The Moscow Lenin order aviation Institute named after Sergo Ordzhonikidze at the faculty of aircraft engines has a student design Bureau (SKB-2), which is headed by candidate of technical Sciences, associate Professor V. V. Serdyukov. Great attention is paid to engines of small displacement, which are widely used in various types of modeling. SKB has considerable expertise in designing such engines. Many of them were exhibited at the exhibition of economic achievements and international exhibitions, and their authors are awarded with medals and diplomas. On NTTM-74 was shown a new “Orbit”.

The Moscow Lenin order aviation Institute named after Sergo Ordzhonikidze at the faculty of aircraft engines has a student design Bureau (SKB-2), which is headed by candidate of technical Sciences, associate Professor V. V. Serdyukov. Great attention is paid to engines of small displacement, which are widely used in various types of modeling. SKB has considerable expertise in designing such engines. Many of them were exhibited at the exhibition of economic achievements and international exhibitions, and their authors are awarded with medals and diplomas. On NTTM-74 was shown a new “Orbit”.

Engine development is underway in the initiative order, and job industry. So, the engines MAI-25R/U and MAI-50P was designed by the order of CKTBI light industry. Earlier in SKB was created engines with different cylinder capacity: 2,5 cm3, 5.0 cm3. At the request of the plant, which produces engines of MD-5 Kometa, work began on a new, with the best parameters.

Extending the class of models has led to the need to focus on creating highly specialized engines. So, the engine for aerobatic model aircraft must develop a relatively small momentum, steadily working on rich mixture: for RC models — broad operating speed range; for high-speed models requires full power, in this connection, recently, using acoustic supercharging.

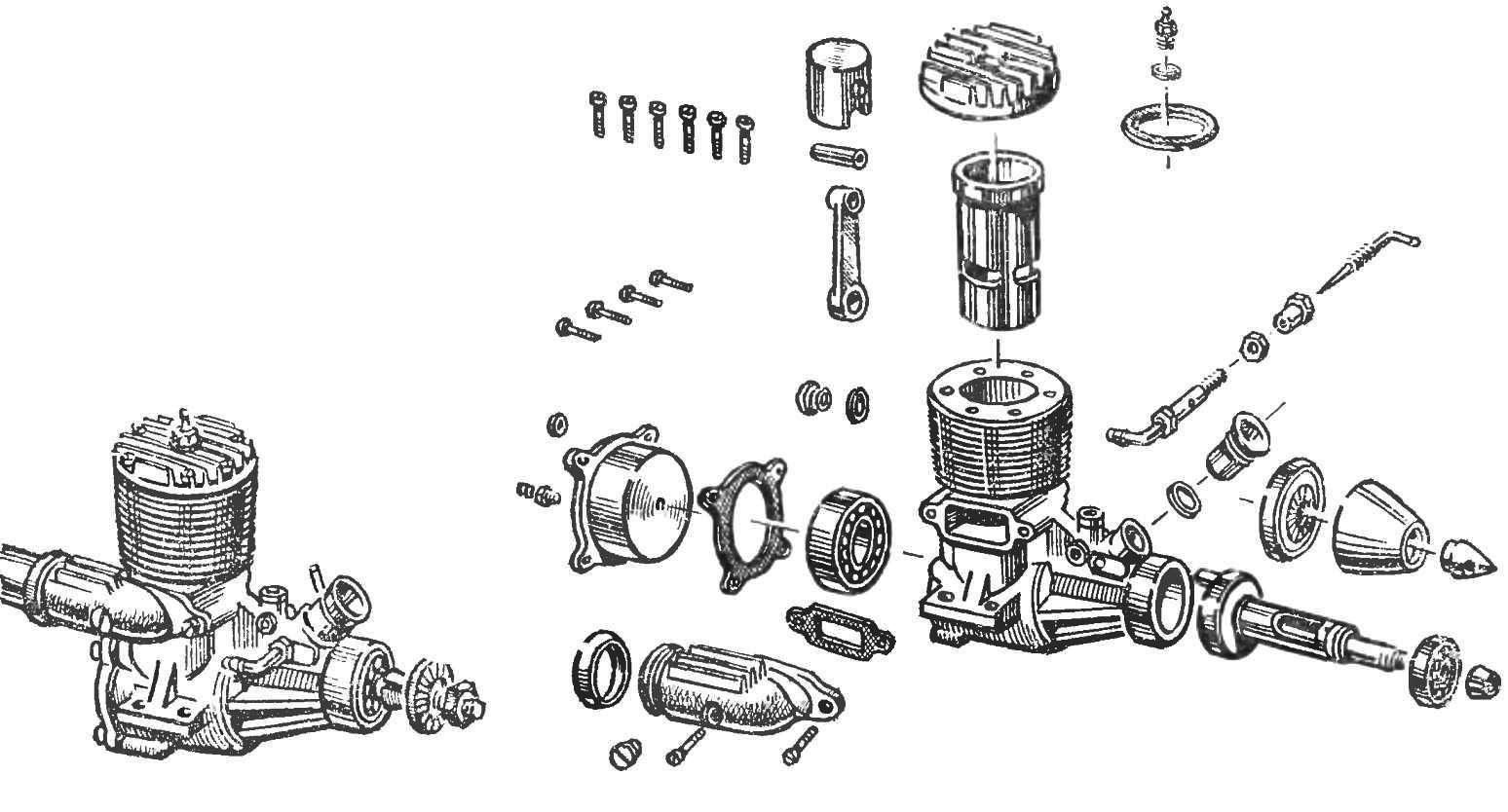

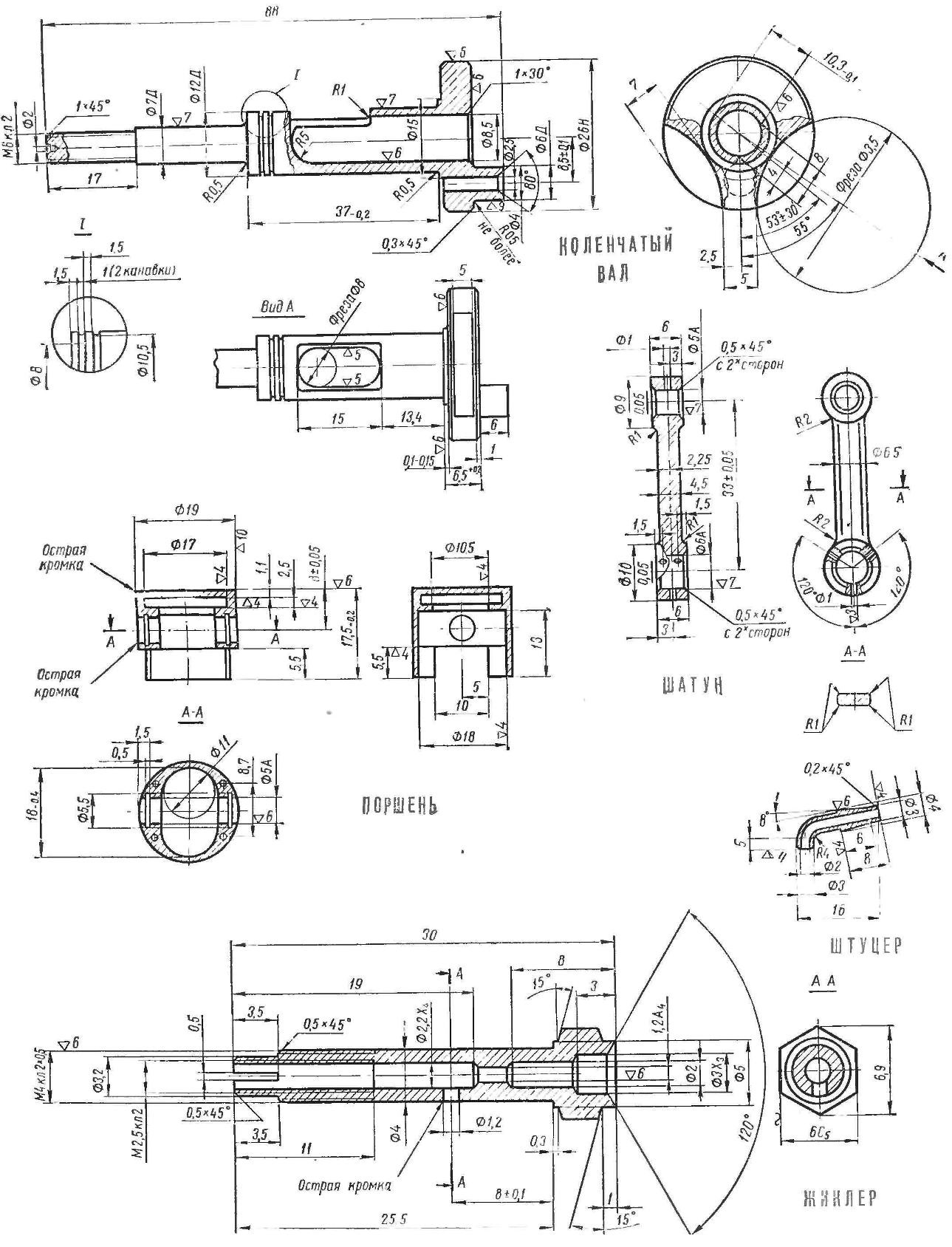

In the creation of the engine with a working volume of 5.0 cm3, other than the authors, was actively involved students of V. S. Dubinin, V. V. Konop. Took the previously created MAI-5. Its design has been significantly revised, with the result that the technical parameters of the engine, znachitelno improved. Called it “Orbit”. On NTTM-74 he aroused great interest.

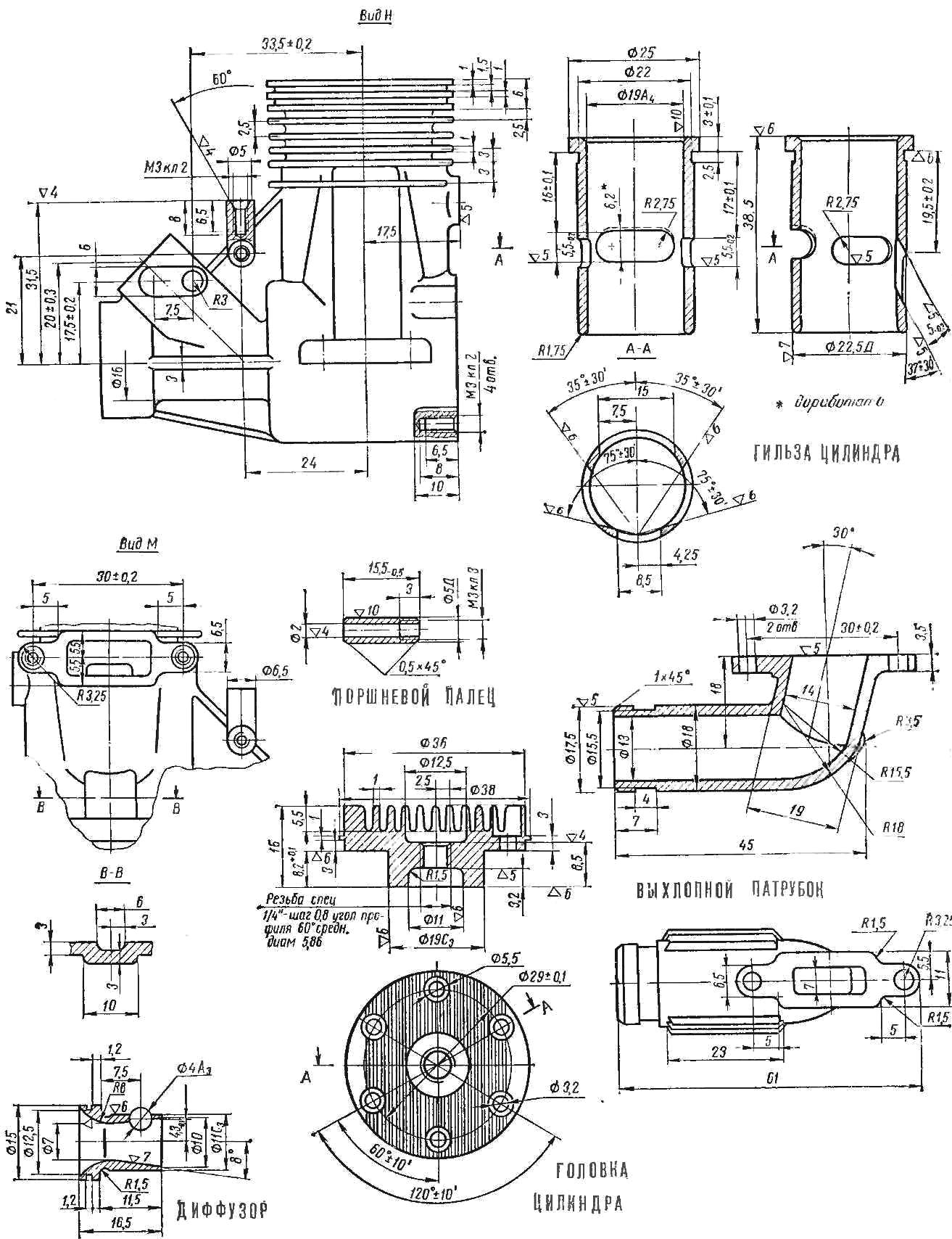

Orbita is a three-channel nozzle, which ensures a good filling of the cylinder when working with an acoustic boost, and without it. The proposed variant of the engine is adapted for operation without resonance pipe, which allows to obtain a gentle external characteristic, is suitable for use by athletes of average qualification. However, it can be easily converted to work with a resonant exhaust pipe, in this case, the height of the exhaust window increase.

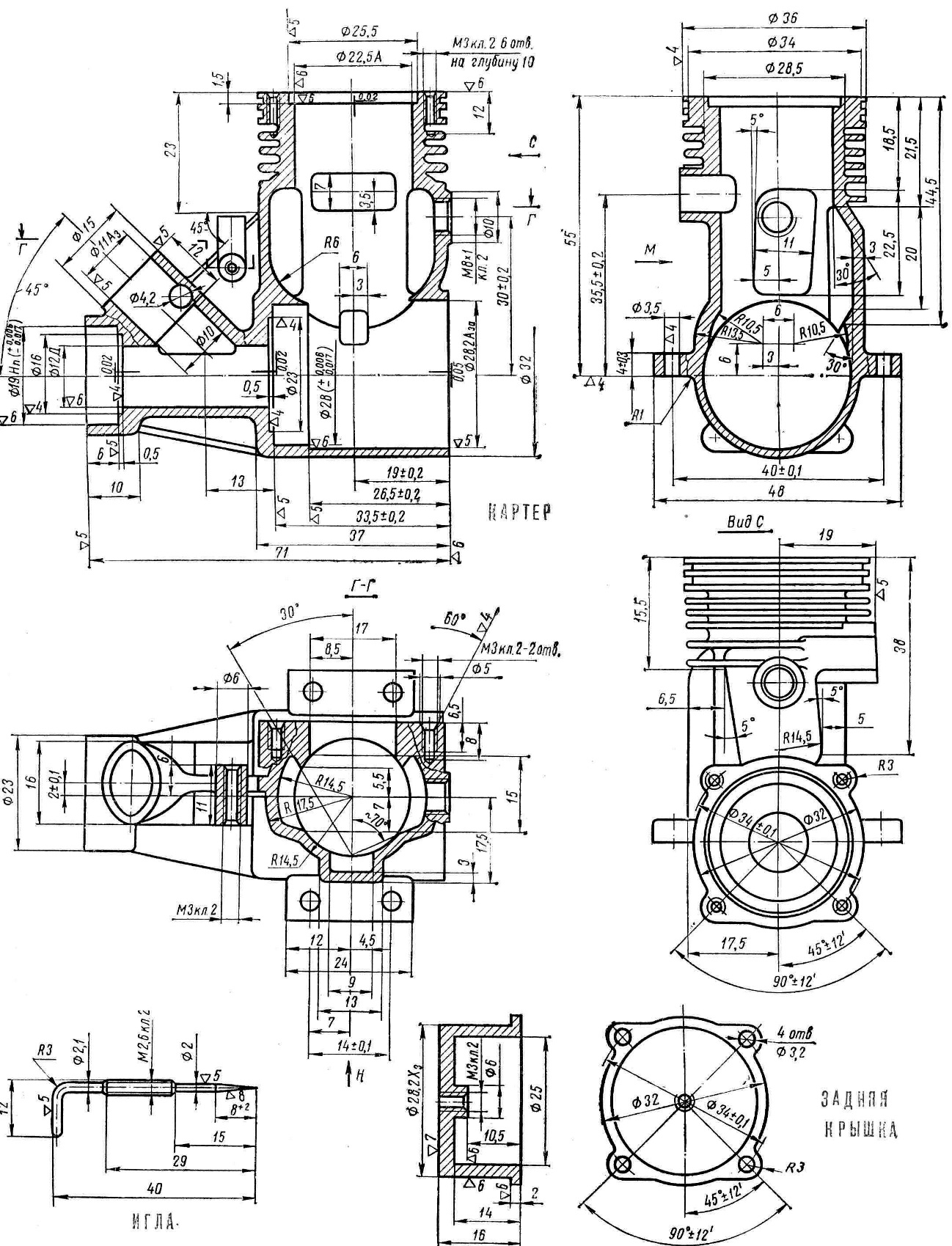

Carter is the most complex part of the engine is fabricated by casting, which allows to obtain casting with final design of intake, bypass and exhaust channels. Material Carter — D16, the last heat treatment, the surface of it peskostruya.

Cylinder — of free-cutting steel A-12. All Windows are made Duperey cylindrical milling cutter Ø 5 mm by-pass window located strictly on the same level. When using a resonance tube the height of the exhaust window is increased to 6.6 mm. Ovality of the sleeve may be no more than 0.002 mm, the lower part (below the upper edges of the overflow boxes) is ground in a taper to 0.15 mm at the base of the sleeve.

The piston is made of gray cast iron of type of mid 28-42, last a long period of natural aging. Internal relief are performed on a lathe. The top of the piston is ground to 0.025 mm for a length of 2.5 mm.

To prevent axial movement of the gudgeon pin, grooved, where to install retaining rings.

The crankshaft is of chrome-Nickel steel 18KH2N4VA; to reduce the volume of the crankcase and the reduction of ventilation losses on the cheek with a balancing shapes pressed onto a brass ring. To increase the strength of crankshaft in the crankcase inlet is offset from the axis ka of 1.5 mm, which also somewhat reduces the gas-dynamic losses. Edges of the inlet ports polished, this reduces the stress concentration.

The connecting rod is made of aluminum alloy D16T. The holes in it are processed on the faceplate of the lathe.

Cylinder head machined from bar stock aluminum alloy D16T. In the jig, drill six holes Ø 3,2, arbor chiseled to Ø 5.5 mm, after the operation, produce a final turning and milling of cooling fins. Available at the head of a band of width 1 mm and height 1 mm is used as the installation when fine-tuning the engine when you want to change the shape and volume of the combustion chamber.

The exhaust pipe is used for the resonance of the exhaust pipe, on the end of it there is a groove for the rubber o-rings. The nozzle changes the direction of the exhaust by 90°. It also can be installed muffler exhaust.

V. ZUEV, N. POLIKARKINA