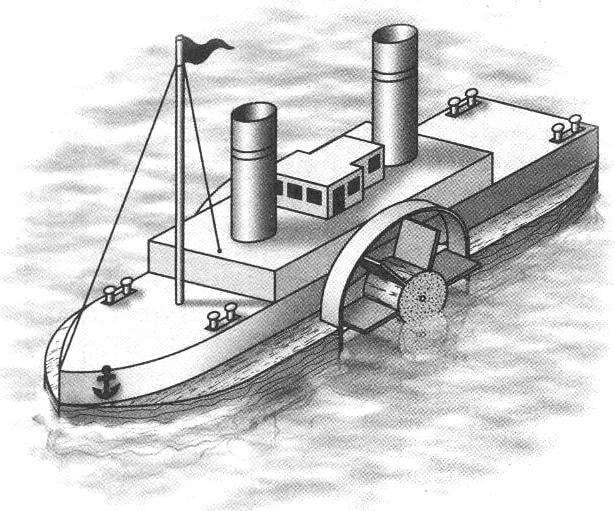

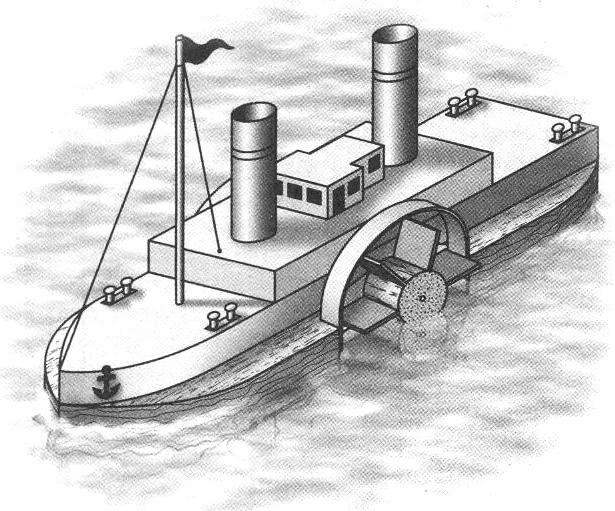

In the soul of every boy living Navigator, so any rain brook — is a river, and a large puddle is a sea calling out to let the boats from the simplest of chips or a sheet of paper, to specially planed, and the more such combined, as proposed by the German magazine “Technium” self-propelled model of a boat. Yes, no ordinary boat, but an old, two-pipe, with paddle wheels at the sides. What child would not want to build like this, especially because the design is quite affordable for independent playback.

In the soul of every boy living Navigator, so any rain brook — is a river, and a large puddle is a sea calling out to let the boats from the simplest of chips or a sheet of paper, to specially planed, and the more such combined, as proposed by the German magazine “Technium” self-propelled model of a boat. Yes, no ordinary boat, but an old, two-pipe, with paddle wheels at the sides. What child would not want to build like this, especially because the design is quite affordable for independent playback.

Indeed, all the details are so simple that can be manufactured and assembled in one evening. Judge for yourself. The model consists essentially of two major parts: the hull with the engine deck and superstructure. And what components they are subdivided — will consider in more detail.

Case

It is a flat plate with a streamlined look. The front end is traditional for ships and boats sharpening, reducing water resistance when moving forward and aft part of the hull just cut in the transverse direction. This is a tin rudder movement. The easiest option of fixing the plunge in the pre-done a crack in the stern. Turning or prizing it, you can put the boat in a circle or change direction.