To check correct Assembly of the frame it was mounted front and rear wheels, then the frame is inverted and in this position, checked the parallelism of the wheels.

The steps of mokiki represent a steel rod with a diameter of 16 mm, recorded in the dedicated to the grommet with a pair of plug lap joint. Foot pegs stretched rubber covers from mokiki. With right side mounted brake pedal, bent steel rod with a diameter of 10 mm, which is welded to the steel sleeve. On this sleeve is fixed by welding the brake lever consists of two steel plates with a thickness of 2.5 mm, and the sleeve frame is welded a support under budenovskoy sheath of the brake cable.

Fuel tank city bike-suitable from cans of 5 liters. To secure the cans on the seat part of the frame provides the cradles of the steel strip 30×2 mm. cross section At the bottom of the canister standard motor tap with filter-sump. In the tube of the fuel tank drainage hole with a simple flap of thin sheet oil-resistant rubber, prevents leakage of fuel in case of accidental fall of mokiki.

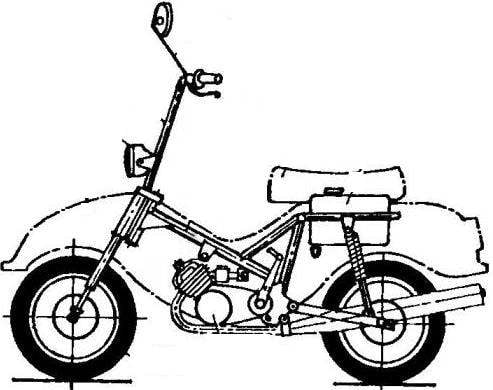

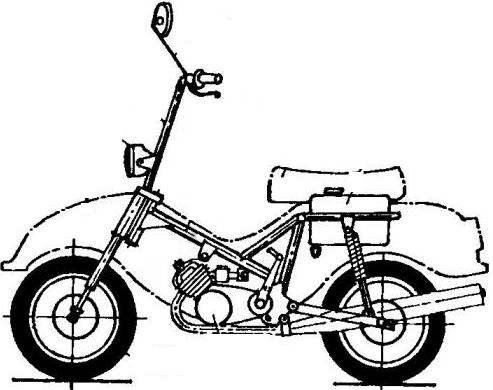

SNT bike with V-twin engine 50.

Frame city bike Assembly with front and rear forks:

1 — front fork (mokiki “Carpathians); 2 — steering column (mokiki “Karpaty”); 3 — solitaire (steel sheet s2,5, 2); 4 — cheek front-mount engine (steel sheet s); 5 — spinal beam (steel pipe 34×34); 6 — part of the frame, seat post (steel pipe 20×2,5); 7 — beam seat post (steel pipe 34×34); 8 — cheek rear hub mounting engine (sheet s); 9 tuning fork a pendulum, back (from mokiki “Carpathians); 10 — cheek bracket left shock absorber (steel sheet s); 11 — absorber left; 12 — bushing mounts foot pegs (steel pipe 22×3); 13 — the case of the hinge of the pendulum fork (steel pipe 22×2); 14 — bushing (Teflon or textolite); 15 — kickstand (steel rod Ø16).

Sizes with an asterisk * are specified during Assembly.

The drive of the brake of a back sprocket:

1 — cover pedal (cut the rubber hose); 2 — pedal brake (steel rod Ø 10); 3 — biscuit brake cable; 4 — the lever of a brake (sheet steel s); 5 — emphasis (sheet s4); 6 — sheath of the brake cable, bozinovska; 7 — bushing, brake pedal (steel pipe 24×4); 8 — footrest (steel rod Ø 16); 9 — case step.

Handlebar city-bike — mini-mokik Riga production, however, is not so difficult to do it on their own from a steel tube with a diameter 22×1,5 mm. fixed in the Headlight is welded to the wheel bracket.

After mounting on suspension city bike seat, engine and exhaust, the car was adjusted and tested on the go.

The latter was made the lightweight fiberglass fairing that gives mokik the right to be called the city bike. The fairing was designed to veclachi of fiberglass on the boob, and it made him not quite the usual form.

The idiot was going from blocks of construction foam. That fairing turned out to be symmetrical, I used the following method of processing boob. First brought only his left side, proshpaklevat it with clay and took the idiot several templates (cardboard). In accordance with these templates processed right side boob. At the end of the work to the clay surface prijateli thin plastic film to ensure the removal of shell from boob after veclachi.

Before Villenoy with fiberglass removed the wax coating, which the fiberglass was soaked in gasoline, but you can anneal — uniformly stretching a strip of fiberglass over the heated hotplate.

As a binder for vyklicky used epoxy resin. To obtain a shell of required thickness needed to impose on the boob five layers of fiberglass.

After polymerization of the resin shell was removed from the boob, putty and visquile, and then covered with soil and autosmart. The finished fairing is secured on the frame city bike at four points: the top bridge of the front fork to the seat post of the frame and the rear mount of the engine with attached to it a threaded bushing.

I. KARAMYSHEV,

engineer

Less and less will see on our roads a nimble scooter. This is not surprising: the main producers and their fates were abroad — in Latvia and Ukraine. So what else from this series is now sold in specialized stores, is cars. Accordingly, the price… To all that volatile MOTOmed gives the consumer a more convenient, more modern cars of the same class — scooters. Miniature scooters with 50-CC engine with automatic transmission and starter, can reach speed up to 80 km/h, providing comfort, who never dreamed of the owner of “Riga” or “Carpathian”.

Less and less will see on our roads a nimble scooter. This is not surprising: the main producers and their fates were abroad — in Latvia and Ukraine. So what else from this series is now sold in specialized stores, is cars. Accordingly, the price… To all that volatile MOTOmed gives the consumer a more convenient, more modern cars of the same class — scooters. Miniature scooters with 50-CC engine with automatic transmission and starter, can reach speed up to 80 km/h, providing comfort, who never dreamed of the owner of “Riga” or “Carpathian”.