Then the first unit to set the cross-bars of the frames, bow and stern boss, carved from basswood. While the nasal boss filing first rough draft (with an allowance), is glued in place and only then is processed completely. The stern boss is immediately executed at the nominal dimensions.

The Board cut from the plywood thickness 1,5…2 mm according to the prepared pattern. In the drawing it is seen that in the nose of the model deck forms a small rise, and therefore when fitting and gluing the sides of the frame will have to be removed from the slipway. Particular attention should be paid to the symmetry of the body. Side to form the bottom bilge “pockets”, which after Assembly are filled with putty. Formed a kind of bilge keels, which positively affect the seaworthiness of the model.

In the forward underwater part of the hull glued formatada additional overlay of the 1.2 mm plywood. Shpaklyuyut joints and vyskazyvat flush with the contours of the bottom. Putty is recommended to apply a homemade —based on epoxy resin with addition of talc or melktert sifted chalk.

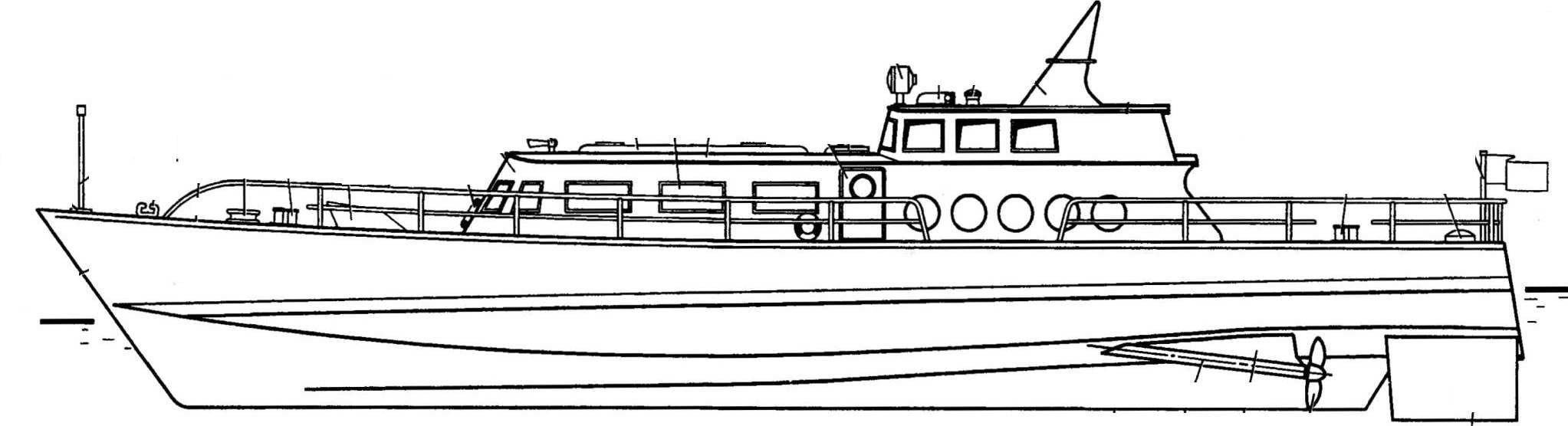

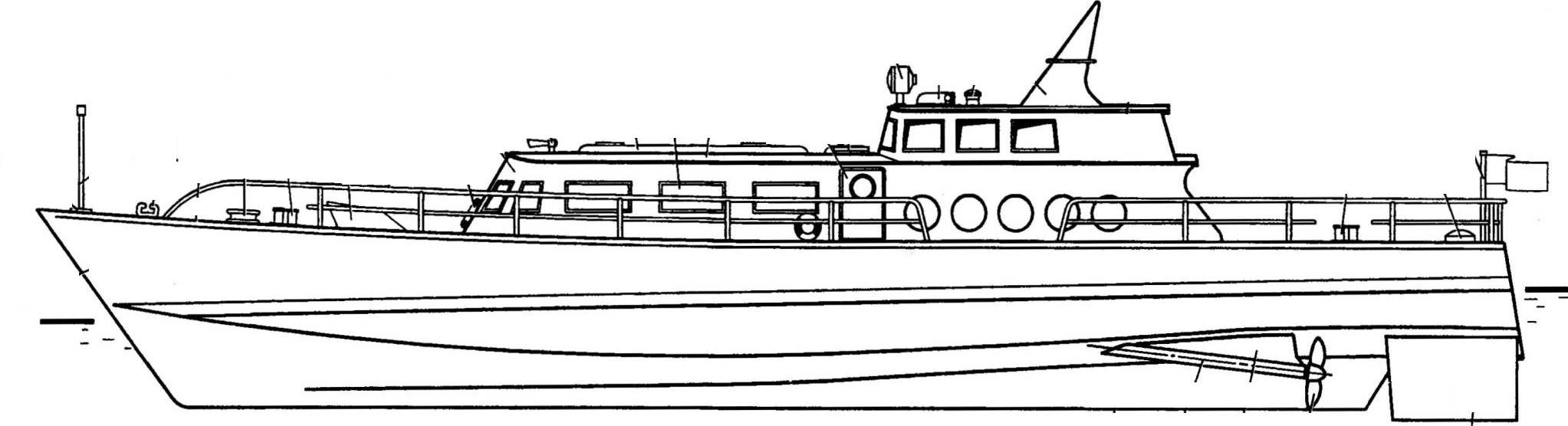

Model motor yacht:

1 — housing, 2 — bearing nasal flagpole, 3 — flagpole nasal, 4 — way Fairlead anchor chain, 5 — deck, 6 — spire anchors, 7 — bollards nasal, 8 — balneoclinic, 9 — rail with fence, 10 — lifebuoys, 11—add, 12— MegaFon ship, 13 — cover of the ventilation shaft, 14 — window 15 — roof superstructure, 16 — the door 17 — Luke 18 — spotlight 19 — fire side, 20 — the siren’s ship, 21 — antenna, 22 — cutting chassis, a 23 — bitts aft, 24 — plug 25 — Flagstaff aft, 26 — wheel, 27 — screw propeller, 28 — solitaire of deadwood, a 29 — deadwood, 30 — Kiel, 31 — stringer deck (pine, raked 8×8), 32 — bilge stringer (pine, raked 8×8), 33 — synchronizer speed of main engines (steel spring).

Form factor:

1 — flagpole socket (tube copper 03), 2 — boss bow (Linden), 3 — a transverse timber (pine, rail 13×5) 4 — lifting on-Board, 5 — beam bow bulkhead (pine, rail 7×4), 6 — transverse timber (pine, rail 7×4), 7 — edging of the deck cutout (pine, rack 10×5), 8 — keel (plywood E5), 9 — electric motor (2 PCs), 10 — a pillar of deadwood (plywood s5), 11 is a transverse timber (pine, rack 10×5), 12 — boss forage (lime, 2), 13 — deck below deck (plywood s 1,2), 14 — stern flagpole socket (tube copper 03), 15 — timber transom (Linden, rake 10×10), 16 —pad bottoms bow (plywood s1,2), 17, 18, 19, 20 — frames 21 — transom, 22 — frame bow.

Add-on:

1 — cross beams, 2 — beam longitudinal, 3 — bars side.

These parts are made of pine slats with a cross section of 5×5 mm. Sheathing (side walls and roof) is made of plywood thickness of 1.2 mm.

Patterns frames.

The numbers of patterns correspond to the positions of pattern “Design corps”.

The whole inner part of the body is covered with three layers of two-component parquet lacquer. Aft of the floor are laid out and drilled two through holes for a copper or brass tube with a diameter of 6 mm and the rudder stocks the diameter of 4 mm. the handlebars Themselves are cut from plywood plates having a thickness of 1.2 mm. Between the plates is clamped baller, and edges of the rudders are glued with each other. The internal cavity is filled with epoxy resin. Cross-section steering turns lenticular and symmetrical. At the free end of the steering shaft threaded M4 under the fixing nut. The surface of the rudder varnished.

The power plant is going on the basis of two DC motors of the type “Mabuchi-380” from the opposite, given the manufacturer’s direction of rotation (necessary for compensation of reactive torque at their work). Power supply are silver-zinc (STSs series) or Nickel-cadmium batteries operating voltage 6…8, and with a total capacity not lower than 4.5 to 5 A-h. Dadude proprietary or self-made. Propellers with a diameter of 45 mm plastic, industrial fabrication, counter rotating. The shafts of the engines from collectors are connected by steel spring (used for seals), which serves as a synchronizer speed. The motors are attached to motor frame with clamps made of tin or soft sheet aluminum.

Oral Davudov should be filled with a syringe with grease “Litol” or “Tsiatim” (you should also lubricate the shafts of the rudders). In the aft underbody dadude brought outside and fixed the gusset of plywood thickness of 5 mm. from Inside the enclosure to the exit of each deadwood enhanced by strips of fiberglass cloth soaked in epoxy glue.

The deck is executed from selected slats section 8×3 mm. Bonding is performed on a sheet of paper or a plastic film. The resulting workpiece from both sides of the treated skin. The aft bottom is glued a plate made of plywood with a thickness of 1.2 mm. Then the deck overlaps the hull is laid out and cut with a small allowance. Next, cut hatch for access to the internal components of the yacht, which is enclosed on the perimeter of the pine laths or strips of plywood to prevent the ingress of water into the housing. The finished deck is glued to the frame. After curing of the adhesive the seam allowance is removed by emery cloth. Above nuts for fixing the rudders are drilled two holes with a diameter of 12 mm socket, which are easily removable plugs from basswood. The entire surface of the deck is neatly covered with four layers parquet lacquer sanding each layer with fine sandpaper.

The superstructure is manufactured from 1.2 mm plywood. The walls and roof are joined with pine slats cross-section of 5×5 mm. Windows and the Windows inside are Packed in a transparent film with a thickness of 0,3…0,5 mm. Superstructure and wheelhouse inside and out three times varnished.

Detailing of superstructure and deck is made of various materials. Antenna on the cabin sawed out of plywood with a thickness of 2 mm; case side lights (left and right) and balneoclinic — of the 1.2-mm plywood; the life preserver is made of polystyrene with a thickness of 5 mm. the Flagpoles are made of pieces of brass or steel wire with a diameter of 2 mm. Bollards, capstan, anchors, fairleads, spotlight, siren marine are machined from chunks of polystyrene or beech. Guardrail and handrail are made of copper tube with a diameter of 3 mm, and additional crossbar of copper wire with a diameter of 2 mm. connection Method — soldering solder GYUS-40.

Before painting yachts the sides and bottom primed three or four times a nitrocellulose lacquer and processed small skin dry. The color is nitro or synthetic enamels in 4…6 layers with intermediate drying. The last layer is finishing and should remain glossy. In nitroemali useful to add 30…35% parquet lacquer for producing a high gloss, and increase water resistance. All small parts are painted separately and mounted in place.

Layout colors: white — Board above the waterline, superstructure and wheelhouse, antenna, half life buoys, searchlight, fencing; green — the bottom and sides below the waterline, starboard light; red — water line, the part of the rescue circles, left side light, end the perimeter of the deck; black — fairleads, bollards, capstan, balneoclinic.

Before you launch the model you need to install the power switch of the motors. His lever during test runs tied the cord or fishing line with a length of 70. ..85 m. After passing the allotted distance with a jerk of the cord the engine stops and the model pulled up to the shore. Debug move — only on calm deep water. In shallow water is strongly affected by near-bottom turbulence, and flows.

Adjusting the straightness of the course is carried out by changing the position of the rudders. At the competition the skill of the Modeler is the ability to consider the impact of wind and waves when calculating the trajectory of a race. In any situation, the position of the rudders on the well-established models it is better not to correct, and all amendments targeting related to the weather and the wave, carried out by lead — pull the bow to the appropriate angle away from the middle of the finish “gate”.

In the proposed model it is possible to establish two-way radio system to control the rudders and engine speed. Motor yacht with great success will follow curly course. Happy sailing and fair seas!

V. ANTIPOV,

group leader,

Moscow

Recommend to read SHELVES FOR BOTTLES… In this mounted mesh shelf is very convenient to keep stock of a wide variety of drinks in bottled packaging—from soda and wine to yoghurt. They are visible at all times, easily... THE TRACK ON THE TABLE… Performance with external power supply grade E-2 is very popular with beginners — they are not too complicated for their production does not require scarce batteries, electric motors and...  Input class EX many other differ a good combination of simplicity of their manufacture and striking appearance. Impressive dimensions and the technical equipment of these models generally provide a decent level of sports and enhanced entertainment, attracting many fans.

Input class EX many other differ a good combination of simplicity of their manufacture and striking appearance. Impressive dimensions and the technical equipment of these models generally provide a decent level of sports and enhanced entertainment, attracting many fans.