Starts with the construction of this aircraft with the fuselage. As a preset it will fit flat Board from aspen, Linden, alder, poplar or spruce nemolodoy. The side surface of the Board need viscoity or completely ostrogat. The thickness of the workpiece after processing can be in the range of 6-7 mm. On one of its sides is applied with a pencil the contours of the future of the fuselage, after which the excess material is trimmed. Then cut a window of relief in the rear and a cutout under the crankcase. From mm plywood cut out two identical blanks for covering the forward fuselage (in the drawing their outlines indicated by white triangles).

These plywood parts are glued on the right and left to the fuselage with epoxy. While the glue polymerizes, beech, hornbeam or ash cut bars motor. To the fuselage can be glued also with epoxy or white glue. The window ease the tail section are glued spacers from pieces of rail section 6×3 mm.

The keel and the keel cut out of birch plywood 1,2 mm plywood 3 mm from the fruit boxes (it’s light, almost white, easily sawn and kuritsa; presumably it is made from aspen veneer on the glue such as CMC). From the same lightweight aspen plywood are cut stabilizer and frame, forming the frame of the Elevator. This “frame” after the treatment, you will need to glue the rib-struts made from pine slats cross-section of 4×3 mm.

Of course, if you cannot find a light aspen plywood from fruit bins for the horizontal tail will fit, and other materials. Thus, the stabilizer can be made of Linden or aspen plate thickness 3 – 3.5 mm or balsa plate with a thickness of about 4 mm. Handlebar height it is easy to carry stacked. The front edge will go to the pine slats 8×3 mm, trailing edge and rib-struts – 4×3 mm.

Training cord model:

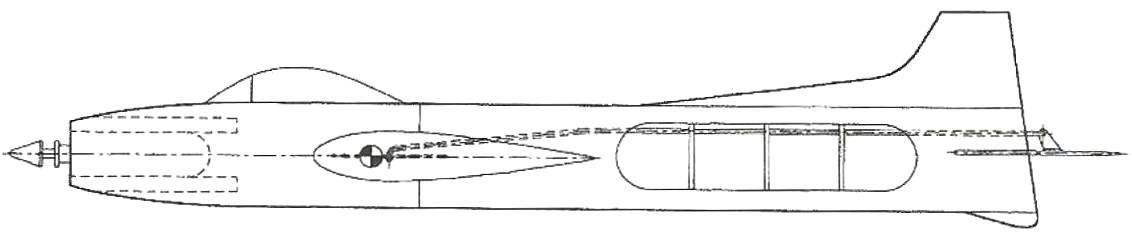

1 — front edge (pine, cross-section of 4×4 mm); 2 – the nose ribs (plywood s1,2); 3 – rib (s plywood 1,2); 4 – shelf side member (pine, section 3,5×6); 5 – leashes cord (wire OVS 00,6); 6 – wall of the side member (plywood s3); 7 – a lining of the wing (plywood s1,2); 8 rocking chair (aluminum s2); 9 – fuel tank (tinned sheet s0,2 – 0,3); 10 – trim the forward fuselage (plywood s 1,2); 11 – engine mount (birch or beech, the cross section of 8×10,11230); 12—load external wing (lead 20 g); 13 – solitaire strengthening end ribs (plywood s3); 14 – back edge (pine, 4×12 section); 15 – pull rudder (duralumin wire Ø3); 16 – fuselage; 17 – stabilizer (aspen plywood s3); 18 – front edge of the Elevator (pine, 3×8 cross section); 19 – “rib” of the Elevator (pine, cross section 3×4); 20 – loop linkage steering (nylon or Mylar threads); 21 – the trailing edge of the Elevator (pine, 3×4 section); 22 – conclusions leash cord (the spring is wound from a cord); 23 – the canopy; 24—position of the center of mass of the finished model (with engine); 25 – the outline of the window facilitate rear fuselage; 26 – the struts (pine, cross 3×6); 27 – vertical tail (plywood s1,2); 28 – horn of the Elevator (high impact plastic)

The easiest Elevator to do if possible, balsa plate thickness of 4 mm (of course, not vypilivaya Windows easier).

In the rear fuselage under the finished stabilizer is performed, the groove. In the finished parts horizontal tail with a thin drill or a rod of hardened steel wire with a diameter of 1-1. 2 mm, sharpened by the tetrahedron, drilled three or four holes for hinge attachment. Their location is shown in the drawing. The hinges are formed by a weave of durable nylon or Mylar threads (the use of fishing line are not permitted). Netting is executed in the form of “eight”. Ready vertical tail and stabilizer varnished with one or two coats of nitro lacquer, after which these details are painted with nitrocellulose brand NTS. The Elevator (if it is not celebarty) fitted by a Mylar film thickness of 25 microns.

The same film or mcalenney pieces of paper on the nitrocellulose lacquer is sheathed with the window aperture easier in the rear fuselage. After the installation of the wing to protect the tail and fuselage (especially the motor) be sure to cover the surface of two-component parquet varnish. For the model, which will be installed Microdrive with glow ignition, such varnishing is required.

The canopy can be made of any suitable material. For weight loss we use a transparent polymer film with a thickness of 0.3 – 0.5 mm, which is glued flat notched “box” of the lantern. For simplicity it is permissible to cut flat contour of the flashlight from thin plywood, paint it before gluing to the fuselage.

Controls (the rocking chair and horn), store – bought or homemade. A rocking chair is easy to cut from dural plate (not thinner than 1.5 mm). Good hog steering is obtained from the corner portion of the plastic boxes (for example, pan from KMD). Mount the horn consists of two M2 screws. The rod connecting the rocker and the wheel height, bent steel spokes with a diameter of 1.8 – 2 mm or aluminum with a diameter of 2.5 – 3 mm. the axis of the rocking chair is made of steel wire with a diameter of 2.5 – 3 mm.

The fuel tank is soldered from the “white” (tin plated) sheet. For secure attachment inside the side wall soldered (at the stage of bending metal pattern) steel screw or bolt М3х14. For drainage and power the motor uses a copper or brass tube with a diameter of 3 mm. When soldering apply the acid (zinc chloride) and the type of solder POS-40. Note that the holes for the tubes in the tank it is most convenient to pierce a homemade awl, made of wire, allied with a diameter of 3 mm. This tool performs a smooth and accurate hole diameter. While the sheet frame is formed to improve the reliability of soldering.

Variant forms of the fuselage

Host rocking (the Positions correspond to the General mean)

Fuel tank

Wing – a typical stacked design. To build his frame would take 10 ribs and 12 nozzles, cut of 1.2 mm plywood and 4 ribs of aspen plywood with a thickness of 3 mm (center section and wingtips consoles). Cross-section longitudinal members of the wing indicated on the drawings. The center section has a double-sided lining made of plywood thickness of 1.2 mm. In the Central part of the wing and at end of the ribs between the shelves of the spar is mounted to the wall of aspen plywood 3 mm. At the end of the outer part of the wing is glued compensating a weight of 15 20 g. the Connection of end ribs with edges reinforce with plywood gussets. Way to install rockers on a curved bar affixed between the flanges of the spar shown in the figures.

Finished the frame of the wing is covered Mylar film or mcalenney paper. In the fuselage the wing is glued already fully finished. After numerous experiments on the selection of adhesives for this operation, the most recognized reliable and durable connection is made on epoxy resin.

Before the first flight it is useful to check the wing in the absence of twist in the horizontal plane, the position of the center of gravity of the model with installed motor and the magnitude and symmetry of the deflection angles of the Elevator up and down. Experience has shown that the maximum deflection angle in one direction should not exceed 30°. Of serial plastic screws provided using a KMD-2,5 is the most appropriate Termik size 230×120 mm.

V. VICTORY

Recommend to read THE CURVING BRANCHES OF SIR KISA We left Britain in the midst of the "great war" as it was called by the British the First world war. Pretty pinched with German "u-bots" merchant fleet. But with huge military, which now... “EASILY TRANSPORTED PROPERTY” We left Russia and its underwater aspirations in a difficult moment for the country, alas, is only the first in suffering the twentieth century. Broke out in 1904, the Russo-Japanese war...  This model has for many years successfully “replicated” by the modelers. The secret of its popularity are the simplicity of design and good flight qualities. And despite the immutability of the size of the “serial” model, in various instances were established micro-motors a working volume of from 2.5 to 4 cm3 in the compression and glow options. But the most often used are widely known for KMD-2,5 and equipped with a propeller diameter 220×120 mm Length of cord, generally used for runs close to the standard value of -16 meters. For the manufacture of parts of the model mainly applies to non-deficient materials.

This model has for many years successfully “replicated” by the modelers. The secret of its popularity are the simplicity of design and good flight qualities. And despite the immutability of the size of the “serial” model, in various instances were established micro-motors a working volume of from 2.5 to 4 cm3 in the compression and glow options. But the most often used are widely known for KMD-2,5 and equipped with a propeller diameter 220×120 mm Length of cord, generally used for runs close to the standard value of -16 meters. For the manufacture of parts of the model mainly applies to non-deficient materials.