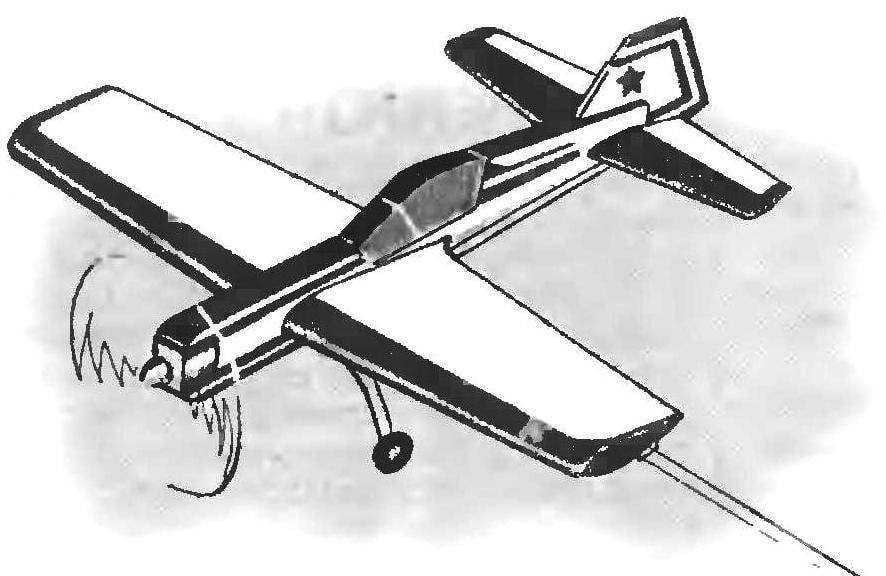

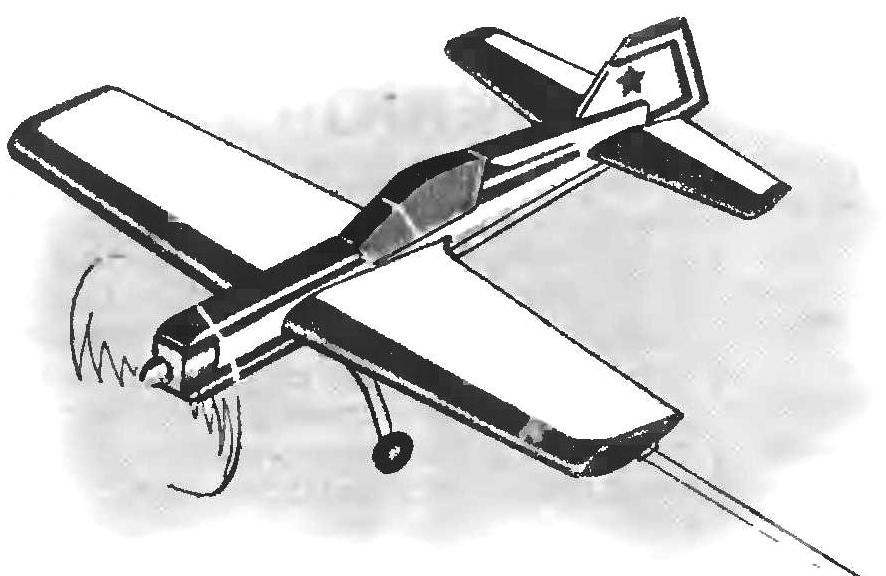

Electrolet cord with external power supply. In recent years, Kostroma modelers electrics are the most popular. One of the latest developments of the laboratory of experimental design syut city of Kostroma — training cord model aircraft, which combines such qualities as good maneuverability, durability, adaptability, low cost, modern design, the possibility of manufacturing in technical circles and in the classroom work in secondary schools.

Electrolet cord with external power supply. In recent years, Kostroma modelers electrics are the most popular. One of the latest developments of the laboratory of experimental design syut city of Kostroma — training cord model aircraft, which combines such qualities as good maneuverability, durability, adaptability, low cost, modern design, the possibility of manufacturing in technical circles and in the classroom work in secondary schools.

The work began with a study of the most successful designs indoor models, analysis of literature and project materials. As a result came to the conclusion that as the prototype is quite suitable beautiful domestic sports su-26. The basic proportions of the model picked virtually the same as that of the prototype and to improve its aerobatic qualities slightly increased the size of the stabilizer, rudder and wing. As a material for fuselage, wing and tail took the easy foam, and the power plant decided to make an electric with external power supply — we have long proven use for cord the rechargeable powerful, reliable and cheap microelectronical, designed for a voltage 12 — 15 V, — a is used in the electric locks of the cars.

In the end, the estimated weight of the model with engine was a little less than 100 g and, as shown by tests, electrolet confidently fly on two cords of insulated copper wire of PEL of 0.25 mm diameter and length up to 8 m.

The model design was performed on a computer using AutoCAD 2000 is the development of working drawings of details, and isometric images, and Assembly drawing elektroleta. After you have printed the drawings on the printer in accordance with them were made tin templates section of the wing, as well as templates for the manufacture of the fuselage, fin, rudder, stabilizer and Elevator.

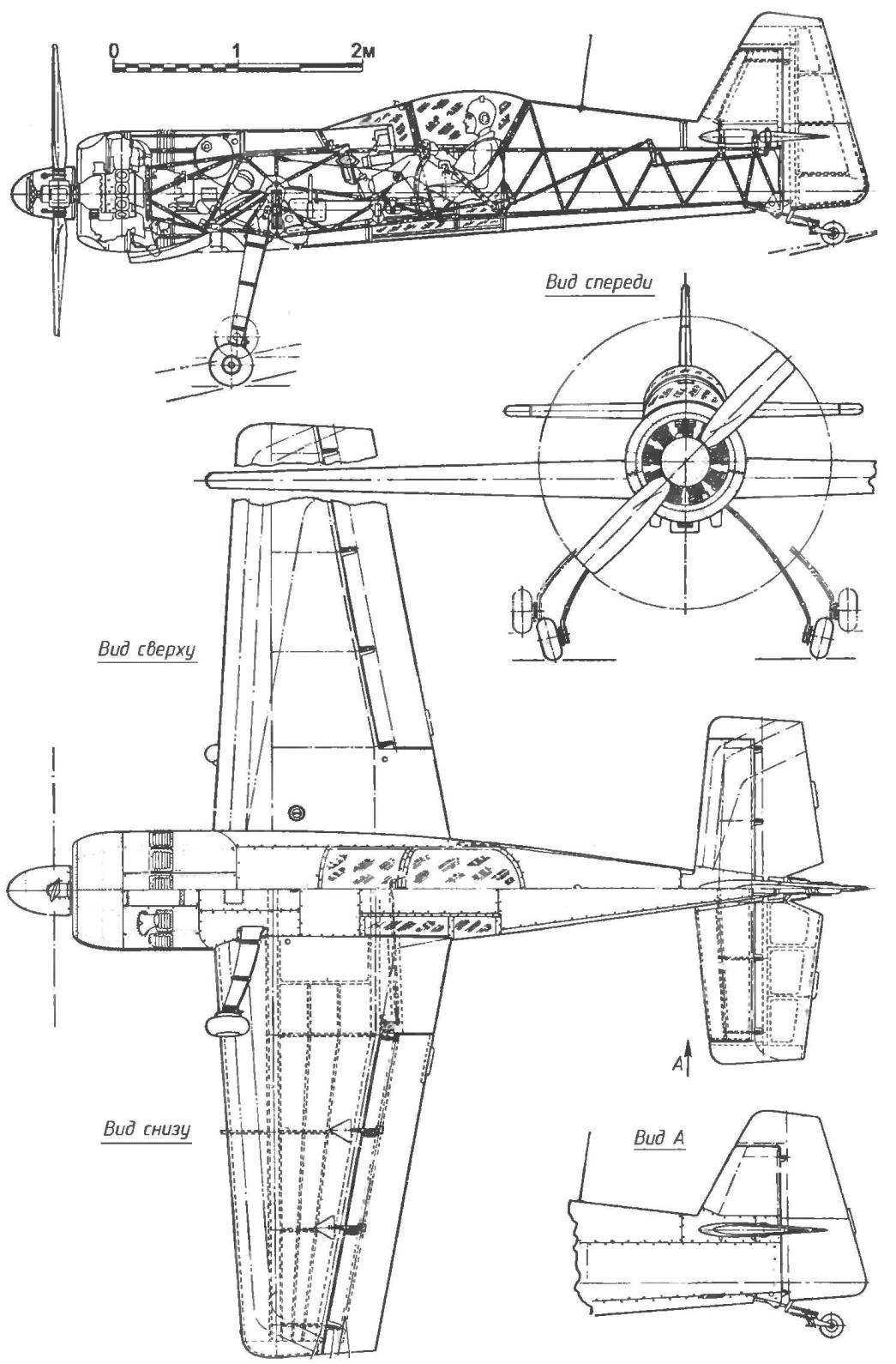

Sports aerobatic aircraft su-26

The fuselage and wings were carved from bars melkosortnogo packing foam templates with the help of Thermaltake consisting of a machine from luchkovoj saws in which the saw blade is tensioned nichrome wire. Last logged on to LOTRO; the optimum temperature of heating was selected experimentally with a trial of cutting foam. After the treatment, the fuselage papered on all sides of the drawing paper.

Motor mount is a clamp, the bent of duralumin plate of thickness 0.5 mm with the holes for the mounting screws and the motor shaft. The fuselage motor mount was attached with glue BF-2.

The lantern is stamped out of a plastic bottle as snap used a wooden punch and a plywood matrix.

For the manufacture of parts of the tail were used the square foam tiles 500×500 mm with a thickness of about 3.5 mm. the Parts were cut on previously prepared templates. Stabilizer and Elevator reinforced edges from lime Reiki. Hinge straps for the rudder cut from strips of nylon fabric (not shown).

The wing of the model as well as the wing prototype aircraft has a symmetrical profile. The left and right console, were joined at the butt with a good quality PVA glue, and the Central part was intensified by a short longitudinal rectangular shape, made from strips of 1-mm of plywood with a width of about 20 mm. In the outer end of the wing is glued lead weight with a mass of 5 g, pre-wrapped thread. On the inner end of the wing was mounted guide plate of 1 mm plywood with holes, through which are passed cords-conductors.

The keel, rudder, stabilizer, Elevator and wing tight fitting thin capacitor paper with liquid PVA-Kea.

Control system model of the traditional design. Rocking control, cut from fiberglass, hinged on the axis (3 mm screws) and glued to a wooden boss, which is mounted on the lower surface of the wing. From the attachment cord on rocking depart flexible stranded wire to the motor (not shown).

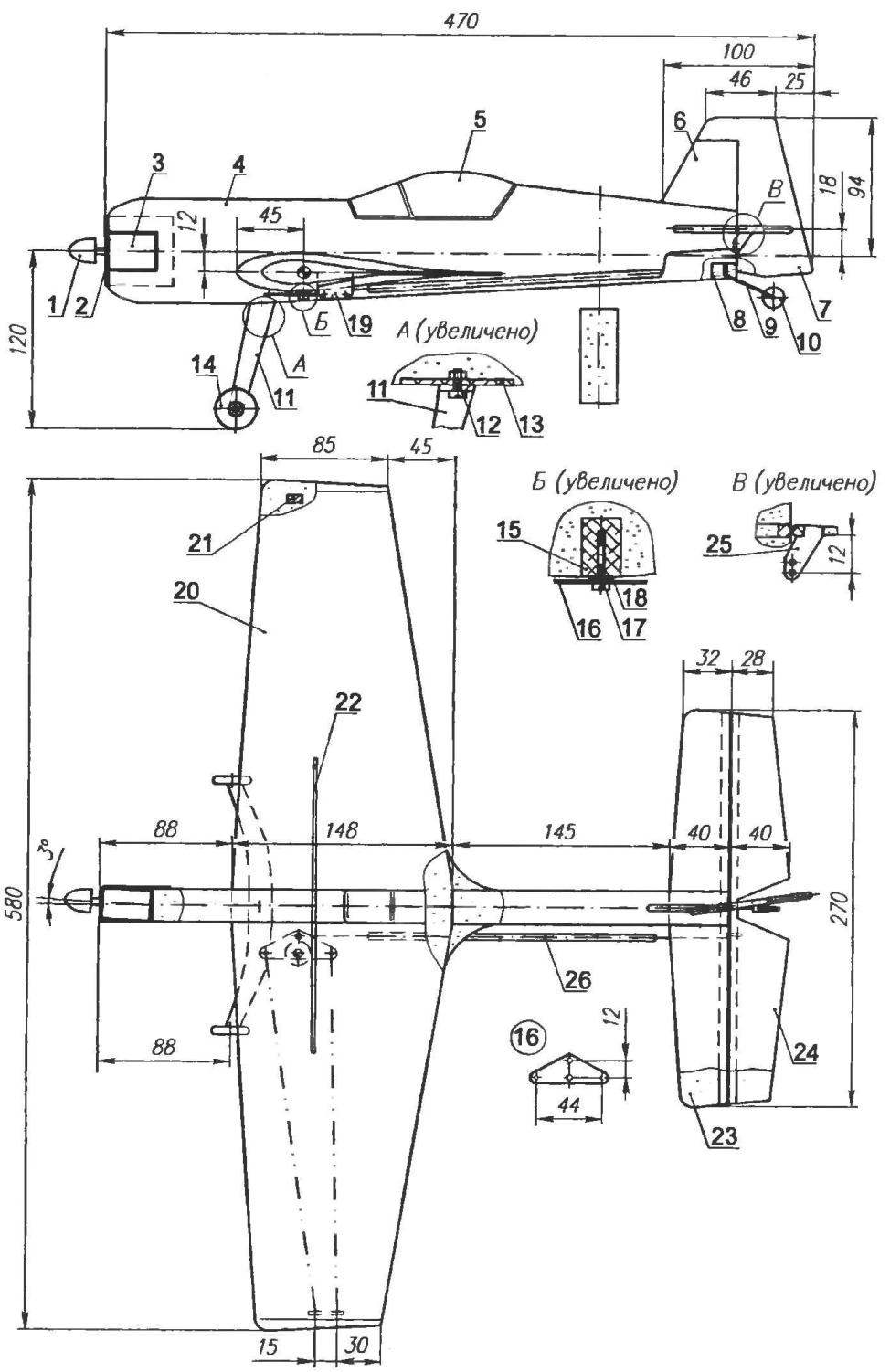

Training control line model airplane motor — polyopia su-26:

1 — propeller spinner; 2 — motor; 3 — motor; 4 — fuselage; 5 — lantern 6 – 7 keel – rudder; 8 — boss strut tail wheel; 9 — tail wheel strut; 10 — tail wheel; 11 — leaf spring suspension; 12 — spring mounting chassis; 13 — plywood plate; 14 — wheel; 15 — boss mount rockers; 16 — rocking chair; 17 — the screw of fastening of a rocking control; 18 — washer; 19 — the guide cord management; 20 — wing; 21 — cargo; 22 — spar; 23 — the stabilizer; 24 — handlebar height; 25 — pylon rudder; 26 — thrust

The propeller is made of basswood. For proper selection of the used stand, which allowed to determine the maximum traction power plant. Different variants of the fastening screw. Preferred “plant” it on the existing motor shaft gear with fixing glue of type “Moment”.

Spring chassis model is made of the elastic dural plate, and light plastic wheels it came from a toy car. Spring fixed bolt on a plywood plate, which is in turn glued to the fuselage.

The wire tail-wheel strut (it is also plastic, from toys) glued on epoxy glue in a wooden boss.

During Assembly of the glider models, it is advisable to first (after careful fitting) to attach the wing slot of the fuselage and then mount the parts of the tail, control system, and chassis. To connect the main parts of the elektroleta except PVA glue and epoxy you can recommend a universal polymer waterproof glue ECO-NASET.

Fully assembled electrolet was painted by nitroenamel with the use of spray-airbrush. The design elements were made of self-adhesive color film. For flights used a power supply consisting of batteries or batteries and hung on the belt of the modeller. It needs to provide on the approach to Kardam length of about 8 m the voltage to 30 V. the control Knob, made of 10 mm plywood, has a power switch.

A. TIKHONOV, candidate of pedagogical Sciences, syt, Kostroma