut chassis; 3 — landing gear cross member (balsa зХ1,5 mm); 4 — tight (micuenta paper); 5 — spar wing; 6 — upper pylon (OVS wire Ø 0.8 mm); 7 — the upper spar of the fuselage (balsa 2X2 mm); 8 — samotna frame (balsa 2X2 mm); 9 — rear wheels (OVS wire Ø 0,8 mm); 10 — frame mounting pin; 11 — pin is for the rubber motor; 12 — the rudder (balsa strips 1,5X1,5 mm); 13 — stabilizer (straw Ø 1.5 mm); 14 — lower longerons of the fuselage (balsa 2X2 mm); 15—upper tie (black thread No. 30); 16 — rear wheel Ø25 mm; 17 — the lower stretch; 18 — the lower pylon (OBC Ø 0,8); 19 — upper wishbone wheel chassis (wire Ø 0,5 OBC); 20—wheel chassis Ø 35 mm; 21—front fork wheel; 22 — wheel disc (Whatman); 23 — bus (foam); 24 — bushing (Linden). G — details of the propeller: 1 — rim blades (straw Ø 1-1,2 mm); 2 — rib; 3 — longeron (straw Ø 2 mm); 4 — bushing (straw Ø 3 mm); 5 — the screw axis (OVS wire Ø 0,8 mm); 6 — washer (tin); 7 — bushing (Linden).

Horizontal tail design similar to the wing, but the profile he has a flat. In the manufacture of the stabilizer from the dry grass the diameter of the stems is necessary to choose equal to 1 mm When you use the balsa edge of the stabilizer should have a section 1X2 mm, and rib 1X1 mm. Cording stabilizer is the same as the wing, from a capacitor paper.

The keel of the model, like the prototype aircraft, with rudder. It’s built with balsa strips section of 1X1,55 mm, covered with condenser paper both sides and is attached to the rear fuselage in the vertical bar from the stem of dry grass.

The propeller — bladed. Hub it is made of cane with an outer diameter of 4 mm and a length of 40 mm. In this hub with both ends inserted into the spars of the blades, made of a stalk of dry grass thick at the root 1,00—of 1.55 mm. During Assembly of each blade it is necessary to withstand the angles of the ribs the ones that are shown in the figure. Upholstered blades of condenser paper on the top only.

After Assembly they should be connected with the hub so that the spars of their tight was part of it. Placing the blades at an angle of about 35° at the second rib, counting from the center of rotation, the connection of the blades with the hub should be sealed up. Front boss model is carved from balsa. In it is drilled a through hole of 1.5 mm, the ends are glued celluloid plate 1 mm with a 0.5 mm. hole Through the plate, the noise, the screw shaft made of steel wire Ø 0,5 mm, terminating in a hook. All up weight is 22 grams, five of them — the weight of the rubber motor with a screw. The rubber motor consists of four strips of 1X3 mm. cross-section For the adjusting of the flight should be spun to 40-50 rpm during test flights the number of turns of twist must be reduced to 250-300, stretching the rubber motor on 30% of its length. The model, being launched from his hands, flies freely in circles for 60-70 C.

Vladimir KOMAROV, head of the aircraft modeling a roundabout club “Metrostroy”