In the literature on model airplanes is not so much focus on radio-controlled models of seaplanes, although, in practice, many enthusiasts prefer them purely “land”, considering the “waterfowl” more interesting for manufacturing and piloting. Many of them also refer to the usability of such models compared to those that are equipped with wheel chassis, because “land” is not everywhere possible to find a large enough area with asphalt or concrete path for takeoff and landing. While any aquadrome — a pond, lake or river to find not so difficult. In addition, experts argue that take-off and landing in the water are not in the example easier.

In the literature on model airplanes is not so much focus on radio-controlled models of seaplanes, although, in practice, many enthusiasts prefer them purely “land”, considering the “waterfowl” more interesting for manufacturing and piloting. Many of them also refer to the usability of such models compared to those that are equipped with wheel chassis, because “land” is not everywhere possible to find a large enough area with asphalt or concrete path for takeoff and landing. While any aquadrome — a pond, lake or river to find not so difficult. In addition, experts argue that take-off and landing in the water are not in the example easier. Readers of RC model flying boat, designed for the engine with a working volume of from 2.5 to 4 cm3. It should be borne in mind that the mini-hydroplane built using balsa, you will be able to set the motor type KMD-2,5, well, heavier model made of basswood and pine, will require a more powerful engine.

Another obstacle to the creation of float seaplanes and flying boats have always been considered the design of landing gears located under the takeoff and landing in contact with the water. Indeed, to create a good planing hull floats or boats — the problem is difficult: they have to glide and smooth water, and when the light ripples, and the excitement, not burying in the water without jumping and keeping the ability to planing. However, it is possible and not “reinvent the wheel” — all of these problems long ago met with success by modelers that create the racing model of the type F3 or FSR: the hulls of these boats is almost finished the landing gear of models of seaplanes.

And again, other “shopwiki” argue that the model of float plane can make a landing only on water. However, numerous experiments indicate that both float planes and flying boats quite well landing not only water, but grass and on the snow, and even asphalt.

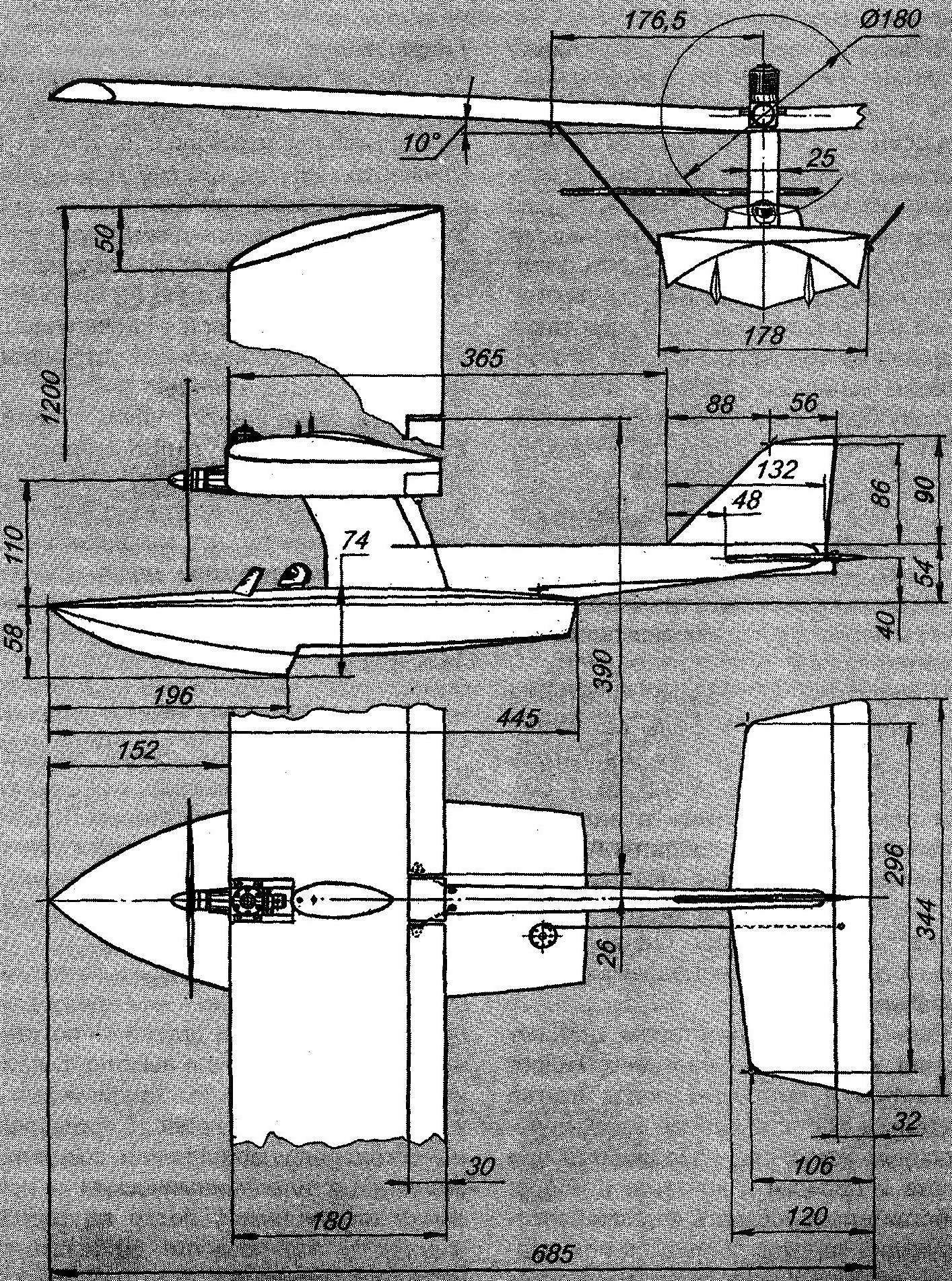

Aerodynamic design model flying boat — high-wing monoplane with a high mounted engine. The wing has an asymmetrical biconvex profile R-II-14% with high load-bearing characteristics, which works well at high angles of attack.

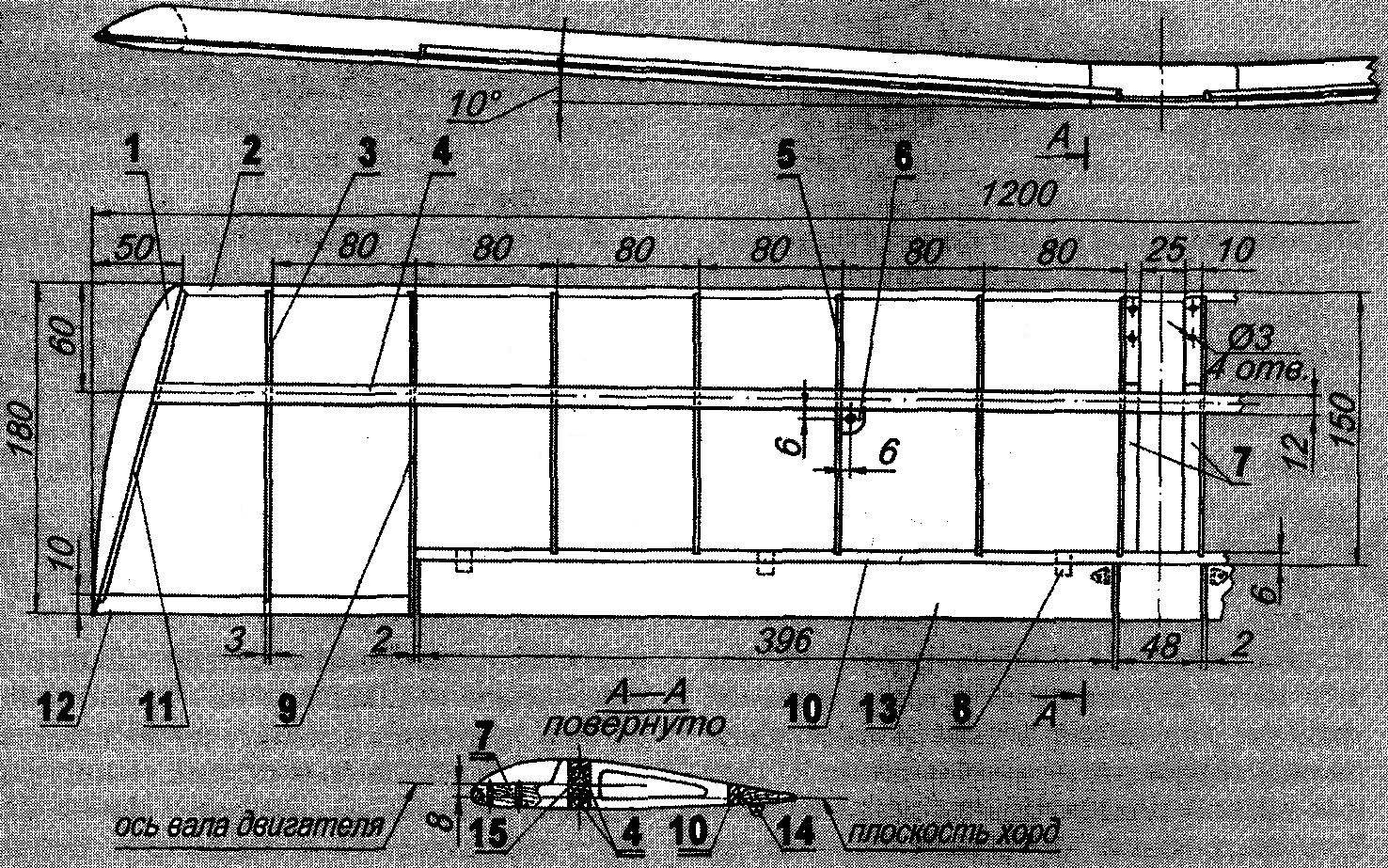

The geometric scheme of the model flying boats.

To drive the model uses two channels: one to roll, to drive the ailerons and a different pitch for the Elevator drive. In principle, one could use the third channel to drive the aerodynamic rudder, connecting it also with the hydrodynamic — the motion of a flying boat on the hydro-port that will enable you to effectively manage model.

Structurally, the model of the seaplane consists of a supporting part (it includes a load-bearing beam, wing, engine, propeller and fuel tank, and a stabilizer and fin) and the landing gear — boats.

Model seaplane “flying boat” with the engine KMD-2,5:

1 — engine; 2 — fuel tank; 3 — hood “pilot”; 4 — head “pilot”; 5, 9 — connecting rods (beech); 6 — thrust actuator Aileron (duralumin, a knitting needle with a diameter of 2.5); 7 — servo actuator Aileron; 8 — a screw-a screw with a diameter of 3; 10 — bearing beam; 11 — the keel (balsa, sheet s6); 12 — horizontal stabilizer; 13 — Aileron; 14 and 21 screws M3 mounting deck; 15 — servo drive of the Elevator; 16 — the location of the battery power supply of radio equipment; 17— deck boats; 18 — boat; 19 — wing; 20 — the location of the receiver; 22 — rod Elevator drive (duralumin, a knitting needle with a diameter of 2.5).

The bearing beam of the model is a composite design, which is a foam disc, reinforced in the front part of a pair of the balsa cheeks and covered with two layers of fiberglass. In its middle, bottom, cut a rectangular niche for the steering servos radio control system model. Also in the bottom beam drilled two cylindrical holes and reinforced with plastic sleeves — they are fixed connecting pins connecting the bearing beam and the boat. By the way, good bushings out of the housings of pens or ballpoint pens. Also note that to cut holes in the foam, is best with a homemade drill made of metal tube of suitable diameter — you need only one hand using the triangular needle file to cut the teeth; to drill holes in the foam should be a conductor of 5 mm plywood. Ready beam vyshkurivaetsya, podsalivaya and painted with enamel of suitable color.

The carrier beam model:

1 — the foam core beams, 2, 4 — bushings (plastic); 3 — glass fiber (two layers of fiberglass and epoxy binding); 5 — reinforcing cheeks (balsa).

Boat model also has a composite construction. To start from the packing foam in accordance with the theoretical drawing of the hull cut blank. Next, she carefully divided into parts so that you can paste in the body amps from a 3 mm balsa plates, frames, transom and rednow Board, and also a longitudinal bulkhead in the back of the boat. In addition to the amplifiers in the Cabinet to paste a fake boss taped them nuts with thread M3 — they are designed for the mounting screws to the deck. Next, the hull is glued with two layers of fiberglass, and the deck of the boat only primed with epoxy. After curing of the resin housing vyshkurivaetsya, primed and on it are fixed beforehand is carved from basswood and fitted to the housing the longitudinal planing steps and installed beech connecting pins, which connect the hull and the bearing beam of the model. At the end of the housing is painted with enamel.

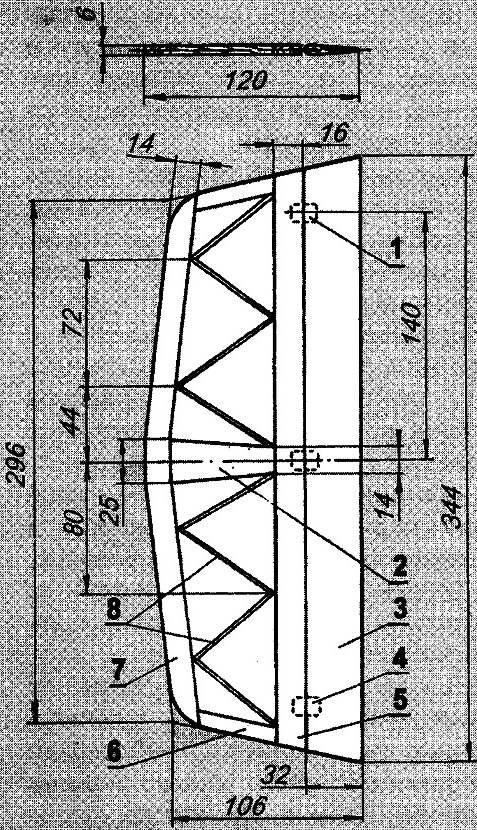

The design of the boat:

1, 2 — a connecting pin (beech); 3 — strengthening of walls (lime, rake 3×5); 4, 6, 9 — frames-amp (balsa, sheet s3); 5 — ridanna Board (balsa s3); 7 — cover (balsa, sheet s3); 10 — longitudinal amplifiers (balsa, sheet s3); 11 — transom boards (balsa, sheet s3); 12 — strong Board of the steering machine (plywood s3); 13-17 — the boss issued with their nuts M3 (lime).

The lines drawing of the boat.

The deck of the boat wikiepedia of epoxy resin and three layers of fiberglass directly on the finished building — just need to cover it so-called “cling film” (in a typically Packed food). A thin film will not only protect the hull of the boat with enough “dirty” work on covering the deck with fiberglass, but will also give the ability to easily separate Vileika from the body. When forming the deck must be done 5-mm overlap at the side of the boat, which will increase the tightness of the housing. After curing of the resin deck vyshkurivaetsya, primed and painted.

To reduce the resistance to movement of the boat on the water the surface after the paint should be thoroughly sanded, cover with another layer of enamel and then polished.

The intersection of deck with the hull of a boat needs to be sealed — to ensure this, the Board should apply a bead of self-hardening silicone sealant, lay on top of his “plastic wrap”, and then to fasten the deck. After curing of the sealant film is removed and between the deck and the hull appears quite reliable seal.

The wing is V-shaped, classical design, it is assembled using dvuhromovo spar from pine slats with a cross-section 4×12 mm with foam filling megalocnus space. Ribs — balsa, cut from plates of 3 mm thickness (no balsa they can be made from basswood with a thickness of 2 mm or foam with a thickness of 5 mm).

The wing of a seaplane:

1—ending (fine-pored foam); 2—the leading edge (pine, rail 6×6); 3, 5, 9—rib (balsa s3); 4—spar (pine, rake 4×12); 6—boss taped her nut M3 (lime); 7—motor mount (birch, plate s10); 8—loop Aileron; 10—posterior edge of the middle part of the wing (balsa plate s6); 11 end rib (balsa, sheet s3); 12—rear end edge of the wing (balsa plate s4); 13—Aileron (balsa plate s10); 14—horn of the Aileron; 15—filling (fine-pored foam).

As already mentioned, the wing has a V-angle = 10° — to ensure that it, each of the shelves of the spar will have to glue with epoxy resin “heads” of the two rails in the simplest slipway of a pair of smooth boards, to ensure maintaining the required angle V.

In the Central part of the wing is a motor mount from birch bars 10 mm thick; between the shelves of the spar in this wing is glued urazalieva Reiki.

The fuel tank is streamlined soldered tinplate with a thickness of 0.3 mm.

The Aileron is balsa, each of them attached to the wing at three loops (they represent segments of a nylon belt), glued in the slots in the ailerons and trailing edges of the wing. Hog drive ailerons made out of sheet aluminum with a thickness of 0.5 mm. Mount them to the ailerons — with the help of brackets made of aluminum wire with diameter 1 mm, glued in the holes of the ailerons. Traction control, connecting the control horns and steering machine of aluminum knitting needles 2 mm in diameter.

The wing — of the Mylar film, the technology of stitched patterns with the help of glue “Moment” and a small electric iron is well known to modelers and to those who regularly read the journal “modelist-Konstruktor”.

Horizontal tail going to epoxy glue the balsa strips with a thickness of 6 mm. the Profile of the stabilizer is flat, rounded at the front. The wing — of the Mylar film. The Elevator celebarty, the stabilizer is exactly the same as the ailerons to the wing using three loops of nylon tape. Pylon rudder is made of cut steel wire with a diameter of 2 mm on one side it is cut M2, and on the other — is bent a ring with an inner diameter of 2 mm. Mount the horn on the steering wheel height using the two nuts and two washers.

Horizontal tail (all wooden parts are cut from balsa plate thickness of 6 mm):

1, 4 — loop of the Elevator; 2 — centre bar, 3 — Elevator, 5 — rear flange: 6 — terminal jumper; 7 — front edge: 8 — rib.

Keel — celeberty cut from plates of 6 mm thickness On the support beam is secured with epoxy glue.

When assembling a model should take into account that the aerodynamic focus (it is at a distance of about 25 per cent of the chord of the wing from its leading edge) must not only coincide with the centre of gravity of the model, but with the front edge of the redan boats. This allows the model during takeoff steadily to get on plane and move along the hydro-port without “peck” and usmiani.

Control the position of the center of gravity should be in the process of making a model, adjusting it if necessary relief or downloading of those or other elements of the model and also changing the location of the receiver and batteries.

Before flight, ensure a reliable sealing of the model. Additionally, it is recommended to protect from moisture receiver and servos using rubber gloves or the envelope of a balloon — thrust and connecting wire thus threaded through the punctures in the rubber. It should also be sealing the receiver switch to make it easier with pharmacy fingertip, pulling it to the outer part of the tumbler. Fixation of the receiver and the batteries in the compartments of the boat is made using strips of foam. By the way, the batteries are sealed it should not be because they can contribute gases and heat.

And — for engine KMD-2,5 is quite suitable propeller with a diameter of 180 mm. Experienced pilots strongly advise you to use on models of the seaplanes wooden propellers — during a failed landing when the propeller hits the water, it literally grinds to pieces.

According to fans of naval aviation, piloting models of seaplane great pleasure “pilot” — especially nice takeoffs from the water and landing on it. “Shopwiki”, is said to be a “pilot” flying boats much more complex than the traditional radio model. However, it is more valuable to the adherents of Russia — they believe that the process of relearning is not too complicated, and the skills of takeoff and landing on water purchased just a few flights. The more that the runway of the hydro-port, as a rule, smooth, and wide, long and long, and on a pond or lake you can always choose the most favorable direction of takeoff and landing is into the wind.

So the motor is running and the direction of takeoff is selected. Note that when you run, you should Orient the model perpendicular to the waves — they generally perpendicular to the direction of the wind. When driving through water do not make sudden movements with the rudders — this can lead to overturning a flying boat. Right santaanna the model will be released on the step, then followed by separation from the water surface, maintaining, and finally take off!

I. SOROKIN