First image of indoor model airplanes made of bird feathers, I saw in the years of the great Patriotic war, even as a boy. Father was at the front, and my mother and my younger sister and brother were among the evacuated from Moscow to Omsk.

First image of indoor model airplanes made of bird feathers, I saw in the years of the great Patriotic war, even as a boy. Father was at the front, and my mother and my younger sister and brother were among the evacuated from Moscow to Omsk.

The act of drawing in the second grade brought me there, too, with Muscovite Slava Belyakov. I often visited him at home: together we painted, played, read. Among them, the book was, as it seemed to me, very special large format in a dark hardcover with glossy paper, large print and gorgeous illustrations—engravings. It was called, I remember, “Magic and entertainment”. We could scroll without end. In it I saw room flying models from bird feathers.

I’ve made this model much later, after graduating from the Moscow aviation Institute, working in the aerospace industry, for his six year old son. It was a tiny rezinomotornaya airplane on a two-wheeled chassis with wings and a propeller from Bareev, which itself was up from the floor, did a lap around the room and gently sat down. Raptures son no bounds.

According to Greek myth a skilled painter, sculptor and architect Daedalus and his son Icarus flew away from Crete king Minos on large wings made from bird feathers, sealed with wax and linen thread.

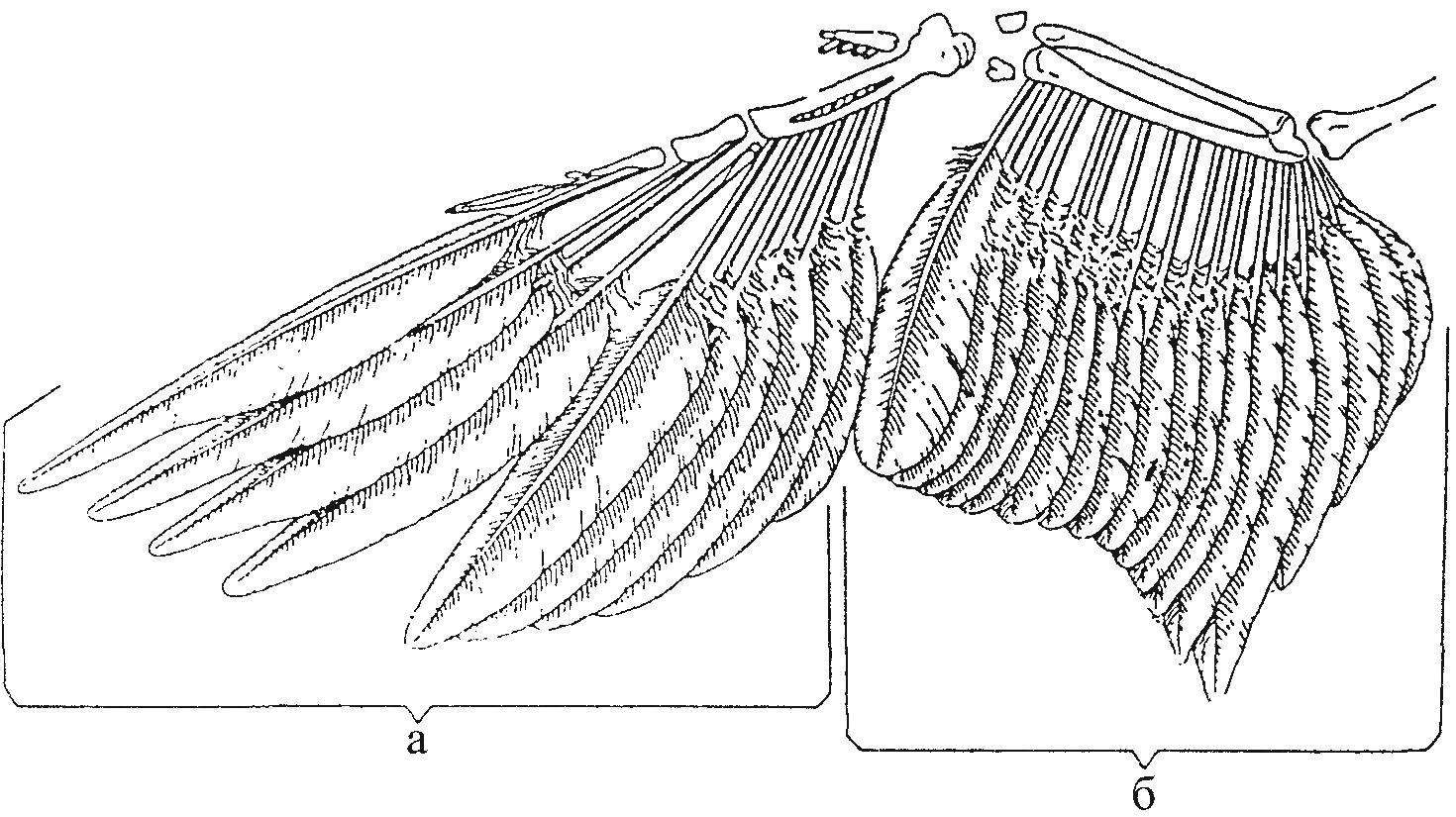

The arrangement of feathers on a bird’s wing

a—the primary feathers; b is a secondary feathers

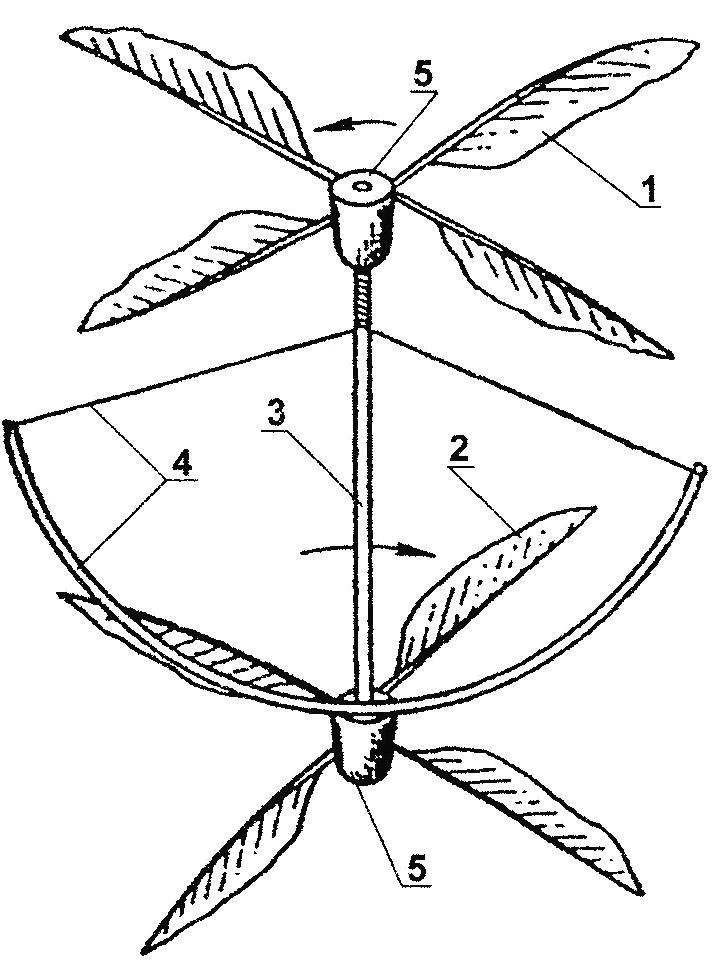

A simple model of helicopter built by the French Bienvenu and Lena in 1784:

1 — the screw of left rotation; 2 — the screw right rotation; 3 — shaft; 4 — wheel drive (a bow with a bowstring); 5 — hub

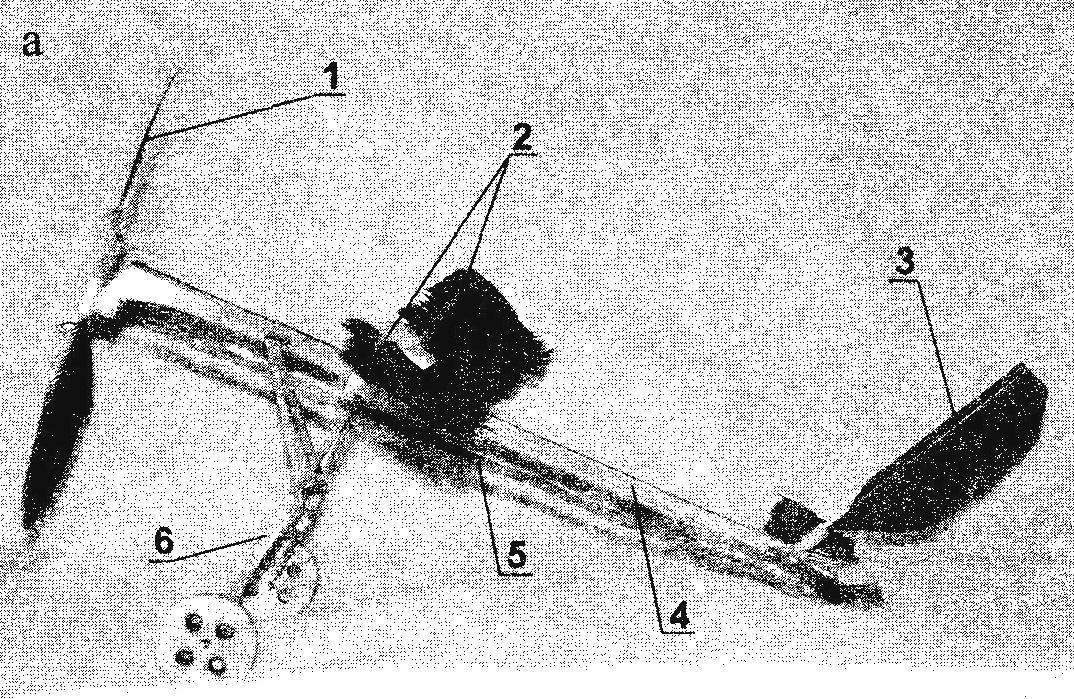

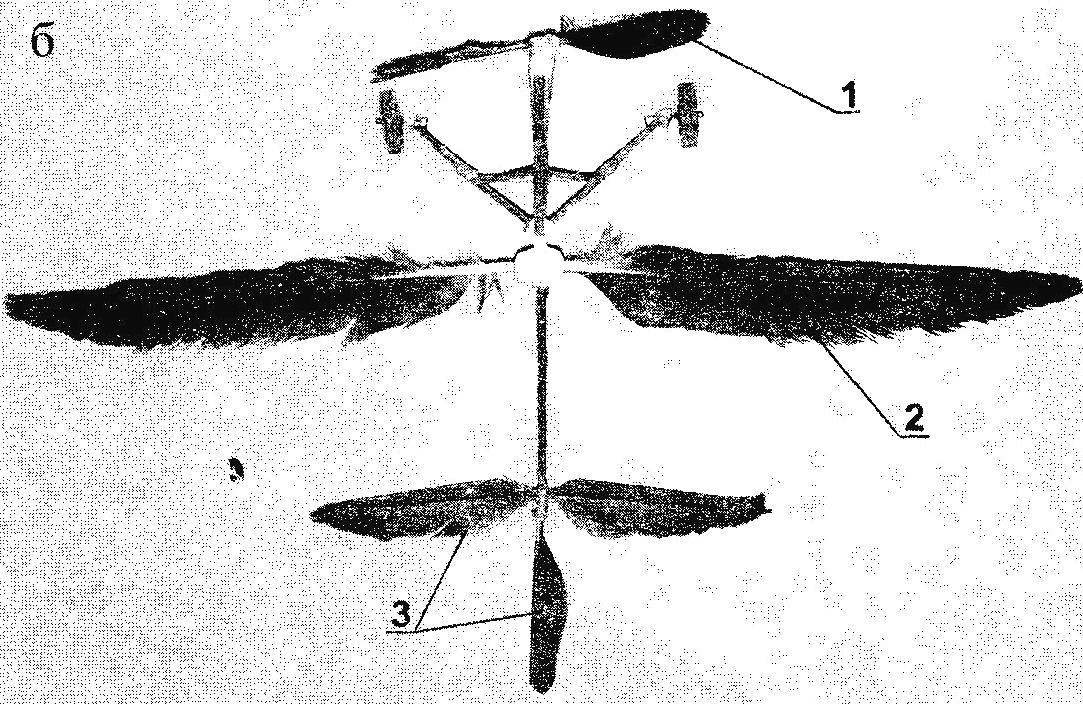

Flying indoor model aircraft from bird feathers (a, b):

1 — screw; 2 — wings; 3 — tail; 4 — fuselage; 5 — a rubber motor; 6 — chassis

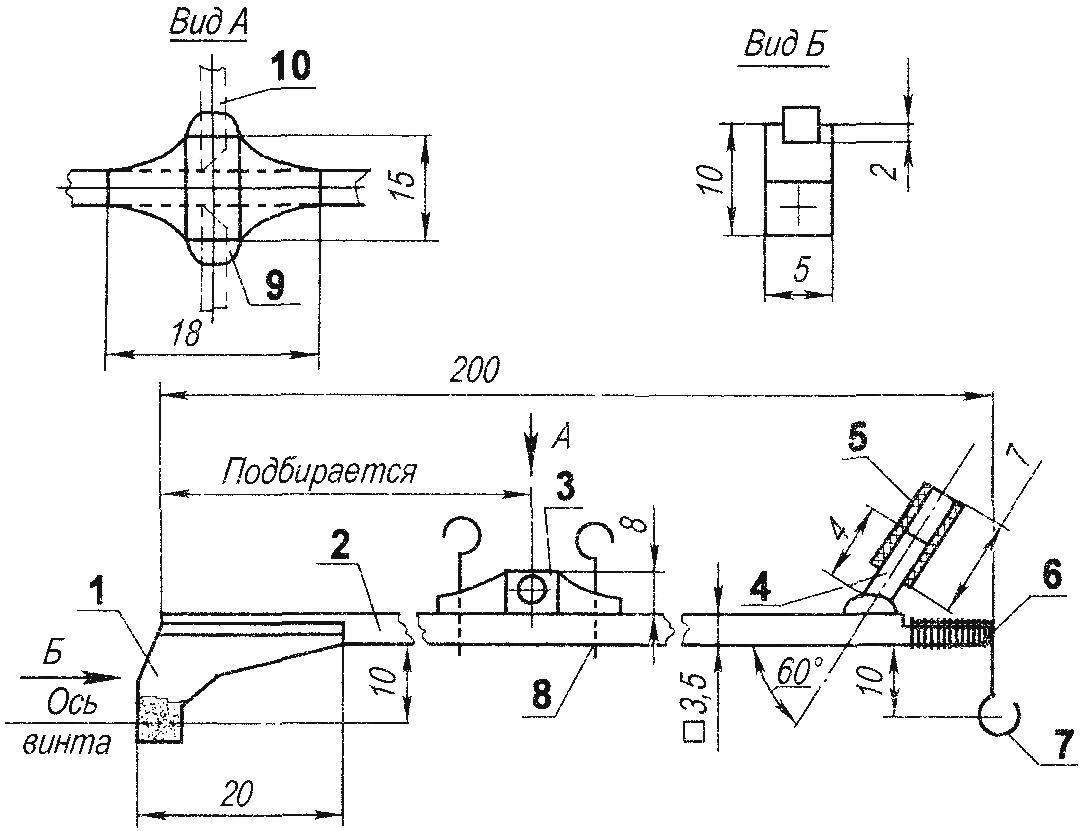

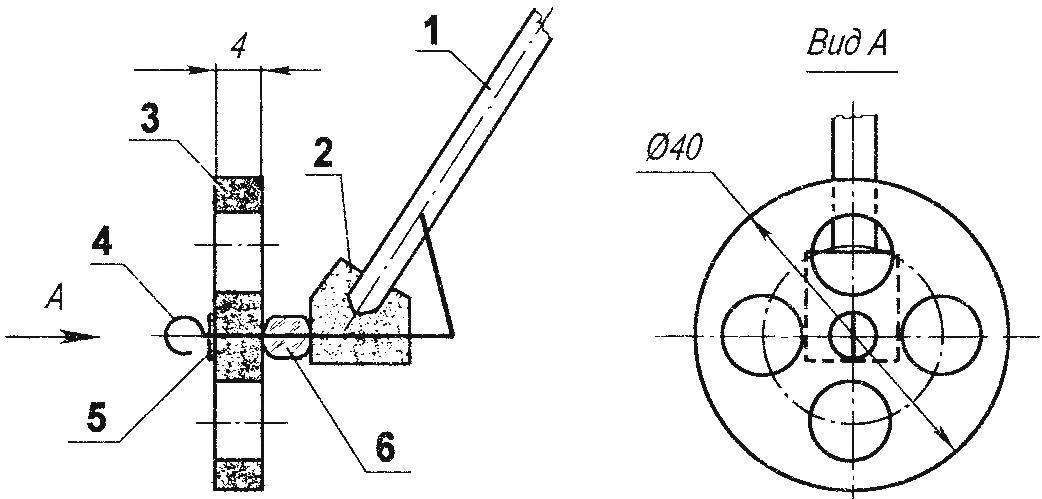

Rake-the fuselage:

1 — beak (foam); 2—fuselage beam (pine rail 3,5×3,5); 3—lug attachment of wing feathers (foam); 4—front of the keel (match); 5 — sleeve the keel (the rod of a ballpoint pen); 6 — brace (thread with PVA glue); 7—crutch-hook reinamora (pin); 8—fastening lugs (pin 2); 9—influx (glue); 10 — wing (ocean pen)

In 1784 this mythical technology was used by the French Bienvenu and Lena, constructing the first model of the helicopter. The model had a pair of four-bladed propellers from bird feathers, a hub which served as a cork impaled on the ends of a light rod. The propellers rotate in different directions from the action of a miniature bow, the string which was wound on the pivot-shaft. This helicopter was well off.

Before you start the story of design and technology of flying models from bird feathers, I want to note that the process is much simpler than the modern classical model. After all, to get bearing and stabilizing their plane, it is necessary for them to produce a frame structure from a sufficiently large number of individual elements: longerons, stringers, ribs, skin.

Every pen in itself is a miniature wing, having in its ready section the aerodynamic profile, made in the relevant proportions on the scale and the chord with precision, only available to nature itself. The Modeler remains only to choose the right size pen to use it as an element of the model: wing, fin, stabilizer, or propeller blade.

Therefore, the manufacturing of the “pen” flying models not only for the novice Modeler, but even those who previously never held in the hands of any tool.

A bird’s wing consists of nearly three dozen different (in size, shape and stiffness) of feathers. Among them are the largest and most durable extreme feathers in the first dozen so-called primaries. They are attached to the carpal bones and form the bearing surface of the wing. The rest of the feathers, the so-called secondary, is connected to the rear part of the forearm.

For the various elements of the model are most suitable primary flight feathers, even from different, but not exotic birds. These feathers can be found almost everywhere in the summer—they fall in birds during molting.

So as wings for small room model is fine feathers of a crow. Of passerine feathers make excellent blades miniature propellers, and of the circumcision dovish elements of the tail:the keel and stabilizer.

Let’s say that we decided to make room rezinomotornaya flying model monoplane with a wheeled chassis. Even after mixing and matching the shape of the feathers we got a wingspan of about 350 mm, which is most likely when using the feathers of a crow. As the power bases we will need to rake the fuselage from a dry pine with a length of 190-200 mm and a cross section of 3,5×3,5 mm.

For mounting the propeller it is necessary to manufacture the bearing of dense foam or cork and glue it with white glue to the rail, pre-cut the flats. Next, take the sewing pin for temporary fixing pieces of cloth (with a ring, not English), and, having heated it the edge over a candle flame or a spirit lamp, it burned a hole in the bearing for the axis of the screw. The axis of the screw will pin.

At the other end of the rod of the fuselage for attaching the rubber motor installed with glue and thread the hook, also made of sewing pins with a ring. This hook will perform the function of conventional aircraft “crutch” during takeoff and landing model. If a pin breaks when you bend it you need to let go (to go) to the flame of a candle or spirit lamp, that is, to heat and allow to cool.

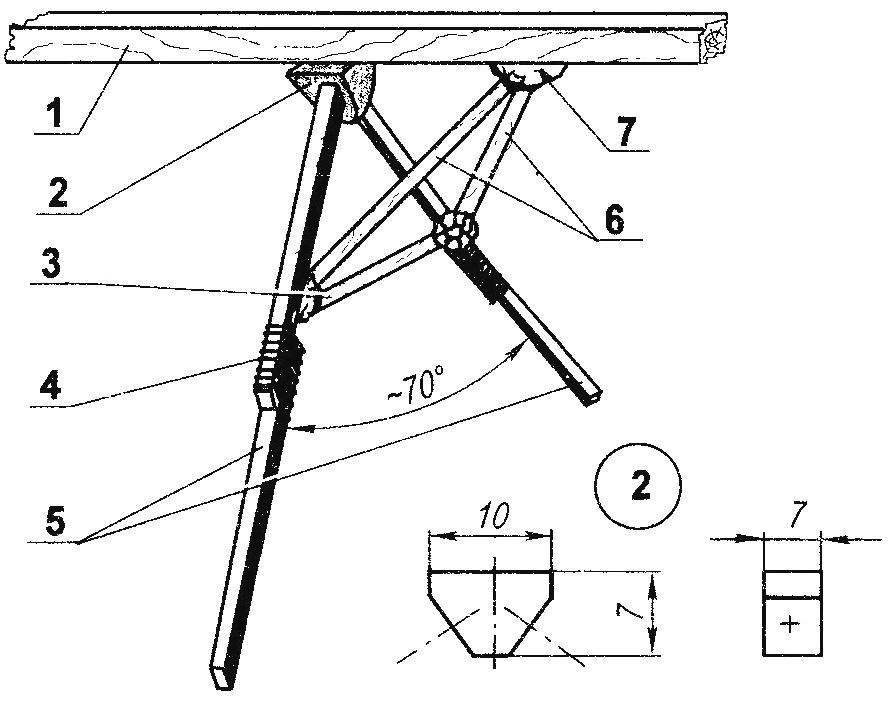

Landing gear models with the struts glued from seven matches and one foam lugs and fasten to rake the fuselage with PVA so that boss defended from the front end of the bearing 70 to 80 mm. In this match stands should be thrust into a boss on the glue. On the lower ends of the landing gear stick the foam boss again on glue, which with the help of pins that perform the function of axles mounted gear wheels with a diameter of 25 mm cut from tubes with holes of relief.

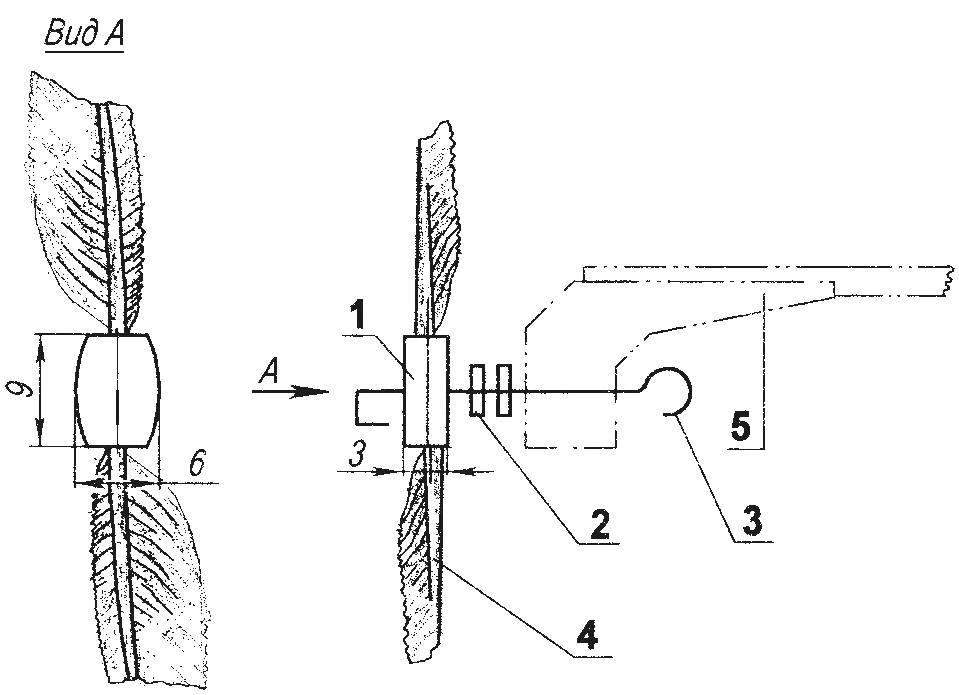

The propeller (prop) model is best done of passerine tail feathers, but can also be from the tips of the feathers of a dove or a crow, giving them the desired shape with scissors. The length of each propeller blade about 55 mm and a maximum chord (i.e. width)—14—15 mm.

The propeller:

1 —Bush (foam); 2—washer (celluloid, 2); 3—the screw shaft (pin); 4—blade (feather, 2); 5 — the beak of the fuselage

Landing gear:

1—fuselage beam; 2—boss mount struts to the fuselage beam (foam); 3—crossbar (match); 4 — bandage (thread and glue); 5—stand (2 PCs. each of 2 matches); 6 — struts (match, 2); 7 — influx (PVA glue)

Chassis:

1 — stand; 2 — boss (foam); 3 — wheel (cork); 4 — axle (pin); 5— washer (celluloid); 6 — friction bushing (silikagelya bead)

Bushing screw size 9x6x3 mm made of dense foam or cork and stick it on the glue, the feathers of the blades at an angle of 23°-33° to the plane of rotation of the screw. But do this so that when replacing the rubber motor (that is, when the plant model) by turning the propeller with the index finger of the right hand from himself, he rested in the forward edge of the propeller blades. Thus the model holds the left hand over the lath on the fuselage near the propeller. Sleeve of the air screw with two celluloid washers strung on the axle (pin) in the bearing. The annealed tip of the pin bent to the side of the sleeve and it sticks.

The rubber motor of a model make one whole thread of the rubber cross section 1 mm2, pulling her 4-6 times between the hooks of the crutch and the axis of the propeller with one link in the bundle and a small slack, which allows the crossbar between the uprights of the chassis. The total cross section of the rubber motor 4-6 mm2. At the tail part of the rail-sloping fuselage glue chip match for installing pivoting of the keel (rudder).

The sleeve is made with a piece of stem from a ballpoint pen. The feather chosen for the keel and inserted into this bushing, is easy to give any deviation. The stabilizer of two peryshkov butt glue to the rear of the rod of the fuselage. Cut from a foam boss and fasten it in two pens-the console chosen for the main wing of the model.

Next on the knife’s edge balancing all the collected model with rubber motor (but without wings), we find the center of gravity and mark it. Then, using technological pins fasten the assembled wing on the rack and the fuselage so that the found center of gravity design accounted for approximately one third of the chord of the wing front edges.

You can now test the alignment of the model in flight planning. If the airplane hollow plans straight, the alignment was found correctly. When you pitch up, the wing should be slightly drawn back, and when you dive, you go ahead. Hold the model with the left hand over the lath on the fuselage near the bearing, the right struck up a rubber motor by turning the propeller with the index finger of the right hand front edge of the blades before the secondary “sheep” (characteristic nodules) on the rubber.

Hands holding model for rail and screw, put it on a flat surface and let go. The airplane must be confident to fly after a short run. The duration of the flight model is quite small, but by adjusting the deviation of the rudder to compensate for the reactive moment of the screw, you can achieve what it is after take off to do the circle and land.

After the construction of the first model you will be able to make many other: gliders of various schemes, tandems, biplanes, triplanes, etc. it is possible to simplify the manufacturing process, performing a tail out of paper. But it already absolutely other technology.

The whole manufacturing process described flying models of bird feathers does not require any special tools and costly, in addition to patience and care are passionate about this occupation, which excess will be compensated by the satisfaction derived from the process and outcome, provided of course that it is that interesting.

M. BULYCHEV