When I bought a used passenger

vehicle and started it, my first mate at the garage has become… the lift that I built the ceiling. Without him I would hardly be able to, for example, such difficult alone operation as engine replacement.

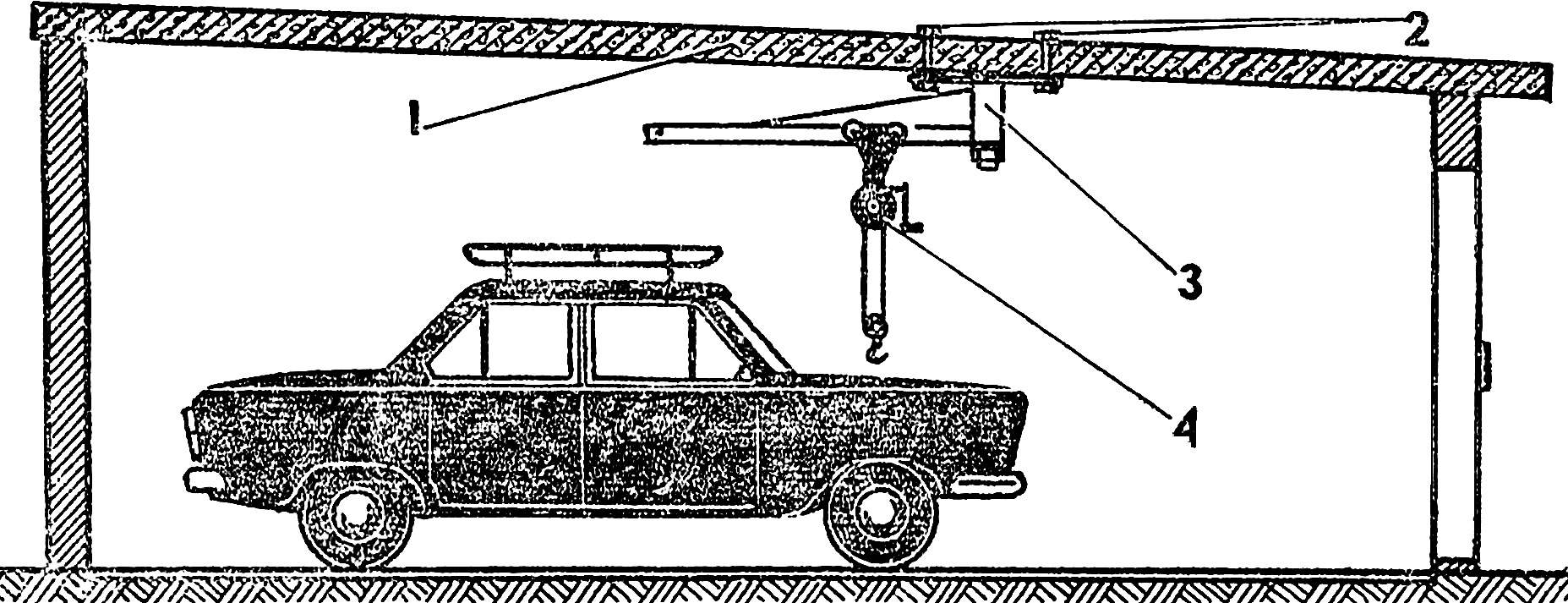

In figure 1 shows the location of the lift in the garage — just above the hood of the car. With a boom length of a little more than a meter, my tap has a working area of approx 5m2 . This is enough for maintenance or repair of the vehicle to remove and return in place of heavy components and assemblies.

Fig. 1. The lift in the garage:

1 — floor, 2 — bolts M16 (4x), 3 — boom, 4 — cargo winch.

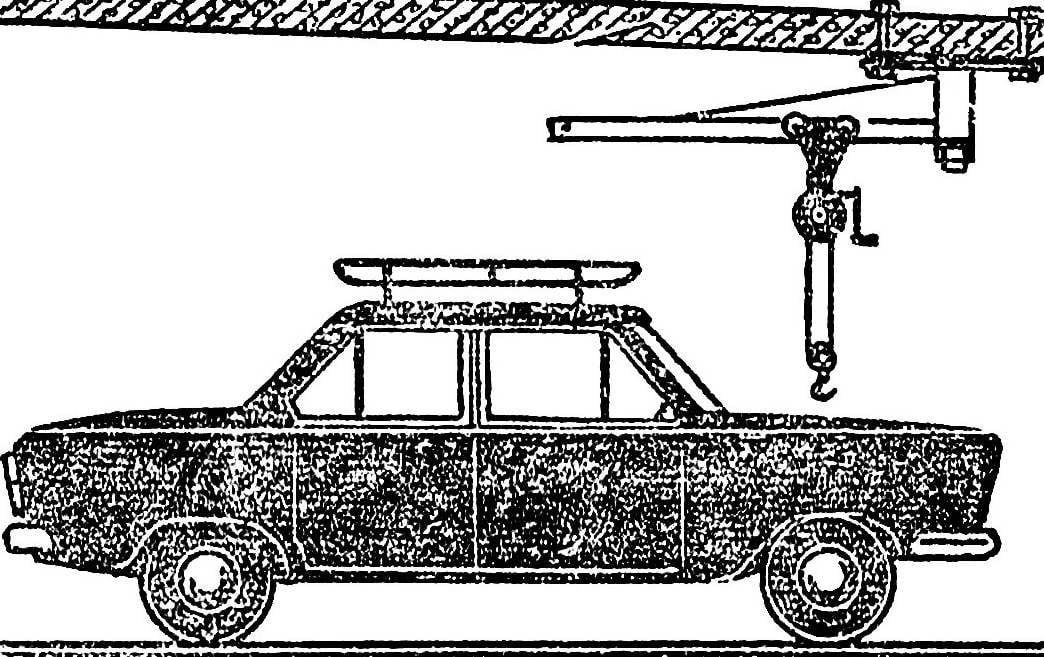

The tap I made on the scheme the inverted strut (Fig. 2): the vertical shaft of the planted l-shaped arrow-console with a cargo winch.

Fig. 2. Crane design:

1 — shaft, 2 — sliding nut, 3 — pin, 4 — puck, 5 — Cup, 6 — bearings, 7 — base, 8 — strut, 9 — corners 50X50 mm, 10 — spacer, 11 — thrust bearing, 12 — bolt-limiter.

The shaft is machined from steel billets Ø 80 mm, wail it into the base steel sheet size 400X400X25 mm and attached to the ceiling by four through bolts M16. The slab in my garage is tilted to the entrance, so that the base is horizontal, I’m a long bolt put a few washers.

Boom welded from strut metre length of two corners of the 50X50 mm and glass. The last pressed two bronze bushings that serve as bearings. On the shaft the whole structure is held spontannoi shaped nut M42X2,0.

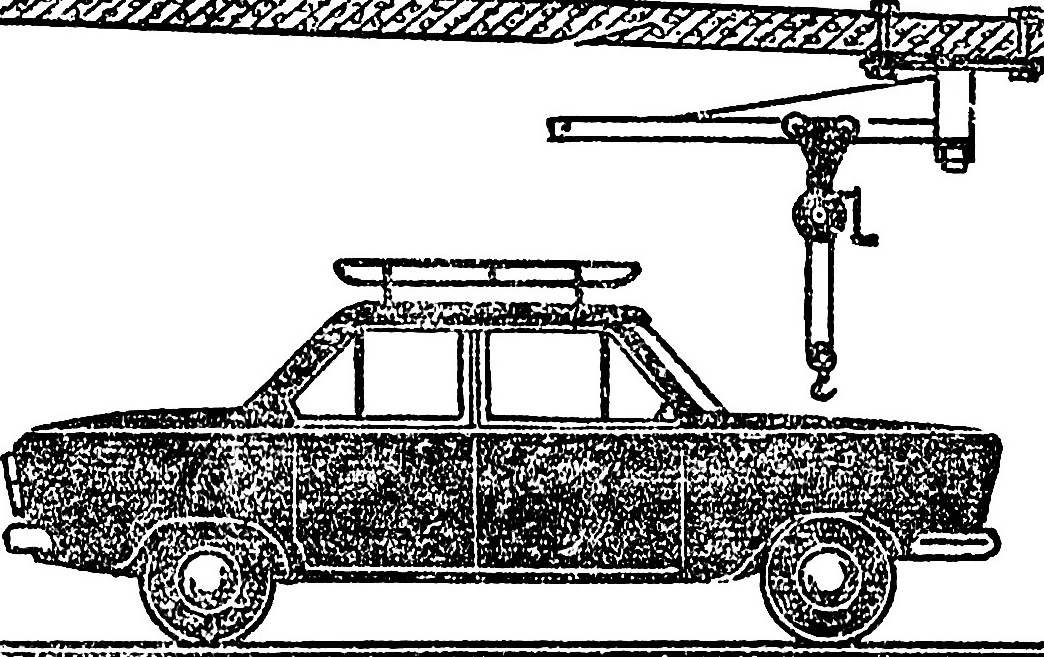

As a cargo hoist could use a manual chain hoist or chain block factory-produced. However, I made myself the winch itself (Fig. 3) with a mechanism designed to adjust the air brake trucks (with ratchet).

Fig. 3. Truck winch truck:

1 — wheel (4 PCs), 2 — cheek carts, 3 — roller, 4 — bearing No. 204, 5 — retaining ring 6 bolts M12, 7 — arm actuator, 8 — winch, 9 — pulley with load hook, 10 — flange.

The Central hole of the worm wheel wasted under cable drum — cut tubes with a diameter of 42 and a length of 150 mm; waril the pipe. Then put the flange ring Ø 80 and a thickness of 5 mm. Attached the drive arm to the shaft of the ratchet.

In both halves of the drum, drilled holes, which brought the ends of the steel cable Ø 4 mm, hung on a single pulley with a load hook. If you rotate the handle, the drum pulls the cable and lifts the hook of the load to the desired height.

Thus obtained the winch I provided a four-wheel truck. It consists of two curved cheeks with cushions which are covered bearings No. 204 is pressed onto them wheels. Last on the rollers hold the spring retaining rings.

The trolley runs on the horizontal shelves corners, and jump-out it prevents the bolt stop from the bearing bushings, mounted on the end of the boom.

A. LAZAREV, Zhigulevsk Kuibyshev region.

Recommend to read HOUSE FOR RABBITS Many interesting developments have been conducted of the Komsomol all-Union competition of means of mechanization for agriculture. Under section livestock unanimous approval of the jury... “CHUK AND GEK” — SNOWMOBILE On the shelves of sports stores you can often see elegant double sledge for skiing the mountains, called "Chuk and GEK". The sleds solidly constructed, brightly colored, very attractive...  When I bought a used passenger vehicle and started it, my first mate at the garage has become… the lift that I built the ceiling. Without him I would hardly be able to, for example, such difficult alone operation as engine replacement.

When I bought a used passenger vehicle and started it, my first mate at the garage has become… the lift that I built the ceiling. Without him I would hardly be able to, for example, such difficult alone operation as engine replacement.