Submarines — class ships to naval fleets, is designed for attacking ships and land-based enemy targets from a submerged position. They are divided into missile and torpedo.

Submarines — class ships to naval fleets, is designed for attacking ships and land-based enemy targets from a submerged position. They are divided into missile and torpedo.

The first armed located in vertical shafts, built into the hull and ballistic missiles. They self-lock onto enemy targets, separated by the distance of 4 thousand km, and the Displacement of these submarines reaches 8000 tons, length 130 m, width 10 m, draft 10 m, underwater speed of 35 knots (1 knot 1 mile/h).

On a torpedo boat set from 4 to 8 machines with a supply of torpedoes or missiles, damaging enemies at a distance up to 60 km, the Submarines can be equipped as nuclear and diesel-electric installations.

In addition, there is another kind of submarines — anti-submarine; their main objective — search and destroying their own kind. They are equipped with powerful sonar, hydroacoustic stations, and are armed with torpedoes and missiles. A distinctive feature of these boats for maximum maneuverability and quiet. Their displacement is about 400 tons, underwater speed up to 40 knots, length 80 m, width 8 m, draught up to 8 m.

THE BUILD

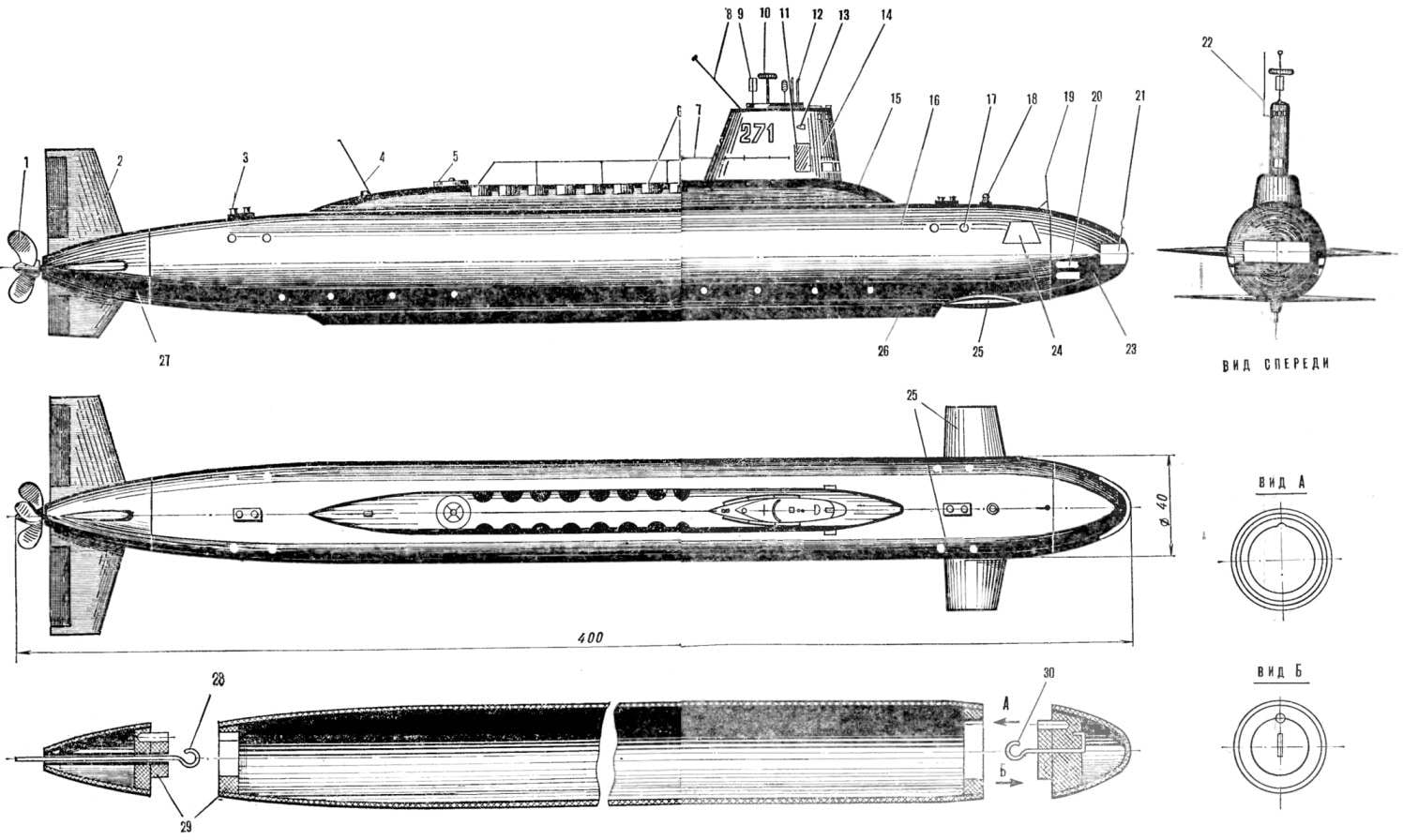

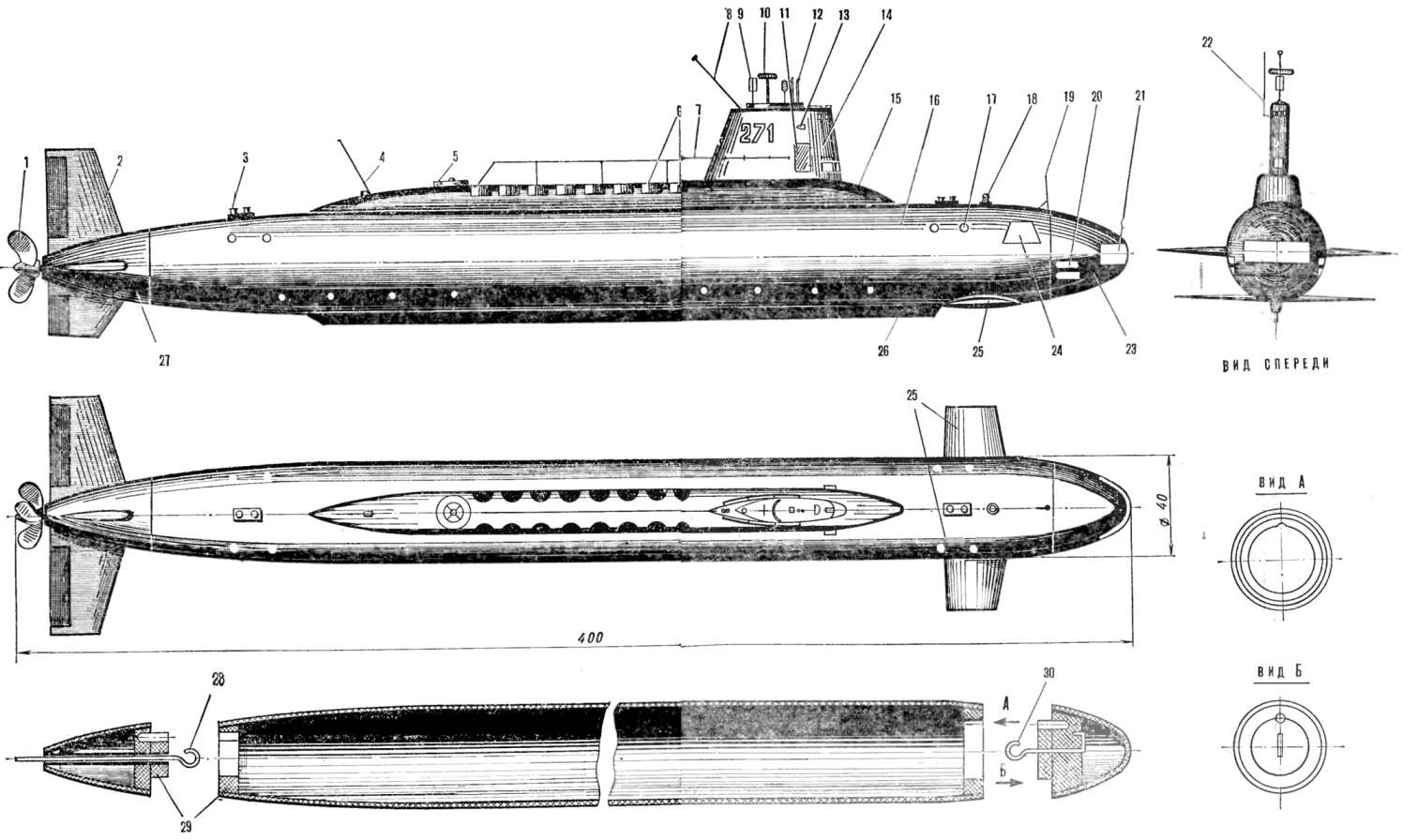

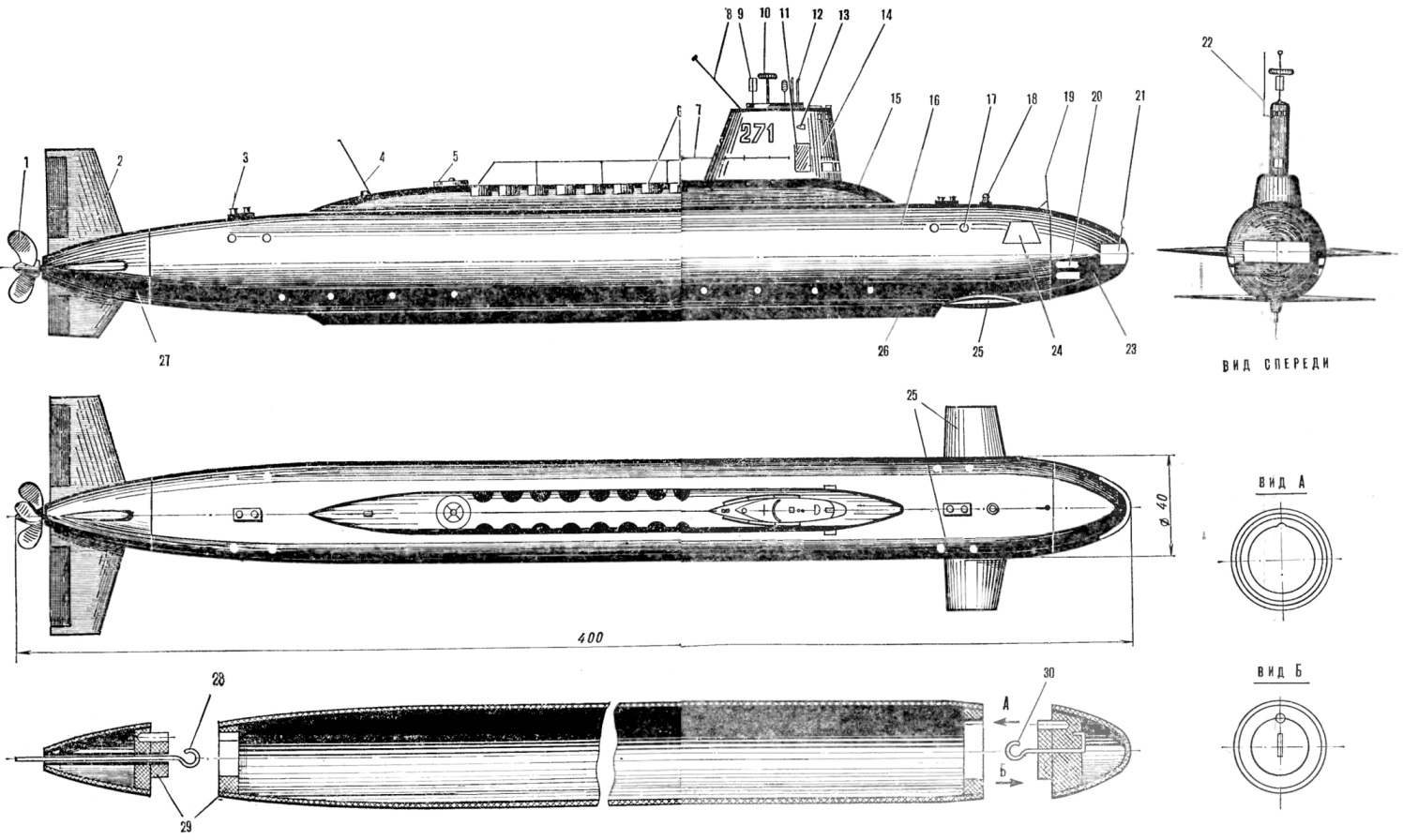

Model submarine of the second type, which we offer you to make, consists of hull, stern and bow ends, deckhouse, superstructure for rockets, propeller shaft, rubber motor, ballast, and vertical and horizontal rudders.

For making models need to first make punch and matrix. The first is performed on the dimensions given in the drawing, of beech or birch stick. Processing is carried out on a lathe, and finally the surface is finished with a file and emery paper. Next, the workpiece ostrugivajutsja a plane up to half in the longitudinal plane of symmetry.

Then from a sheet of plywood with a thickness of 5-6 mm and a size 600X250 mm make a matrix. This is done so. In the center of the sheet, put the punch and encircle it with a pencil. Add allowance for thickness of material (polystyrene, Plexiglas, plastic) and cut out with a jigsaw along the marked contour. The remaining sheet of plywood with a hole and will fulfill the role of the matrix.

Next stage. A piece of polystyrene the size of 500X250 mm is heated over a stove or in an oven Until tender and using tongs, put it on a wooden punch and tap on top of the matrix. The operation continues until, until the plug will not upholstered polystyrene. The resulting billet polucarpus models cool wet rag. Now start squeezing the second half of the body and handle both blanks with sandpaper or a file, ensuring that every detail was exactly half the diameter of the shell model. Then the parts are glued together, sanded with a file and sandpaper and, in accordance with the drawing, cut the front and back. And last of Plexiglas with a thickness of 5-6 mm are machined on a lathe the coupling sleeve and glued them to the ends of the hull (bow and stern part of the model). The same technology used to manufacture the superstructure and the wheelhouse.

Beacon, the spire and the bollards will have to carve on a lathe out of aluminum slide-on device (locator, periscopes, direction finders, Leer, flagpoles) solder scraps of wire. The missile hatches, doors, Windows, chassis (distinctive) lights are made of celluloid . and glued with acetone.

Device propeller installation, the size of its details and methods of mounting is clear from the drawing. We only note that screw Ø 25-30 mm are cut from sheet and soldered to the propeller shaft Ø1. 5-2 mm (it can be made from the spokes). Horizontal and vertical rudders are cut from polystyrene.

Submarine with rubber motor:

1 — screw, 2 — vertical steering wheel, 3 — cleats, 4 — pole 5 — a rescue buoy 6 — the missile hatches, 7 — layer, 8 — pole 9 — finder, 10 — radar, 11 — door 12 — open 13 — navigation light, 14 — cabin, 15 — add-16 — body 17 — hole to fill water, 18 — spire, a 19 — gaystock, 20 — in torpedo tubes, 21 — sonar 22 — retractable antenna VHF, 23 — the bow of the hull, a 24 — hawse hole, 25 — horizontal handlebars, 26 — ballast, 27 — aft body, 28 — back catchy hook, 29 — connecting device 30 is the front hook.

To paint the model it is best diluted with nitro. To avoid water stains, the paint is applied by spray in several thin layers techniques. The color and finish, pick up yourself, but it is better to make a model bright that it was visible on the water.

Storage subs have plywood or Plexiglas with a thickness of 4-5 mm to make a stand. A depression in the top of the keel blocks is to repeat the shape of the hull.

To adjust the course of your little submarine, you first need to pick up ballast from a steel strip or twig. After the final inspection afloat and determine the exact place to glue the ballast inside the boat or outside.

After winding of the rubber motor the fore end I put on a hook and, holding the screw with your hand, pull the model on the water. If it is not moving in a straight line, a vertical rudder turn in the direction opposite to the move. Done properly, the model must pass 8-10 m. For the manoeuvre of the immersion model bends fore and aft horizontal rudders.

For example, models of river passenger ship, tugboat and ship our little submarine is easy to convert for the motor.

However, there is in this work and some features that have not met us in the manufacture of previous models. What are they? And here it is. If the tug or the ship was kept all the time on the surface, and the tightness of the buildings had special value, our new model floats mostly under water. The ingress of moisture into the case will cause a short circuit. “Clogging” the boat is easiest using a thin rubber o-rings-gaskets between the case n bow and stern bosses.

The motor we put the same type that was used on the previous courts. It must be placed in the stern so that the axis was parallel to the waterline. Just as before, the screw is soldered to the needle, but the hook on the end to do. The rotation force of the motor (torque) we will pass through the rubber tubing, is tightly fitted on the screw shaft and on the axle. Engine mount — tension band of thin sheet metal or — even easier — a ring of sponge rubber, tightly crimping the motor and abutting the external circumference in the housing wall.

Battery litany type “343”. Three elements should be connected in series, Packed into a tube of heavy paper. To the Donets and to the head of the extreme elements of the solder wire. One print head in front of the bollard, and solder another to one of the contact plates of the engine. From the second plate make a withdrawal on the same bollard, but a different head. It remains to close the jumper with a copper wire contact, and the model will go.

Placement of new elements in the body will dramatically change its alignment. After determining the new center of gravity the case with the elements of secure housing with a few drops of any adhesive.