In winter, diesel fuel causes considerable trouble for farmers, as well as other owners of automotive and tractor equipment. At low temperatures, it becomes thick, and the paraffin contained in it crystallizes. This threatens rapid filter clogging and cessation of fuel supply from the tank. As a result, starting diesel engines and operating machines sometimes turns into a tormenting problem, which they try to solve by using widely advertised expensive additives, which unfortunately often turn out to be ineffective.

Some of the trusting and hasty turn to “recipes from experienced ones,” but… Using “saving” gasoline and kerosene as additives reduces engine service life, and external torch heating of the fuel system is prohibited by safety regulations.

More cautious ones decide to heat the fuel itself (to the temperature at which paraffin crystals disappear) using special technical systems, in which the main source of heat is, as a rule, electric heaters of constant power. However, typical electric heaters in pre-start mode noticeably “drain” batteries and also have unreliable, expensive control and protection devices that require special maintenance.

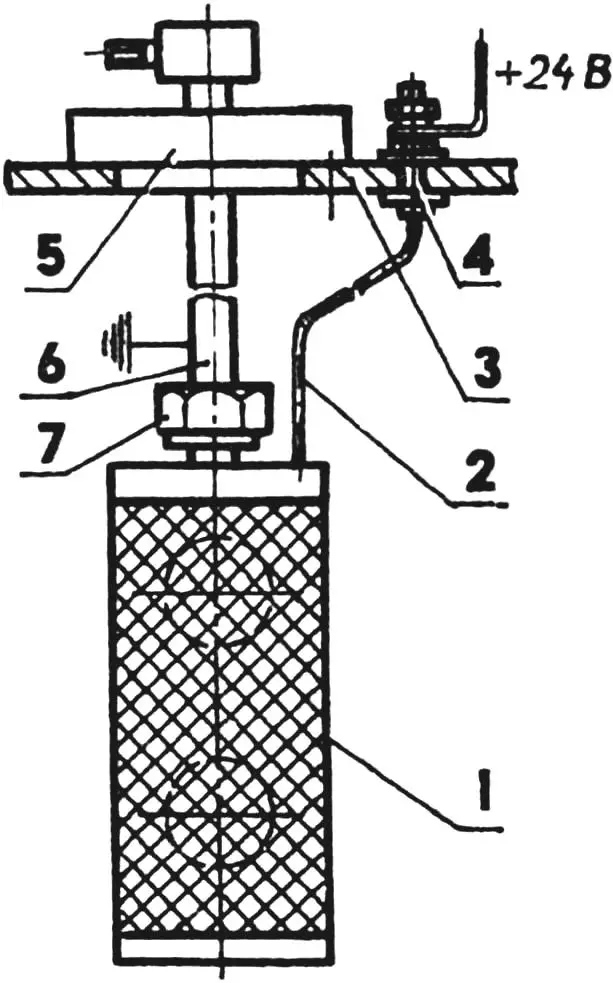

1 — heater; 2 — gasket; 3 — screw; 4 — filter cover; 5,6 — sealing gaskets; 7 — filter housing; 8 — wires

The listed disadvantages are absent in modern and compact (placed directly in tanks and filters of automobile and tractor engines) PTC diesel fuel heaters — PPDT, created on the basis of semiconductor thermistors with a positive temperature coefficient of resistance (about PTC thermistors see “Modelist-Konstruktor” No. 11, 1999).

Similar heaters were previously used only in special equipment (primarily space). Having no moving parts and complex control systems, these devices have a unique self-regulating property and provide fuel heating to the required temperature within a few minutes. Their continuous operation life is more than 10,000 hours.

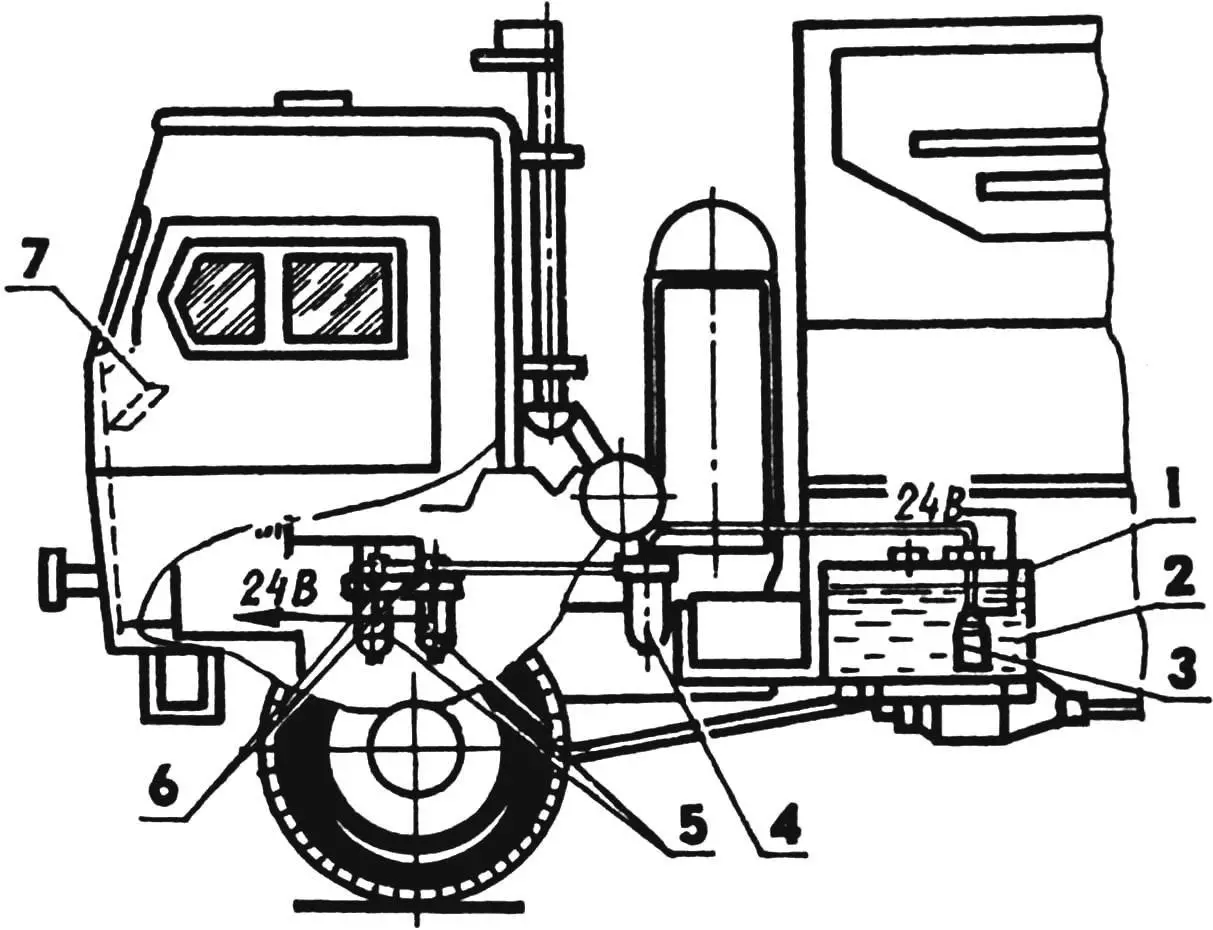

1 — fuel tank; 2 — diesel fuel; 3 — heater in tank; 4 — coarse filter; 5 — fine filters; 6 — heaters in fine filters; 7 — button and indicator on instrument panel

The high efficiency of PPDT is evidenced by the fact that their power consumption (when installed in fine and coarse filters, as well as in the fuel tank of the “Bychok” vehicle) does not exceed 300 W at 12 V. This is quite acceptable for vehicle operation with normally charged batteries. Moreover, the time spent on heating fuel using PPDT does not exceed five minutes.

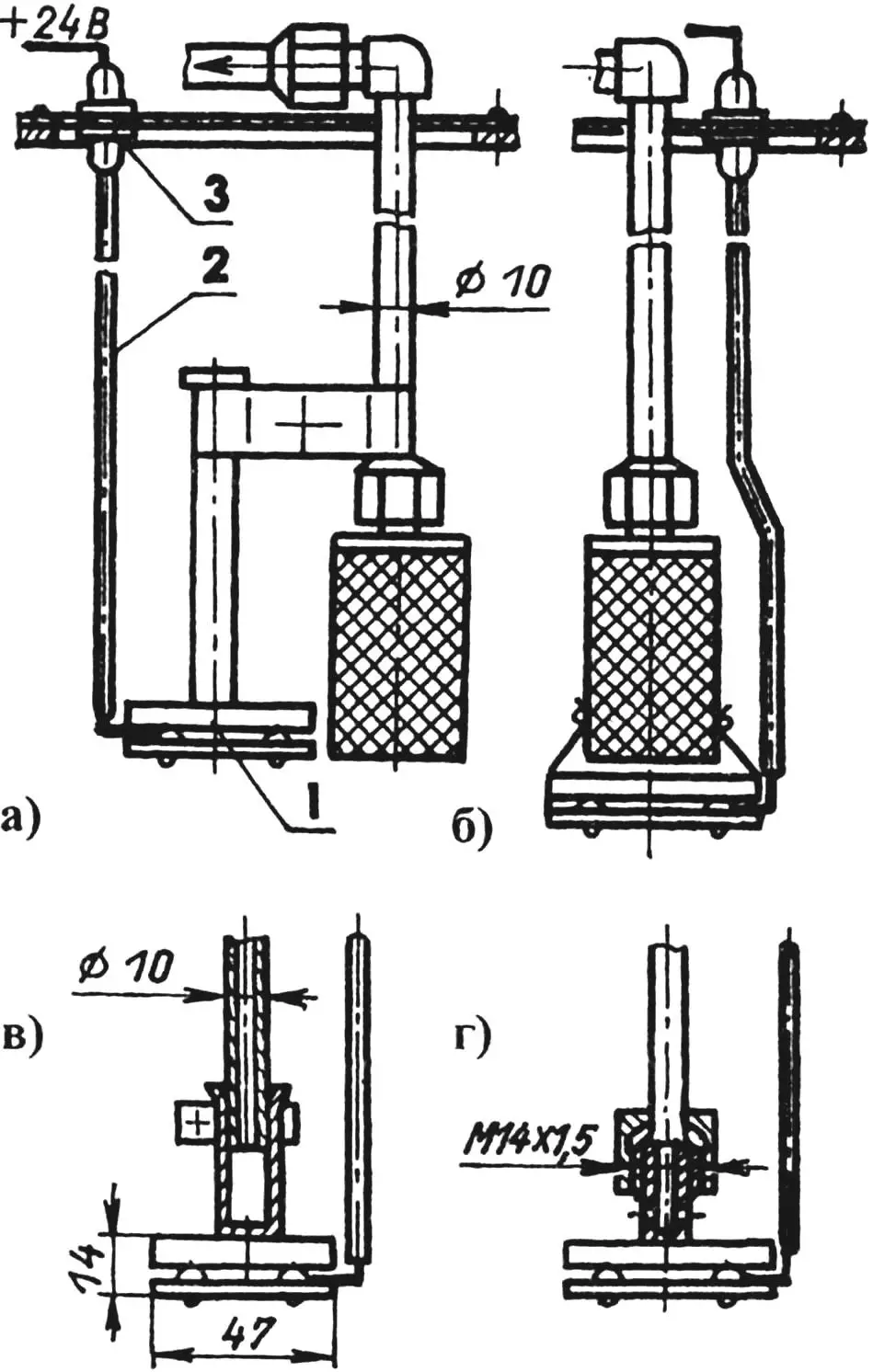

Any electrician-mechanic servicing automotive and tractor equipment can install a domestic PPDT without special training. Especially — in the fuel filter (Fig. 1), which is greatly facilitated by the heater design itself, in whose metal housing semiconductor heating elements are successfully built-in, connected to the vehicle’s electrical system through a starter relay. When installing such a PPDT, sealing gaskets are used between the filter cover and housing, followed by tightening with an elongated screw (included in the delivery set), supplied with a special gasket.

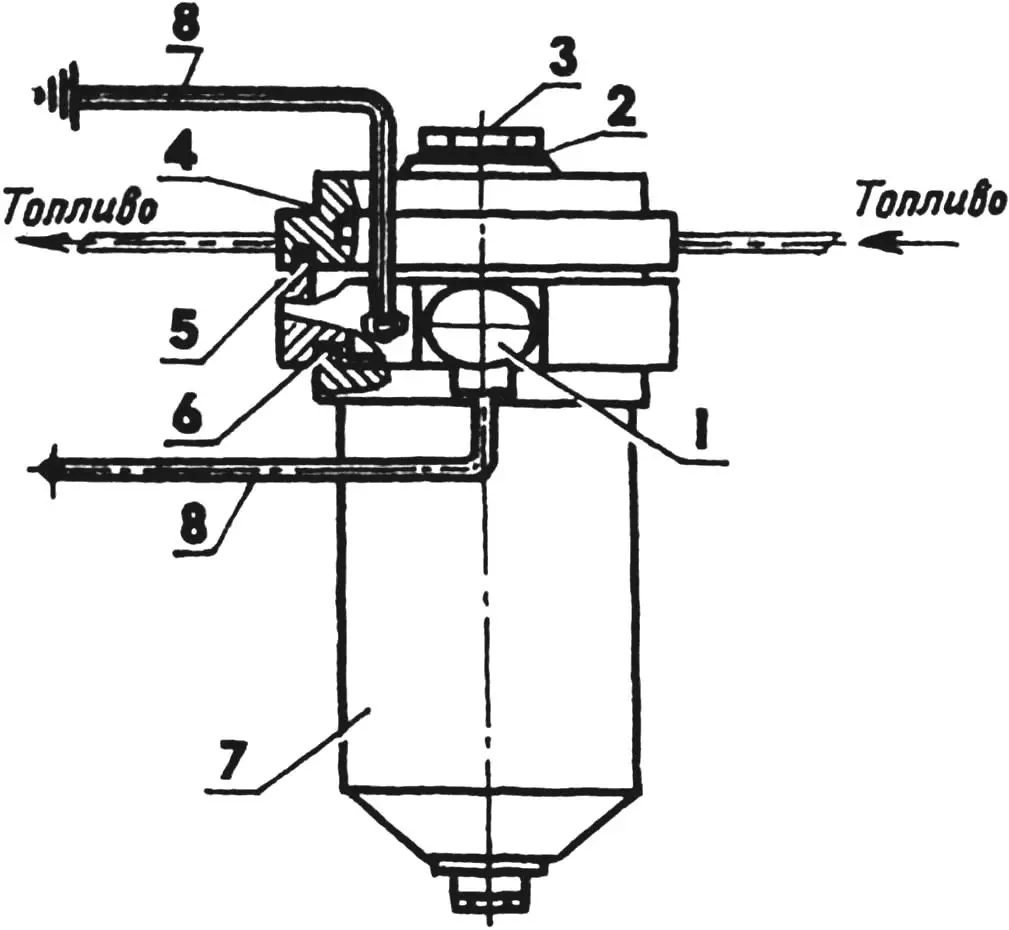

1 — heater; 2 — wire; 3 — tank wall; 4 — insulator; 5 — flange; 6 — suction pipe; 7 — nut

Equally simple is the typical installation of PPDT in the fuel tank of a vehicle or tractor (Fig. 2), where the heater is an aluminum cylinder (mesh), into which from one to six elements are built-in, depending on the tank capacity and fuel consumption.

In such a vehicle as KamAZ, it is recommended to place several PTC heaters (Fig. 3). And the algorithm for their use then comes down to an easily memorable sequence of simple actions.

Before starting the diesel engine, the fuel heaters in the tank are turned on, and in continuous operation mode.

Overheating is practically excluded thanks to the unique property of the PTC heater — the ability to self-regulate. Its semiconductor elements gradually “lock up,” thereby reducing current consumption to zero. PPDT in the fine filter is also turned on for 2—3 minutes or for continuous use.

a — next to filter; b — on filter end; c — on suction pipe; d — on pipe with union nut;

1 — heater; 2 — wire; 3 — insulator

The diesel is allowed to run at idle at increased crankshaft speed. After the engine reaches normal operation, the heaters themselves gradually stop heating the fuel, or they can be turned off.

Well, if a situation suddenly arises when engine power begins to drop due to fuel paraffinization, the heaters should be immediately turned on again from the vehicle cab until normal diesel operation is restored.

Install PTC diesel fuel heaters on your automotive and tractor equipment! The costs will pay off.

V. ISAKOV, V. TOCHILIN