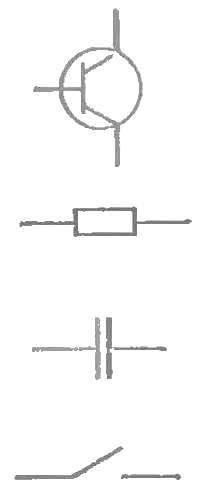

Each constructor of RC models knows how many times spent the time to draw a wiring diagram. In a hurry is not always possible to sustain the necessary proportions between the individual elements, thoroughly implement the conventions. And then this scheme is not only messy, unsightly, but it often creep annoying bugs and inaccuracies. What to do in this case? To help here you can the cliches. More precisely, a set of moulds from which to select the desired image of the scheme. There are only about twenty: resistor, capacitor, diode, transistor, transformer, etc.

Each constructor of RC models knows how many times spent the time to draw a wiring diagram. In a hurry is not always possible to sustain the necessary proportions between the individual elements, thoroughly implement the conventions. And then this scheme is not only messy, unsightly, but it often creep annoying bugs and inaccuracies. What to do in this case? To help here you can the cliches. More precisely, a set of moulds from which to select the desired image of the scheme. There are only about twenty: resistor, capacitor, diode, transistor, transformer, etc.

At first make a matrix — form for the pressing of the stamp is made of plastic. On a flat lead fee with a thickness of 1,5—2 mm pencil applied to the image of the drawing or drawing on which you intend to make a stamp. Then applied the pencil outline light hammer blows using a small chisel to form the recess. Their width depends on the thickness of the lines of the future of the stamp. Moreover, from the definition applied to the matrix of the picture quality of the stamp depends in the first place: deepening should be the same everywhere, right angle and carefully processed.

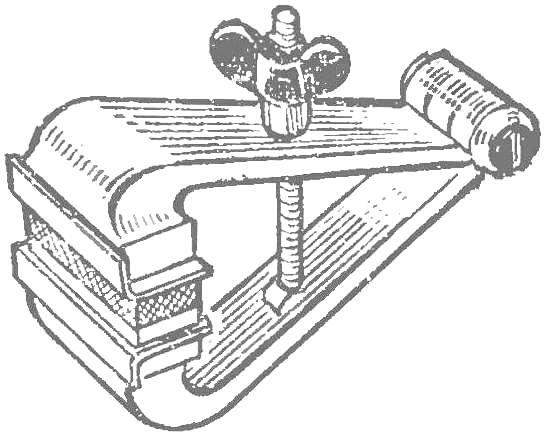

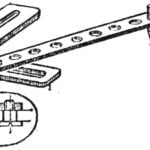

Then prepare the base for the stamp. Small pieces vinyl chloride insulation from telephone wires wrapped in foil from a candy and put under a hot iron (temperature controller needs to be installed on low heat). The softened plastic in the form of a plastic block is transferred to the lead form and placed between two metal plates. Then the “sandwich” was compressed in a vise (Fig. 1).

Fig. 1. The workpiece in a vise.

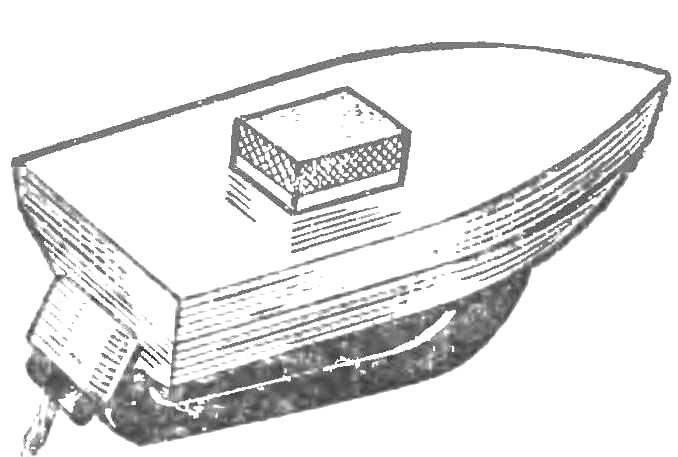

Fig. 2. The formation of the stamp.

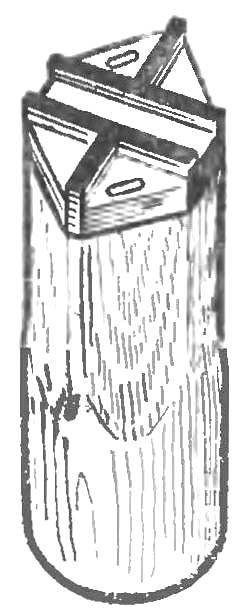

Fig. 3. The stamp on the wooden holder.

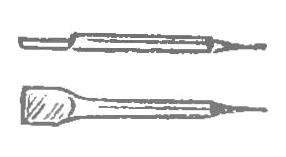

Fig. 4. Stud.

Fig. 5. Wiring is made using the stamps.

This operation can be performed otherwise. Turn over and iron on the top flat part is put in a lead matrix with imposed plastic (Fig. 2). The latter is heated up until the plastic begins to melt and fill the recesses in the matrix. Then the workpiece laying between the metal plates, heat sinks and clamp in a vise.

When after about 5 minutes the workpiece has cooled, the finished stamp is removed from the matrix. Now it can be mounted on a wooden holder (Fig. 3) use PVA glue and pins (Fig. 4). The picture on the stamp is aligned fine-grained sandpaper, making sure that the imprint was clear.

After a set of stamps ready, you need to make stamp pad. In a small metal box, put a piece of felt from an old hat or folded in several layers of cheesecloth and pour stamp ink or black ink with a few drops of glycerin. Then it is not as fast drying.

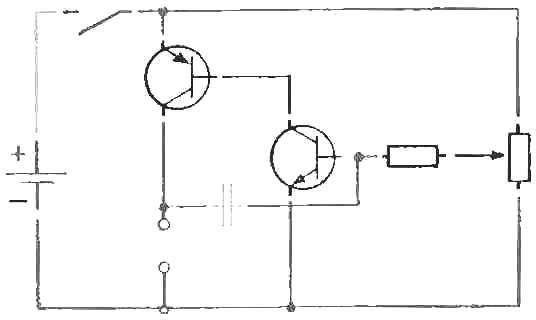

As an example, figure 5 shows the circuit diagram made using the stamps.

V. PRISHCHEPENKO, Chengdu

Recommend to read

FOR ANY RADIUS

FOR ANY RADIUS

Comfortable and high-performance tool — the jigsaw is much easier and straight and curved sawing of wooden workpieces. Simple Supplement thereto, proposed by the Hungarian magazine... ELLIPSOGRAPH

ELLIPSOGRAPH

ELLIPSOGRAPH — is the name of this simple device. It can be used to draw an ellipse with any ratio of the semiaxes. It is enough to set into the holes on the line of alignment pins to...

Each constructor of RC models knows how many times spent the time to draw a wiring diagram. In a hurry is not always possible to sustain the necessary proportions between the individual elements, thoroughly implement the conventions. And then this scheme is not only messy, unsightly, but it often creep annoying bugs and inaccuracies. What to do in this case? To help here you can the cliches. More precisely, a set of moulds from which to select the desired image of the scheme. There are only about twenty: resistor, capacitor, diode, transistor, transformer, etc.

Each constructor of RC models knows how many times spent the time to draw a wiring diagram. In a hurry is not always possible to sustain the necessary proportions between the individual elements, thoroughly implement the conventions. And then this scheme is not only messy, unsightly, but it often creep annoying bugs and inaccuracies. What to do in this case? To help here you can the cliches. More precisely, a set of moulds from which to select the desired image of the scheme. There are only about twenty: resistor, capacitor, diode, transistor, transformer, etc.