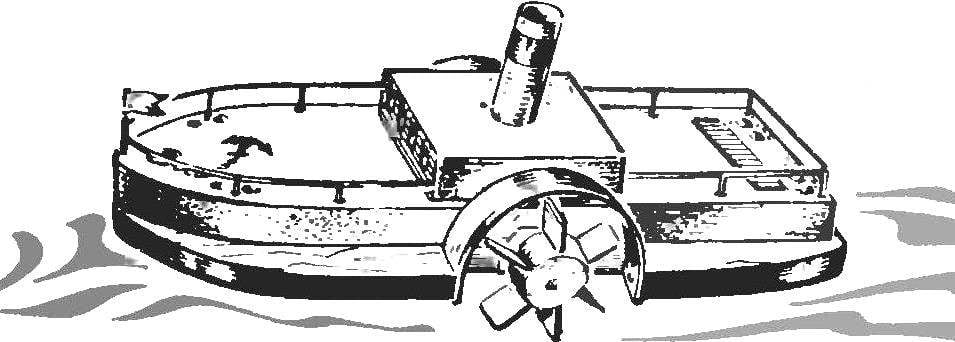

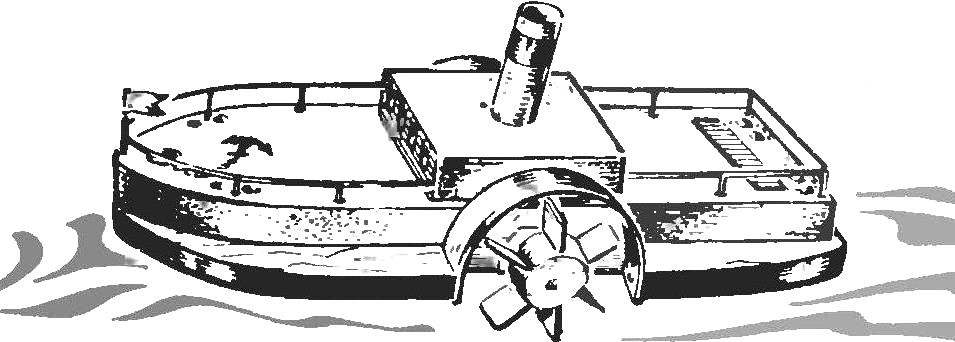

It’s amazing — currently none of our rivers has not remained exotic steamers with paddle wheels, and any boy youngsters will surely be able to tell how these look! There is something unusually attractive in this ancient technique.

It’s amazing — currently none of our rivers has not remained exotic steamers with paddle wheels, and any boy youngsters will surely be able to tell how these look! There is something unusually attractive in this ancient technique.

To immerse yourself in the romance of bygone days and observe the slow movement of the steamer, followed by measuring slipanie of PLIC on the water, it is not necessary to be able to build larger ships. Enough… skills acquired in school lessons. For students we offer development models with paddle wheels created by the readers of Czech magazine “ABC”.