Winter has arrived, and the flow of motor vehicles on the highways of our country has noticeably thinned. The fleet of cars and motorcycles belonging to individual owners is almost completely put away for the winter. There are many reasons for this, but one of the main ones is the mismatch between automotive “footwear” — tires — and driving in winter conditions. Snow drifts and thaws, ice ridges and black ice create such difficult conditions for tire operation that in some cases movement becomes completely impossible. Single-track vehicles have it especially hard in winter. That’s why motorcycles, scooters, and mopeds rest until spring, not to mention bicycles!

Meanwhile, about forty years ago, Soviet inventor I. Bozhko received an author’s certificate for special metal studs for bicycle tires that allow riding in winter as confidently as in summer. Moscow streets at that time were not cleared of snow as well as they are now, and the inventor, being a persistent person, regularly rode his unusual bicycle on icy pavements.

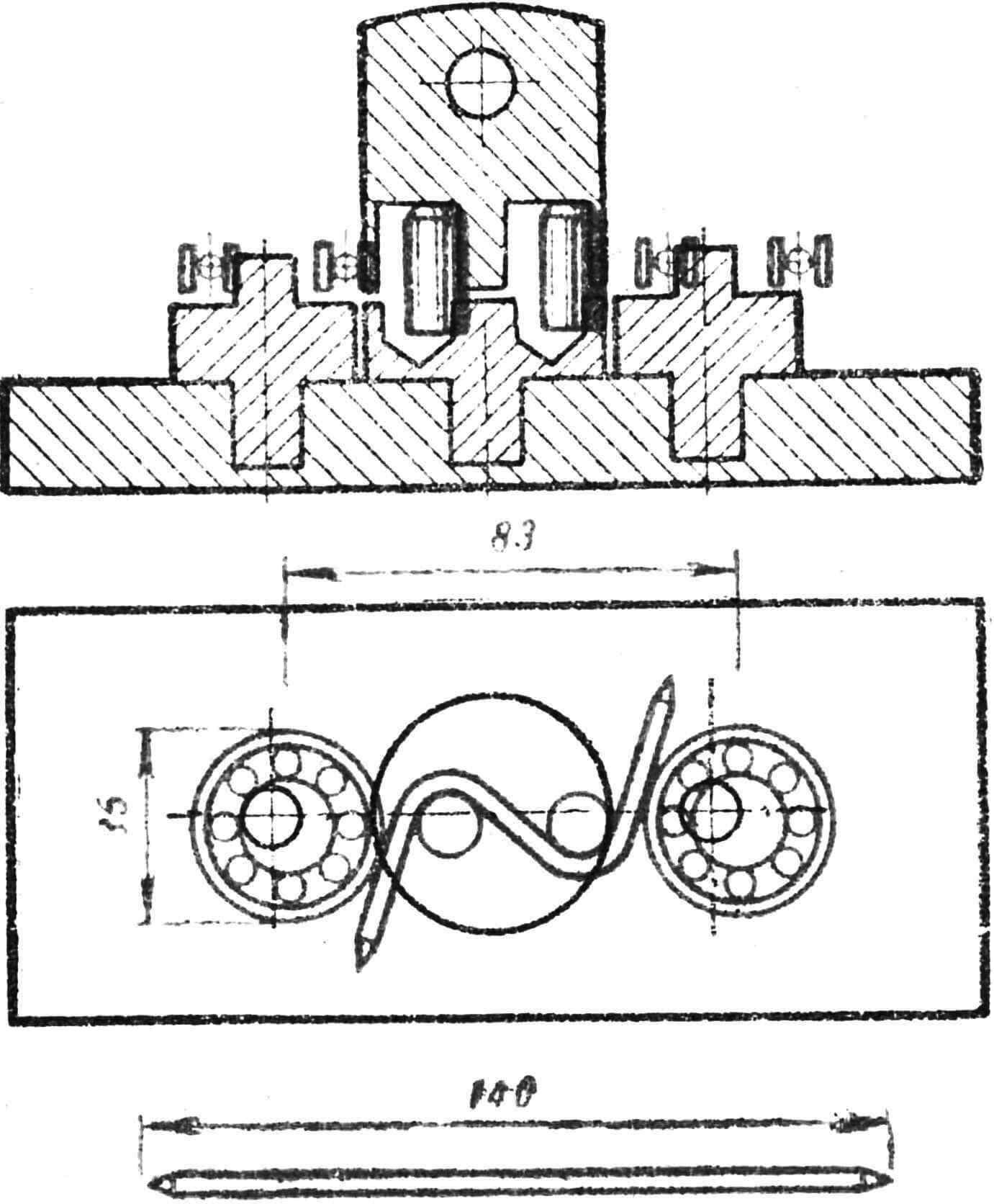

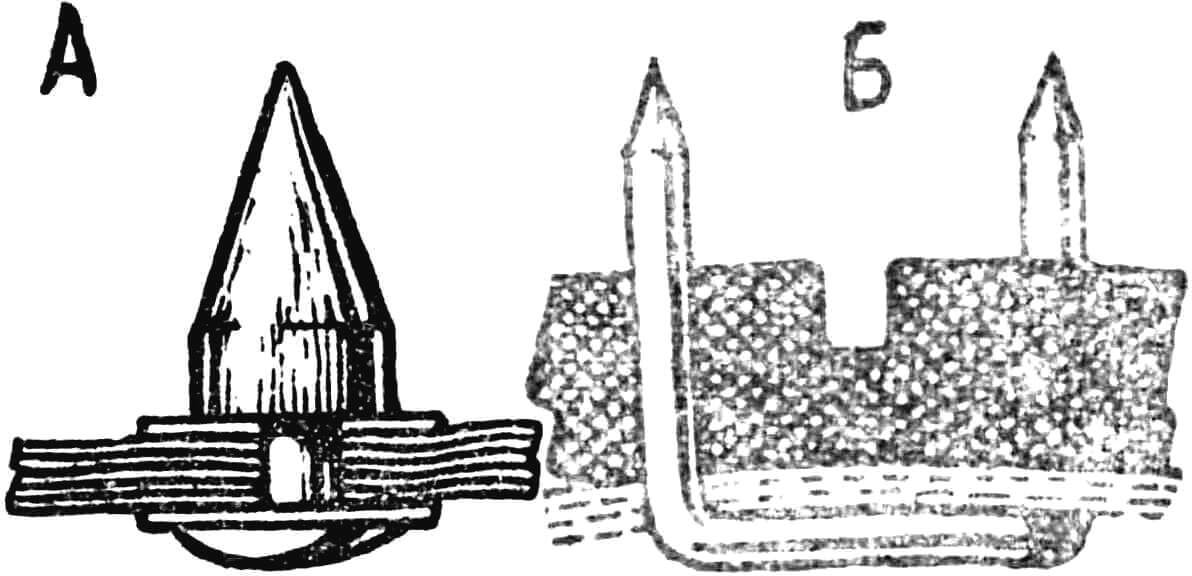

A — studs made of steel wire by N. Zakrevsky’s design on a motorcycle tire; B — studs turned on a lathe by I. Bozhko’s design on a scooter tire.

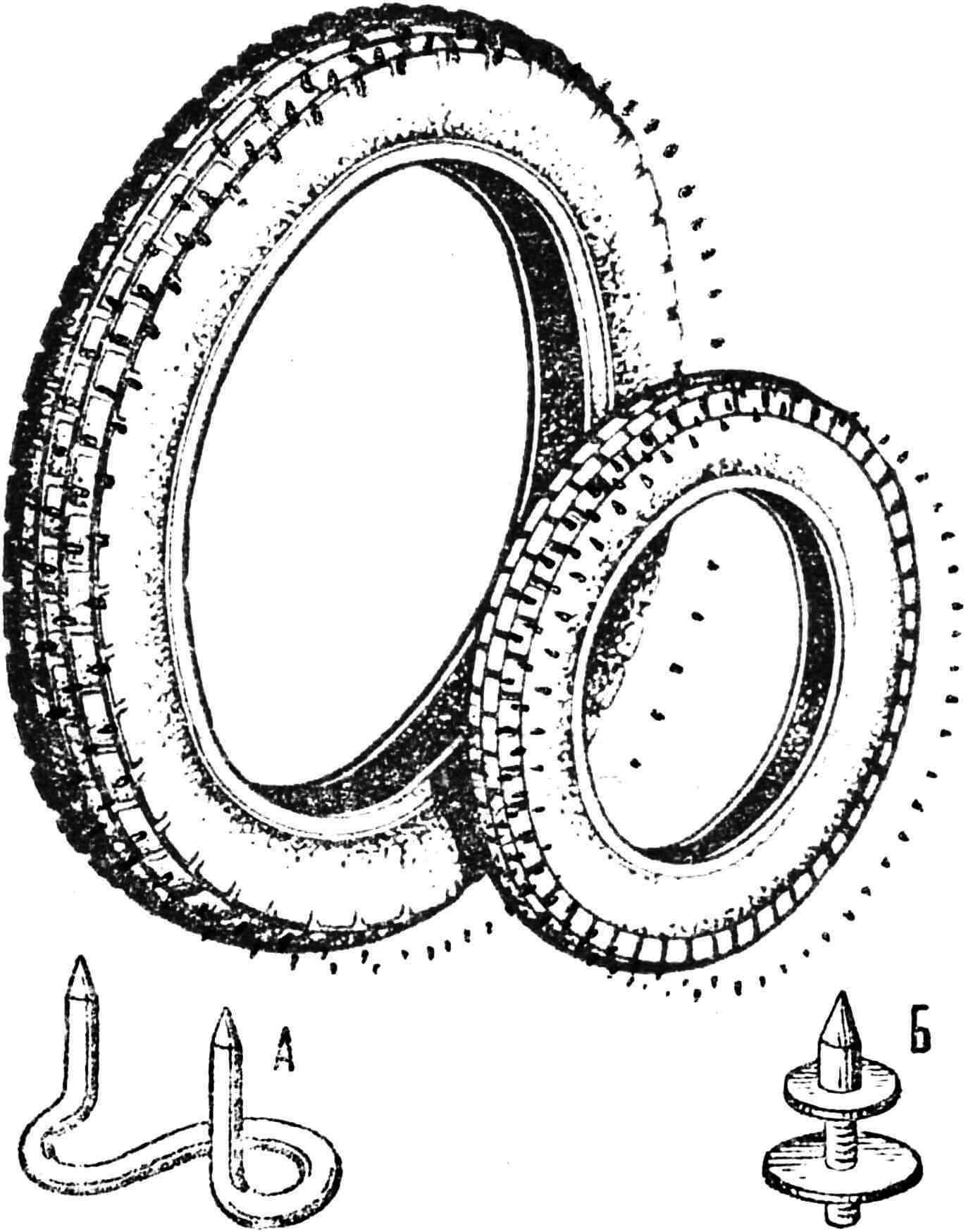

Studs of I. Bozhko’s design are shown in figures 1 and 2. Made of high-quality steel and heat-treated, they were quite wear-resistant and durable. Students of the State Central Institute of Physical Culture, where I. Bozhko worked, appreciated the invention and regularly conducted out-of-town winter training on bicycles equipped with studs of his design. Thus, these studs became the prototype of all devices for improving tire traction in winter conditions created later. And there are many of them. Some of them can be made in amateur conditions, with the simplest equipment, without much expense.

In this article, we will introduce readers to the use of various studs intended mainly for single-track vehicles, and subsequently — we will tell about anti-slip bands and chains, also used on cars.

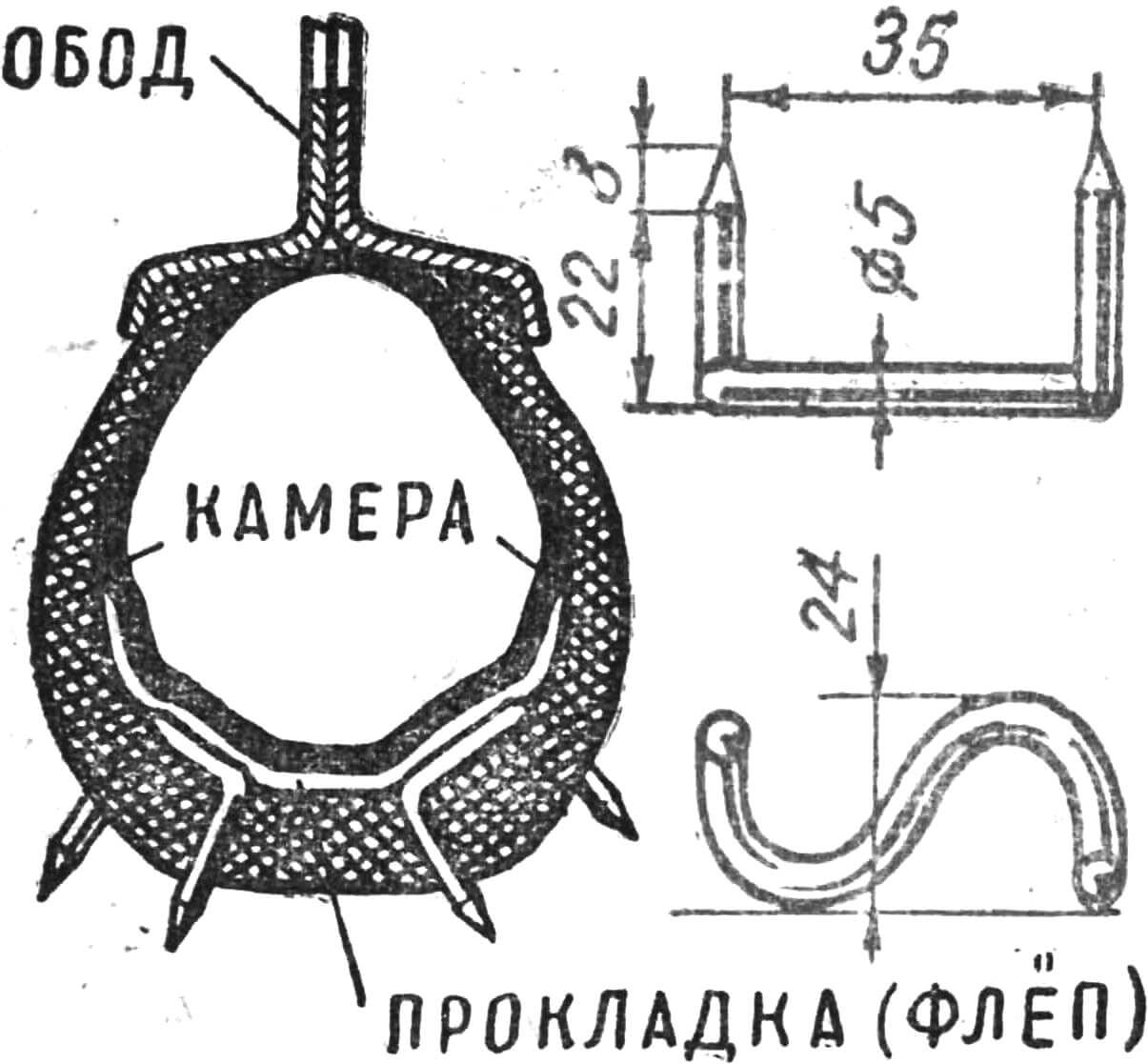

If you have a lathe, you can turn cylindrical or conical studs of various shapes and purposes, similar in their basis to studs of I. Bozhko’s design. Studs with threads and a conical nut inside the tire are mounted faster and easier than studs that need to be riveted on a washer from the inside.

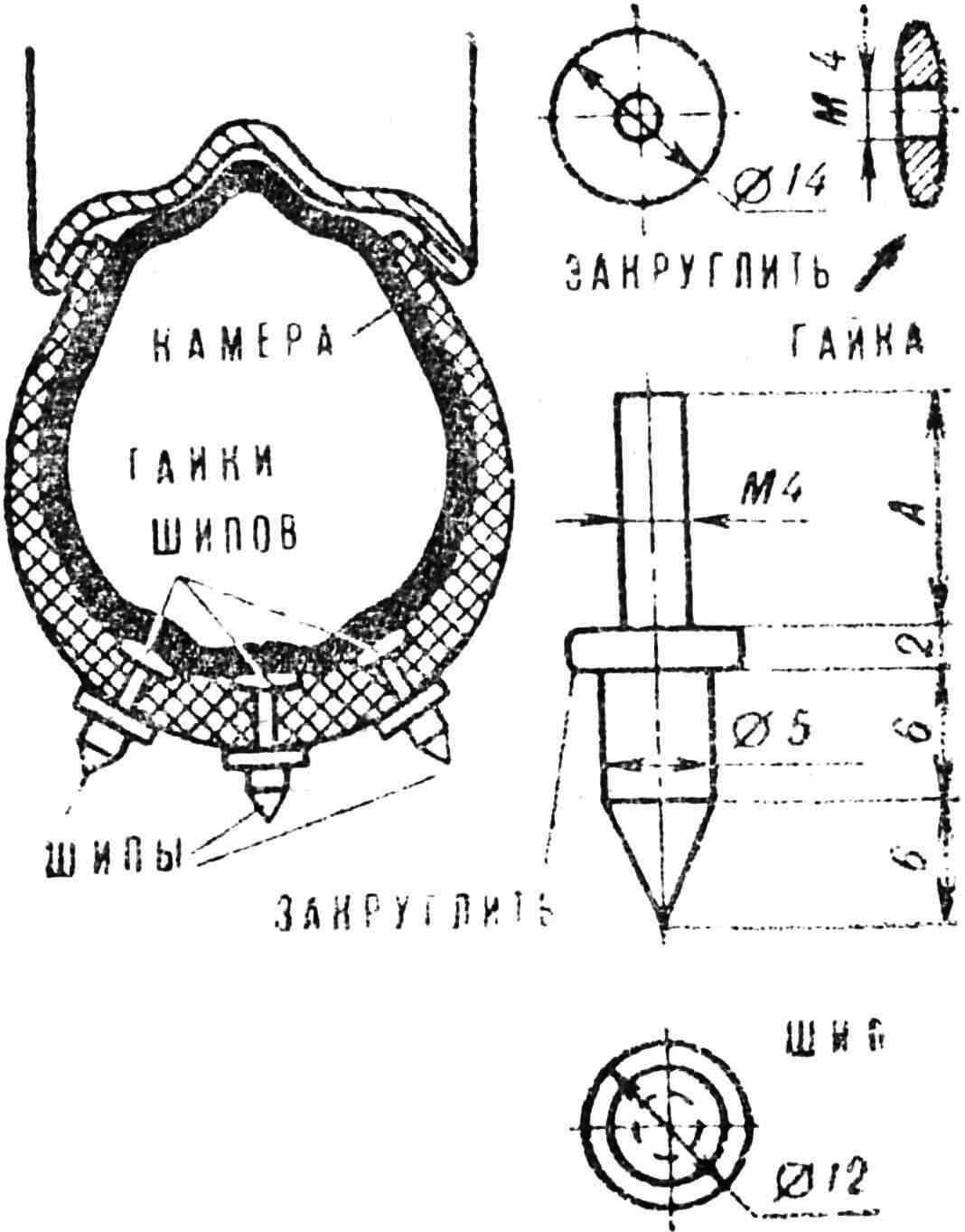

If an amateur who wants to “stud” their wheels doesn’t have a lathe, this circumstance should not discourage them: excellent studs can be made from so-called “piano” wire, or OVS wire, on ordinary bench vises. These studs were invented by the famous Soviet motorcycle racer engineer N. Zakrevsky (fig. 1 and 3). To speed up the work, you need to make a simple bending fixture (fig. 4).

Studs made of steel wire of N. Zakrevsky’s design are manufactured in accordance with the drawing and the thickness of the tread of those tires on which they are intended to be installed. The distance between the centers of the legs should correspond to the distance between the high tread blocks, so that most of the leg is in the “body” of the tire. This ensures a stable position of the stud in the tire and to some extent reduces the likelihood of the stud “tipping over,” possible under heavy loads — driving on very difficult roads, strong impacts.

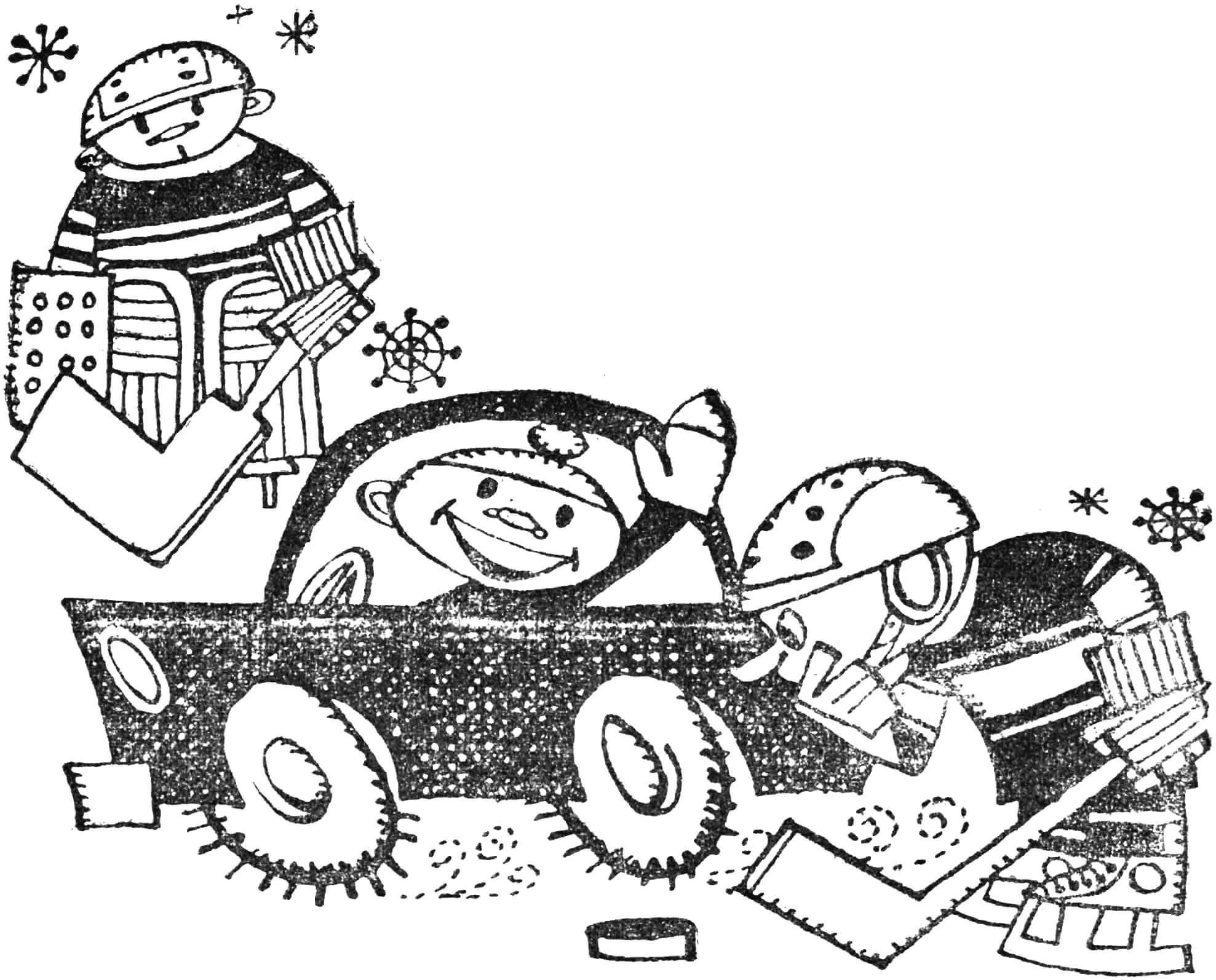

To protect the inner tube from damage and premature wear, under studs (brackets) of N. Zakrevsky’s design and other types of studs, an old bicycle tire or rubberized canvas (“flap”) is laid between the tire and the inner tube from the inside, as shown in figure 3.

The thickness of the wire from which studs of N. Zakrevsky’s design are made should correspond to the weight of the machine and the conditions in which this machine will be operated. So, for example, for a bicycle on which it is planned to ride on ice for winter fishing, OVS wire with a thickness of 2 mm will be sufficient, and for scooters and motorcycles of the “Kovrovets,” IZH, “Pannonia” or “Java” type, thicker wire (about 4—6 mm) will be required. Therefore, the dimensions of the bending fixture should correspond to both the size of the stud and the diameter of the wire used. Before making steel S-shaped studs, it is recommended to test your fixtures by bending several studs from softer material — iron or copper wire — for practice.

The sequence of installing S-shaped studs on a tire is shown in figure 3. The number of studs is determined by the number of high tread blocks. After counting them, marking and punching are done from the outside, along the tread blocks, and the studs are installed from the inside. The stud must be tightly seated in the made hole. For this, the tire is placed on a vise and struck with a heavy hammer on a wooden block placed on the stud bracket. The tip of the stud should protrude above the tread surface by 8—15 mm depending on the purpose of the tire (for hard tracks — shorter, for soft — longer). So, the total height of the stud “leg” also depends on the thickness of the tire. Studs of N. Zakrevsky’s design are cheap and simple to manufacture, but they work worse than turned studs made of high-strength steel. This should be kept in mind when preparing wheels for winter driving or for sports competitions on cross-country tracks.

The studs described in this article can be used not only in winter, but also in the off-season, as well as on washed-out clay roads and heavily rugged terrain. They can be of invaluable service to residents of taiga regions, tundra zones, new construction sites of the ninth five-year plan — in short, everywhere where there are still no good roads! Therefore, we recommend that every owner of a motorcycle, scooter, or moped get a second set of wheels, carefully “stud” them, and always keep them in a state of readiness.

G. MALINOVSKY, Master of Sports

Over many years of operation of wheeled vehicles, a whole range of simple devices for improving the cross-country ability of three-wheeled and four-wheeled machines has been created.

Until recently, about 75% of amateur-built microcars have wheels and tires from SZA motorized wheelchairs. We will talk about improving their “all-terrain capability.”

First, about tires. As is known, our industry produces a large assortment of special tires with increased cross-country ability for various cars. There are tires with very relief tread lugs resembling the teeth of giant gears; there are tires that look little different from ordinary ones, but equipped with strong steel studs in the thickness of the tread layer. Finally, there is “automotive footwear” with solid rings — bands made of metal links resembling a watch bracelet. Using such tires, you can confidently drive on very bad roads without using any special devices to improve cross-country ability.

Unfortunately, for microcars, all this assortment is not yet applicable. Owners of motorized wheelchairs and designers using wheels from SZA have in their “arsenal” a single model of type B tire, size 5X10, and are forced to drive on it all year round.

The relatively low cost of wheels and tires for the SZA motorized wheelchair allows you to get an additional set of rubber and discs equipped with various devices that improve cross-country ability. Having an additional set of high-cross-country rubber, you can very quickly adapt to road conditions, replacing either all four wheels at once, or only the driving ones, depending on the situation. And since the situation in the off-season and winter changes very often, you should carry not one “spare” in the trunk, but two.

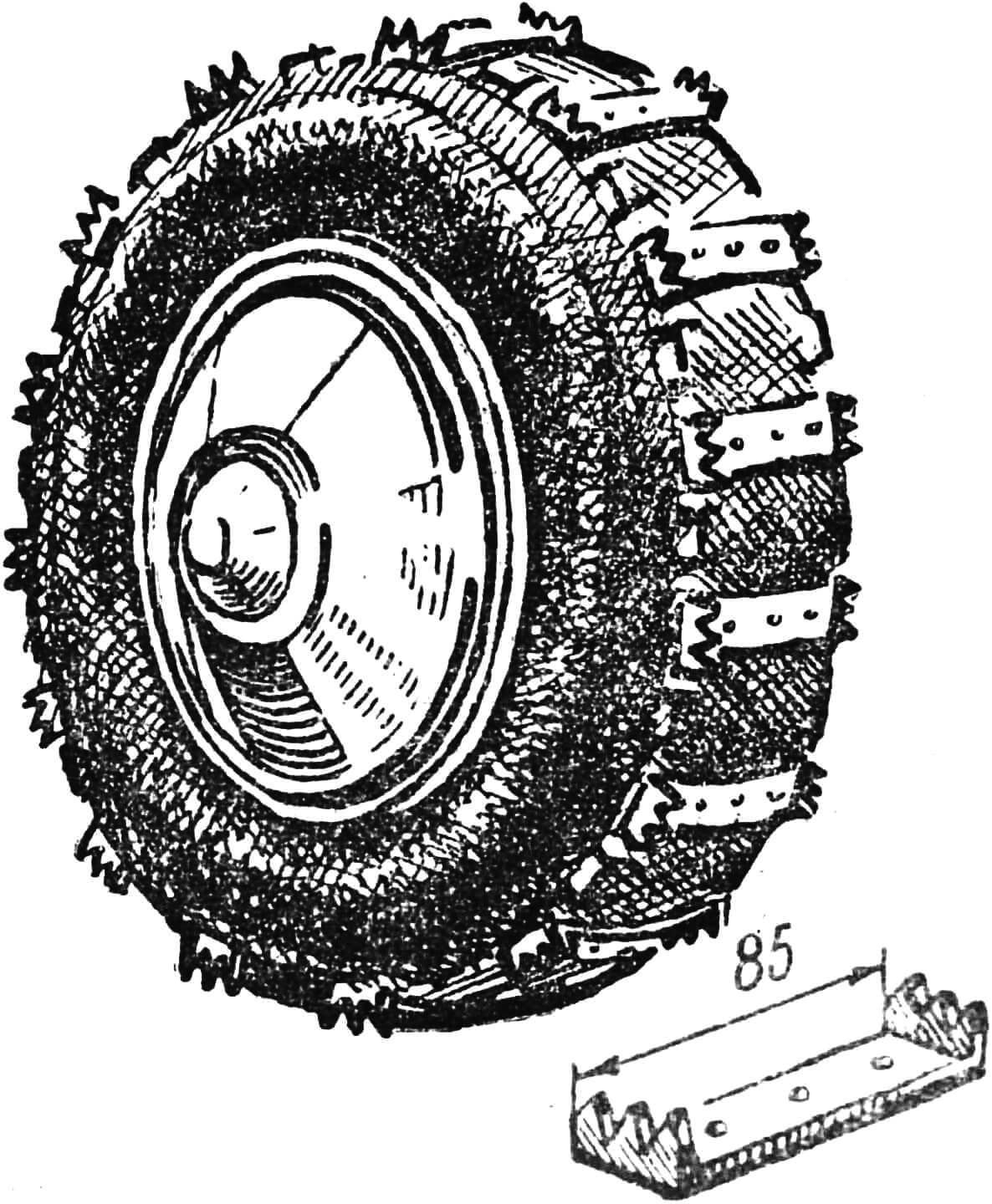

For machines with a load on one wheel of no more than 150 kg, studs of N. Zakrevsky’s design made of OVS wire Ø 4—5 mm can be recommended. Their manufacture was described in the previous article. To reduce the cost of a set of high-cross-country wheels, studs should be installed on tires that have already been used. After installing the studs, a gasket (“flap”) should be laid between the tire and the inner tube, which is best made from an old bicycle tire, having first removed the wire from the beads. Studs of Zakrevsky’s design have a very valuable quality: when driving, they self-sharpen, maintaining sharpness until complete wear. This happens due to the elasticity of the tire and the elastic deformations of the stud itself. To prevent the studs from tipping over, their height above the tread should be 1/3 less than the part of the stud “body” that is inside the tire (fig. 1). The pressure in studded wheels should be increased by 0.25 atm. compared to normal. The number of studs for tire B 5X10 can vary depending on operating conditions from 20 to 25 pieces per wheel. The central part of the running track is left unstudded, as shown in figure 1. When driving on smooth ice (for example, winter fishing), studs should be used on all wheels. Otherwise, the machine’s handling noticeably deteriorates.

A — Bozhko (Tomasov) design on a band, B — Zakrevsky stud in the tire body.

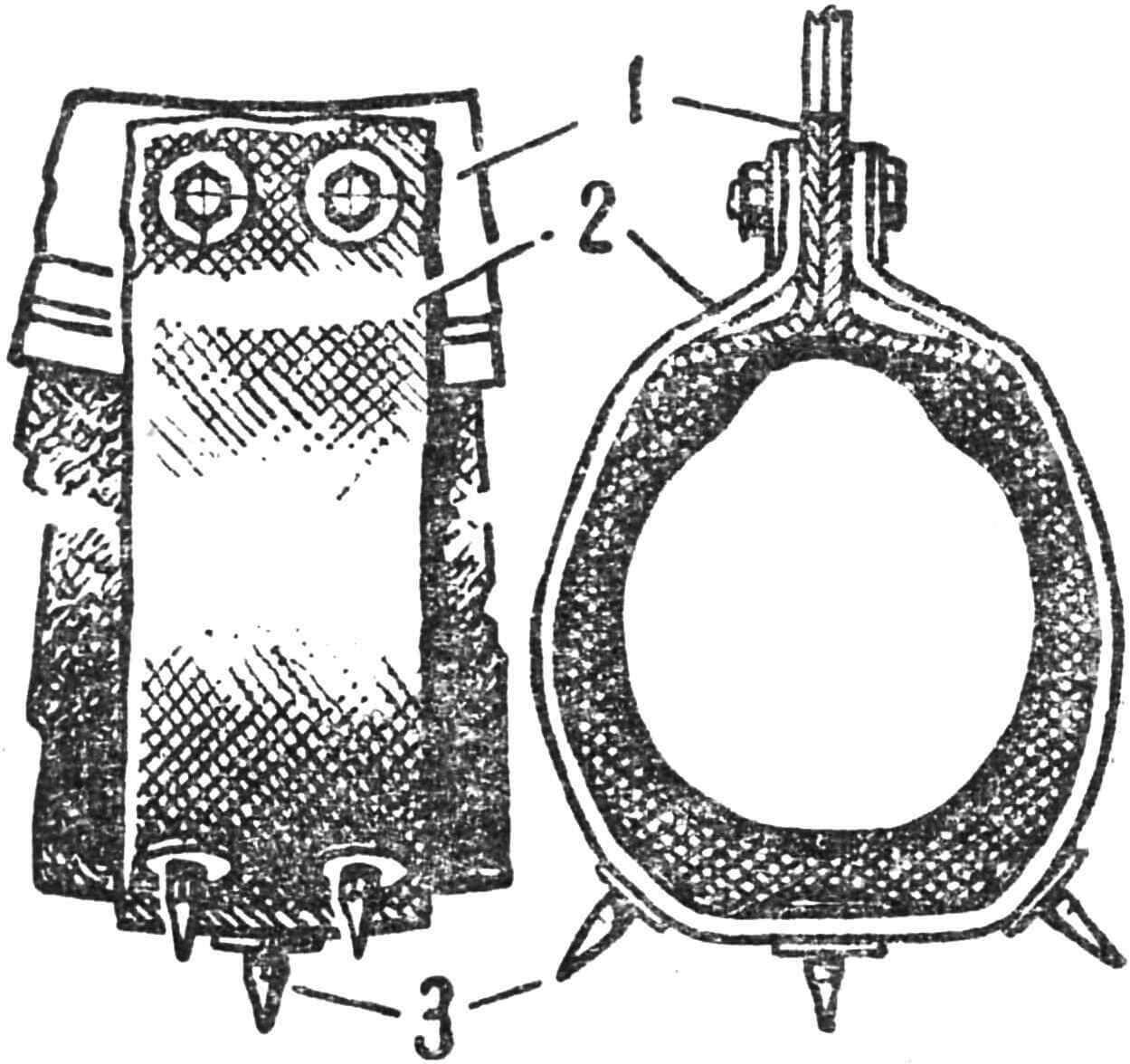

Some amateurs successfully use brackets made of strip steel, riveting them to old, “bald” tires. This creates a kind of cleats, or tracks (fig. 3). Their service life is not long, but it can be increased by making brackets from higher quality steel with subsequent heat treatment. Wheels with such brackets are used only as driving wheels. In a number of situations, it is more rational to use removable devices that improve the machine’s cross-country ability only temporarily. These are anti-slip bands, or cuffs, pads, bracelets, chains, and tracks. Figure 4 shows the simplest band made of cord fabric at least 5 mm thick and 60 mm wide with riveted studs of Bozhko (Tomasov) design. These studs provide good grip on icy road surfaces, but wear out much faster than Zakrevsky’s designs. To some extent, the disadvantage is compensated by the fact that the tire is not subject to punctures, and a separate tire is not required for installing studs. Mounting bands on the wheel discs of the SZA motorized wheelchair presents certain difficulties, since these discs have a narrow flange for connection to brake drums, in which it is impossible to cut holes for the band to pass through. Therefore, bolts Ø 6 mm are used for its fastening, as shown in figure 4. At least three and no more than five bands of the described type should be installed on each wheel.

Anti-slip pads differ from bands in that they lack cord fabric, and instead of studs, a ground lug is used, made of steel T-profile or two welded angles measuring 20X20X3 mm (see fig. 5). Fastenings to the disc — with bolts. The length of the “chain” is selected so that the pad is tightly pulled to the tire tread and cannot tip over during driving.

1 — disc, 2 — cord fabric, 3 — stud.

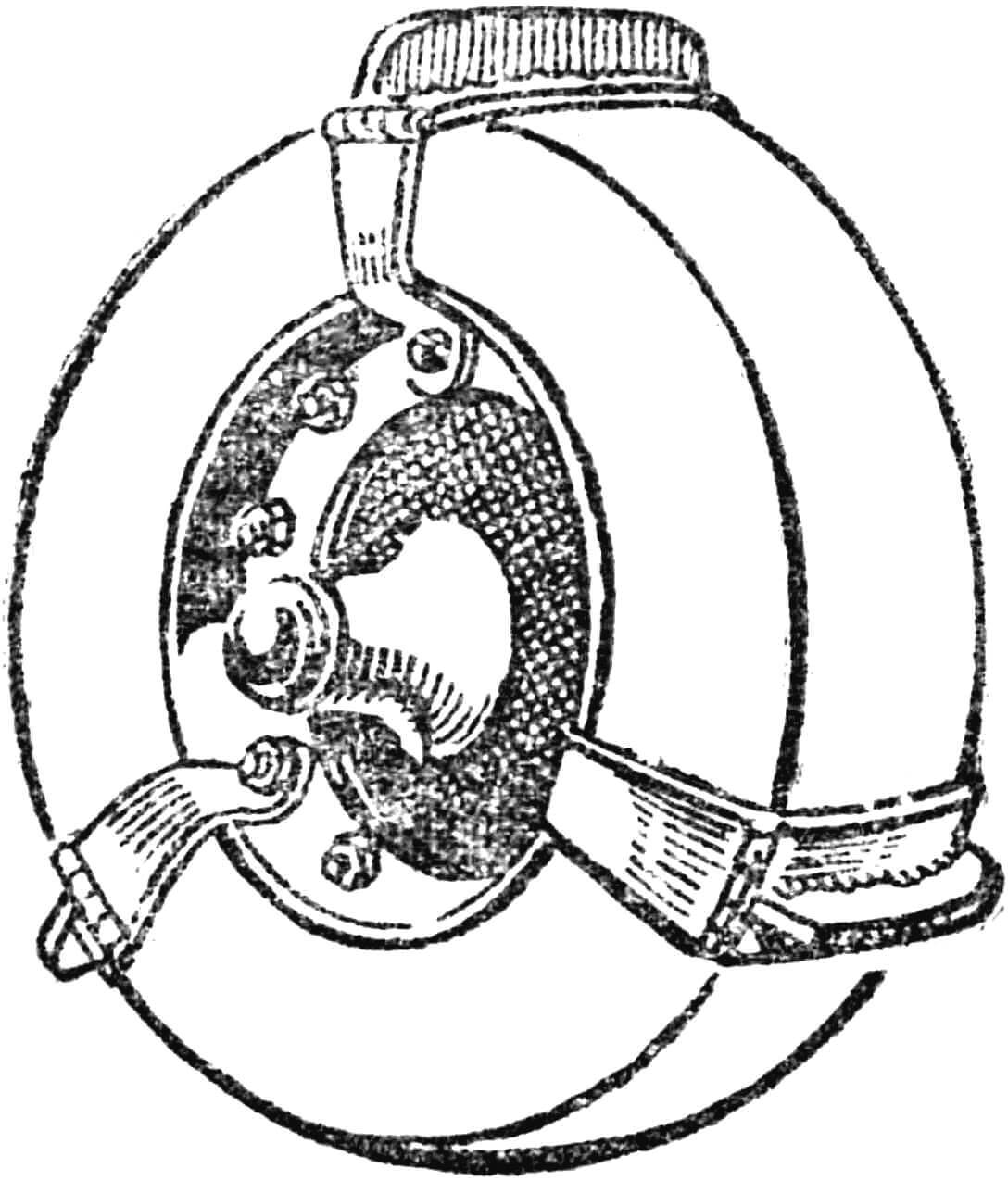

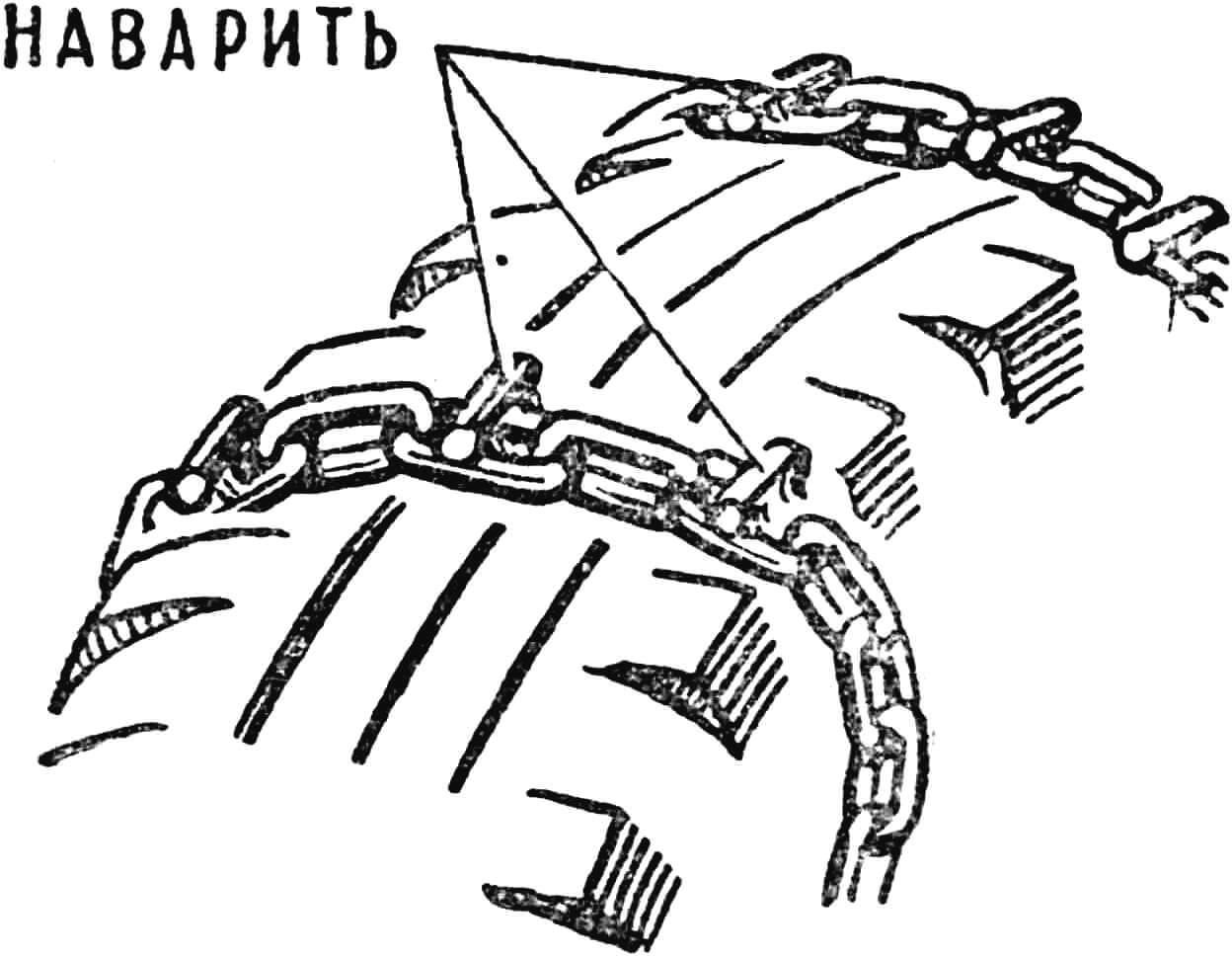

A bracelet made of chain with well-welded links made of steel wire Ø 6 mm (fig. 6) is a very reliable and at the same time simple anti-slip device. The bracelet is attached to the disc with a bolt through the end links with steel washers Ø 20 mm as backing. Six bracelets are placed on each wheel. They should not be too tightly tightened on the tire: in a free state, they provide better grip on the road. The service life of bracelets can be increased by welding small pieces of thick wire to the links lying flat on the tread (fig. 7).

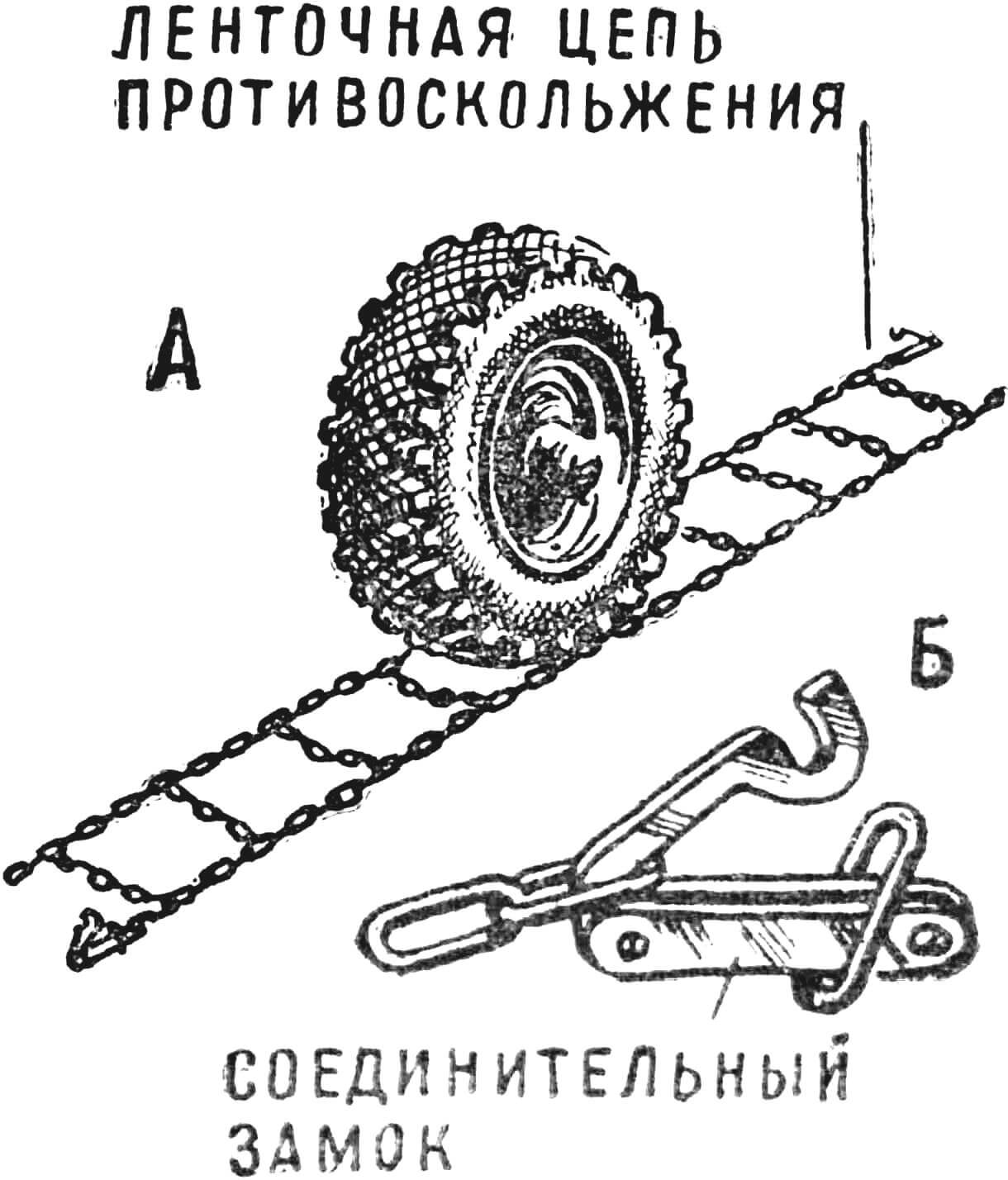

A more complex chain device for improving cross-country ability is shown in figure 8. This is the so-called strip anti-slip chain. Its advantage is that it does not require drilling holes in the wheel disc and is quickly attached to the tire using a simple lock (hook). The number of links in the longitudinal and transverse branches of the “ladder” is selected so that the chain fits tightly, but not too tightly, around the wheel. The strip chain is put on the wheel as follows: spreading the “ladder” on the ground in front of the wheels, drive onto it, after which the ends are placed on the tire and connected with a lock. However, chains are recommended to be put on not when the machine is already stuck, but in advance — when approaching a difficult-to-pass section of the road.

A — before installation on the wheel, B — connecting lock.

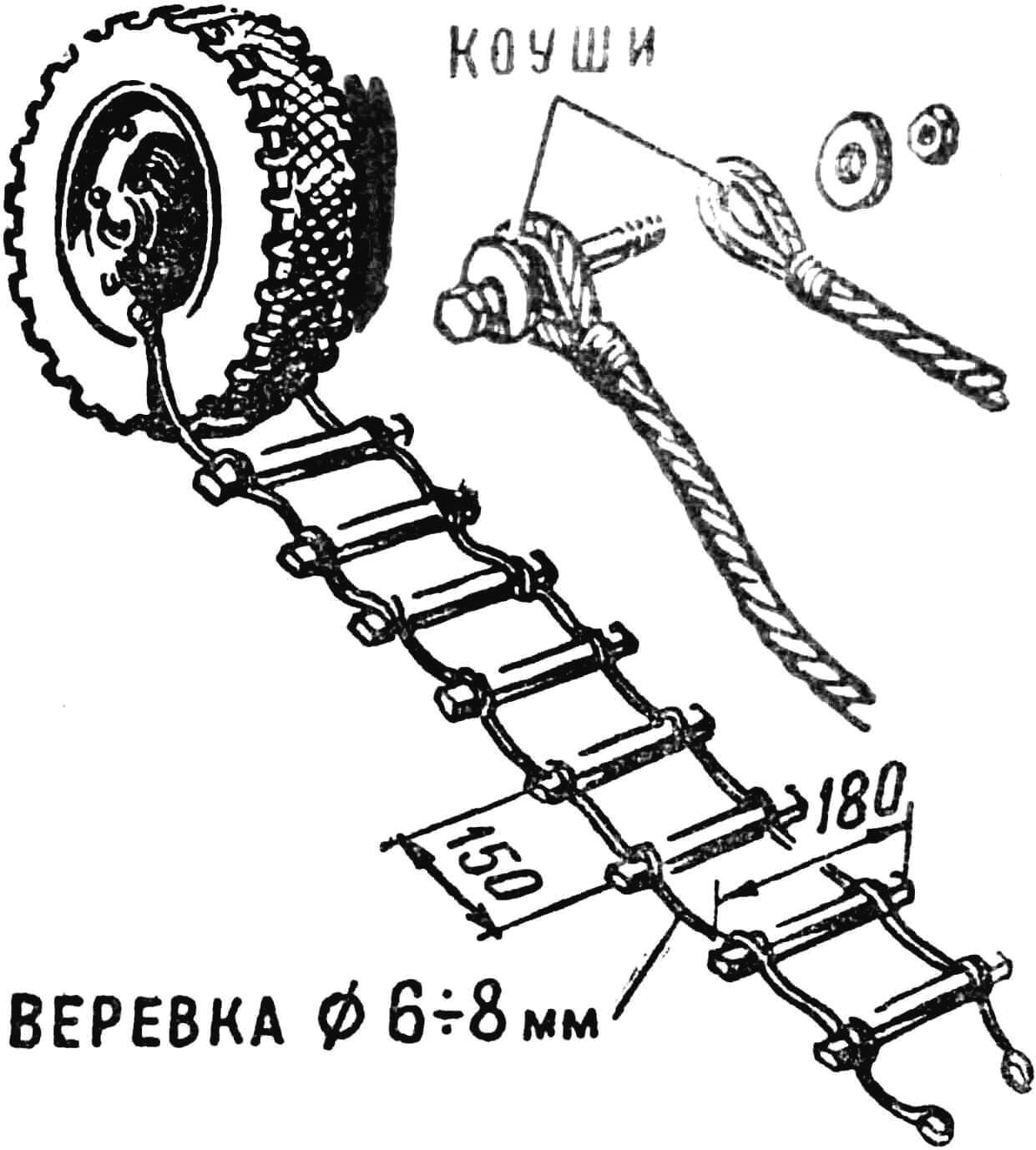

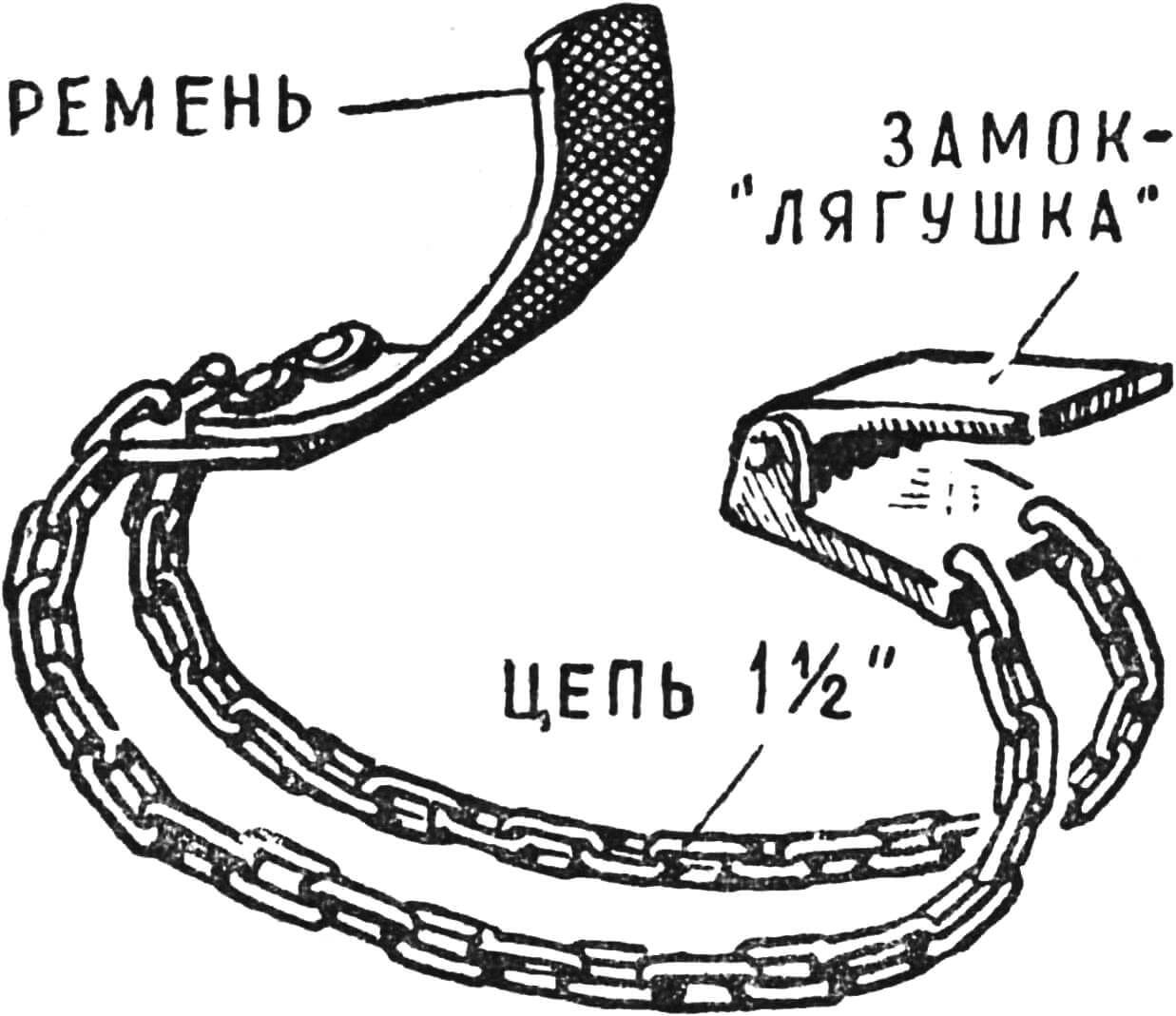

The simplest track, which can be of invaluable service on slippery climbs, washed-out or rolled places, is shown in figure 9. Its dimensions are given in relation to tire B 5X10. To make the track, you will need a strong rope made of non-rotting material (capron, polypropylene) and strong round or polygonal blocks. After tying the “ladder,” the knots should be coated with epoxy glue or BF-2 glue — they will have to work in very difficult conditions. The track is used where the machine hopelessly slips or gets stuck. You cannot drive with it for a long time. Industrially produced tracks are usually made of metal, they are more wear-resistant and can be used for everyday driving on difficult roads. And figure 10 shows a band that is now widely available for car enthusiasts. But it is only suitable for cars with wheels from “Zaporozhets” or “Moskvich.” Nevertheless, its design can be used in making bands for wheels from SZA motorized wheelchairs and scooters of various types.

O. ANDREYEVSKY, Mechanic