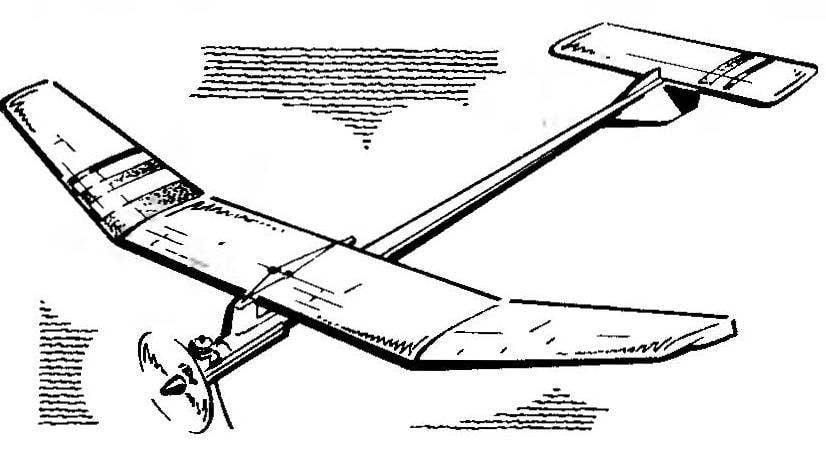

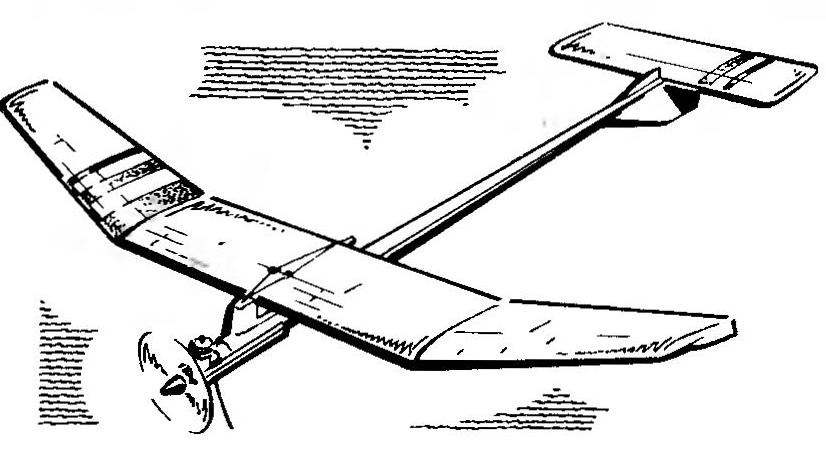

In any case, the journal is pleased to present today TimerStop new development model that is of the transitional type. We think you can consider it one of the most optimized solutions. It embodies the experience of many past years, along with the knowledge of the present level, and the amount guaranteed reliable (which is more than important at the middle level!) flight results will help to keep “afloat” mass education time. It should still be noted that the proposed development is designed for those who have amassed at least some experience in modeling before and it will not have problems in the methods of selection and processing of wood and its gluing (which, incidentally, applies to all models, tan or otherwise, designed for participation in the competition).

according to a good scheme. Perhaps someone will challenge the profitability and prospects of such decisions. But, sure, it will be modelers, few familiar with the characteristics and conditions of modern mass societies.

So, the new timer — the old reliable scheme. But, in fact, to tell something about her too much, there is no need: so everything is clear from these drawings! Therefore, we focus only on the moments, not very widely known. In the first place this applies, for example, the choice of wood. So many details we used the aspen (not to be confused with alder or poplar!). In most cases the “old” people will say that the best would be lime. But at the same density of aspen in the diagonal set of frame advantageous — it is tougher and firmer. Thanks to the features of this light wood, managed to create amazing strength and rigidity of the wing and stabilizer.

Special attention deserves the choice of pine for the longitudinal elements of the frame. In the presence of “musical” of sorts with a density of 0.4-0.45 g/cm3 is possible, for example, on the wing to meet on the longitudinal parts in weight 95 g (this is even with the plywood wall of the spar, installed without gaps on the scope!). At a similar density aspen the weight of the entire set seemingly peremeschenii ribs (with their thickness of 3 mm and 6 mm) is also equal to approximately the sum of there is an opportunity to create a unique, very strong and stiff in torsion, the wing weighing just 230 g ready covered. With careful Assembly IP-opisaniem unchanged plasticized resin type To 153 and the careful selection of wood we have in this scheme and the size of the parts, re-| will incur one value of weight – 214 g.

You also need to tackle the fuselage. When pine density 0.42 g/cm’ you can build a very solid bearing beam Assembly weighing less than 110g. It is important to remember that the best mechanical properties will be obtained only if the annual layers at the ends of the workpieces will be positioned parallel to the larger side section. The wing pylon is collected separately and mounted (on the pitch) on the finished beam.

With aerodynamic point of view, the new timer has a number of features. On the wing used thin (especially for the conditions of the frame without hard zalivok the forehead) profile PLANO-convex type with a sharp leading edge turbulators. The possibility of applying such a thin profile ensuring a high torsional stiffness of the frame with a powerful diagonal ribs and a covering of thick polyester. In addition, the General scheme of the set of twists of the wing, calculated on the terms steady start without the involvement of any mechanization leads to unusual Vicosa engine. Don’t be surprised if the overflight of a new model to identify the need for deviation of the axis of the screw to the left!

Circled Tierney of the type proposed is no problem. However, in extreme situations you will be amazed by the “persistence” model and will appreciate a diagram with the detachable “ears” of the wing. In total, despite the complete lack of “space” composites, when the Assembly of the frame at the desired pitches the operational strength of the model is much higher than the modern supertiling with “duralumin” wings. The new machine is not capricious from the point of view of accuracy and strength of the throw at the start, which definitely makes it more advantageous for mid-level athletes.

Launch is right on a stretched spiral — seven seconds of engine operation is performed from one-half to one whole turn. Stop motor perezalivat fuel. Power pressure bleed from the crankcase through a simple fitting valve. Brake screw in our case, tan as diesel stops much faster than uncompressed “Kalinka”.

KMD is being finalized for the following positions: due to the selection of cylinder-piston pairs, or chrome plating and grinding of the piston increases compression; head with cylinder “leans” back to prevent slippage of the connecting rod with the crankshaft; a rear wall in accordance with prior publication in the journal rotates at 900 and refined or, even better, made a new type of “Rhythm” with open-through section (depending on the technical condition of the engine section futorki carb can be increased up to 0 7 mm). In addition, the expanding middle the bypass duct in the crankcase, the shirt and the sleeve of the cylinder and frays controlling, which is usually too tight and stretches when heated itrh shells. In the center of the combustion chamber in controra you can perform up to three holes and a 1 mm to a depth of 1.5 mm. some of | samples of engines when using fuel mixtures with a high content of amyl nitrite is further stabilizes the operation mode at high rpm and increases the power.

Maximum attention should be paid to the selection of the optimum propeller. And unfortunately, past experience does not give statistical data suitable for our conditions. Therefore, in any case, you will have to do experimentation. We use a screw with narrow lobes, an increased pitch and diameter. Theoretically, when the forced diesel engine this model is the height of rise may be enough to give even the cars equipped with heavy-duty “kalikai”. Only it is important to consider in the calculations that diesel is not capable (with acceleration) on such a pronounced promotion: but it is profitable in the initial stages of take-off due to increased thrust and increased the efficiency of the propeller of large diameter.

Vladimir NIKOLAEV,

the head of the circle

Unbeatable the development of composite and “duralumin” technology in the championship class expense of building a traditional Р2С, n unfortunately has a negative side. First of all it concerns the mass popularity of time. The fact that the technology which provides the elite group unikalnye results, not tan available in regular krukowski conditions. In Patni to apply the techniques of the masters also do not necessarily guarantee expected performance and technical data in connection with many subtleties at all stages of model generation. Moreover, starting from the selection of raw materials, adhesives, technologies, tooling and ending with the balancing and debugging machines, originally designed under a single superdigital. Important is the problem of the scarcity of the same materials and adhesives.

Unbeatable the development of composite and “duralumin” technology in the championship class expense of building a traditional Р2С, n unfortunately has a negative side. First of all it concerns the mass popularity of time. The fact that the technology which provides the elite group unikalnye results, not tan available in regular krukowski conditions. In Patni to apply the techniques of the masters also do not necessarily guarantee expected performance and technical data in connection with many subtleties at all stages of model generation. Moreover, starting from the selection of raw materials, adhesives, technologies, tooling and ending with the balancing and debugging machines, originally designed under a single superdigital. Important is the problem of the scarcity of the same materials and adhesives.