The muffler is easy to manufacture, and its installation is preceded by a little modification of the engine. To do this, the motor was disassembled, Carter was enshrined in the mandrel and cylinder head with the exhaust window is machined to a diameter of 29 mm.

The most difficult element of the muffler clamp. It is made from a piece of duralumin brand D16T size 50x40x12 mm.

On the blank marked the center and bored a hole with a diameter of 28.7 mm. (If you do several sets, to handle the clips better package to 5 pieces Machined of the workpiece should be mounted on a special cylindrical mandrel with a diameter of 28.6 mm. of the thin sheet material cut pattern of the outer contour of the clamp, put on a mandrel and use it to mark the top of the workpiece. To treat the external contour preferably on a vertical milling machine, attaching the mandrel with the package blanks in the vise Next to each part should be marked up and milled the exhaust groove 12×6 mm at a 10° angle, drill holes and cut thread M3. After disassembly of the package at the clamps to cut with a hacksaw through the slot in the clamping foot.)

For camera jamming was used in the case of electrolytic condenser of suitable size. The lower part is cut away on a lathe, and the body free from content. Then at the bottom marked and drilled two holes with a diameter of 3.2 mm and needle files cut exhaust window size 12×6 mm.

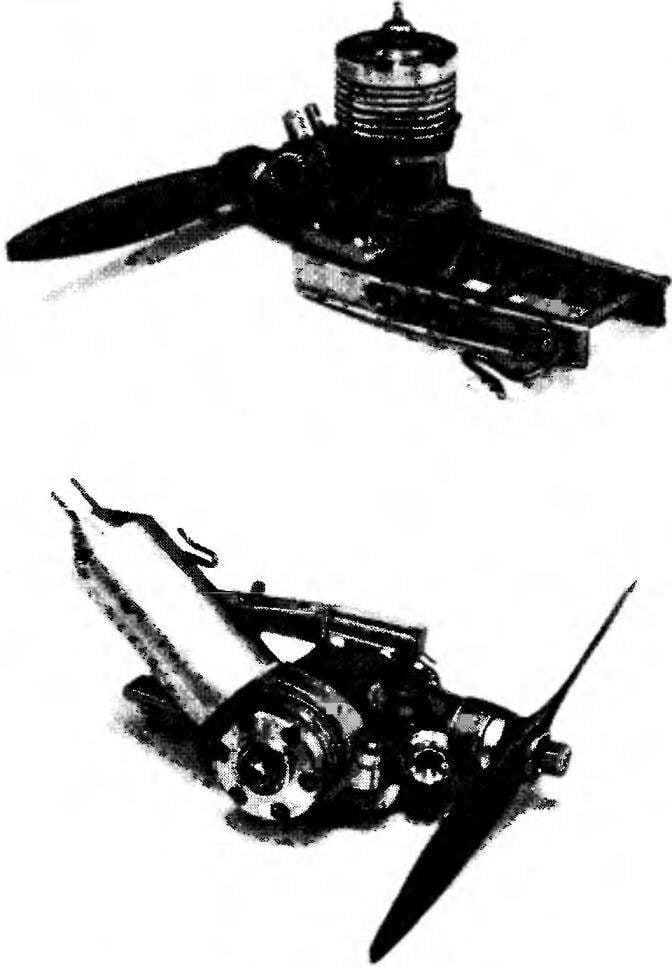

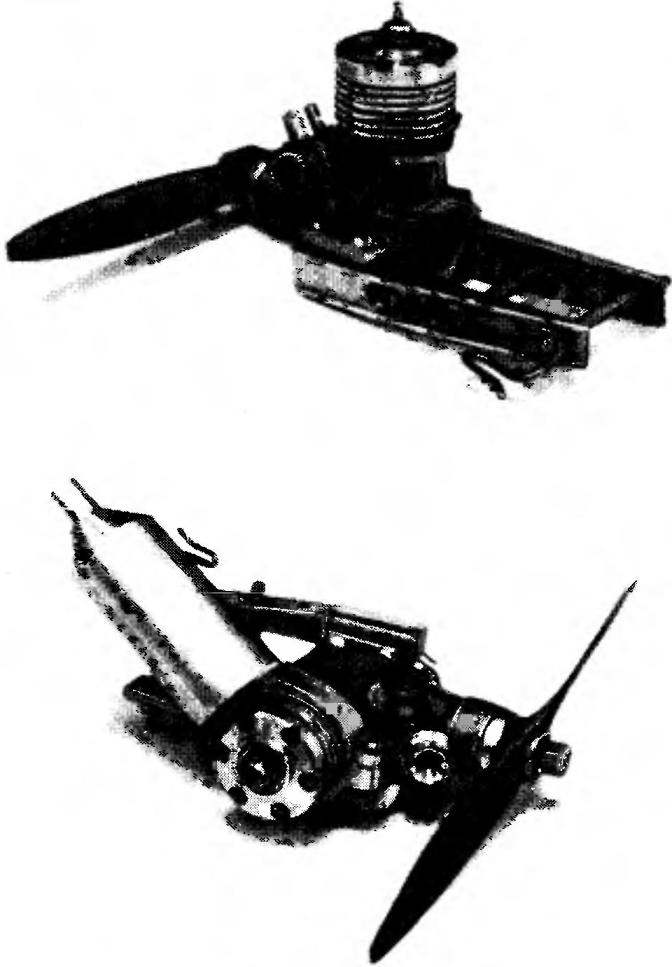

The muffler to the engine CSTOM-2,5:

1 clamp, 2 – jamming, 3 – clip 4 – cover, 5 – screw with washer Grover.

The lid is carved out of D16T with the same setup: first, internal processed, and then the outer surface.

Before Assembly, the mating surfaces were carefully degreased with acetone and then coated with silicone autoerotica. They also lubricated and the screws of the camera to the muffler clamp. For secure camera connection and cover they drilled two holes with a diameter of 1.5 mm, through which is passed and rasklapanje made of copper 1 mm wire.

Muffler installed on the cylinder head with a slightly decompressed at the time of the clamp. And so that exhaust window motor strictly coincide with the exhaust window in the clamp.

Due to the increased mass of the propeller installation, the engine had to be fixed near the leading edge of the wing model. To this end, the forehead, the wing is cut a semicircular recess under the silencer and covered with aluminum foil to prevent burnout plating.

The use of a silencer reduced the effective power of the engine, therefore, to provide speed at the same level, was picked up by a suitable propeller.

N. BAYAZITOV,

athlete-an aeromodeller

Salavat

Recommend to read The intricacies of opening a padlock Today in various spheres of our life are widely used padlocks of different nature. For example, they can be seen on garages, sheds. In addition, they meet and in the case of summer... “ANTENNA” FOR RAVEN, OR HOW TO PROTECT THE ROOF Where a person lives, there's a crow look is not necessary — it is everywhere, including near our garden plots Ravens fly around, sit on a high place, the roof and, looking out edible,...  The new rules of competition in the class of models of “air combat” prohibit the use of glow engines without mufflers. Offers its readers the most successful I have developed silencers for the engine CSTOM is 2.5. It consists of a clamp, camera jamming, staples, lid and M3 screws with spring washers.

The new rules of competition in the class of models of “air combat” prohibit the use of glow engines without mufflers. Offers its readers the most successful I have developed silencers for the engine CSTOM is 2.5. It consists of a clamp, camera jamming, staples, lid and M3 screws with spring washers.