Work on making notebookservice start with the selection of bearings. It is from their geometrical parameters will depend on the size of the bearings, shafts, and rollers. Of the most common best suitable bearings 205, although Epolene permissible and others.

Housing bearing units carved from sections of steel pipe 58×4 mm. In essence, you ottercat these segments on a lathe to make a groove under the bearing races and penetrate the annular grooves under the retaining washers.

The shafts of the rollers from the pipe 20×3 mm in the bearing housing, then install them using transition bushings, fixed on the shaft plug lap joint (so-called connecting elements are received by welding, when one of the mating parts, drill a hole, and then, when mounting parts, make; filling the hole with metal and bears the name of elektroskripka).

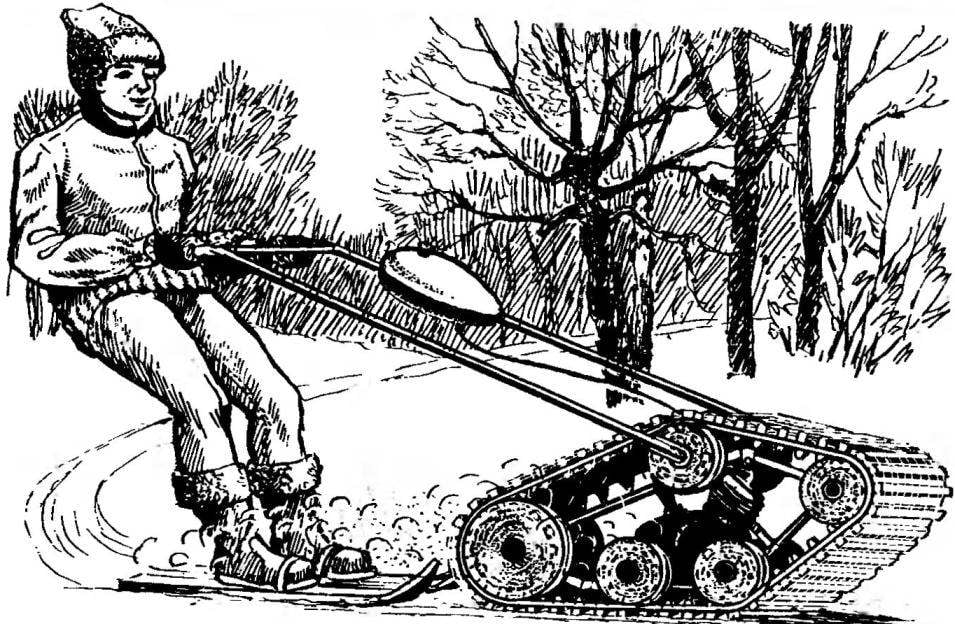

Crawler notebookservice “Seal”:

1 — arm control notebookservice; 2 — leading ice rink; 3 — tape tracked; 4 – fuel tank; 5 — pole; 6, 12 — support rollers; 7 — skating rink suspended; 8 — engine V-50; 9 — frame; 10 rink front; 11 — exhaust pipe; 13 — circuit of the drive leading rollers; 14 — sprocket drive shaft.

Frame notebookservice.

The design of the bearing arrangement:

1 — split lock washer; 2 — bearing; 3 — elektroskripka; 4 — housing unit; 5 — Bush transition.

To build the frame of notebookservice suggest to use the simplest slipway-Plaza — smooth wood-stove, on which is drawn a side view of the frame.

First thing in the centers of location of rollers with long studs fasten the bearing housing. At the same time try to ensure the parallelism of their axes. Otherwise it will be difficult to achieve the normal operation of caterpillar tracks.

Next, choose a suitable tube, preferably of square section as to bend these simpler — you just have to cut out a wedge with a hacksaw, bend in accordance with the image at the Plaza and make the resulting joint.

This way, prepare two tubes of the frame — top and bottom, then using a soft steel wire wire with bearing blocks. To this end, the tubes in the area of the front and rear bearing units drill holes, through which pass the wire covering with the loops of the bearing assemblies. Then with the help of the ratchet the wire tight twist so as to form a sort of “Telegraph” of the band (the so-called connection wooden Telegraph pole with base-PA-son). To the rest of the bearing assemblies (except the top) of the pipe frame also attach the wire twists

After a thorough inspection of the parallelism of the bearing housings tack weld them to the frame by welding, then remove the wire and again check the frame, if necessary podejmuje her. In the end joints of the frame with the bottom bearing units strengthen scarves from a steel sheet with a thickness of 2 — 2,5 mm.

Brackets engine mounts will break first out of cardboard and practise shape and size. When the contours are determined finally according to the obtained patterns cut out of steel sheet 3 mm thick the actual brackets, drill holes in them with a diameter of 8 mm. the Brackets bolt on the engine, then the engine using the pull wire to the frame in accordance with the image on the drawing or on the Plaza. Then tack weld the brackets, check the accuracy of their location and finally weld to the frame.

The engine has no special muffler — it is the function of the lower part of the frame. This exhaust window motor by means of a branch pipe connect with the cavity of the square tubes of the frame. For exhaust in the last drill the bottom holes of 5 mm diameter (holes will need not less than fifty, otherwise, the engine will not develop the nameplate capacity).

Now, about the manufacture of rollers. They are all leading, supporting and tensioning the same design. Each consists of a Central sleeve, welded of the two steel disks and a section of a pipe, two aluminum disks and twelve (large rollers) or eight (for small) ties. The latter are steel studs with impaled on each segments of rubber hose, studs are mounted on the wheels nuts. This design of the rink is quite simple and is able to set in motion a caterpillar notebookservice.

As can be seen from the drawings, the upper pair of rollers can move along the frame, thereby to regulate the tension of the belt.

The leading rollers are fixed on the shaft cone pins, the holes for which are drilled in the Central sleeves mounted on the drive shaft prior to final Assembly of rollers.

Leading (A) and slave (B) rollers of notebookservice:

1 — drive roller (made of anodized aluminum z); 2 — VIN M5; 3 — nut M8; 4 — rubber bushing; 5 — stud M8; 6 — Bush Central; 7 — disk Central hub (steel s); 8 — washer.

Caterpillar:

1 — grouser (birch rack 30×30); 2 — feed crawler (belt WB); 3 — comb (steel s2,5); 4 — M6 bolt.

Joining tracks:

1, 6— palapeli (steel s1); 2— bushing (aluminum, pipe 6×1); 3 — tape tracked; 4 — rivet (aluminum Ø4); 5 — axis hinges (steel Ø6).

Mover “Seal” consists of two rubber strips cut from an old conveyor belt and combined into a single track of wooden rails — cleats. In ring bands joined with a knot, reminiscent of the piano loop. When assembling the tracks is strictly aged the distance between the rails-dirt-claws — it should be a 57,5 mm. Each rake-grouser rubber attached to the ribbon by a pair of bolts and nuts, with the outer side of the tape located in the rake and with the internal — toothed comb carved from a steel strip of thickness 2.5 mm. the Ridges allow the leading rollers “rewind” the crawler belt, thereby causing it to move.

Notebookservice is controlled by the drawbar, on which are mounted the motor arm type; on the right is rotatably mounted on the grip throttle, on the left — drive clutch mechanism and the switch gear box from a “heavy” bike.

Engine notebookservice will have little to alter a regular starter. Pedal kick starter remove and shaft vprasajte pin. Run the engine with a handle, resembling a car. On the shaft of the starting device put on the ratchet handle sharply and rotate a quarter turn.

I. MNEVNIKI

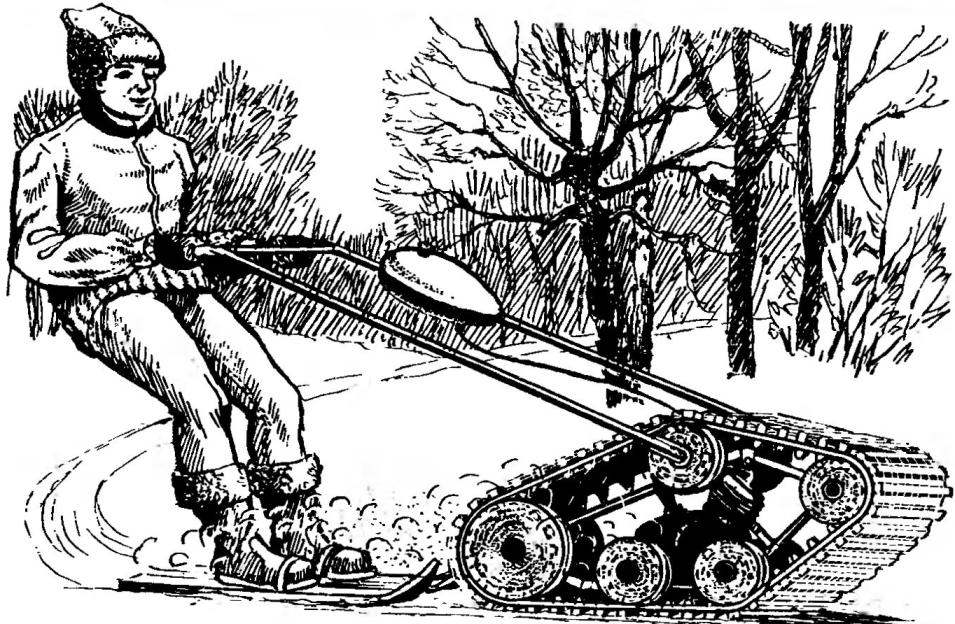

Recommend to read “THE FLASH” WILL SERVE AS Do not rush just to throw move zip. She will have some time to serve, if only the rear part of the carriage gently squeeze the pliers. A. DREMUK, Voronezh Plowing… with a shovel I made this soil-working tool to lighten the hard work, since digging the ground with an ordinary shovel—constantly bending and straightening—had become harder and harder over the years....  Many of you probably heard about the interesting winter sport — skijoring in which competing skiers towed by a motorcycle. In the Nordic countries is cultivated in this sport — towage of the skier by a horse. The vehicle, which we would like to introduce you to, will allow you to fully experience the charm of a high-speed slide on the slopes without resorting to using horses and not burdening a fellow motorcyclist (who wants to travel in the winter on an open two-wheeled car!).

Many of you probably heard about the interesting winter sport — skijoring in which competing skiers towed by a motorcycle. In the Nordic countries is cultivated in this sport — towage of the skier by a horse. The vehicle, which we would like to introduce you to, will allow you to fully experience the charm of a high-speed slide on the slopes without resorting to using horses and not burdening a fellow motorcyclist (who wants to travel in the winter on an open two-wheeled car!).