Only four of the class includes one of the most “fresh” categories of model rockets — on the duration of the flight with the rotor — S9. The competition in this category will start only single-stage models, which utilize the principle of autorotation of the main rotor as the only way to “soft” landing on the ground. Autorotation should occur only along the longitudinal axis of the model and result in the erection and operation of the rotor.

Only four of the class includes one of the most “fresh” categories of model rockets — on the duration of the flight with the rotor — S9. The competition in this category will start only single-stage models, which utilize the principle of autorotation of the main rotor as the only way to “soft” landing on the ground. Autorotation should occur only along the longitudinal axis of the model and result in the erection and operation of the rotor.

Rotocut is a rigid construction. Soft materials can only be used for coating (plating) of the hard parts of the frame. In flight, the model of rotachute should not be divided into two or more parts. Championship the class of rotor models is the class of S9. Requirements are as follows: maximum launch weight of 60 g, the smallest diameter — 40 mm, pulse motor is no higher than 2.5 NS, the maximum flight time in a round — 3 minutes (180 c.).

Since 1992, the FAI code and in our rules-category S9 is listed as model on the duration of the flight with the rotor. For some time, while there was the development of models of rotochutes, their inclusion in the programme of official competitions is not possible. But we must pay tribute to the work of creating rotary models was conducted (more in Europe). After all, from a technical point of view these machines were interesting.

And only the experience of the design of rotochutes allowed to include their program starts in some events. At first it was a demo (exhibition) flights.

In my memory model authorityrules descent in our country was the first to demonstrate Mr Menshikov from the city of Uray. It was a unique design — a kind of symbiosis of two categories — S6 (with tape) and S9 (with rotor). Frankly, it is the appearance of this model in the experimental embodiment, and its demonstration flights has expanded for many “rocket scientists” perceptions of models authorityrules descent. By the way, it belonged to a “container” type. But more on that later. After some time in the foreign press published an article about models with authorityrules screw Englishman Stuart Lodge.

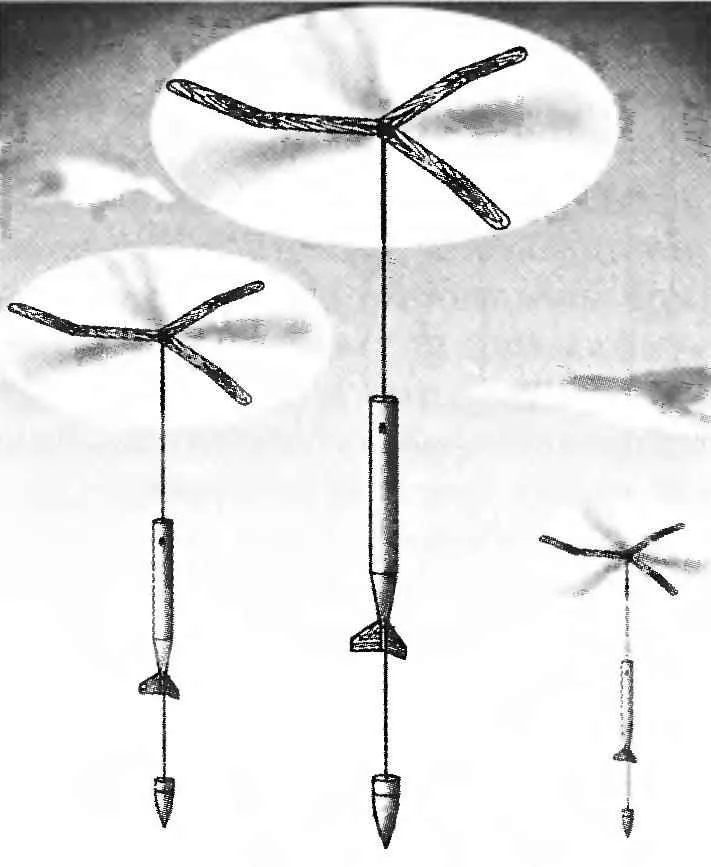

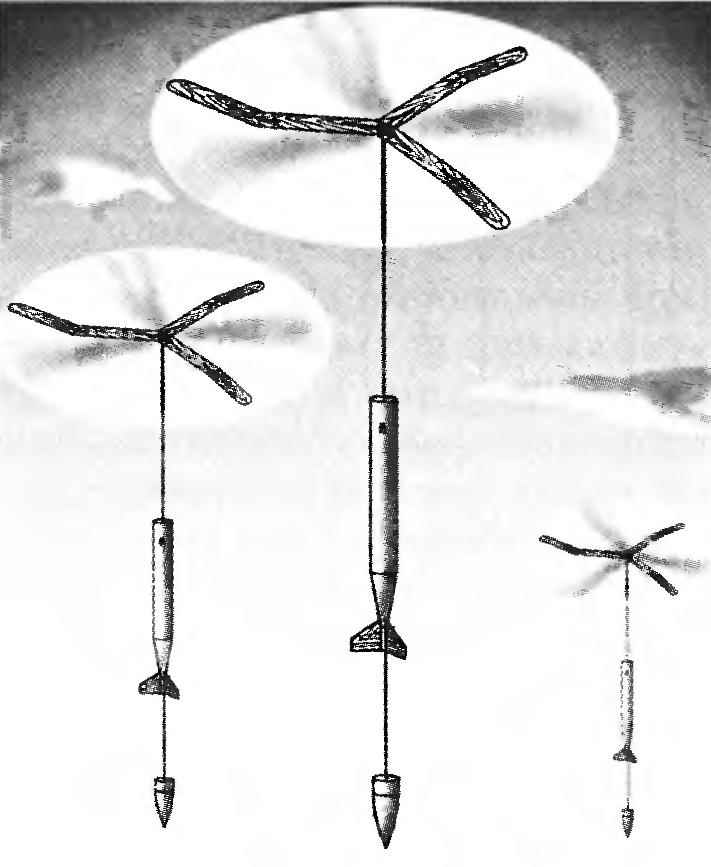

The first time I saw the “reality” starts missile with rotary models in 1998, a Cup competition named after S. Korolyov. Even then, there were several schemes and designs. But, in my opinion, on this background, stood the model of the winner of Alexander Yurtaev from Moscow. Bribed its simplicity. Bearing surface (sweeping) was created due to the rotation of the rotor of four blades. What it (the rotor) and provided the autorotation. Blades had a PLANO-convex profile of a large thickness (about 6 mm) and after folding them along the axis of the formed body of the model rocket.

After liftoff, at an altitude of 150 — 180 m worked lifting charge MRD, which is made of threads of the fixation of the folded blades. And at this moment they are under the action of elastic return trended upwards, forming a four-bladed “Daisy” — rotor. He created an autorotation.

With a similar model in 1999, the champion of Russia among students in the class S9 was Ivan trokhin (Elektrostal). Of course, in comparison with model A. urtaev, she had significant improvement: improved the blades they were attached to the curved profile of the plate. As a result, the corps acquired a cylindrical shape, the midsection was round.

In 1998, the model rotochutes (class S9A) were included in the program of the championship of Russia in Orel. And the first winners of a steel: Sergey Zhdanov (New York) — among young men, and Elena Kurkova (Moscow) — among adults. Since then, the class of models of rotochutes constantly “present” in the program of many competitions.

In the world championship category rotary model rockets debuted in 2002 alone. The first winners were: Maxim Timofeev (Russia) juniors and Karel Probetec (Poland) — in adults.

I must admit that the model of rotochutes is, in my opinion, one of the most interesting creative directions in rocket-space modeling and flying sport. In this category there is a large field for technical and technological search, which is clearly illustrated by the history of development and formation models of rotochutes.

As noted above, the first flying models with the rotor housing formed of blades. The folded (flight) form between them there were gaps, sometimes of different widths. Of course, these models were far from perfect: the design — peretyazhelena, aerodynamics — not at the proper level, which in the end was not possible to achieve high altitude in the existing MRD. But it was the teething problems of development.

And of course “born” any new technical solution is to “lock” the rotor at the start of the container. This has become not only “fashionable” but also aerodynamically justified — has increased altitude. Rotochutes models of this type got the name “container”. Unfortunately, their authorship could not be detected.

Main bearing element of the rotor for take-off — was in the housing (container) and the model in the starting position did not differ from normal models starting classes SA, Ѕ6А. Leaders in the class of rotochutes then was: Alexey Sokolov (Sergiev Posad), Sergey Shamanin (Elektrostal) and Grigory Sergienko (St. Petersburg).

With the emergence of new demands for maximum diameter model rockets grew to 40 mm. of Course decreased and the height of their flight. But the creative idea in the category of rotary models not standing still. The desire to increase the duration of the flight has prompted many athletes to the revolutionary step of breaking rotor blades. Thereby almost doubled the diameter of the sweeping surface, and hence the area of the bearing surface. And, as a consequence — decrease of the specific load. And this, in turn, significantly reduced the vertical speed, which resulted in an increase in flight time.

The next step in the further technical perfection of models of rotochutes — emergence of the sweep blades. One of the first in our country to use it Alex Griazev (g Chelyabinsk). Today about 70% I’ve seen many competitions rotochutes have folding blades with their angle of sweep of the order of 15° — 18°.

In 2006, the championship of Russia Gennady Voronchenko (Meshcherino) presented the original model of rotachute having two rotors disposed coaxially, three blades each. Is this sports the ball allowed him to then become the champion among juniors.

Another unique model was demonstrated then, and Nikolai Sergeyev (Moscow). Console blades of rotachute was made of real goose feathers.

Today a lot of controversy (technical) is among the athletes about the necessary number of blades on the rotor. Their number varies from three to six. By the way, are ardent supporters of six blades — poles. Advantage they confirm the winning starts. By and large, aerodynamically justified by the large number of them. But we must recognize that improving the quality of flow and increase the efficiency of the screw is not always associated with reliability and operation of the rotor — setting and adjustment. And the possibility of failure of any node or element is greatly increased. From the variety of schemes and designs, I would pick a model in Belgorod “missile” sports “shells” master of sports of the international class Alexey Reshetnikov and Alexander rotocut people from the city of Biysk. The latter will tell more.

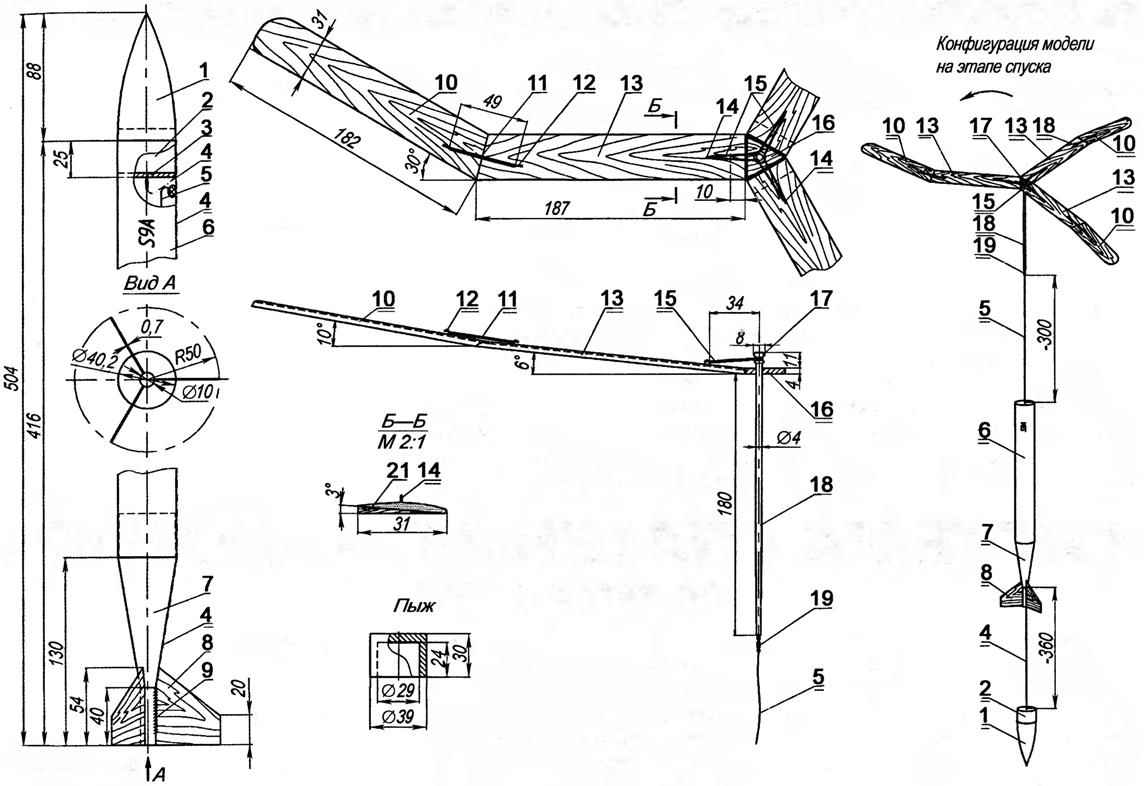

0pt;line-height:115%; font-family:”Calibri”,”sans-serif”;mso-ascii-theme-font:minor-latin;mso-fareast-font-family: “Times New Roman”;mso-fareast-theme-font:minor-fareast;mso-hansi-theme-font: minor-latin;mso-bidi-font-family:”Times New Roman”;mso-bidi-theme-font:minor-bidi; mso-ansi-language:EN;mso-fareast-language:RU;mso-bidi-language:AR-SA”>Model rotocut class Ѕ9А:

1 — fairing;

2 — “skirt” fairing;

3 — frame;

4 —thread mount fairing;

5 — thread (rope) of the suspension of the rotor;

6 — housing;

7 — tail cone (block);

8 — stabilizer;

9 — place the mounting thread of the suspension;

10 — the console of the blade;

11 — gum disclosing the console.

12 — hook hanging gum;

13 — vane rotor;

14 — hook elastics disclosure of the blade;

15 — band disclosures of the blade;

16 — base of the rotor (prism);

17 — attachment of gum in the disclosure of the blades (“tribox”);

18 — rod;

19 — hinge suspension Assembly (vertloc);

20 — the profile of the blade;

21 — adjusting wedge.

Alexander Puzikov, the teacher of additional education of the House of technical creativity them. F. Savchenko from 1988 All these years, finds pleasure and delight in a modest, and in my opinion honorary work of a teacher and educator of young people of school age. Giving children the elementary lessons technical design, engaging them in the world of “big” equipment, he at the same time improved both in creative and in sporting terms. How many know Alexander, and it is about 20 years old, all the while amazed at his desire to show something new in his sport “the shells” — the rocket modeling. They seems a sound approach to the design, the use of modern technologies of rocket simulation.

Since 1992, regularly participates in the championship of Russia for sport flying. It then became the bronze prize-winner in a tough class S — model-copy on the altitude. Then, three years later — the champion of Russia in the class of models of raketoplana ( Ѕ4А). Despite the remoteness from the center (Biysk, Altai Krai), trying to take in the “light” of their wards to participate in national and international events. If it is not possible — traveling by myself with my own money, and always acts with dignity. It was a 12 x all-Russian competition for flying sports for the Cup of S. P. Korolev. It seems to me that the proposed design rotachute A. puzikova will be of interest to young “rocketeers”.

Rotocut class Ѕ9А Alexander puzikova applies to models of container type. Recovery system — rotor before takeoff fit in a medium (container). A distinctive feature of his model I would call simple and easy to manufacture, especially its bearing surface — of the rotor.

The basis of it — the connecting element is a prism. She is an equilateral triangle with sides equal to 31 mm, and 4 mm thick, bonded balsa veneers. Its sides banded with celluloid. In the center of the prisms drilled hole and glued the bottom rod with a length of 185 mm. it is possible to use the skewer wooden skewer. While the top is left a small cut (1.5 — 2 mm) free. Sharpen it slightly and stick to it a peculiar shaped parts (fungus) with the greatest diameter of 9 mm. Its carved out of wood. It serves to attach the rubber bands to the disclosure of the blades. In the lower (free) end of the rod fasten the suspension unit housing fishing vertljuzhok, which, in turn, tied the thread pendants (FAL).

Of the rotor blade (three of them) are made of balsa plate with a thickness of 3 mm, a width of 31 mm and a length of about 370 mm, profiles, form the ending and cover with a layer of nitrocellulose lacquer. The profile at the same time — PLANO. After processing the blade cut across (almost equally) and by processing the end face of the blade and console, give it the desired sweep (about 15°) and an angle V of about 10°. Bottom blade console and paste a strip of ribbon (nylon fabric), getting swivel. From the top, at a distance of 25 mm from the folding of the glued two hooks for rubber bands disclosure console. Free (root) end of the blade from the bottom glue a wooden wedge with a width of 10 mm and a length of 31 mm. It is the adjusting element to obtain the same angle of all three blades for levelling of the lower plane of gluing strips of fabric for swivel prism. It follows this sequence. First, glue “Moment” fabric underside of the prism. Then, once dry cut it around the edges, leaving a free strip of width about 10 — 11 mm and krepjat to them all three blades of the lower planes. Thus it is necessary to monitor the equality of angles “V” of each blade. For this you need to make a template. After drying, gluing on top of the blade at a distance of 30 mm from the center of prisms are fixed hooks for hanging rubber bands disclosure of the blades. For hooks you can use brackets from a stapler. Gum disclosing blades and consoles represent loops made of segments of rubber thread with a diameter of 1 mm. To obtain the same tension they must be of equal length, and it is chosen empirically. Gum disclosing blades are hung on hooks fixed in them, and “cap” fungus of the prism.

The carrier (container) of Rotorua performed by a known technology — it is formed of two layers of glass, of a thickness of 0.03 mm with epoxy binder on the mandrel of variable cross section. After drying, the resin preform of the container on the mandrel lathe at low speed (450 — 500 rpm) and butt length — 416 mm. In the rear glue three feathers of the stabilizer, carved from balsa veneer with a thickness of 0.7 — 0.8 mm. In the place of fastening of one of the stabilizers glued the thread suspension fairing. And in the upper part of the container is fixed inside the thread of the suspension of the rotor — tether. The second end of the tie before the start of the suspension unit.

Fairing is molded the same as the housing, using mandrel arched form. After treatment in the lower part of the glued splice sleeve (“skirt”), and then she fastened the bulkheads from balsa, 4 mm thick, pre-vkliw in a noose for tying the threads of the suspension.

The model preparation of rotachute to start is carried out in that order. First of all “put” the engine, checking the reliability of its fastening. Then folded the console of the blades to the lower surfaces of the root elements and folded the blades are placed along the rod. Thread suspension (FAL), wrap tissue paper (condenser) or a film of PTFE. In a container put the wad made from the foam and then folded rotor. Next, insert fairing. The model is loaded and ready.

Launch mass of rotachute — 20 g, the motor —Zenit-A-13.