Among the many exhibits already the Leningrad Museum of artillery, engineer and signal corps holds a unique exhibit—76-mm divisional gun model 1942 with serial number 4785. This is one of the 46 thousand 76-mm field guns of this type are made in the factories of the people’s Commissariat of arms of the USSR during the great Patriotic war.

Among the many exhibits already the Leningrad Museum of artillery, engineer and signal corps holds a unique exhibit—76-mm divisional gun model 1942 with serial number 4785. This is one of the 46 thousand 76-mm field guns of this type are made in the factories of the people’s Commissariat of arms of the USSR during the great Patriotic war.

An unusual battle destiny this is not the most powerful, but formidable in the right hands of Soviet soldiers guns. Your first shot on the gun Nazis did on the Kursk bulge near the village of ponyri in the summer of 1943. Almost two years she participated in the battle, supporting the infantry fire, the liberation of Soviet land, then fought, liberating Poland, in the spring of ‘ 45, her “voice” heard in Nazi Germany. Fortune was in his favor: it was not crushed in battle and on the March the German tanks, not bombed dive-bombers. Cannon was fighting on the front line the roads 6204 km, made during this time, 3969 shots, it destroyed 33 tanks, 21 self-propelled gun, 74 vehicles, 14 artillery guns, 17 mortars, and five planes on the ground. April 21, 1945, in 18 hours 10 minutes calculation tools under the command of senior Sergeant I. M. Rodionov opened fire on Berlin.

Divisional gun ZIS-Z with the amazing destiny of Leningrad Museum not only preserved from the times: at the museums and memorials on the old battlefields and in military units cherish these guns as the memory of the immortal feat of the Soviet soldiers who won “the brown plague”.

The appearance in 1890-h years on arms of armies of many countries of rapid-fire guns caliber 75 — 77 mm, intended for direct infantry support, associated with the invention in France in 1884 by de La smokeless slow burning powder, which allowed to remove a number of issues related to the development of these tools. Caliber guns was optimum to set before them combat tasks, their shells could destroy light fortifications, destroy enemy manpower and even his field artillery. Guns of greater caliber were significantly heavier, making it difficult to maneuver them on the battlefield. In 1892 the French designers PUTEAUX and Dupor has created a 75-mm cannon with independent line of sight.

The first Russian 76-mm, or according to the classification adopted at that time, the three-inch gun, developed at the Putilov factory in 1900 engineers L. A. Villager, K. M. Sokolowski, and K. I. Lipnitsky on the basis of the works of the founder of rapid-fire artillery, V. S. Baranovsky. The gun had a fixed barrel, a reciprocating breech and the carriage with the wheel devices. Design mast with hydraulic recoil brake and nachalnikom with rubber buffers have been proposed by the military engineer A. P. Engelhardt. The brake cylinder is attached to the sled, gliding in the shot with them mounted on the gun barrel along the guide rails of the machine, the rod was located between the beams of the machine guns. In 1902 Putilov suggested improved version of three-inch plank, developed under the leadership of the outstanding scientist-gunner N..Zabudsky. This gun is the barrel when the rollback is moved along the guide rails located on the cylindrical cradle and the breech ring is rigidly connected with the cylinder of a hydraulic brake rollback spindle type, located inside the cradle. Spring nachalnika was in the gap between the brake cylinder and cradle. The very cradle with axles attached to the machine located on the guidance mechanisms. As ammunition for the .. .. sample of 1902 used the unitary rounds with high-explosive and incendiary grenades into the steel casing and shrapnel. Piston bolt with two plain and threaded sectors allowed the calculation is prepared to produce up to 10-12 rounds per minute.

Three-inch plank was a very rational design—they have proven themselves on the battlefields of the First world and Civil wars. Trehdyuymovym almost no significant changes were produced until 1930, when it was modernized under the leadership of V. N. Sidorenko. 4477 upgraded 76-mm guns of the sample 1902/30 years stood on the red Army at the beginning of the great Patriotic war. Ballistic data on this weapon was so successful that they were used as a basis when creating a new Russian cannon, developed in Soviet times.

In 1932, the Main artillery Directorate of the red Army issued technical specification Design Bureau of all-Union gun-Arsenal enterprises (KB voao) to develop 76 mm universal and semi-universal divisional guns. Simultaneously to the creation of a universal gun started KB the Leningrad plant “Red Putilovets” and a semi — construction Bureau of factory No. 8. The idea of universal guns, able to fire at air and ground targets, were fashionable in the West in the early 30-ies of XX century, and among the leadership of the red Army were adherents of the idea of universalization.

KB voao was created as a powerful center of development of artillery weapons with well-equipped pilot production and was located in the village of Kalinin in the territory of present Moscow city Queens, next to the Moscow cannon factory No. 8—one of the largest domestic enterprises of this profile. The development of a universal gun was directed by S. E. Rykowska, and a semi—V. G. Grabin. First estimations showed that the universal and poduniversal guns will be much harder, heavier and, as a consequence, more specialized anti-aircraft guns and field artillery. But most importantly—they both will have mediocre performance characteristics. But “gears” of the planned economy began to spin, and by the end of the year, both the Department prepared a presented several avant-projects of new guns. At this time in the leadership of the people’s Commissariat matured plans, and in late 1933 by order of the G. K. Ordzhonikidze KB voao eliminated, and the building, equipment and almost built a pilot plant was transferred to L. V. Kurchevsky—the founder of the Soviet dynamore-active guns. New enterprise was awarded the title CCH-38. Wanting to do Dynamo-reactive cannon to GKB-38 was a little, and most of the professionals moved on to other enterprises. The group of twelve engineers and one technologist, headed by V. G. Grabina proposed to continue work on a semi gun And-51 on the new artillery factory No. 92, recently built in Nizhny Novgorod.

Artillery production at the plant at the time was minor and was carried out on the documentation developed in other enterprises. The plant was urgent staffing issue—not enough skilled workers and engineers in the technical Department of the plant worked three constructors and several draftsmen. They made corrections to the drawings in which there is a definite error. The work of newcomers to the plant designers started with the help of the plant in the delivery to the customer party of ten guns of the sample in 1930. Artillery production was artisanal in nature, one manifestation of which was the manufacture of individual parts and components of guns unaccounted for in the design documentation: some experienced workers was used to create drawings brought from his previous place of work. The utilization rate of the metal was low: often, the workpiece mass is ten times superior to the finished part. Therefore, the work of designers in the new place enough, and their desire to continue work on the establishment guns A-51, received the new plant index f-20, with the consolidation of their authority in the workplace were understanding. Shortly after the arrival of V. G. Grabin, which experts saw not only the boss, but informal and authoritative leader, managed to convince the leadership of the people’s Commissariat of heavy industry of the need for 76-mm divisional guns, specialized on the solution of traditional tasks. V. G. Grabin was to create universal and semi-universal guns of this caliber for infantry dead-end direction. The Ministry has allocated 100 thousand rubles for the execution of development works (ROC) for the gun, which received factory index f-22. On the performance of the ROC by the people’s Commissariat established a period of eight months, in this case, the time for inspection, artillery weapons, planned GAU at Sofrinsky range.

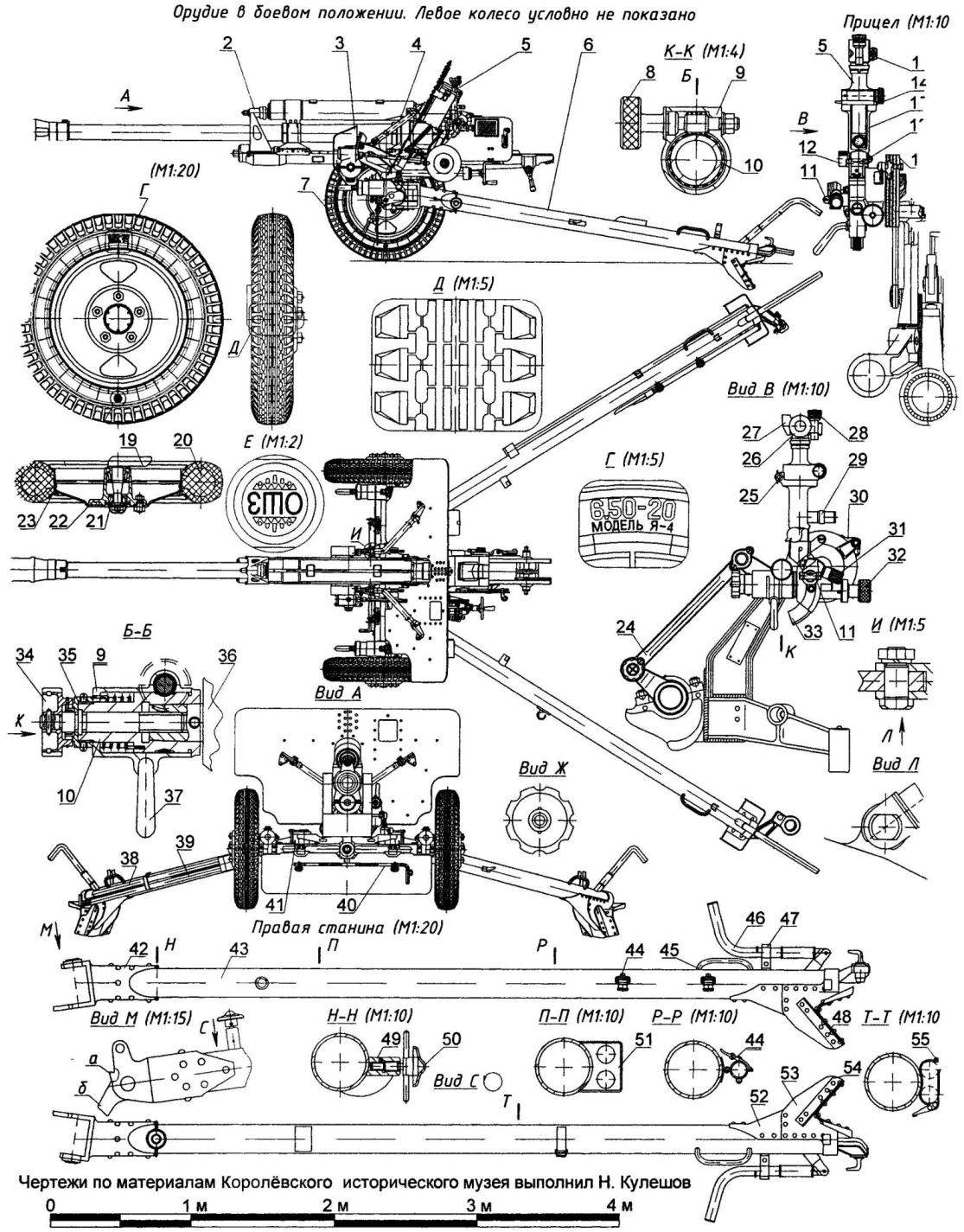

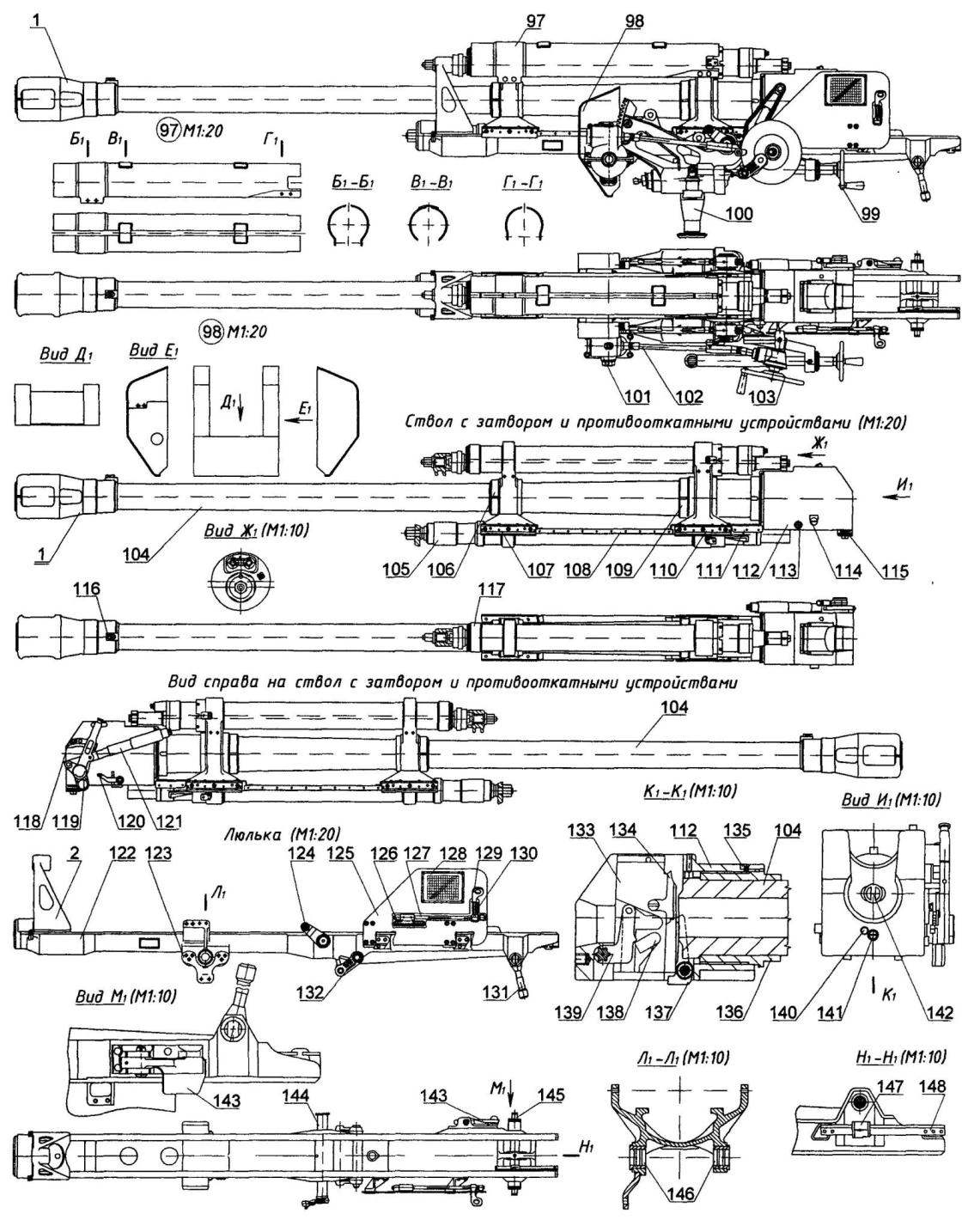

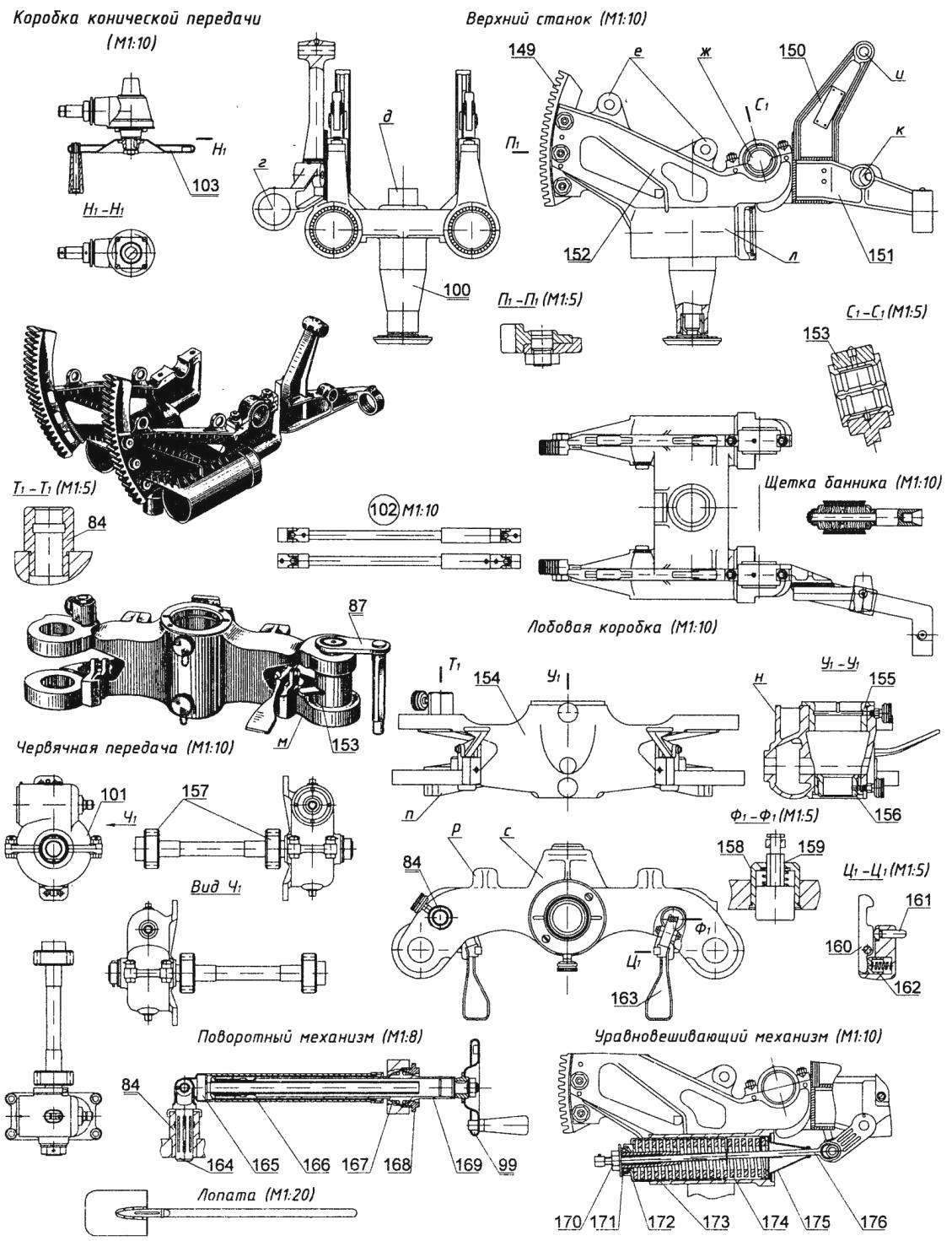

76-mm divisional gun model 1942 ZIS-3:

1—the muzzle brake; 2—an arm of the cradle; 3—movable shield; 4—plug; 5—the case of the panorama; 6—left frame; 7—bus type GK from the GAZ-AA; 8 — flywheel screw; 9—axis housing; 10—; 11—longitudinal level; 12—latch panoramas; 13—sighting device; 14—flywheel screw protractor; 15—basket panoramas; 16—transverse level; 17—remote drum; 18—drive; 19—the axle shaft; 20—spongy rubber; 21—roller bearing; 22—hub; 23—side ring; 24—rod swing mechanism of the sight; 25—the clamping screw of the basket, 26—reel panoramas; 27 lens reflector; 28 — flywheel screw to move the drum in a vertical plane; 29—the eyepiece of the panorama; 30 pointer; 31 —flywheel screw longitudinal level; 32—handwheel worm installer remote drum; 33—notched stem of the sight; 34—handwheel of the mechanism of the transverse swing of the sight; 35—coupling nut; 36—the case of sight; 37—crank mechanism transverse swing, 38—rod; 39—the landmark, 40—stopper the lower folding shield; 41—right bracket (left—mirrored) view; 42 — right fork; 43—tube; 44—shovel holder; 45 — handrail; 46 rule; 47,71 — linki; 48—spade opener; 49—the case of the wheel brakes; 50—screw with the fifth and arm; 51 — block; 52—bracket; 53—panel; 54—gon; 55 is a holder of milestones and rod; 56—right half of the upper panel; 57—retainer shield; 58—the left half of the upper panel; 59—box panoramas; 60—visor; 61 —a box for brushes, swab, discharger and wooden boxes for formulary; 62nd eye; 63 pocket for the device “Luch-2”; 64 bar; 65—the top stop of the movable flap window of observation; the 66—latch; 67—movable plate; 68—the lower limiter of the movable plate; 69—lower shield; 70—loop; 72—eyelet; 73—fuse; 74 — cover glass 75 glass 76—spring; 77—thrust; 78—constipation; 79—cover with mesh; 80—housing of the outer cylinder; 81—rubber buffer; 82 — a hook to attach the chain to the Shoe brake; 83 —locking bushing of the rules, 84—stand rotation mechanism; 85 — right wings; 86—military axis; 87 axis left fork; 88—release lever; 89—bracket fixing roller fixing the swinging of the gun in its stowed position; 90—spring stopper 91, the stopper pivot paws; 92—half-cushion; 93 —right pivot foot; 94—left pivot foot; 95 ttings; 96—HASP-lock; 97—a reservation of nachalnika; 98—movable shield; 99—flywheel rotation mechanism; 100—pin upper machine 101—housing of the worm gear; 102—swivel-wheel drive; 103 —flywheel vertical aiming; 104 pipe; 105—recoil brake; 106—front nut; 107 front clip; 108—front tire; 109—rear nut; 110 rear clip; 111—rear tire; 112 barrel; 113 — the axis of the ejector; 114—pusher; 115 — catch; 116—stopper muzzle brake; 117—lakatnik; 118—a guide arc; 119—the bolt handle; 120—arm extractors; 121—closing mechanism; 122—the case of the cradle; 123—a bracket of the lifting mechanism; 124—the bottom arm of the rolling mechanism of the sight; 125—flap; 126—push of the trigger; 127—axle; 128—table to determine the amount of liquid in nikitniki; 129 trigger arm; 130—spring; 131—arm to block the swinging of the gun in its stowed position; 132—the axis of the counterbalancing mechanism; 133 — wedge gate; 134—Cam extractors; 135 — stopper; 136—coupler; 137—ejector; 138—lever axis platoon; 139—crank; 140—stopper axis of the crank; 141—socket for screwing a hook for the production of artificial rollback; 142—a cover of the drummer; 143—copier; 144—pin; 145—cushion locking mechanism in its stowed position; 146—sleeve; 147—slide; 148 rail pointer rollback;

and there’s a ledge that limits the cultivation beds b—ledge, which drops into the stopper of frames in combat; the hole for the bolt-retainer fighting the axis

Appointed to the Commissariat on the date the factory # 92 produced and sent in the suburbs experienced three guns: a semi f-20, f-22 with folding frame and painted yellow f-22 with a solid frame.

All the guns met the requirements of the GAU. Universal weight—1550 kg, which was 200 kg less than the mass established the terms of reference, the easiest was the f-22 with a solid frame—1450 kg. However, even the lightest of cannons, they created weighed into a fighting position 350 kg more than standing on the arms of the red Army divisional gun model 1902/30. Besides, to reduce weight the designers used a high alloy steel, while the role model made of alloyed and carbon steels.

For review June 14, 1935 at Sofrinsky the ground arrived I. V. Stalin, V. M. Molotov, K. E. Voroshilov, V. Y. Chubar, G. K. Ordzhonikidze, V. I. Mezhlauk, and the representatives of the people’s Commissariat of defense. Have built a line of guns stood their chief designers, who were reported to have arrived heads of the submitted samples. On the right flank were the first 76-mm universal gun factory “Red Putilovets”, developed under the leadership of I. A. makhanova, next to her 76-mm divisional semi-universal gun 25K of factory No. 8, under the guidance of V. N. Sidorenko. Next were three 76-mm cannon of the plant number 92. Closed Stroy gun adopted by the red Army: 76-mm antiaircraft cannon F. F. Lender on a truck chassis, the 122-mm freestanding gun A-19 and a number of guns of large caliber, including 203-mm howitzer B-4. Stalin liked “yellow” gun, and he returned to her when other members of the government continued to check other guns. He asked V. G. Grabin, the design of the gun and its tactical characteristics. After the demonstration firings on the range the government has taken the decision to continue further work on the gun f-22 with a solid frame. After the polygon and military trials, and significant improvement of a number of nodes (charging chamber converted into a unitary cartridge gun model 1902/30 year, from the trunk of a dismantled muzzle brake and increased the number of nodes) in 1936 f-22 was adopted, and V. G. Grabin was awarded the order of Lenin. As a result of the rejection of the muzzle brake and enhance the design and weight of guns increased to 1,700 kg. during the production of the design Bureau of plant No. 92, carried out activities to improve the adaptability of the f-22. If in 1937 for the manufacture of f-22 with a mass of 1700 kg left 11 895 kg metal, in 1938—8350 kg, and in 1939—6684 kg.

In April 1938 at a meeting with Voroshilov V. G. Grabin learned that the Bureau of the Chelyabinsk Kirov plant under the supervision of I. A. makhanova task of GAU from March 1937 designs to replace the f-22 divisional gun, the tests which revealed a number of defects, the removal of which, according to estimates by Vasily Gavrilovich, was supposed to take about 10 months. Then V. G. Grabin made a proposal to give the opportunity to improve the f-22, bringing its characteristics to the level of technical specifications GAU, issued by the Kirovsky factory. The adoption of the f-22, developed at factory No. 92, contributed to the unity of the collective enterprise, which has clearly identified prospects. Compared to 1934, it was already another group was significantly increased qualification of workers of the design Bureau to work on new guns, and this work was carried out in close cooperation with the factory technologists. The designers have acquired the necessary experience in the development of tools, and develop their nodes were more rational and technologically. When designing guns KB grabina one of the first drew attention to the ergonomics of workplaces of the calculation from the point of view of maintaining high efficiency when firing and consulted on these issues at the doctor-the physiologist L. N. Aleksandrova. In 1938, the plant for the first time since the start-up coped with their targets, for which a large group of factory workers were awarded orders and medals.

V. G. Grabin made a plan, which was also shared with their colleagues after returning to the Bitter. To develop technical documentation for this plan was given three to four months, the prototype was followed to fabricate six or seven months after the start of work on the factory test was given a month and a half. At the same meeting, Vasily Gavrilovic said that the development time of the tools, compared to the generally accepted norms of the time, is small, and the rules of war is unacceptable high, so the team in time of peace must learn to work as during the war. New divisional gun has received factory index f-22УСВ.

Manufacturing divisional gun ZIS-S in the factories of the people’s Commissariat of arms of the USSR in 1942 -1945 years.

Note. According to the memoirs of V. G. grabina, in the second half of 1941 the factory # 92 produced and handed over to the customer about 1000 guns ZIS-3.

Faith in the strength of the team was justified. Seven months later, the shop was the first experienced gun f-22УСВ, which used up to 50% of the parts and assemblies f-22. Compared to its predecessor, it looked more bulky and heavy. But her weight was 40 kg less than the established terms of reference and was 1460 kg. the Gun has been successfully tested, and in 1939 it was adopted and in 1940 launched the gross production at the plant number 92. In total, the red Army on 22 June 1941, was 2686 divisional guns f-22 and f 1170-22УСВ.

Before the Second world war, the Soviet Union began work on the creation of tanks with cannon-proof armor. The leadership of the people’s Commissariat of defense had information that carried out similar work in Germany. In this regard, the construction Bureau of plant No. 92 started to create anti-tank gun, capable of hitting future tanks. Analysis of the capacity of 45-mm guns, made the construction Bureau of plant No. 92, showed that the increase in the initial speed of the projectile up to 1000-1200 m/s does not allow you to get a gun with the necessary characteristics for armor penetration and survivability of the trunk. More promising was recognized as the 50-60-mm anti-tank gun with a muzzle velocity of 1000 m/s. Artillery Committee of GAU was offered the caliber of 55 mm, and an Artillery Academy.F.Uh.Dzerzhinsky — 60 mm. For development of anti-tank gun ZIS-2 (after the assignment of the plant number 92 named after I. V. Stalin, the development of KB were to assign new codes) chose a caliber of 57 mm, while the optimal had a projectile weight of 3.14 kg with an initial velocity of 1000 m/s For the cartridge ZIS-2 chose a sleeve from 76-mm divisional gun with probation of Dulce from 76 to 57 mm. the Capacity of the new gun was equal to 160 tonne-metres, which was four times more than a “rotation” of 1937. To reduce the time of issue of technical documentation as the basis for the selected waste constructiondevelopment scheme 76-mm regimental gun f-24. A month and a half of the specifications for the ZIS-2 was ready, a prototype was produced three months after the start of design. Development was carried out with the consent of the people’s Commissar of armaments B. L. Vannikova on the tactical and technical assignment drawn up by the Bureau of plant No. 92. Work on the 57-mm antitank gun, financed by the people’s Commissariat of weapons. The first shots from the new gun was completed in October. The material part of VMS-2 worked flawlessly.

By the autumn of 1940 the construction Bureau of factory No. 92 was on the rise: it has a distinguished reputation in the Commissariat and GAU, to work on different artillery systems team has enriched the interesting design solutions.

The successful testing of the 57 mm anti-tank gun ZIS-2 was the impetus for the development of divisional guns ZIS-C Compact carriage ZIS-2 was light, reliable, provide high mobility of cannons: fire and on the March. He is, however, and the cradle, and wheel the device, and the guidance mechanisms could be used without significant modifications for the new divisional gun. So after the first firing 57-mm antitank gun ZIS-2 in KB of the factory # 92 was discussed in a narrow circle of the plan of the new divisional gun. Thoughts on the new weapon Vasily Gavrilovich Grabin shared with his colleagues D. I. Schaeffer, K. rønde, V. D. Meshaninov, I. A. Gorshkov and L. D. Kotov.

According to the version of V. G. Grabin, the development of a new divisional guns were the following reasons.

First, even a rough calculation showed that the red Army by the beginning of 1941 the guns of this type will be less than in the Russian army before the First world war, and production orders of f-22УСВ from the people’s Commissariat of defense is no longer in sight. The scale of the war was more war coming, the certainty of which no one in doubt. Therefore, the possibility is not excluded that in case of war will have to resume production of f-22УСВ, which he regarded as a transitional model to a more perfect gun. Therefore, it would not hurt to have in case of war, the new divisional gun, which by its characteristics superior to f-22УСВ.

Secondly, power and ballistic solution was put into serial production divisional gun f-22УСВ fully satisfy the requirements for the advanced divisional gun ZIS-Z. So it would be rational to overlay a 76mm barrel f-22УСВ on the carriage of the ZIS-2. On the basis of the current at this time of practice, initially for the new guns took the maximum angle of elevation equal to 45 degrees, providing a maximum firing range. Shooting at high angles of elevation will lead to a significant increase in the maximum load on the carriage (ZIS-2 elevation angle was 25 degrees), to reduce them decided to equip the barrel of the ZIS-S muzzle brake, which would reduce the energy of the rollback 30%.

Offers V. G. Grabin met with understanding and support from participants.

The development of the barrel ZIS-S according to the design scheme similar to the ZIS-2, instructed the designer I. S. Gribany and the chief of section V. D. Meshaninov. 76-mm pipe of the barrel was required to enter into the casing anti-tank guns. Griban quickly developed a sketch on the pipe and passed it into production, and he started drawing on the barrel. After studying the structures of different muzzle brakes as a prototype for a new gun with variable length rollback chose brake 122-mm corps guns A-19 sample 1931. From the blank barrel for f-22УСВ on sketch I. S. Gribane manufactured barrel guns experienced, which established a modified muzzle brake. The barrel mounted in the cradle ZIS-2 and after completion of the Assembly of the gun the night she was made the first fire on the factory site reduced, normal and increased charges at zero elevation. In the morning, delivered to the shop the gun examined: deformation and destruction of structure is not found.

This allowed us to begin the second stage — the detailed design of the main units of divisional gun ZIS-Z.

The overall design of the cannon was entrusted to A. E. a Twig— an experienced designer that performed more than one arrangement of tools in different KB. Refinement of the top machine took A. P. Shishkin. The sight instructed B. G. Pogosyants and 3.M.Minaevoy. The most difficult task—the development of a mechanism for variable-length rollback entrusted a recent graduate of Leningrad military mechanical Institute, F. F. Koleganov, who participated in the creation and debugging protivootecona devices ZIS-2. After consideration of the same devices he chose as a prototype design concept brake roll back all guns A-19, created under the leadership of V. N. Drozdov.

The task of creating a gun was made easier by the fact that KB V. G. grabina was the initiator of high-speed design methods artillery for their wide operations work closely with factory engineers when the designer at the early design stage to take into account the features of the technological processes developed by the plant. The joint work of the designer, A. P. Shishkin with technology: foundry G. I. Captaim and specialist machining Gordeyev has allowed ahead of schedule to file the top of the machine for Assembly. No problems with installation of the sight: designers B. G., Pogosyan and 3.M.Minaev, Deputy head of aim workshops by Seliverstova promptly performed the work.

During testing the guns at the range, the designers have noticed that when fired, it behaves quite steadily. It made me think: is it possible to opt out of the brake with variable length of the rollback? The idea was extremely tempting; in this case, almost no need to alter for the ZIS-S recoil device ZIS-2 gun-carriage which had by that time repeatedly tested. It was necessary to check how this will affect the accuracy of fire. Assessment of the accuracy checked out a traditional shooter with shields set to fixed length of rollback brake. The first counting group shots performed at a distance of 500 m. Got great results. Re-shooting did not give differences and not inferior to the accuracy of the battle of f-22УСВ. Shooting at a distance of 1000 m showed results worse. At the same time when firing at maximum range for the selected length of the rollback required or to increase the height of the top of the machine, or digging when firing at maximum range rovik under the cradle between the frame. At the same time reducing the angle from 45 to 37 degrees C reduced the range of fire high-explosive shells 0.7 km (up to 13.3 km). But in this range adjust the firing of the 76 mm gun was difficult.

76-mm divisional gun mod. 1942 ZIS-3:

84—stand rotation mechanism; 87—axis right fork; 99—flywheel rotation mechanism; 100—pin upper machine 101 —housing of the worm gear; 102—swivel-wheel drive; 103 — box bevel gear; 149—tooth sector; a 150—bracket sight; 151—bracket mechanisms aiming; 152 — basting; 153—spacer tube; 154—the base of the frontal box; 155—brass sleeve; 156—the needle bearing; 157—gear; 158—housing of the retainer; 159—stopper of beds; 160—hook pedals; 161 push pin; 162—spring pusher; 163 — pedal; 164—plug; 165—spindle; 166—housing; 167—spherical bearing; 168—nut; 169 plain; 170—regulating nut; 171—bearing; 172—thrust washer; 173 — domestic Cup; 174 — spring; 175 cover; 176—thrust; in—the hole for the bolt-retainer fighting the axis; g—hole for installing the rotary mechanism; d—stop the declination angle of the barrel; e—eyelets for attaching the upper panel, the hole for the axle cradle; and a hole for fastening of a sight, K—hole for installation of a bevel gear; l — cylinder balance mechanism; m — tide to pusher pin push button; n—stop rotation of the upper machine; a u—ledge, limiting the breeding beds; R—rush to limit the swing battle axes;—inflow of fastening of fighting the axis

As the ZIS-S was developed in the initiative order, I decided to limit the maximum elevation angle of 37 degrees. This allowed increasing the line of fire of only 50 mm, to maintain the compactness and squat, typical for anti-tank ZIS-2. The transition to a full-length rollback required significant redesign of the gun, and A. E. Twigs brilliantly coped with this work. The modified cannon has successfully passed the factory test. The results delighted the creators of the ZIS-Z. She, not yielding f-22УСВ in the tactical characteristics was 400 kg lighter, more compact and technologically in the production and, most importantly, is three times cheaper than its predecessor. Maximum rate of fire of the gun was up to 25-30 rounds per minute. But ZIS-S created in the initiative order, and was a big minus—one knew neither to the UNIVERSITY nor in the Commissariat. It was necessary to choose a suitable occasion to present the gun to the GAU leadership and bring the work to its logical conclusion—polygon and military trials, and in their positive results—the procedure and launch of gross production.

Such an occasion soon presented itself. In March 1941, in the Bitter came the chief Marshal of GAU G. I. Kulik, who supported a year ago V. G. grabina when you create the ZIS-2. This time Marshal was little concerned with questions of production and development of divisional guns, and he stopped the attempt of the chief designer to discuss the matter. And the gun remained shrouded in the experimental shop waiting in the wings.

And this is the hour: June 22, 1941 German troops crossed the Soviet border. The Great Patriotic war:

The rapid advance of the German troops, the environment, and boilers, which were the troops that entered into battle in the border districts has led to great losses in manpower and weaponry. The evacuation of many enterprises from the European part to the East. In these circumstances, from those plants, which were outside the combat zone, required a sharp increase in the production of weapons and military equipment. In accordance with the mobilization plan, the production of f-22УСВ was to expand the plant number 92 to them. Stalin and factory No. 221 “Barricades”. Moreover, due to the difficult situation at the front, the production had to increase by much in comparison with the volumes in which these cannons were made in time of peace.

A month after the beginning of the war, the plant increased the production of guns three times. But it wasn’t enough. The enterprise arrived construction a party of several thousand people. Less than a month they built a new building for the production of normal and recoil devices with an area of 10 000 m2. To aid the plant in equipment of the production horizontalvertical, boring and surface grinding machine has arrived the Commissioner of the State Defense Committee G. I. Ivanovskaya, former Director of the country’s largest Kryvyi Rih metallurgical plant, and during the war—Deputy people’s Commissar of state control. Such equipment existed on the plant milling machines, but the Director did not give it, said that affected production. Of two evils chose the lesser—machines gave the gunners. In the evening G. I. Ivanovsky said on the phone to the Director of the plant, which equipment should be transferred immediately. After an hour on the enterprise profit machine workers of factory No. 92, which not only has been dismantled and transported machines, but was able by morning to install and run them on a new place.

On the first day of the war, Marshal of the Soviet Union G. I. Kulik has replaced on a post of the head of GAU General N. D.Yakovlev. As recalled by V. G. Grabin in July 1941, having obtained the consent of D. F. Ustinov, people’s Commissar, he turned to the Deputy people’s Commissar of defense for weapons G. I. Kulik asking to learn about new developments, Bureau of plant No. 92 and make the decision on expediency of their adopting. The show was scheduled for 22 July in the courtyard of the people’s Commissariat of defense. The bitter was taken 57-mm self-propelled anti-tank installation: ZIS ZO on the chassis of a tracked armored tractor Komsomolets and ZIS-41 on the chassis of the GAZ-AAA and ZIS gun. Despite the good impression made by the work of the gun crew, the conclusion of Marshall about the ZIS-S was negative.

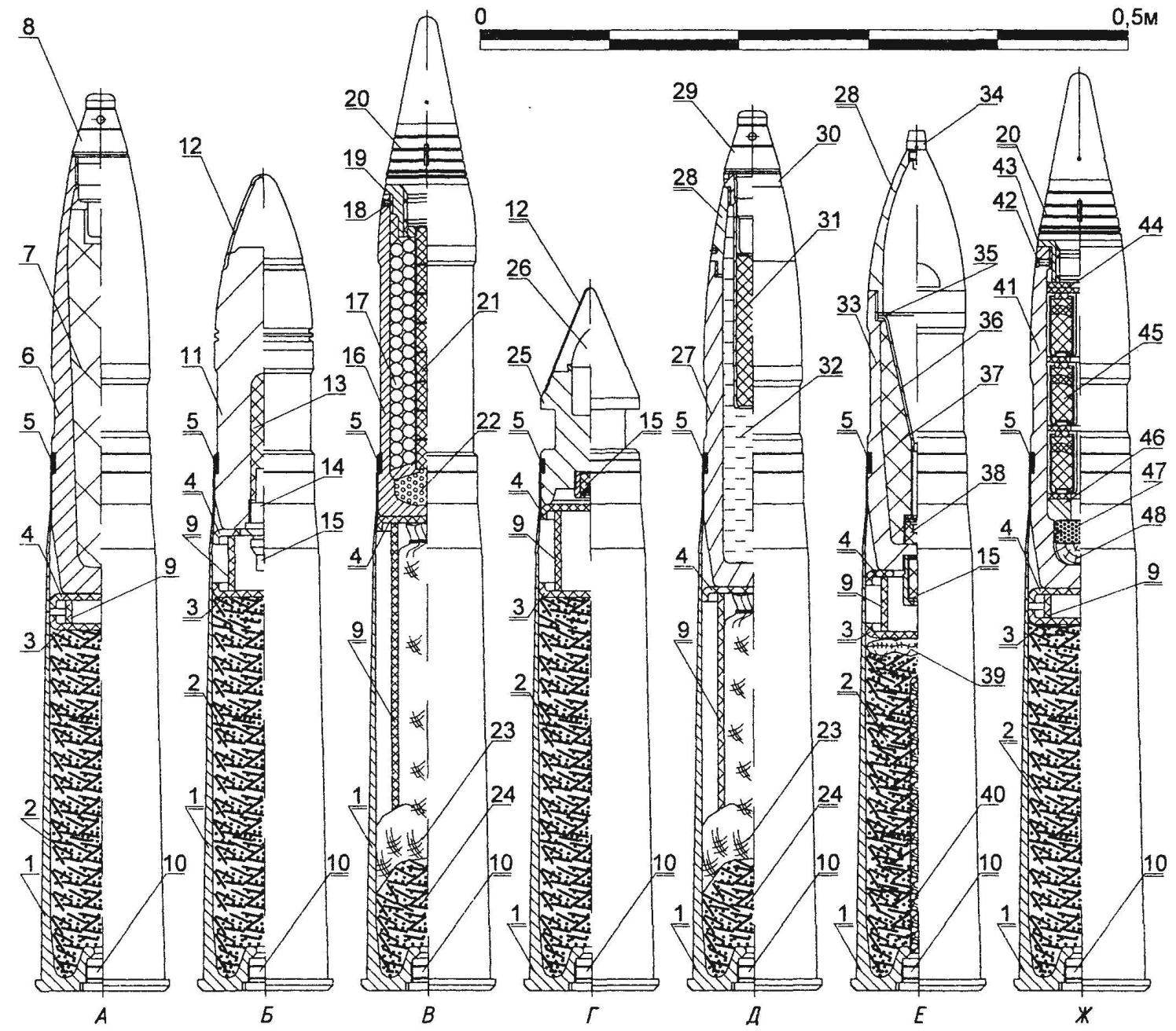

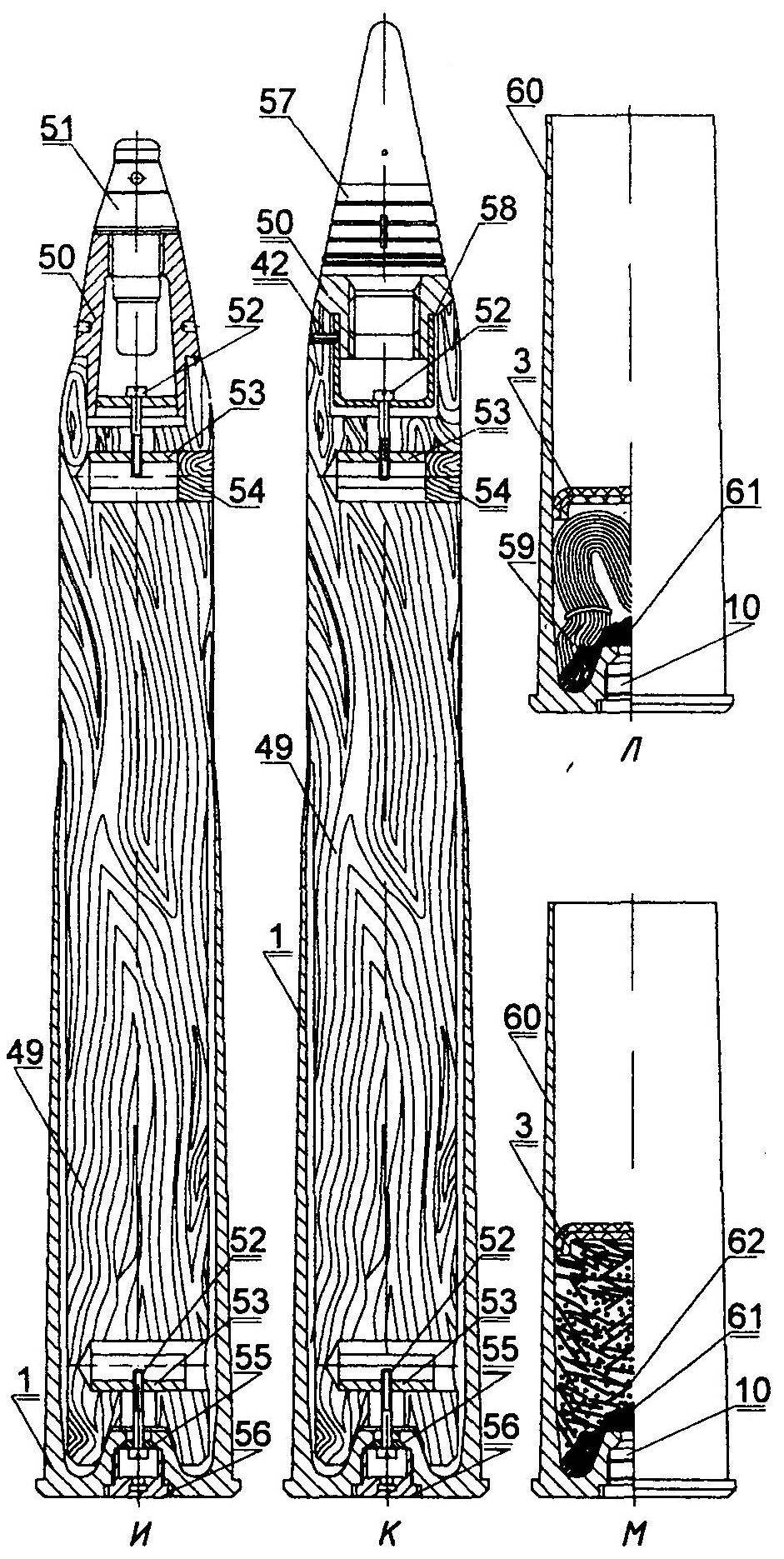

Ammunition for the 76 mm divisional gun mod. 1942 ZIS-3:

A—unitary cartridge UOF-354М, fully charged with high-explosive grenade long-range steel OF-350; B—unitary cartridge UBR-354А with a full charge with armor-piercing tracer BR-350A; — unitary cartridge УШ354Ш with incomplete charge with bullet shrapnel sh-354Т; G is a unitary cartridge UBR-354П with a full charge of subcaliber armor-piercing tracer BR-354П; E — unitary cartridge UD-354 with an incomplete charge-flue steel shell D-350: E unitary cartridge UBP-353М flameless with a full powder charge with a cumulative (brennprogramm) steel shell BP-350M; W is a unitary cartridge UD-354 full charge with an incendiary long-range steel shell 3-350; And — training cartridge with a grenade; — training cartridge with ogoloshennya remote handset T-6; L is a single shot with a charge of gunpowder brand or WMO WMO 17/32 17/16; M — blank shot with a charge of gunpowder brand WTOD; I – liner; 2,24 – powder charge; 3 — cardboard cover; 4 seal; 5 leading a band of red copper; 6 — housing high-explosive grenades; 7,13,31—bursting charges; 8 — fuse КМТ1 (CMTS-1); 9—cylinder of cardboard; 10 —percussion cap sleeve KV4: 11 —body armour-piercing tracer projectile BR-350A: 12 — ballistic tip; 14—the bottom of the fuse MD-8:15 — tracer; 16 – the case of the bullet shrapnel; 17—lead bullet; 18.42 – retaining bolts; 19,28 — preventie head; 20—remote phone dual-action T-6; 21 — Central tube; 22 — lifting charge: 23 — powder charge in the cap; 25 — tray Podolinec armor-piercing projectile; 26 — the core of hard alloy: 27 – housing smoke rounds; 29—fuse KMT-2: 30 — pilot glass; 32—smoke-forming substance; 33 — case cumulative steel shell; 34—fuse BM; 35—construction; 36—copper cladding of the charge; 37—the shaped charge; 38 — detonator cap; 39—cap from calico with black powder (optional flash Hider); 40 paper tube with a powder column (main flame); 41 case steel long-range incendiary projectile; 43 — head bushing; 44—pad; 45 incendiary segment; 46—aperture; 47 — lifting charge; 48—wooden boss; 49—a wooden shell; 50—head; 51 —ogoloshennya fuse KMT-1; 52 — screw; 53 — nut; 54—tube; 55—washer; 56—ogoloshennya capsule sleeve; 57—ogoloshennya remote tube T-6; 58—bracket; 59 — igniter; 60—short sleeve: 61—a charge of gunpowder brand or WMO WMO 17/32 17/16; 62—a charge of gunpowder brand VTOD

Since the plant was daily required to increase production of guns, f-22УСВ, f-34 and ZIS-2, in contrast to the pre-war period, when the plant № 92 issued one (sometimes two) guns type, required drastic measures to execute resolutions of the State Committee of Defense. V. G. Grabin invited the Director of the plant following the decision of this task. In production you must run the ZIS-S, which gradually in gross production will replace the f-22УСВ. Order ahead of time “not to tease geese”, the muzzle brake has decided to do in pilot production. Assembly ZIS-S without the barrel produced simultaneously with the ZIS-2. The first batch of ZIS-S collected in night shift and in the morning presented to the customer, he refused and went to report the senior military representative of the engineer-Colonel I. F. Teleshova, who reported it to the UNIVERSITY. The answer did not come immediately, but the guns began to take.

At the same time the plant performed measures to reduce the complexity of the produced guns. Primarily in the KB decided to simplify the design of the gun by reducing the number of parts and their unification, without reducing their tactical characteristics. To do this, grabinsky each gun had its own gate, and was in production for five. The f-22 to its modernization, it consisted of 116 items, many of them quite complex. The most simple shutter was 57-mm ZIS-2. He was taken as a base when creating a unified shutter, common to all guns. The new shutter had 57 items. Organized production line for its production. The shutter began to make four times faster than before. Before the upgrade, VMS-S and VMS-2 had 2080 parts, and after the upgrade—1306.

In the December 1941 issue of guns has increased in comparison with the prewar five-and-a-half times. The plant has fulfilled its obligations, however, the front demanded more. The company was visited by Voroshilov, who, the whole day was familiar with the process and were pleased with what he saw.

In early 1942 V. G. Grabin was summoned to a meeting of t-bills is scheduled for January 4, was the opportunity to show the ZIS-S to Stalin and to seek adoption of its service. Their plans V. G. Grabin shared with Ustinov and he was allowed to bring a gun to Moscow. GKO meeting was convened at the direction of the military, who claimed that the upgraded guns will fall to pieces during the artillery barrage to be done according to the old drawings.

At the meeting of the GKO Stalin criticized the work of V. G. grabina sharp criticism, accusing him of a design itch, which the country will be left without guns. Depressed Vasily Gavrilovich went to the hotel. Early the next morning he had a telephone conversation with Stalin. The Supreme Commander has approved the work done by a factory team and V. G. Grabina. Taking the opportunity Grabin told Stalin about the ZIS-Z and asked him to look at her.

ZIS-S and f-22УСВ was delivered to the Kremlin. Stalin came for a visit with members of the t-bills and warlords. Stalin ZIS-Z liked it, and it meant that finally she will be able to obtain official registration in the army.

After showing divisional gun ZIS-S in the Kremlin it was the official field testing. Commission on field trials of six people was headed by Panyin, head of Artillery small arms and tactical Committee of the chief of artillery of the red Army.

In the act the results of tests of a new divisional gun was recommended for adoption and noted that it is not inferior to its predecessor—divisional gun f-22УСВ and has compared it with the following advantages:

— lighter by 420 kg;

— has more ground clearance is 360 mm (f-22УСВ—330 mm);

— has a lower height that allows better and faster to disguise it in position;

—placement of the guidance mechanisms on the one hand made it more convenient for anti-tank defense;

—it has fewer parts and are more simple to manufacture;

— the manufacture of one instance of a new gun takes less 420 Stanko-hours, saving 1,400 kg of ferrous and 110 kg of non-ferrous metals.

Among the shortcomings identified by the Commission in conducting field tests of the gun and which should be eliminated by the KB together with the factory to putting it on gross production;

—to eliminate the leak in nikitniki;

—to ensure the length of the rollback 750 + 50 mm;

—to strengthen the bracket of the sight the top of the machine, the side to strengthen the level and mechanism of the transverse swing of the sight.

GKO decree of 12 February 1942 76-mm divisional gun was adopted into service. At factory No. 92 was set the target for the production of 76-mm divisional guns: in March—400 f-22УСВ and 200 ZIS-Z in April—650 ZIS-S in may—700 VMS-C In may, the plant № 92 issued by divisional and tank guns, and 13 times the pre-war level, in December this figure has increased 16 times. In the first half of 1943, production of guns increased and reached 18-fold increase compared to pre-war level. Factory # 92 produced guns more than the whole military industry of Germany.

In a multiple increase in the production of guns no less important role is played by technological service of the plant, which led to a constant search for reserves to increase production. 54 upgraded machine and 50 tombstones to them replaced 164 universal machine that resulted in the release of 2453 m2 production area, transfer to other work 247 work and save 23,9 million rubles. The complexity of the ZIS-S decreased from 1053 to 633 Stanko-hours. The cost of the ZIS-S after the modernization was increased to 15 thousand rubles, while in its predecessors the f-22 and f-22УСВ she were, respectively, 120 and 60 thousand rubles.

Cutting holes in the breech ring under the wedge gate performed on slotting machines work of the highest caliber. Technology proposed to fulfill this hole with a broach. In production line together with put slotting machines broaching machine, made by the factory. Work on it was E. V. Uglova, who had only the third rank. Transferred to control of the first breech was made better and faster than the traditional way. Careful measurements showed that the manufacturing precision of the holes and the purity of his treatment on twang machine is much higher, and labor is spent many times less.

For finishing the barrel channel occupied by traditional technology (boring floating cutters) about 12 hours, first I used a broach on the machine design ENIMS, but it reliably worked hydraulics. The design Department of machine tool industry under the leadership of K. I. Borodkina created screw 100-ton broaching machines, more simple and reliable. Finishing broach began to take only 15 minutes. This unit has been upgraded over 200 machines 66 types and 20 types of new special machines.

On the proposal of the head of the Assembly shop A. Kovalev made a wooden trough, through which rolled the carriages, put on wheels and assembled in the carriage shop. The carriages are installed by crane and connected among themselves the special hitch. The gun on the conveyor belt is moved using a mechanical hoist. At the end of the process chain guns were sent to the factory ground; one gun was rolled into the body, the second towed on the trailer.

The number of fixtures for the manufacture of parts has grown three times in comparison with pre-war. A great contribution to the increase of labor productivity at the plant was made by the Deputy Director for metallurgy Professor Strasilla, specialist shapes and centrifugal casting. At his suggestion the blank of barrel steel to centrifugal casting. Factory metallurgists mastered chill casting muzzle brake. Previously it was made of forgings. Forged version of the part required 30 hours of hard work, and now needed only half-hour of mechanical treatment. The Germans were unable to develop this technology, though tried.

Muzzle brake for guns they forged before the end of the war.

In 1943, production of the ZIS-Z joined the plant number 235 in Votkinsk and plant No. 13 in Ust-Katav, which contributed to increasing productivity cannons, developed under the leadership of V. G. grabina.

During the great Patriotic war it became obvious the need to create self-propelled artillery. In the autumn of 1942 under the leadership of chief designer of the plant N2 38 (Kirov), mn.Shchukin was developed self-propelled artillery SU-76 on the basis of a light tank T-70. The production of this tank was conducted at several companies, including at the Gorky automobile plant. As the main gun on the machine gun was used ZIS-Z. the first SU-76, taken into service, the operation at the front found serious defects in the power unit. In the factory the GAS is significantly modified under the guidance of A. N. When I was under the designation SU-76M launched into mass production.

On the first self-propelled gun ZIS-Z were used without beds and with a new armored cradle and wheel device. In the future, was developed by modification of the ZIS-S for the SU-76M, taking into account the specifics of the placement on the chassis: the upper machine gun was attached to the channel established across the fighting compartment, the maximum elevation angle restricted to 15 degrees, introduced foot descent. In the future, this modification held a significant share in the total production of the ZIS-S, and the SU-76M was the most massive Soviet ACS made during the war. Just released 13 732 SU-76M, of which during the great Patriotic war—11 494. Manufacturing installation is continued until 1946.

On a technical level gun ZIS-S there is documentary evidence of the head of the artillery structures of the firm Krupp—Professor wolf. Comparing this weapon with the German, he wrote; “For the 76-mm cannon model 1942 the ratio of muzzle energy-to-weight guns in firing position is 131. This is a surprisingly high figure. Have the best German 75-mm guns 16 (obviously, we are talking about 7.5 St Cancer. 40. — Approx. ed.) this option is 80,3… the figures show a significant superiority of the Soviet system. It manifests itself in maximum firing range. Gun, the weight of which is 73 percentage by weight 75-mm German guns, sends the projectile at 1000 yards. And the projectile itself, which is 13 percent heavier than German… So the view that it is the best 76 mm gun of the Second world war, it is absolutely justified”.

Unlike many of the guns manufactured during the great Patriotic war, the ZIS-S it did not last: in the newsreel of armed conflicts in Africa or in Afghanistan sometimes and today you can see the gun.

The performance characteristics of the gun ZIS-3

Initial velocity of the projectile, m/s:

OF-350…………………………………………………………………….680

BR-350A……………………………………………………………………662

The largest tabular firing range, km…………13,29

The guns rate of fire, RDS./min:

maximum…………………………………………………………..25

sighting………………………………………………………………15

Transfer time from traveling to combat, with….30 — 40

The greatest angle of elevation, deg……………………………37

The greatest angle of declination, deg………………………………-5

Angle horizontal fire, hail…………………………..54

The height of the line of fire (taking into account precipitation of tyres), mm……………..875

Gun length with flattened frame, mm…………………..6095

Width of the gun with flattened frame, mm……………….1645

The height of a gun on Board, mm…………………………………………1375

Mass of gun in firing position, kg………………………….1200

N. JAY (the Article is prepared on materials of the Royal historical Museum)